- New Sailboats

- Sailboats 21-30ft

- Sailboats 31-35ft

- Sailboats 36-40ft

- Sailboats Over 40ft

- Sailboats Under 21feet

- used_sailboats

- Apps and Computer Programs

- Communications

- Fishfinders

- Handheld Electronics

- Plotters MFDS Rradar

- Wind, Speed & Depth Instruments

- Anchoring Mooring

- Running Rigging

- Sails Canvas

- Standing Rigging

- Diesel Engines

- Off Grid Energy

- Cleaning Waxing

- DIY Projects

- Repair, Tools & Materials

- Spare Parts

- Tools & Gadgets

- Cabin Comfort

- Ventilation

- Footwear Apparel

- Foul Weather Gear

- Mailport & PS Advisor

- Inside Practical Sailor Blog

- Activate My Web Access

- Reset Password

- Pay My Bill

- Customer Service

- Free Newsletter

- Give a Gift

How to Sell Your Boat

Cal 2-46: A Venerable Lapworth Design Brought Up to Date

Rhumb Lines: Show Highlights from Annapolis

Open Transom Pros and Cons

Leaping Into Lithium

The Importance of Sea State in Weather Planning

Do-it-yourself Electrical System Survey and Inspection

Install a Standalone Sounder Without Drilling

When Should We Retire Dyneema Stays and Running Rigging?

Rethinking MOB Prevention

Top-notch Wind Indicators

The Everlasting Multihull Trampoline

How Dangerous is Your Shore Power?

DIY survey of boat solar and wind turbine systems

What’s Involved in Setting Up a Lithium Battery System?

The Scraper-only Approach to Bottom Paint Removal

Can You Recoat Dyneema?

Gonytia Hot Knife Proves its Mettle

Where Winches Dare to Go

The Day Sailor’s First-Aid Kit

Choosing and Securing Seat Cushions

Cockpit Drains on Race Boats

Rhumb Lines: Livin’ the Wharf Rat Life

Re-sealing the Seams on Waterproof Fabrics

Safer Sailing: Add Leg Loops to Your Harness

Waxing and Polishing Your Boat

Reducing Engine Room Noise

Tricks and Tips to Forming Do-it-yourself Rigging Terminals

Marine Toilet Maintenance Tips

Learning to Live with Plastic Boat Bits

- Boat Maintenance

The Best Marine Varnish: Exterior Wood Finish Tests

Two-part varnishes leading in durability as long-term test reaches 24-month mark..

Like spotting land after a long passage, were glad to say that the end of our long-term exterior wood finishes test is finally on the horizon. Time, weather, and Southwest Floridas unrelenting sunshine have clearly taken their toll on the test panels over the last 24 months, and as the evaluation moves into its third year, only 19 of the original 54 test products will continue on in our survival-of-the fittest finish matchup. Given that most wood coatings are rarely expected to last longer than two years in the marine environment-particularly in super-sunny locales-its no surprise that we’ve seen more significant changes in the coatings in the last six months than we had in previous checkups.

Our search for the ideal wood finish-relatively easy to apply, easy to maintain, lasts multiple seasons, and is affordable-began in 2007 when we took a look at the different types of exterior wood finishes on the market, their pros and cons, and how easy they were to apply ( one-part varnishes , August 2007; varnish alternatives , October 2007; two-part varnishes , December 2007; teak oils and stains , April 2008). Launched in 2008, the long-term panel test aimed to determine which type of coating offers the best and longest protection and which products stand out among their peers.

We hope the comparison enables readers to decide which finish best matches their own taste, potential labor investment, and wood protection needs.

We’ve rated the test products every six months and reported on the coatings durability in the May 2009 issue ( six-month checkup ), December 2009 issue ( 12 months ), and January 2011 ( 18 months ) issues. Here, we offer the two-year report on the survivors.

How We’re Testing the Marine Varnishes

Testers applied dozens of exterior wood finishes (22 one-part varnishes, six two-part varnishes, 18 synthetics and satins/varnish alternatives, and eight teak oils and sealers) to small panels of bare solid teak. Each was assigned a number for blind judging and was applied per manufacturers instructions. If makers gave a range for the number of coats to apply, testers went with the minimum.

Initial testing rated each products ease of application and original gloss and reflective qualities. In the summer of 2008, the test panels were mounted on a wooden rack (aka: The Rack), which was set up in an unobstructed area on the roof of the PS workshop in Sarasota, Fla., to ensure that all panels received the same amount of weather exposure. The top part of each panel was covered to create a control area that testers used for comparison over time. Every six months, we disassembled The Rack and rated the panels on how well their coating integrity, gloss, and color had fared over time with constant exposure to the elements.

The test was designed as an endurance test, a fight to the finish, so we have not done any maintenance coats or touch-ups to the test panels. These products can be expected to have much longer lifespans if they are regularly maintained.

How We’re Rating the Marine Varnishes

Testers rate each panel on three long-term performance criteria: coating integrity, gloss retention, and color retention. Excellent and Good coating integrity ratings mean that no maintenance is needed; a Fair indicates that its time for a maintenance coat; Poor means the fat lady has sung, and the coating would need to be removed and re-applied. Excellent ratings are given only to those with an uncompromised coating. This time, panels with Poor and Fair- coating integrity were pulled from the test.

Color and gloss retention ratings are relative to the panels original finish. Initial gloss and ease of application are relative to the field within each coating category; these were assigned immediately after the panels were coated.

It was tougher to pick Recommended coatings at the two-year mark, as most wood finishes aren’t intended to go that long without maintenance. One-part varnishes that earned PSs recommendation this go-round were rated Fair for coating integrity (none rated better than Fair ) and had no Poor ratings. Recommended two-part systems rated Good or better for coating integrity with no Poor ratings. No varnish alternatives or teak oils/sealers were recommended at two years.

VALUE GUIDE: Varnish Alternatives

What we found.

What a difference a season makes! With the exception of a few two-part products, the test coatings had lost their sparkle at the two-year mark. Ratings slipped across the board. The UV abuse had obviously taken its toll, sucking the life out of most of the coatings, particularly the clear finishes.

Those clinging to life with Fair coating integrity are still protecting the wood, but they’ve lost their looks. In the real world, all of the one-part varnish and varnish alternative test panels would be due for a maintenance coat, and some-like HMG K Type Varnish, West Marine WoodPro Plus (rebranded Epifanes Rapidclear), and Ace Spar Varnish-would be overdue.

The biggest overall decline was within the one-part varnish test group: Not a single one rated better than Fair for coating integrity or gloss retention, and nearly half of the test field was retired after this rating round. Just six months before, eight of the 19 products rated Good for coating integrity and six rated Good for gloss retention. In 12 months, seven dropped from an Excellent coating integrity to a Fair.

The one-part varnishes offering the most protection after two years are Detco Crystal, Le Tonkinois Vernis, and Pettits Z-Spar Captains 2067. However, their extended protection comes with tradeoffs: Detco rated only Fair for application, Le Tonks gloss started to slip after one year, and Pettits 2067 started losing its original color after 12 months.

One hardware store varnish has surprisingly held its own over the long haul: Minwax Helmsman Spar Urethane. At half the cost of the Recommended one-part varnishes, Minwax slacked in the color retention department, but it has proven its multi-season durability.

Four of the nine varnish alternatives have been voted off The Rack after two years, and none performed well enough to earn our recommendation for two-year wood protection.

The Cetol products are still at the head of the pack, albeit a somewhat mangy-looking pack. The cloudy, opaque look of the Cetol Marine and Marine Light products may not appeal to everyone, but the fact they’ve maintained their color for more than a year is a good example that higher-solids finishes tend to offer better UV protection.

The Cetol Natural (with gloss) test panel fell from a Good coating integrity six months ago to being dropped from testing. Its performance mirrors what we’ve seen in the field: Give it a little loving once a year with a scrubby pad and a fresh coat, and it’ll last the long haul.

Its taken two years, but the two-part varnishes are finally starting to show their age. Surprisingly, the first products to be dropped from this group are two that performed well in past PS tests: Bristol Finish and Honey Teak. This is likely because the life of a wood finish in Florida is always going to be shorter than in our past test locales in New England.

The other two-parts are still holding up well, with Interlux Perfection and Nautiking Nautithane offering uncompromised protection and better-than-expected gloss after 24 months. Perfection has been reformulated since the test began and is now sold as Perfection Plus.

The temporarily discontinued (since 2009) Smiths Five Year Clear has also proven to be a top-notch finish, but its not available at this time.

While HMG Acrythane XSC didn’t earn our Recommendation this time, it was a top 18-month finish, it still looks good, and it costs less than the Nautithane.

Conclusions About Exterior Varnishes

After two years of testing, we’ve come to accept that perhaps there’s no Holy Grail of exterior wood finishes. It would appear, unfortunately, that we can’t have it all: easy to apply, easy to maintain, long-lasting protection, and a budget-friendly price tag. The reality is that, like much in life, wood protection is all about compromise and balancing your needs with your wants.

There’s no one-size-fits-all solution, and the boat owner who finds gratification in the wet, glossy look of a two-part varnish borne of painstaking preparation and careful application will weigh our test data much differently than the one who regards brightwork maintenance as a masochistic endeavor. For the latter, we recommend seeking out a varnish alternative (easy to apply, easy to maintain) that suits your tastes. With modest maintenance, the Cetol products with gloss overcoats have proven to be the most durable.

For areas where slippery-when-wet coatings wont do, Cetol Natural (without gloss overcoat) or our top-pick teak oil, Star brites Tropical Teak Sealer (classic teak) should be considered. The Star brite will need to be reapplied every three or four months.

If you’re looking for a harder, more abrasion-resistant finish that’ll make it past the year mark, check out the top one-part varnishes like Detco Crystal or Pettits Z-Spar Captains 2067. Boat owners in sailing areas that see less sunshine than our Florida test site should also consider Pettits Flagship 2015 or Captains 1015. One-part varnishes require a little more work upfront and quick attention when they are scratched or dinged, but they also offer a more traditional, high-gloss look. The one-part varnishes in our test slipped dramatically after a year and half, so we suggest an annual maintenance coat, whether they look like they need it or not.

As this test has shown, when it comes to long-lasting protection and gloss, two-part varnishes just can’t be beat. They may be a pain to apply-and should you let the coating fail, you had better invest in a heat gun-but their durability is unmatched.

The top two-part after two years of testing was Interlux Perfection. Because we’ve not yet tested the reformulated Perfection, the top pick honors go to Nautikings Nautithane. While its price tag ($120 per quart kit) is a bit hard for most of us to swallow, Nautithane earned across-the-board Good ratings after two years.

Practical Sailor often supplements panel testing with product challenges aboard our test boats to see whether top products still earn their keep in the real world and to try out new products. Two such evaluations are our exterior wood finish tests.

In the January 2011 issue, we introduced a head-to-head matchup of varnish alternatives—market-newcomer PolyWhey from Vermont Natural Coatings versus perennial favorite Interlux’s Sikkens Cetol Natural Teak—that had been applied to our Cape Dory 25 test boat. For that test, we’ve just let nature run its course: no band-aid touchups, no maintenance coats, no freshwater rinses, no TLC at all.

Comparatively, we’ve been testing Cetol Natural aboard our Chesapeake Bay-based Union 36 test boat, where it was laid on with the Cetol gloss overcoat in 2008; in this evaluation, testers have applied annual maintenance coats and given the coating regular TLC. Here’s the latest on both of these tests:

PolyWhey vs. Cetol Death Match

In the fall of 2010, testers applied three coats of Caspian Clear PolyWhey to the coamings and companionway trim on the Cape Dory, which is sailed several times a week and lives on a mooring in Sarasota Bay, Fla. We also applied Cetol Natural to the boat’s toerail, and previously had applied it to the tiller and forward hatch trim.

PolyWhey is a unique wood finish that uses whey protein, a by-product of the cheesemaking process, as a binder. It’s touted as a more eco-friendly and more sustainable coating than petroleum-based polyurethanes, which can have up to 75 percent more volatile organic compounds (VOCs).

Consistently among the top varnish alternatives in PS’s tests, Cetol Natural is not as muddy-looking as its predecessors, Cetol Marine Light and Cetol Marine—like the Caspian Clear, it allows the wood’s natural grain to show and has a low gloss.

As far as application, both the Cetol and PolyWhey are quick and easy to apply, with much shorter recoat times than hard varnishes and less (or no) sanding between coats. The main difference that we found in these two finishes was with durability.

The PolyWhey turned out to be a much softer coating than the Cetol. It held up for about two months, but after three months, it was in need of a recoat, and at six months, it needed a total takedown—and Cetol had emerged as the death-match victor.

The PolyWhey on the coaming was the first to go: Where crew backs often lean against the wood, the finish was all but gone after four months. The PolyWhey on the companionway slides held on for about that long, but by six months, they were ready for a do-over as well.

The Cetol on the toerail was in need of a few touchups after six months, mostly in areas where fenders and docklines came in contact with it. But the tiller and hatch trim were still fairly well-protected almost a year after application. Although we’d recommend a maintenance coat at this point, testers plan to see how many more months we can eek out of the coating before we reach the point of no return.

Bottom line : We applaud VNC’s efforts to offer a “green” wood finish—and their creative recycling of dairy industry “trash”—but we can’t recommend it over Cetol for an exterior coating in the marine environment.

Cetol with Overcoat

Testers applied three coats of Cetol Natural with Cetol Marine Gloss overcoat to the Union in March 2008. Once a year, we scuff it up with a 3M pad, give it a freshwater rinse, and brush on a maintenance coat.

Compared to a clear, glossy varnish, it looks decent and the maintenance regimen is more realistic for our tastes and available time. However, one downside to softer, varnish alternative coatings—even those with an overcoat—is that they don’t stand up as well as hard finishes to dings and abrasion. Example: The Union’s toerail has one place in need of touching-up where a fender line wore away the finish. (See photo above.)

Bottom line : The Cetol Natural with overcoat has held up very well. While applying the topcoat may mean added effort, both our panel tests and test-boat evaluations have shown that the coating will last much longer and need fewer bandaids if the soft Cetol is protected with the semi-hard topcoat.

Teak oils and other naturally based finishes like PolyWhey, need maintenance coats every few months. Their chemical cousins, however, like Cetol, have proven they can offer good protection with only annual nurturing and the occasional touchup.

- C-Tech Marine (Bristol)

- Deft Finishes

- Le Tonkinois

- Premapro (Coelan)

- Signature Finishes

- Smith’s Five Year Clear

- Vermont Natural Coatings

- West Marine

- Woodplus Marine

RELATED ARTICLES MORE FROM AUTHOR

17 comments.

I’m surprised you didnt include Alwood from Awlgrip

Search Awlwood on the website. We have a couple reports. October 2014 (chandlery), and June 2015 issues. Download the PDFs, because the tables haven’t been loaded online yet. It is broadly comparable to Sikkens Cetol.

opps, Awlwood not alwood

All very interesting……The “bottom line” is just flush the line in fresh water.

Thank you for the great info. I am going order year of Practical Sailor.

What is your opinion of covering a 2 part varnish with a one part?

It is certainly a comprehensive test. I’ve taken the journey of sticking with one of your “good” one part varnishes, Epiphanes Wood Finish gloss 10 coats with Epiphanes final two matte finishes. I’ve been quite impressed with it over the past 8 years on both my Cape Dory Typhoon and my Alberg 30. My conclusion is, read your directions carefully and be patient through all phases of application. Teak requires a caregiver! Great read especially during this pandemic period.

Great review. Your test is useful for me because I want to buy but dont know which product is the best. I must say that I like all of those mentioned above and price is really cheap. It’s always good to hear other input.

You missed out Pettit’s Gold, a water-based varnish. I have used it, and it’s great. For long life? Too soon to tell. Cetol has mostly been a disaster, especially with the Gloss overcoat. Applying Cetol can be tantamount to vandalism.

That’s really nice post. I appreciate your skills. Thanks for sharing.

Did you continue with testing to date, I am after a product that want yellow or bloom because of constant direct sunlight. I am in the North West of Australia where the temp at it’s coolest is 30+ Celsius for a couple of months and peeks over 50 + Celsius for a lot more than the couple of cooler months.

I use Rust-Oleum 207008 Spar Varnish. So much better than those water-based varnishes. This stuff protects almost forever. We used to use this kind of spar varnish in the Navy to protect the woodwork exposed to salty air.

The Interlux Varnish became my favorite varnish on teak fixtures when I tried it out 2 years ago. This is because of the immense difference it makes in the way it lends my pulpit or anything made of teak with a sophisticated, good-as-new finish.

It’s strange that you call out Pettit Z-Spar Captains 2067 as a top performer in the conclusions, but it’s not shown in the chart. Those Pettit products that are included in the chart don’t appear to be top performers. I’m confused.

After less than a year the Bristol finish I used on my boat looks terrible and will have to be removed. The folks at Bristol are absolutely no help at all. Their disclaimer is that they know nothing about boats. I most strongly advise against using this product for marine application. I have photos taken immediately after application, two months after, and eight months after if anyone is interested. By the way, the problem manifested on well prepped old teak and well prepped new teak. Could have just been a bad batch of finish but as I said, the folks at Bristol were no help. I ADVISE AGAINST USING BRISTOL FOR MARINE APPLICATIONS

I’m certain that the analysis of marine varnish was expensive and time consuming but one area that could benefit many subscribers if it was conducted continuously. Practical Sailor is the only place that I can rely on for accurate, up-to-date information on the products I need and use.

This is an important maintenance topic to me. Maintaining brightwork is a lot of labor. This article was last updated in June 2020. I would appreciate an update. I have been using Epifanes clear high gloss varnish for the last five seasons. It gives a good finish but it needs to be touched up one a year even though my boat is under cover for six months of the year. I sail on Lake Erie.

LEAVE A REPLY Cancel reply

Log in to leave a comment

Latest Videos

Bahamas Travel Advisory: Cause for Concern?

Island Packet 370: What You Should Know | Boat Review

How To Make Starlink Better On Your Boat | Interview

Catalina 380: What You Should Know | Boat Review

- Privacy Policy

- Do Not Sell My Personal Information

- Online Account Activation

- Privacy Manager

Boating Basics Online is reader-supported. When you buy via our links, we may earn a commission at no cost to you. Learn more

The Best Marine Varnishes

Written by J. Harvey / Fact checked by S. Numbers

Let’s face it, we don’t give as much credit to the almost perfect combination of boats and varnishes. After all, vessels aren’t exactly cheap. They aren’t immune to deterioration as well. If there’s one solid way for you to preserve the life of your investment and even take her beauty up a notch, wouldn’t you seize it?

For my part, I can wholeheartedly say that these varnishes are great investments, especially if we’re talking about the best marine varnish. These concoctions go beyond their practical benefits, lending anything made of wood with a nice finish that only unlocks and magnifies their natural exquisiteness.

I can say as much for the products I’ve featured here. They have given me noteworthy, if not outstanding, results that make the others I’ve tried in my more than ten years of boating and fishing pale in comparison.

- Great finish

- Easy to use

- Great value for money

- Superb satin finish

- High gloss protection

- Very versatile varnish

- Easy to apply

- Excellent UV protection

Table of Contents

1. Rust-Oleum 207008 Marine Spar Varnish

2. totalboat gleam marine spar varnish, 3. epifanes cv.500 clear varnish, 4. mccloskey 7509 man o’war spar marine varnish, 5. totalboat 482869 lust marine varnish, 6. epifanes wfm.500 wood finish matte, 7. minwax 63200444 helmsman spar urethane, 8. interlux iva316/qt cetol natural teak varnish, 9. mccloskey 7505 man o’ war spar varnish, 10. pettit marine paint flagship varnish 2015, 11. system three 1855s16 marine spar varnish, 12. duralux m738-1 spar varnish, 13. old masters 153617 spar marine varnish, factors to consider when choosing marine varnish, what is the best marine varnish, what is the difference between spar varnish and marine barnish, how do you apply marine varnish to wood, how long will marine varnish last, is marine spar varnish waterproof, best marine varnish reviews.

If I’m going for all-around reliability and protection from sun and moisture damage, I’d choose this varnish in a heartbeat.

This is my go-to varnish for anything wood found in my sailboat. Whether it’s furniture or railing or sometimes even the bow, I often get the kind of maintainability I want every time I use this. The finish is no less attractive and only gets glittery over time in a number of my past applications.

Thinned up to around 30%, it dries quickly enough to apply multiple coats in a day. Sometimes I go for as low as 20%, down to even 5%. It’s because thinning too much does tend to backfire and lead to the varnish taking a long time to dry. It’s easy to use with everything considered.

If you want the best results, I’ve found that using a fresh foam brush with every coat would result in optimal smoothness. It may seem like a waste, buying multiple brushes, but the results are unrivaled, to say the least. I’ve had applications that lasted for a good 3 years before I needed to refinish them.

- Excellent UV and water protection

- More affordable but with high-end results

- Low shelf life

This varnish smoothly combines ease of use, beautiful finishes, and above-average durability. The winning formula for successful marine finishes for wood, in short.

This varnish is versatile in that it leaves plenty of routes open for you to take. For one, I like that they give you plenty of freedom when choosing the shine you want. It’s also available in different sizes, so I always get to buy only the proportions I deem fit for a specific project.

I have to be partial to the satin finish, though, since it delivers the exquisite luster I like to see in my indoor boat furniture and fixtures like railings. However, I always make sure to apply a high-gloss varnish if I’m working on anything that has to be exposed to the sun for long hours. That being said, I like that this product gives you both satin and gloss options.

I make sure to apply the high-gloss varnish as a topcoat, and I’ve gotten excellent results, mostly 1 to 2 years of unblemished finishes, with this practice. Sometimes, it’s shorter than that, especially on wooden areas that are more exposed to the elements. Yet, it’s protection you normally expect and can get from high-gloss varnish. In addition, it’s a varnish that’s also noticeably on the thin side, so I kind of get that it wears away faster than thicker varieties.

- Uncomplicated to apply

- Has multiple sheen and size options

- Not as durable as others

Another safe option, Epifanes marine spar varnish is anything but average with its status as a crowd favorite. Expect superior finish and durability if you choose this.

This varnish easily earns a spot here, considering its unchanging and undeniably positive reputation among boaters. Simply put, it’s hard to fault because of the wonderful results it can bring. The shiny, attractive gloss that has the Epifanes trademark is rarely surpassed by other marine-grade varnishes in my opinion.

What’s equally neat is that it’s not difficult to apply. You don’t really need to sand it with every coat, unlike the majority of other brands out there, but I still suggest you do it, especially in the later coatings. I recommend using marine spirits as a thinner with a 2:1 ratio, and take the time to pour it through a strainer to guarantee a smooth finish. At best, you’ll have to set 5 to 7 days of gradual coating to get the kind of attractive finish you want; and I mean capital-A attractive.

As in other great exterior varnishes, this product is an example to follow when imparting UV protection. At least, that’s what I think is primarily responsible for the excellent finish and the overall durability. I use this as much on my sailboat’s wood portions above the waterline and furniture as well as furnishings in my home, and the finish often lasts for 2 years on average.

- Amazing shine and finish

- Takes a while to dry

- Short shelf life

McCloskey’s Man O’War spar varnish is durable, to an almost no-brainer degree. It’s what I buy if I want to get the best out of what spar varnish offers to the average boater.

Despite its relatively hard finish, spar varnish tends to wear out faster than urethane. It’s a natural thing, so I won’t bother to list it as a con. You can’t mimic the deep amber tint, caramelization, and versatility of good old spar varnish, and this brand delivers no less than that trio of perks.

If I’m going to name a worthy brand representative of spar varnishes, I’d promptly pick this one. It adheres excellently to any kind of wood, so I generously slather any wooden fixture in my boat with this once I get a hold of a bottle.

While it’s easy to use, you’d better be prepared to invest time working with this varnish. I use mineral spirits for thinning, and I make sure to apply thin coats, starting from the middle, using a mini roller and a brush, mohair and ox hair respectively. I sand in between coats, and overall it takes time since it dries slowly.

The durability stems a lot from the outstanding UV protection. My sailboat’s wooden bow that has this finish has been battered by rain a good number of times already, and it’s still holding up after a year since the initial application. Since it’s effortless to apply, I just sand and recoat every once in a while.

- Outstanding UV protection

- Adheres to most types of wood

- Classic, eye-catching spar varnish finish

- Slow-drying

- Limited availability

TotalBoat is a household name in the marine industry as far as paints and varnishes go. This is the brand’s best offering if we’re going to consider fundamental factors like durability, shine, and value for money.

I need to stress outright that this varnish is extra thick, almost honey-like. If you don’t thin it out to at least 50%, you’ll only end up grappling with it to less than desirable results. It’s not exactly beginner-friendly with that considered, but it does pay off since you get optimal protection and the kind of shine any boat owner would be proud of.

Speaking of the finish, it begins to shine through once you hit the one-year mark. At least, that’s what I get from most of the vessels and furniture I apply it to. I can say that it’s smooth sailing once you take the time to know the right consistency.

I often use a roller and apply 5 coats then do a recoat after 2 hours in a whole day. Ideally, the last two coats should only be thinned by about 10% only. It might get tricky applying it then but, trust me, you’ll get the hang of it.

I get the results I want within a day or two — or more at times during less than optimal humidities and temperatures. Even so, that’s obviously quicker than handling traditional varnish, which takes weeks to settle. I do acknowledge the thinner’s role in helping with the drying time.

- Excellent shine and finish

- Proven durability

- Becomes easy to use with practice

- Quick-drying

If we’re talking about top-of-the-line, marine-grade durability, this one deserves to be called the best marine wood finish.

This is my favorite to use on teak because of its proven waterproof capabilities and the fact that its satin finish has just the right amount of sheen, for me, at least. It brings out the beauty of the teak and almost any wood I apply it to, for that matter, and this is coming from someone who has tried numerous marine-grade varnish before. I’ve had furniture that managed to maintain its finish for an impressive 5 years with the help of this varnish.

It’s a bit of a challenge to apply. It actually flows well enough as it is, and I rarely have to thin it with every application. However, you have to make sure that you apply it evenly with every coat and oftentimes as quickly as possible. Once I get patchy and bubbly results, that’s the only time I thin it, and I sand after the first coat, totaling up to 3 coats on average. It will dry more slowly if I thin it, though.

- Excellent durability

- Nice satin finish

- Flows smoothly without thinning

- Brings out the beauty of the wood extremely well

- Fairly cost-effective

- Not beginner-friendly

Though not marine-grade, Minwax has proven to be just as durable as many products with that label. It’s very easy to use and delivers just the right amount of shine.

I often use this on my sailboat’s furniture, and if left with no other options, even the wooden exterior of the hull and bow. It goes well with canoes, but I only tend to apply it on the ribs, rudder, and planking. While not marine-grade, it’s great for outdoor furniture, and, to me, that’s always a good sign of heavy-duty UV protection.

If I want to reinforce the protection, I only need to apply more layers, 4 coats at most but not less than 2. I’ve only used it on oak-made fixtures, though, and I get the longevity and finish I want with that kind of simple setup. The varnish lasts up to 1 to 2 years before recoating becomes necessary, with minor peeling only appearing after a year based on my experience.

I like that they give you plenty of options with regards to sheen and container sizes. I prefer satin for my interior furniture. I once made the mistake of not mixing it well and got a result that’s almost similar to high gloss. To avoid this, you need to make sure you mix it for a good 5 minutes and scrape the sides and bottoms of the can as you do so. This guarantees the soft shine you’re aiming for.

- Plenty of sheen and size options

- Decent durability

- Dries quickly

- Not exactly marine-grade

This varnish earns my thumbs up with the kind of inimitable finish it can deliver and its relatively easy application.

This has since become my favorite varnish on teak fixtures when I tried it out 2 years ago. This is because of the immense difference it makes in the way it lends my pulpit or anything made of teak with a sophisticated, good-as-new finish. It’s not overly glossy, which I attribute to the “natural teak” claim, and only darkens the wood a tad so it will still maintain its natural hues.

I’m glad it didn’t cause any yellowing, and after my second application, I can still say the same. It has a runny consistency that merits forgoing thinning on the first coat. I like to use a brush when applying it to have better control over coverage, which is great enough as it is, and all I can say is that I’ll apply this to my boat’s bow and rails the moment they start showing signs of wear.

Nonetheless, it would be pushing it to say that it’s as durable as the other varnishes here. It only took a year before my bow showed signs of peels and cracks. However, after I applied a single maintenance coat on the entire thing, I found that it limited or delayed the damage since I’ve yet to see signs again after doing a recoating. That being said, I suggest applying a fresh layer at least once a year to make the most out of this marine varnish for boats.

- Outstanding finish

- No sanding and thinning required in most cases

- Good coverage

- Minimal darkening

- Well worth the money

- A bit pricey

- Not durable

Budget-friendly, reliable, and just as good as other solid brands, this McCluskey varnish is a must for anyone choosing to go for value for money all the way.

The fact that this varnish can give you outstanding satin finishes and superb durability without going overboard in cost should give you a ready hint why a lot of boaters are shifting to this product. When I say superb durability, I mean thick coatings that you’ll be confident will last for years.

In my case, the minimum is 3 years on all my wood projects, boat bows, railings, and furniture included. You may start seeing peels and scratches here and there, as evidenced by the 7-year-old canoe that I refurbished 3 years ago. But, to me, it’s still none the worse for wear and nothing a minor recoating job won’t remedy.

The finish is not unlike the ones I get from the other varnishes mentioned here. It accentuates the natural color and look of the wood, and I’m saying this for redwood, teak, and light oak, which are the types I’ve applied it to. It dries in a day like most spar varnishes and typically doesn’t need to be thinned, though sanding is ideal per coat.

Incidentally, I need to underline the fact that this varnish is one of the few that doesn’t skin over in the can after you’ve stored what’s left of it. At least, that’s what I can say for most of the cans I’ve purchased and stored, with about a third of the can full in a year.

- Works well for most types of wood

- Superior durability

- Doesn’t skin like other varnishes

- More reasonably priced than other brands

This rarely figures in marine varnish review posts, and that’s unfortunate considering it’s another top-quality marine varnish that doesn’t yellow, imparts a glossy and thick appearance, and superb UV protection.

Usually, I use this as a general-purpose varnish for the teak and cedar parts and fixtures of my one and only yacht. It gives a deep-colored, thick, glossy, grainy, and smooth finish that I can’t get enough of. It doesn’t yellow at all, probably because of the UV additive used, at least, partly. Anyway, this is one positive quality I always like from any alkyd varnish that is done right.

I prefer to spray this one, following the 20% thinning guideline. Spraying shortens the time for full coverage. I sand lightly between coats using 220-grit sandpaper, and by and large, I only need 3 to 4 coats to get the beautiful finish I described above. It takes almost a whole day to dry, but I don’t mind since I get quality results.

As for durability, I can safely say it’s UV stable. I often leave a couple of chairs and tables out on the deck if the weather’s great, oftentimes, for an entire day. Besides a few scratches in some parts, which aren’t UV-related, they haven’t peeled yet and have maintained their shininess after 2 years since application. I can say the same for the yacht’s teak pulpit.

- Doesn’t yellow

- Superb UV protection

- Proven gloss retention

To me, this is the best boat varnish if we’re only considering durability. It also earns a ready checkmark in protection and attractive finish, making it nothing short of tough to beat.

As far as durability is concerned, the longest that I’ve seen this last without undergoing any kind of major peeling or cracking is close to 3 and a half years. It was on my favorite canoe, which I use fairly regularly for freshwater fishing. 3 years is the maximum for any exterior wood varnish for me, and without a doubt, many boaters would say the same.

I attribute most of the longevity to the excellent water and UV protection. My canoe has borne the brunt of rain and water splashes over the years. I can say the same when I expose it to extensive sunlight exposure when I go fishing in Lake Erie. Top-tier durability in my book.

I sometimes use a thinner with this varnish, but I’ve found that you don’t really need to thin it if you use an HVLP spray gun. Sure, it takes a while to dry and you have to be extra careful, but I’ll take that any day if I get to enjoy these perks and results consistently.

- Outstanding durability

- Relatively attractive finish

- Easy to apply with a sprayer

- Comes in gloss and satin varieties

- Dries slowly without a thinner

A true gem of a find, Duralux exceeded my expectations with its durability and versatility.

In almost any kind of marine varnish for exterior doors, durability and protection immediately go well together. This spar varnish proves it doesn’t belong on the back burner by delivering both. One of my canoes that I applied this on is still going strong for more than a year, and that’s a quality not a lot of products can boast of.

I’ve had varnish that didn’t take more than a month to start peeling and cracking. That’s after a fresh application, mind you, and, yes, I follow brand recommendations to a tee if I haven’t discovered a better way to apply it. This varnish has kept my other canoes shiny every time so I deemed it deserves the spotlight.

Moreover, it doesn’t yellow over time, unlike some clear varnish I’ve used before. You may argue that there’s a lot of variables when it comes to varnish yellowing, like sanding and possible chemicals it can react to. I’m not sure whether this is spar polyurethane, but I’m betting it is since that’s the only type of varnish I’ve used that doesn’t give me the yellowing effect even with minimal to no sanding.

- Satisfactory finish

- Uncomplicated application

- Doesn’t yellow over time

- Doesn’t dry quickly

Old Masters’s varnish shouldn’t be overlooked for its conveniences and quality that only a few top-tier varnish brands can bravely claim they can deliver every time.

This is among the lesser-known spar varnishes that don’t yellow even after a long time has passed. The canoe that I refurbished 3 years ago would prove as much, as it’s still holding up well, surprisingly if I might add. To be honest, this was a second option when I bought it as I didn’t have TotalBoat and McCluskey varnishes available back when I did the finishing job.

I was pleasantly surprised by how things turned out. I followed the instructions and stirred it well. It’s just the right kind of thick, to the point that I don’t have to thin it when applying with a brush or roller. I do have to thoroughly sand and clean the surface first, and it evens out nicely with every coating.

It dries quickly enough for me to apply a second coat in a single day, making me think it’s an exception among oil-based spar varnishes. At best, I give an allowance of 8 to 10 hours before brushing the next coat. Obviously, that’s a time-saving perk I’ll take any day.

It doesn’t produce a yellowing effect, even when applied to parts of my canoe that are regularly exposed to heat, sunlight, and the elements. That’s noteworthy considering it’s a clear varnish. I even have to say that the slightly weathered look it has gotten lends it a charm that most boaters would appreciate.

- Easy application

- Decent durability and finish

- Doesn’t yellow with age

- Limited to small pint-sized cans

Based on my experience, there are many “safe” marine varnish options out there. This only means you’re likely to not run out of beginner-friendly brands and can guarantee high-quality results at the same time. Whether it’s high-gloss or satin, all spar varnishes are easy to apply over new wood or previously coated surfaces. Marine varnish is also not partial to any type of wood and can accommodate those commonly found aboard or form part of a vessel, like teak, redwood, oak, etc.

However, that doesn’t completely discount the need to pay attention to certain factors when making your decision. These are usually the ones I make a note of when planning to start a varnishing job.

- Durability – I’ve found that marine-grade polyurethane is hard to equal when it comes to finishes that are guaranteed to last. Most spar varnishes pale in comparison to their urethane counterparts in this regard because polyurethane tends to last for a minimum of 3 years before re-coats are needed, based on my experience. This is why they’re great options as a marine varnish for outdoor furniture.

For spar varnishes, I’ve had finishes that only lasted a year or even less. At best, these two offer equally potent UV protection, waterproof benefits, and even resistance to scratching.

- Drying Time – Are you working with a severely limited timeframe and need to complete coats within a day? You may want to consider varnishes that dry faster like water-based spar urethane since these can dry in only a few hours. Most spar varnishes require a whole day of waiting to apply coats, assuming climate conditions are optimal.

- Ease of Use – To ensure you won’t end up throwing away your money, don’t ignore how easy or hard a specific varnish is typically applied.

- Shelf Life – It won’t hurt to pay attention to how long a specific can of varnish will last while in storage.

- Gloss – This is admittedly a largely subjective factor, but if you’re opting for high-gloss varnish, it’s almost always the one with the best durability. However, do you like your wood to be extra shiny? There are semi-gloss and satin finishes that are just as attractive, if not more, especially when used on anything wood that is below deck.

We also need to discuss the possibility of a varnish yellowing or darkening the wood that it is applied to. Sometimes, the darkening could be due to the UV additive or tint used; thus, making it unavoidable unless you opt for a different varnish brand altogether.

As for yellowing, there are ways to avoid it. I shall discuss it below, but sometimes, it’s due to the actual product as well, especially if they are clear, alkyd, or oil-based. It’s not an absolute thing, though, and there are products that prove to be exceptions to this rule.

You’ll hear a lot of experienced boaters recommending brands like Epifanes, TotalBoat, McCloskey, and Rust-Oleum. I agree with them because, to me, these brands can easily meet the standards of high-quality marine varnish. Each one has qualities where they serve to shine better, and the reviews I outlined above should give you a good idea about what they are.

Nonetheless, I’m not completely discounting the other brands I included here. I daresay that they’re just as good as those top-dog brands, especially in essential factors like durability and a long-lasting aesthetically appealing finish. Moreover, I find them to be valuable substitutes if any go-to brand happens to be unavailable and won’t even hesitate to pick them as the main option based on certain requirements of a finishing job.

Incidentally, you may have noticed that I didn’t include ease of cleaning when discussing these brands. That’s because most, if not all, of them are very easy to clean for me. At least, for the almost uniform smooth finishes that I get out of them.

There’s not much, really. When boaters use the term “spar varnish”, chances are, they’re also automatically referring to marine varnish. You can also see this in how brands usually label their products in online stores, like Sherwin Williams marine spar varnish or TotalBoat gleam marine spar varnish, to cite a few examples. If you’re using spar varnish, it’s almost always marine-grade.

Both terms give the ready connotation of finishes that provide heavy-duty protection against the harsh elements usually involved when boating, fishing, and cruising. You’ll find plenty of oil-based spar varnishes (i.e. tung oil, alkyd resin, etc.) that are imbued with additives that serve to accentuate the natural beauty of the wood, as well as solvents and other chemicals that promote fast drying and add UV protection.

Since certain varnishes have different components or are more natural or synthetic, it’s best to stick to the manufacturer’s instructions when applying any kind of varnish. However, we can’t deny that most projects share a few essential guidelines, such as the following:

- Preparation usually entails sanding between coats. The most ideal to use for this purpose is 180 to 220-grit sandpaper or even a Scotchbrite pad will do sometimes. Take note that some varnish products can do without sanding, especially for the initial coat. But, this would still depend on whether you’re applying it to a bare wooden surface or if it’s been previously coated before. If it’s the latter, then you’d most likely need to sand it first.

- Clean the dust that forms after sanding using a clean rag. I wipe it down further with a tack rag to ensure no dust or debris would still be present the moment I start applying coats.

- As for temperature and humidity, it’s best to apply any kind of marine varnish if the temperatures during the entire day don’t go above 80 degrees Fahrenheit. Humidity should be 50 to 60% or even slightly lower than that. I found that the smartest route to take is to be patient and wait for the right climate before going ahead with a project, especially if you know that it will take a number of days to finish.

- Thinning depends a lot on the product. If it’s too thick, it’s often necessary to do this, even if the brand doesn’t mention it in the instructions. The safest route for this is to follow a 2:1 varnish to thinner ratio. Mineral spirits are recommended.

- I also recommend taking the time to strain the varnish using a paint strainer to ensure a smooth finish. Sometimes, this can make all the difference in the world in getting the kind of finish that any boater would be proud of.

- As for applying coats, there are certain products that require you to start from the middle so that you can ensure an even coating. Others would caution about wiping too much, while many suggest, as is often the case in spar oil-based urethane, to make thin coats for every layer.

- Bristle brushes and badger-hair brushes are often the standard tool for application. But, again, there are products that are easier to apply with a spray or roller.

Most marine varnishes typically last for at least 2 years. There are brands that have a minimum of 3 years before they begin showing signs of damage. I can attest to marine varnish that keeps its shine and protection for 5 years, and I’ve highlighted the exact products that can achieve that.

Ultimately, if you keep its sun exposure to a minimum, you’re guaranteed to extend any kind of varnish’s lifespan. I’ve noticed that varnished fixtures and furniture in my yacht tend to last significantly longer than the ones that are exposed to sunlight extensively, regardless of the varnish’s UV-protective capabilities.

This is almost always the case considering this type of varnish is marine-grade. Most experts attribute this to spar varnish’s flexibility (i.e. its ability to expand and contract with the wood). However, equally many attribute it to the simple fact that spar varnish is mainly oil-based, allowing to wick away moisture with ease.

Now, do you have a good idea of what the best marine varnish brings to the table? With all things considered, the best parting advice I can give is to not hesitate to try out the options available to you. Sure, there will always be no-brainer choices, but it didn’t take long for me to find out that it pays to try out other brands because they may give your boat the kind of shine or longevity you’ve always wanted.

“I am James Harvey – founder of Boating Basics Online. It is established with the drive to help out first-time boaters, which are those desiring to explore their way through the water. So if you are new to boating, start from here with me. “

What’s the Best Varnish for Your Yacht?

Varnishing your yacht is an essential part of its care and maintenance. The benefits are twofold: yacht varnish protects your boat from the elements, while also giving it a beautiful shiny finish. But with so many different yacht and marine varnishes to choose from, it can be difficult to know which one is best for your boat. In this article, we’ll run through some of the most popular types of yacht varnish on the market to help you choose the right option.

What is Yacht Varnish?

Yacht varnish is an extremely durable solvent-based coating that is designed to protect the wood that yachts are made of and stop it decaying over time. Most varnishes are made up of a penetrating oil, resin and solvent. Although most yacht varnish is applied with a brush, it is possible to buy yacht varnish spray.

Different Types of Yacht Varnish Finish

There are many different types of finish to choose from, so you’ll need to know a little about them to decide which is the best yacht varnish for you.

Clear Yacht Varnish

A clear yacht varnish does what it says on the tin: it will create a transparent, glossy finish that does not alter the colour of the wood it is applied to.

Matt Yacht Varnish

Using a matt coloured yacht varnish will result in a dull, non-shiny finish that does not reflect light. This can be ideal for hiding flaws or imperfections in wood.

Yacht Varnish Satin

A satin varnish falls between clear and matt. This type of finish will create a pearl-like sheen, without being overly shiny or reflective.

Yacht Varnish Brands

There are various brands that produce yacht varnish. Here are a couple of the most popular:

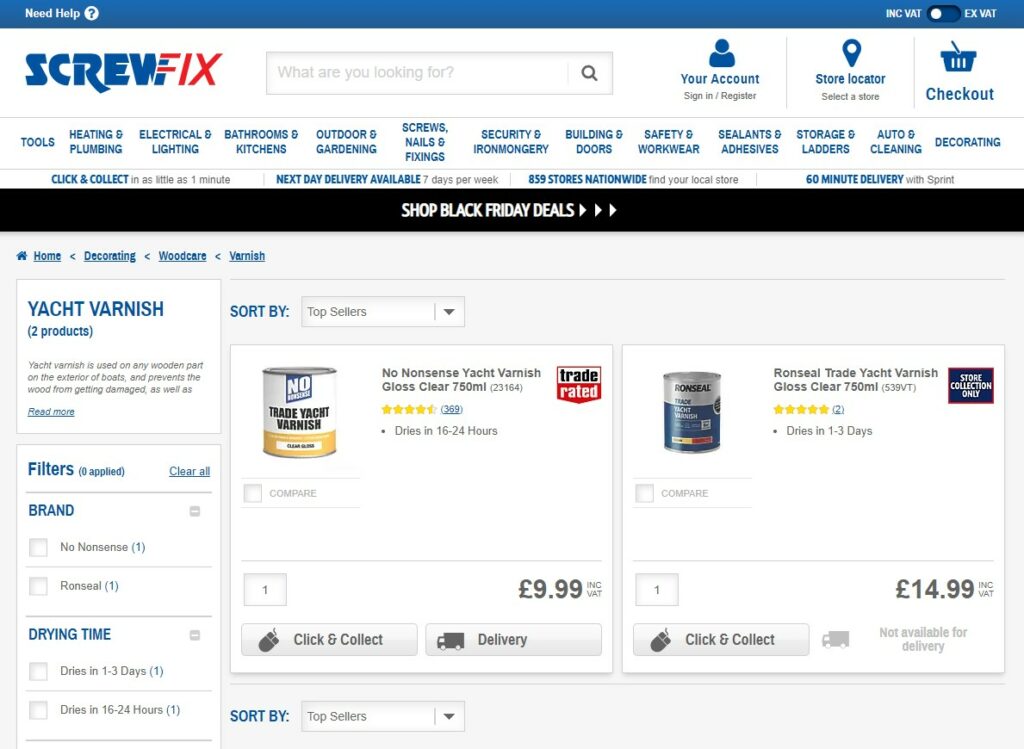

Screwfix Yacht Varnish

Screwfix is a retailer in the UK that sells a variety of products, including hardware and building supplies. They may carry different brands and types of yacht varnish. Yacht varnish provides resistance to water, UV rays, and other environmental elements. Yacht varnishes often contain additives to enhance their durability and performance in marine conditions.

Ronseal Yacht Varnish

A durable, long-lasting marine varnish for wood that flexes with the movement of the wood and resists peeling and cracking. This varnish is slightly more pricey than the Screwfix varnish, but gets great reviews. You can buy the Ronseal brand of yacht varnish in B&Q and other retailers.

How to Varnish Your Yacht

Varnishing a yacht is fairly straightforward, if a little time-consuming. First you’ll need to carefully sand down the entire surface that you want to varnish to get it looking smooth. Then use a soft brush to wipe off any excess dust and debris, since you don’t want it getting trapped in the varnish. Finally, use a paintbrush to coat the yacht with varnish. Leave it to dry for the recommended amount of time on the tin, then apply additional coats as required. Always check the instructions of your varnish type, and if unsure consult with an expert before starting.

How long does it take for yacht varnish to dry?

Yacht varnish generally takes 4 – 6 hours to dry, although you should check the instructions for the specific product you’re using. You’ll probably want to do two or three coats of varnish, leaving sufficient drying time in between coats.

Is yacht varnish good for decking?

This depends on the product you choose. Some yacht varnish is suitable for decking, while others are not because they do not have an anti-slip formula.

Is yacht varnish good for floors?

Yacht varnish should not be used as an indoor floor varnish. It is difficult to dry indoors, and contains chemicals that can be toxic if it is not used correctly.

Is yacht varnish safe for animals?

Yacht varnish is solvent-based and contains toxic chemicals, which means it should not be used for varnishing animal enclosures (for example, rabbit hutches or reptile enclosures).

What is yacht varnish used for?

Yacht varnish is used for sealing and protecting wood on boats and yachts. It is also commonly used for outdoor items such as wooden doors, window frames or pergolas.

What type of varnish is yacht varnish?

Yacht varnish is a solvent-based outdoor varnish that is extremely durable. It is usually made up of tung oil and polyurethane resin.

What is the best varnish to use on a boat?

The type of varnish that is best for your boat will depend on the type of wood your boat is made from and the finish you are looking for. Tung oil varnish is a safe bet for most boats, or you may prefer to use a one-part polyurethane varnish for added durability.

What is the difference between yacht varnish and outdoor varnish?

In general, yacht varnish dries quicker and is designed for marine conditions, so it’s likely to be more durable than outdoor varnish. However, yacht varnish is unlikely to have an anti-slip formulation, making it unsuitable for decking around the home.

Looking for yacht and boat insurance ? Buy your sailing yacht insurance online at Admiral, or contact our expert team for advice.

Admiral Marine is a trading name of Admiral Marine Limited which is authorised and regulated by the Financial Conduct Authority (FRN 306002) for general insurance business. Registered in England and Wales Company No. 02666794 at Beacon Tower, Colston Street, Bristol BS1 4XE.

If you wish to register a complaint, please contact the Compliance and Training Manager on [email protected] . If you are unsatisfied with how your complaint has been dealt with, you may be able to refer your complaint to the Financial Ombudsman Service (FOS). The FOS website is www.financial-ombudsman.org.uk

Boatbuilders

Useful links, yachts & boats we insure.

+44 (0)1722 416106 | [email protected] | Blakey Road, Salisbury, SP1 2LP, United Kingdom

Part of the Hayes Parsons Group

- Facebook Page

- Twitter Page

- Instagram Page

- Youtube Page

What is it you're looking for?

Yacht varnish

Yacht Varnish protects outdoor wood all year long so it’s perfect for windows and doors. It’s a tough traditional varnish and resists cracking, peeling and blistering.

- Long lasting protection for outdoor wood

- Waterproof and protects from the sun

- Extremely tough – resists cracking, peeling and blistering

- Highlights wood’s natural colour

- Prevents wood from greying over time

- Protects against sun damage

- Won't crack, peel or blister

How much paint do I need?

Measure your area precisely, drop the numbers into this smart calculator and it will tell you straight away how many litres you'll need to complete your project.

Need to know

This no-nonsense varnish is extremely tough and durable, giving you a long-lasting glossy finish.

Eight hours might seem like a long time to wait between coats, but it guarantees you lasting protection and the best finish.

3 coats give you a glossy finish

Varnishes up to 16m2 per litre

Brush it on

Smooth exterior wood like doors and windows

How to use Yacht Varnish

Before you start.

Make sure your wood is dry before you begin. Choose a day that’s reasonably warm (above 10°c) and dry.

This varnish isn’t suitable for decking though.

How to prepare wood for varnishing

- You will need to remove old stain or varnish by sanding it down. Use 120 grit sandpaper and sand away the old finish.

- Wipe down the surface with white spirit and a cloth to remove the leftover dust.

If your wood is brand new, you will need to sand it to remove loose wood and clean with white spirit.

Application

- Thoroughly stir your varnish to make sure it’s smooth and there’s no lumpy bits.

- Test it on a small patch of your door. It’s clear varnish but it may still darken the natural colour of your wood so make sure you’re happy with it.

- If you are, start painting with a brush. Go in the direction of the grain and for best results, apply two or three coats. Wait eight hours between each coat.

- Before you apply your last coat, lightly sand the surface and use white spirit to remove the excess dust. This will give you a nice smooth finish. Your last coat will be dry in four hours.

Once your varnish is dry, you’ll be able to clean your door as normal. Keep on top of the dirt and grime for a friendly welcome to your home.

You can clean your brushes with white spirit or brush cleaner.

It’s easy to repair your varnish if sections of it become damaged. Simply use some sandpaper to sand down and smooth out the damaged part and then add a couple of coats so it’s good as new again.

Technical Specification

Find the right product.

Tell us about your DIY project and we’ll show you which products you need.

Find the right product for you

Practical Boat Owner

- Digital edition

Best boat varnish: 7 top options for gleaming woodwork

- Drew Maglio

- October 13, 2022

Different varnishes do different jobs. Understanding their properties will help you decide what's the best boat varnish for your woodwork. Drew Maglio explains all...

Few things are as quintessential to the archetypal sailboat as gleaming, iridescent woodwork that is indicative of a recent coat with one of the best boat varnish products on the market.

Choosing a product and methodology to apply marine varnish to achieve such results is not as simple as it would seem at first glance however, and this guide aims to make the whole process easier for novice and seasoned boat-owners alike.

First things first, what exactly is boat varnish? Put simply, varnish is a chemical solution of three parts which includes a penetrating oil, resin, and solvent.

Boat varnish for exterior use, aka. “spar varnish” — aptly named because it was designed and envisioned as a flexible protective coating to protect a yacht’s wooden spar in the harsh (outdoor) marine environment — both protects and beautifies a vessel’s wood parts.

It does so by sealing the wood with a somewhat hard, yet flexible, clear protective barrier that can last up to three years of UV and element exposure in temperate climates for the most durable two-part product formulations.

These days, most high-end boat varnishes use tung oil and an alkyld or polyurethane resin. Of the two types of resin, polyurethane — either one or two part — is going to be much more durable and resistant to UV, abrasion, fuel/solvent spills, and impacts.

While a two-part product cannot be applied over a one-part product, a two-part product is going to last much longer and be far more durable. Hence for high traffic areas like cabin soles, a two-part polyurethane product cannot be beat for longevity and durability.

Boaters should be aware that the most onerous task of applying boat varnish is the surface prep, which requires removing all flaking previous coatings by sanding, washing with solvent to degrease the surface, in addition to taping nearby areas to keep the varnish off.

Because of that, I highly recommend using quality products over cheaper, lower cost options which will mean your boat needs revarnishing far more often.

International Perfection Plus two-part varnish

Best polyurethane boat varnish

International Perfection Plus is a well-known two-pot polyurethane

International Perfection Plus (sold in the US under the Interlux brnad) is arguably the best overall marine spar varnish on the market. This two-part polyurethane formulation is not only the most aesthetically spectacular, but also the most durable and longest lasting when exposed to UV.

This two-part product is applied to bare wood after careful sanding and degreasing and can be rolled/brushed or sprayed. It uses a proprietary Interlux thinner and one’s results will be excellent if one follows the recommended procedures to the “t.”

Of all the boat varnish products on this list, this two-part product is probably the least DIY-friendly.

Reasons to buy

• Most durable marine varnish in terms of hardness and flexibility • Best UV resistance • Most beautiful (glossy) varnish if applied properly • Hardness and longevity makes it a prime contender to redo cabin soles and floor boards (after proper surface prep)

Reasons to avoid

• Difficult application for inexperienced laymen • Expensive

Buy International Perfection PLUS two-part varnish on Amazon (UK)

Buy International Perfection PLUS two-part Varnish on Gael Force Marine

Buy Interlux Perfection PLUS two-part varnish on Amazon (US)

Buy Interlux Perfection PLUS two-part varnish on West Marine

Note: We may earn a commission when you buy through links on our site, at no extra cost to you. This doesn’t affect our editorial independence.

Epifanes clear varnish.

Epifanes Clear Varnish includes tung oil and alkyd

Epifanes offers quality marine paints and varnishes at reasonable prices and their Clear High Gloss Varnish is no exception. With 64% solids content (tung oil) and an alkyd base, this varnish is sure to be brilliant in terms of gloss with reasonable durability and longevity.

With one-part alkyd products, boat owners can expect up to two years of protection before maintenance is required if left out in the elements year-round. This product can be brushed, rolled, or sprayed.

• Affordable, quality one-part product • High solids content results in very glossy finish • Relatively easy to apply and achieve satisfactory results

• Not as much UV protection as other offerings • Not as impact or abrasion-resistant as other offerings

Buy Epifanes Clear Varnish on Amazon

Buy Epifanes Clear Varnish on West Marine

International Paints are also sold in the US under the Interlux brand

International Schooner Premish Varnish

A traditional marine spar varnish — albeit a good one — is Interlux’s Schooner Varnish.

With an alkyd base, 47% of tung oil solids, and UV inhibitors to boot, this product is a well-balanced one-part product that is suitable for a variety of uses. This product can be brushed, rolled, or sprayed.

• Affordable, quality one-part product • Well-balanced product in terms of UV protection and solids content • Relatively easy to apply and achieve satisfactory results

• More expensive than Epifanes • Not as impact or abrasion-resistant as some other offerings • Not as much UV protection as some other offerings

Buy International Schooner Varnish on Amazon (UK)

Buy International Schooner Varnish on Gael Force Marine

Buy Interlux Schooner Varnish on West Marine

Total Boat Lust High Gloss Marine Varnish

Best value boat varnish

In recent years, Total Boat has become very popular offering products comparable—and sometimes superior—to the “big three” of Interlux, Petit, and Epifanes, at a fraction of the cost and their “Lust High Gloss Marine Varnish” is no exception. This one-part formulation uses linseed oil and a modified polyurethane base.

• Very affordable one-part proper “marine” varnish • Does not require sanding • Comes in matte for those seeking a satin finish • One-hour re-coat time

• Tends to cure quicker than most varnishes and therefore can cure before properly “flowing out” • Requires 6-8 coats

Buy Total Boat Lust High Gloss Marine Varnish on Amazon (US)

Buy Total Boat Lust High Gloss Marine Varnish on Walmart

Cetol Marine Wood Finish

Best boat varnish for external teak

Cetol has been making alternative wood finishes for a long time. While this product does not have the aesthetic beauty of freshly applied gleaming varnish, it lasts far longer and stands up to UV better than every one-part varnish on this list.

When I had peeling varnish on my 1987 Ericson 38-200 sailboat moored in the tropical Florida Keys, I elected to use Cetol’s “Natural Teak” offering in lieu of varnish and found it incredibly easy to apply and long-lasting, requiring no surface prep to speak up but a quick hand sand and power wash. For outside teak, Cetol cannot be beat.

• Incredibly easy to achieve satisfactory results • Affordable • Long-lasting even when exposed to UV

• Not as beautiful as real varnish • Softer and less durable to impact/abrasion compared to most varnishes, especially polyurethane formulations

Buy Cetol Marine Wood Finish on West Marine

Miniwax Helmsman Spar Urethane

The last product featured on our list is Miniwax’s one-part polyurethane spar varnish. While not the most beautiful finish available, this product is durable (hard and abrasion-resistant), easy to use, and very affordable, making it a good choice for touching up one-part varnishes inside a boat’s cabin.

For repairing, touching up, or even redoing cabin soles, this would also be a decent budget option and therefore is included on this list. Unlike the many UV-resistant offerings on this list, Miniwax Helmsman is not very UV-resistant and therefore is not recommended outdoors.

• Very affordable, even for a gallon • One-part polyurethane enhances durability and longevity over alkyd-based products • Good for sailors on a budget needing to repair and touch up existing interior varnish

• Not as beautiful as alkyd-based marine spar varnished • Not very UV-resistant • Yellows in sunlight

Buy Miniwax Helmsman Spar Urethane on Amazon (US)

Hempel Dura Gloss

Best solvent-based boat varnish

Hempel Dura Gloss Varnish is a urethane modified alkyd, ideal for interior use

Hempel’s Dura Gloss Varnish is a urethane modified alkyd, ideal for interior use

On the downside, alkyd varnishes lack resistance to abrasion and usually only one coat can be applied per day, which can make varnishing a drawn out process.

The more expensive types are formulated to speed up cure times, improve gloss retention and generally last longer.

Buy Hempel’s Dura-Gloss Varnish on Amazon

Varnish properly applied to brightwork is a joy to behold. Photo: Thornton Cohen/Alamy

Which type of boat varnish to choose?

Varnishing often appears to be a simple task, but there’s a bewildering choice of boat varnishes on the market, writes Rupert Holmes.

An understanding of the qualities of different types of varnish is needed to choose the optimum one for each purpose. This is particularly true for exterior woodwork which has to withstand the ravages of sun, rain and frost.

There are only a few basic types of varnish, although in many cases hybrid products are available, particularly alkyd/ tung oil and alkyd/modified urethanes that can offer a wider range of desirable properties.

Polyurethane boat varnish

Polyurethane varnishes are a harder option with good wear resistance, but they lack the flexibility of alkyds. In addition, they tend to sit more on the surface of the timber, so often do not adhere as well to the substrate, which can make them prone to flaking and chipping.

The lack of flexibility makes a pure polyurethane unsuitable for traditionally planked boats, but it can be ideal for plywood , as well as for cold moulded and strip planked hulls.

Polyurethanes are available as both one-pot and two-pot products, the latter giving a harder coating and faster cure, which allows multiple coats to be applied in one day.

Article continues below…

Boat wood: a complete guide for yacht owners

Boatbuilder and finisher Lyndon March explains which types of wood work best for different repairs and modifications on board

How to re-caulk teak decks: Vagabond 47 owners explain how they did it

First, they removed the old caulking between the planks using a Bosch Palm Router and pinned a guide into the…

Teak alternatives: How to make your decks look as good as the real thing

However, according to a recent report by the Environment Investigation Agency, there are grave questions over the sustainability and sourcing…

If you need to save the varnish overnight, take a look at this top tip on preserving two-part varnish in the fridge. However, they are a much more expensive option.

N.B. One-pot polyurethane can be applied over two-pot varnish but not the other way round.

Ultra-flexible single-pot polyurethanes, such as Coelan have an elasticity of more than 300%. It can also seal cracks, is highly resistant to impact damage and doesn’t need overcoating for several years and can last twice as long as traditional varnishes.

The biggest downside is that it’s four or five times more expensive than typical basic alkyd varnishes, so up-front costs are higher, although its long term performance means the total cost difference will be smaller.

Many boat varnish products can be painted, sprayed or rolled

Tung oil varnish

Tung oil is also frequently used in traditional varnishes: it soaks in well and, although a pure tung oil product will usually cure very slowly, the final finish is very tough.

Solvent-based varnish

Traditional solvent-based one-pot alkyd varnishes are ideal for use with traditionally built wooden boats. The coating is soft but flexible, which makes it resistant to cracking when used on timber that expands when wet and contracts in dry summer weather. Additionally, the initial coats tend to soak into the timber effectively.

Epoxy resin

Epoxy resin can also be used to coat timber, but generally has poor resistance to ultra-violet light, so a varnish needs to be applied over the top. Beware inexpensive ‘yacht’ varnish sold in DIY stores – the low prices are usually easy to explain in terms of extended drying times or poor long-term performance when used outside.

Dealing with surface damage? Don’t delay!

Whatever type of varnish is used, don’t delay on sealing any areas of damage. The key priority is to keep water out, so don’t wait until you have time and suitable weather for a full repair – touch in the damaged area immediately.

This may not have a silky smooth finish initially, but don’t worry. Even if it’s a few weeks before you’re able to do a proper fix you know there won’t be any further degradation.

Top boat varnish tip

A useful tip is to clean out one of the small match pots DIY stores sell to enable customers to test household colour schemes and fill it with varnish. They have a brush built into the lid, which never needs to be cleaned, thus making a quick touch up of damage a task that only takes a couple of minutes.

Find out how to get the best finish with these 8 top tips for varnishing .

Didn’t find what you’re looking for? Head to Amazon’s dedicated boating page for more marine products.

Which Yacht Varnish Is Best For My Boat?

Yacht varnish is a specialized type of varnish that is often used on boats. It has several advantages over conventional varnish, which is why it is becoming more and more popular among boat owners. In this guide, we will discuss the benefits of yacht varnish. We will also answer some common questions about yacht varnish. So if you are interested in learning more about this topic, keep reading!

Yacht varnish is a type of varnish specifically designed for boats. It is typically made from a tougher resin that can withstand the harsh conditions that boats are exposed to, such as salt water and sunlight. Yacht varnish also often contains UV inhibitors to help protect the wood from fading and other damage caused by exposure to sunlight. Conventional varnishes are not as durable as yacht varnish and will not stand up to the same conditions. This makes them less suitable for use on boats. However, they can still be used for other applications, such as furniture or around the garden.

Which types of varnish to use on my boat?

Marine varnish can be divided into three different types, each with its own perfect uses. Yacht owners choose to use one or all of these types for better performance.

Tung Oil-based varnish

Is the most popular type among yacht owners who take boat maintenance seriously. International Schooner or Goldspar Boat Varnish are both oil-based varnishes that coats the wood evenly leaving a smooth finish while requiring minimal preparation work before it can be applied. This only requires a couple of coats. Is advisable to lightly sand the surface between coats to achieve the highest quality glossy finish. The smooth, high gloss finish will protect teak parts from water stains and help to maintain their appearance over time! Its UV protection helps prevent mould growth too which is especially important in wetter climates. Oil-based varnish is easy to apply and can be repaired by sanding and re-oiling the wood, meaning it will last longer than other conventional varnishes. It's also easier to apply compared with water-based yacht varnish which requires no sanding or priming before application.

Water-based boat varnish

Often used on marine boats where there is not much exposure to agitation or rubbing, making oil-based varnish too heavy for use. This yacht varnish type tends to leave a thin, powdery residue that needs sanding down after drying but offers better penetration into the wood than its oil counterpart. Polyurethane boat varnish - is much more hard-wearing than oil or water-based yacht varnishes. Stronger than oil-based or water-based yacht varnish, polyurethane yacht varnish tends to dry quickly and offers an ultra-hard surface that is resistant to impact, scratching and denting. This yacht varnish type has a high gloss tough finish so it's best suited for areas of the boat that are exposed to more wear and tear. This type of varnish can also be divided into two categories as one part polyurethane boat varnish and two-part polyurethane varnish.

One Part Polyurethane Varnish

The yacht varnish that is most commonly used for yacht paint jobs. The yacht varnish offers a quick drying time and can be easily re-coated within hours between each coat. It should be noted that due to its rigidity it is not recommended to be used for painting highly flexible wooden areas as it might crack in time leaving the wood exposed to elements. Two-Part Polyurethane Varnish - is the varnish with longer working times, making it easier to apply on larger boats. It's advisable to use only one part polyurethane yacht varnish for smaller projects as two-part yacht varnishes tend to leave an unprofessional finish when applied by hand. This type of varnish is extremely tough and consists of two products mixed together. It offers very good protection from moisture and UV damage but the same as the above this is not suitable for some areas on your yacht (such as spars) and it will crack as the wood moves and will leave the wood exposed to the elements.

Is yacht varnish waterproof?

Yes, yacht varnish is typically waterproof. This makes it a good choice for protecting boats from the elements. It can also help to keep the wood of the boat looking its best for longer.

Does yacht vanishes need a primer?

No, yacht varnish does not typically need primer. However, it is a good idea to test it on a small area of the surface you are going to varnish to make sure it adheres properly. If you do decide to use primer, make sure it is designed for use with yacht varnish.

Does yacht varnish seal wood?

Yes, yacht varnish seals the wood. It forms a protective barrier that helps to keep the wood from damage and keeps it looking its best for longer.

How long does yacht varnish last?

The lifespan of yacht varnish varies depending on the brand and the conditions it is exposed to. However, it typically lasts for several years, anywhere from two to three years before you need to apply a new coat or two. Some varnishes obviously last longer than others depending on the area where they will be applied.

Which is better? Woodstain or yacht varnish?