Log in or Sign up

You are using an out of date browser. It may not display this or other websites correctly. You should upgrade or use an alternative browser .

Aluminium sailing catamaran build

Discussion in ' Multihulls ' started by Donnavan Wright , Sep 9, 2019 .

- aluminium construction

- aluminium fabriacation

- study plans

Donnavan Wright New Member

Good day all you salty legends ! I’ve been searching the internet and came across your page . Being a metal fabricator I have put in a lot of thought about building my own aluminium sailing catamaran , 40 to 45 foot would be ideal . I have access to a cnc plasma and aluminium mig welders . Space not a problem either . Time not a problem either as I’m working an ever 6/6 day roster with a 5 year plan . I’ll be starting from scratch building the gigs and developing templates and so on , my question is do I approach a boat designer or is there a site I can download the study plans , drawings and procedures from ?

oldmulti Senior Member

Hi Multihull Structure Thoughts thread on design net. The flowing pages have some aluminum boat details. Page 5 Banana Split 42 aluminium cat with thick skin. Page 14 Osram 7 48 foot cat, another tri. Page 20 Kat'alu 42 aluminum cat. Also Bruce Roberts does some aluminum cat plans in the size range.

bajansailor Marine Surveyor

Here is a link to the thread mentioned by Old Multi. Multihull Structure Thoughts https://www.boatdesign.net/threads/multihull-structure-thoughts.62361/ Kat'alu is post #298. Old Multi had posted their catalogue which I will also add here, as she is a pretty neat design. It does help to illustrate though that there is a LOT of work involved in building a cat of this size. I think that Richard Woods recommends staying under 40' (or maybe even 35') unless you are building a commercial boat, as the time frame for an amateur builder will literally stretch into years.

Attached Files:

Kat'alu 42 catalogue.pdf

Alik Senior Member

This design can be converted to aluminum. SC44 Sailing Catamaran - Designed by AM Design, Thailand http://www.amdesign.co.th/Stock_design_SC44.html

fallguy Senior Member

bajansailor said: ↑ Here is a link to the thread mentioned by Old Multi. Multihull Structure Thoughts https://www.boatdesign.net/threads/multihull-structure-thoughts.62361/ Kat'alu is post #298. Old Multi had posted their catalogue which I will also add here, as she is a pretty neat design. It does help to illustrate though that there is a LOT of work involved in building a cat of this size. I think that Richard Woods recommends staying under 40' (or maybe even 35') unless you are building a commercial boat, as the time frame for an amateur builder will literally stretch into years. Click to expand...

jamez Senior Member

Peter Kerr has designed/built several successful alloy cats https://lizardyachts.com.au/

guzzis3 Senior Member

If you are a really good Al welder and have access to the gear it might make sense. Just remember building the hull is at best 1/3 of the build. Also remember the time and cost to build te hulls is proportional to the weight. Personally I have never understood big bridgedeck cats. If you build an open deck cat the same weight you get longer hulls, equivalent accommodation, faster speeds and nicer motion. I guess you do get stuck with bigger rig and more expensive registration and storage fees. A 45' open deck cat would still have massive accommodations...

guzzis3 said: ↑ If you are a really good Al welder and have access to the gear it might make sense. Just remember building the hull is at best 1/3 of the build. Also remember the time and cost to build te hulls is proportional to the weight. Personally I have never understood big bridgedeck cats. If you build an open deck cat the same weight you get longer hulls, equivalent accommodation, faster speeds and nicer motion. I guess you do get stuck with bigger rig and more expensive registration and storage fees. A 45' open deck cat would still have massive accommodations... Click to expand...

Try Berckemeyer Yacht Design | plans for modern and classic sailing yachts http://www.berckemeyer-yacht.de/yachts/New%20Yachts/BM39_dash.html An aluminum 39 footer open bridge deck cat that can also be done in ply if you want.

BM39 dash general.jpg

Bm39 dash interior.jpg.

oldmulti said: ↑ Try Berckemeyer Yacht Design | plans for modern and classic sailing yachts http://www.berckemeyer-yacht.de/yachts/New%20Yachts/BM39_dash.html An aluminum 39 footer open bridge deck cat that can also be done in ply if you want. Click to expand...

- Advertisement:

Slava. At 50 foot you need a good designer as the cost of materials alone will be high. ALIK of AMD designs is a good designer but there are many other designers who can do a good design. The real question you need to ask is what is your real requirements. You can have a simple chine V bottom open 50 foot bridgedeck cat built of 10 mm thick aluminum with minimal framing and tube cross beams. Or you can have a round bilge open 50 foot bridgedeck cat built of 5 mm thick aluminum with a lot of framing and tube cross beams. The more complex the design, the more expensive. There are many stock aluminum cabin bridgedeck designs in the 40 to 50 foot range from many designers. Please understand at 50 foot the design criteria to suit you is often more important than the cost of the design, as the total cost of the boat is going to be hundreds of thousands of dollars.

Aluminium Cat designs

Aluminium catamaran plan

Aluminium Wing Mast

A bit of sailing history

Proa Rudderless, Down Wind sailing!

Sailing outrigger canoe

Extend Rudders on 10metre sailing catamaran

Dangers of shallow draft for sailing cat?

Proa sailing for beginners?

Amended single rudder for small sailing cat

- No, create an account now.

- Yes, my password is:

- Forgot your password?

Professional BoatBuilder Magazine

An aluminum expedition catamaran.

By Dieter Loibner , Apr 5, 2022

With 110′ LOA, a 35′ beam, and 45′ (33.5m, 10.6m, and 13.7m) of bridge clearance, the H-2 catamaran seeks to make a case for U.S. custom boatbuilding.

Hauling toys beyond the horizon is the raison d’être for a rugged go-anywhere catamaran designed and built in the U.S., a notable exception in the world of big yacht projects.

Gunboat might have left town, but there’s another big catamaran under construction in its old facility in Wanchese, North Carolina. It’s called H-2 , short for Hippocampus 2 , a stout 110-footer (33.5m) that liberally and intentionally quotes from the expedition/workboat vernacular. It’s built from aluminum and was conceived to go to the back of the beyond, where adventure beckons and Vessel Assist doesn’t operate. Aside from commodious and cushy accommodations, the boat offers grid autonomy, ocean-crossing range, and cargo capacity to match the mission of hauling a 26 ‘ (7.92m) tender, a 17 ‘ (5.8m) skiff, a two-person submarine, a four-seat ATV on the main deck, and a small helicopter on the flight deck aft.

The boat was commissioned by Brian Schmitt, 67, a real estate executive in the Florida Keys, who pilots his own plane to commute to the Bahamas, where he keeps Hippocampus , his current 57 ‘ (17.37m) cold-molded wood/epoxy catamaran. I asked him about the jump from 57 ‘ to 110 ‘ . “I never thought I’d have the ability to do that in my own boat until probably the last few years,” he replied, adding that “it would be 120 ‘ [36.58m] if I had to do it today.”

Its predecessor, Hippocampus, built in wood/epoxy, was launched in 2003. At 57′ (17.37m), it is about half as long as H-2, but with 22,500 miles under its keels, it was a useful starting point for designing the new vessel.

Wearing shorts and a shirt with the new boat’s name and logo to our meeting, Schmitt talked openly about his project, which he manages as attentively as his real estate brokerage with 130 agents. Communication is his thing, responding to e-mail questions in near real time (in ALL CAPS) and talking to contractors directly. No project manager.

A passionate diver who habitually explores remote and exotic locales, Schmitt said he was happy with the first Hippocampus , which has three staterooms and cruises at 15 knots on twin 370-hp Yanmars. “It was the vehicle that got our 17 ‘ tender wherever we needed it.” But running the little boat 60 or 70 miles a day lost its charm. “One of the things I wanted was a twin-engine tender that would have more room for dive gear. That ended up being a 26 ‘ Calcutta, so I needed a bigger mother ship.”

With accelerating climate change, the carbon footprint of ships and large yachts is under scrutiny, but hydrocarbons still win when speed, range, and payloads are priorities. While H-2 doesn’t break the mold there, Schmitt pointed to the project’s virtues as a U.S. domestic build. “You can’t complain about global warming when you’re flying around in your G500 jet that’s contributing more CO2 emissions than anybody else in the world,” he said. “You can’t complain about all the boats being built in Germany, The Netherlands, and Italy, and then go buy a boat [there].” Schmidt wanted to build locally, keeping jobs and money in the U.S. Besides, he noted, this approach simplified communications and enabled him to personally check on progress during COVID. Perhaps most importantly, he could pick a team of trusted and compatible mates to turn his dream into a boat.

The vast build hall left vacant when Gunboat left Wanchese, North Carolina.

He selected John Marples, a fellow pilot, inventor, and multihull specialist for the design and Felix Herrin to build H-2 . Both men had worked for him on Hippocampus , and their familiarity helped when meeting today’s challenges, such as damaging trade tariffs that drove up aluminum prices, and a pandemic that killed millions, wreaked havoc on global supply chains, and caused labor shortages in industrial sectors. These factors have conspired to delay H-2 ’s launching by roughly two years and counting.

Advantage Aluminum

A key decision early on was to build in aluminum, which promised a robust structure but required extra steps to deal with corrosion and noise mitigation. “Construction was reduced to something simple—a V-bottom deadrise model, stretched out,” Marples explained. “There wasn’t any benefit to round bilges on an aluminum boat. You’d have to add internal structure to support the flat panels, and it drives the cost and difficulty of construction way up. We’re talking about a speed-to-length ratio of 2 or less, which is not a big deal. His current boat would do a speed/length of about 3, so the extra length means that you’re never really pushing the boat that hard, so shape was not a huge consideration.”

Marples and Herrin go back at least three decades to their mutual acquaintance with naval architect and boatbuilder Dave Dana, who assisted Marples with the hull design for Admiral Pete , a catamaran passenger ferry still serving Puget Sound. Herrin works with different construction materials, but having built crew boats for Petróleos de Venezuela (PDVSA) at Sea Force in Palmetto, Florida, he has spent considerable time with aluminum.

Taking a break during IBEX 2021 are builder Felix Herrin (left) and owner Brian Schmitt. H-2 is their second joint project with designer John Marples.

The structural components on H-2 are 5083-H32 alloy aluminum plate and extrusions of 6061-T6 alloy. Scantlings, materials, and weldment comply with the American Bureau of Shipping’s (ABS) 2016 design guidelines for pleasure motoryachts. Hulls and wing structures have transverse frames and bulkheads spaced on 36 “ (0.91m) centers. Those frames are supported by substantial centerline vertical keels (CVKs) welded atop twin 3 “ x 8 “ (76mm x 203mm) solid extruded-aluminum-bar keels. Intermediate subframes in the forward and aftermost hull compartments strengthen the hulls for operating in ice. Schmitt indicated he wants to traverse the Northwest Passage. For the same reason, there’s 3⁄8 “ (10mm) plate running the length of the boat above and below the waterline.

The topside and underwing plating is primarily ¼ “ (6mm), with areas of 5⁄16 “ (8mm) to strengthen slamming zones in the bow. The main deck plating is also 1/4 “ while the foredeck plate is specified at 5⁄16 “ . The bottom plating is 5⁄16 “ in the aft two-thirds of the hull and 3⁄8 “ forward. “We built all the frames and bulkheads first, then scarfed together the keel sections [and] lined those up on the bunks that we built on,” Herrin explained. “We welded the CVK on top of the keel, then started installing frames.”

Hulls and wing structure have transverse frames and bulkheads on 36″ (0.91m) centers. The hulls are supported by centerline vertical keels.

Herrin said he changed aluminum suppliers midway through the project, sourcing from Bayou Metal Supply , an ISO 9001:2015–certified distributor in Slidell, Louisiana. “We sourced the material from Greece and from domestic suppliers,” said Taylor Smith, who handles Bayou’s sales. Tariffs, he said, did not slow down business much, but the aluminum cost more. “Felix sent cut files. We had the material in inventory, we cut it, processed it on a router, and shipped it on time. Everything flowed well.”

Naval and structural engineering and detailing was contracted out to Van Gorkom Yacht Design in Portsmouth, Rhode Island. “My first responsibility was looking at structures,” Geoff Van Gorkom said. “Given that this is an aluminum yacht, we can do literally all the structures in 3D and have all the metalwork precut before it came into the yard. All the frames and longitudinals and all the primary structure were precut, which saved huge amounts of time.” Van Gorkom said he uses Rhino 3D and some of the numerous modules such as Orca 3D for hydrostatics and hydrodynamics, and 2D AutoCAD to produce construction details.

Helping save time and money, 3D-modeling allowed frames, longitudinals, and the primary structure to be cut before being sent to the building site.

Van Gorkom observed that H-2 is not a fussy high-performance vessel that needs minimum weight to achieve maximum speed. Besides ABS guidelines that address torsional loads in catamaran structures, he also consulted A.L. Dinsenbacher’s paper “A Method for Estimating Loads on Catamaran Cross-Structure” ( Marine Technology , Vol. 7, No. 4, October 1970) to estimate load conditions in beam and quartering seas. “This is going to be a very stiff boat. It’s going to be a very strong boat simply because it has to be, and that was one of the criteria that Brian put out there right from the very start of the project. The boat is sturdy and stout, a strong expedition yacht.”

Van Gorkom also engineered the setup for a folding deck crane housed under a flush hatch in the helideck on the port side to launch and retrieve the two-man submarine or the ATV. “It’s basically an enclosure that opens up, so the crane extends out,” he explained. “It comes up on a telescoping pipe to swing out and pick up something from the side of the boat.” It required support from beams on each side of the crane and cutting a slot in the helideck for the lifting bridle so the loads can move inboard or outboard. On the starboard side, the 5,500-lb (2,492-kg) Calcutta tender is an even heavier load moved by twin overhead beam cranes. The 17 ‘ Twin Vee is launched and retrieved from the foredeck with a 2,500-lb-capacity (1,153-kg) crane.

Catamarans are known to be weight-sensitive, so how will H-2 handle the weight of all the toys and high superstructure? The arch over the flybridge is 33 ‘ (10.05m) above waterline, Van Gorkom confirmed. “Add another 10 ‘ [3.05m] for the radar, mast, etc., so a comfortable bridge clearance would be around 45 ‘ [13.7m].” Marples conferred with Van Gorkom about the effect of the added weight on the center of gravity, which was deemed “almost imperceptible,” Marples remembered. A quick calculation suggests that a 5,500-lb deck load is equal to only 1.57% of a full-load displacement given as 350,000 lbs (158,550 kg).

High Power, Low Noise

Van Gorkom hired engineers at HydroComp to evaluate the design’s hydrodynamics and propulsion systems, including the influence of hull-shape parameters and demi-hull spacing on resistance. HydroComp also offered a speed-power prediction to aid with engine selection and recommended optimum shaft rpm and propeller parameters. Technical director Donald MacPherson, who prepared the report, outlined the process and findings: “Particularly interesting for this project was the use of its novel analytical distributed volume method [ADVM] for the vessel’s resistance modeling. This 2D technique (between parametric methods and CFD) uniquely allows for assessment of the influence of local sectional area curve regions (such as ‘shoulders’ or inflections) in wave-making drag. It also directly evaluates the effects of catamaran hull spacing.” HydroComp helped optimize the hulls by identifying the regions that contribute most to wave-making drag, and securing a 3% reduction in total drag at the design speed by making what MacPherson called “very minor changes to the immersed volume distribution.”

Rob Ayers works on the installation of the starboard engine’s Evolution Marine Shaft System that will be fitted with a 36″ (0.91m) five-blade propeller.

That simulation was mapped to benchmark performances of four similar catamarans, and the process was run for two design variants, followed by a propulsion simulation for partial-load conditions. The hull-spacing study concluded that the originally designed 35 ‘ (10.7m) beam remained suitable despite the boat being 20 ‘ (6.1m) longer than originally drawn. The chosen propulsion system comprises two MTU 10V 2000 M96, 1505-mhp diesels with ZF 3000 flange-mounted marine gears, providing an estimated top-speed range of 20–22 knots, cruising speeds of 12–15 knots, and 10–13 knots for long-range voyaging. Actual performance will be established during sea trials.

The recommended propeller specifications developed by HydroComp were for five-blade models with 36 “ diameters. HydroComp applied PropElements, a wake-adapted propeller-analysis tool, to determine the advisability of installing a nozzle or shroud to restrict transmission of pressure pulses to the hull and to create a more uniform inflow. This would reduce interior noise but would increase appendage drag and power demand. Schmitt said he will wait to see if cavitation or prop noise is an issue before making a final decision.

He invested heavily in noise and vibration mitigation, knowing that an aluminum boat won’t provide the natural sound-dampening of a wood/epoxy structure like that of his first Hippocampus . Consulting with Soundown of Salem, Massachusetts, Schmitt wanted to replicate what worked well on his old boat, starting with the Evolution Marine Shaft System, in which the prop shaft runs in an oil-filled tube and uses roller and needle bearings instead of standard water-lubricated bearings. “You have a lot less shaft noise, but one of the primary benefits of an integral thrust bearing is that it transmits all the thrust directly into the hull, as opposed to pushing on the gearbox or the engine and gearbox combination,” said Sam Smullin, Soundown’s marketing and quality assurance manager. “It allows for a much softer engine mounting, so you reduce the noise from the shaft itself and get a much quieter engine installation, which reduces structure-borne noise.” Because of the relative weight sensitivity of catamarans, Smullin said, “it’s particularly important to do a really good job on the driveline.” His father, Joseph Smullin, president of Soundown and J&A Enterprises Inc., an engineering firm for noise and vibration control, estimated that this could reduce driveline noise levels by 5 dBA to 10 dBA compared to a conventional system.

Clemente Perez, one of Herrin’s build crew, works on the interior. The extensive sound and thermal insulation includes foam sprayed into the cavities.

Soundown also looked at the two 38-kW Northern Lights gensets, which have double-isolation mounts to reduce structure-borne noise. The firm also recommended structural changes to ensure that the mount foundations were as stiff as possible.

Energy from propulsion or generator engines invariably transmits to the boat structure and then resonates through big, flat panels like bulkheads, decks, ceilings, and liners, causing the familiar vibrating rattle. To dampen those vibrations, Herrin said he used Roxul, a lightweight, semi-rigid stone-wool insulation for fire resistance and sound control. His crew also sprayed cavities with Dow Froth-Pak, a quick-cure polyurethane foam for thermal insulation, and installed Sylomer (a microcellular PUR-elastomer) between the structural components and the floors, walls, and panels. “We glued the Sylomer, which is kind of a spongy foam, to the structure of the boat, and then the plywood of the subfloors and walls are glued to that,” Herrin explained, adding that this created a floating interior without any fasteners.

The plywood, called QuietCore, is a composite sandwich panel comprising marine plywood skins and an acoustic damping layer that converts acoustic energy into small amounts of heat that are dissipated. Soundown claims that an 18mm (0.7 “ ) QuietCore bulkhead can reduce noise transmission by up to 10 dBA, an audible reduction 50% greater than with regular marine plywood of equal thickness.

Electricity for a Small Town

Going off grid on H-2 does not mean anyone will suffer, as long as the electrical system keeps powering the boat’s myriad house loads—hydraulic Maxwell windlasses and thrusters; a Webasto air-conditioning system; two full-size stand-up freezers, two refrigerator freezers, and two under-counter refrigerators in the galley, all by Vitfrigo; Krüshr compactors for recyclables and garbage; Headhunter sewage-treatment system; Alfa Laval fuel-polishing system; two FCI watermakers; a complete set of Garmin navigation electronics with full redundancy; and a Böning vessel control and monitoring system.

Two Northern Lights 38-kW gensets are the heart of H-2’s AC system, which also includes a 37-kW Atlas inverter to connect to shore power in foreign ports.

Much of the AC side was designed and specified by Ward’s Marine Electric in Fort Lauderdale, Florida, in cooperation with OceanPlanet Energy of Woolwich, Maine, and principal Bruce Schwab, who helped design and integrate the DC components. “Today there’s a big trend in the industry to use shore-power converters as inverters and superlarge lithium-ion battery banks to provide power, at least temporary power, for major loads like air-conditioning, chiller plants, and things like that,” said Ward Eshleman, chairman of Ward’s Marine Electric. “So, rather than using only smaller inverters and synchronizing them and stacking to get additional kW, the trend for the larger vessels is to use shore-power converters as inverters. There is an inverter bus in the main switchboard.”

True to its go-anywhere mission, H-2 was fitted with an Atlas 37-kW inverter to connect to shore power in places that do not serve 60 Hz, 240V single-phase power. “We can take anything from 90V to 400V and pretty much anything from below 50 Hz to the 60 Hz and single- or three-phase,” Herrin explained.

Eight GTX24V315A-F24 lithium-ion batteries from Lithionics are split between a house bank that can run all DC loads for at least 24 hours, and an emergency bank to operate critical DC loads—display screens, radios, nav lights—for 24 hours. The boat is equipped with 10 Solara Ultra-S 160W panels paralleled in two groups of five each, connected to two Victron SmartSolar MPPT 100/50 solar controllers to charge the house bank. Given enough sunshine, solar and battery power should be “capable of running lights and refrigeration but not air-conditioning or heating,” Schmitt said. “Since we will likely spend most of our time in the tropics, we did not believe that solar power alone could do the job we needed.”

OceanPlanet Energy specified four Victron Buck-Boost DC-DC converters, two for each engine, to help charge the house bank from the starter batteries without having to modify the engines’ stock alternators, which would have voided the warranty. “The converters activate based on the input voltage from the starting batteries,” Schwab explained. “With lower rpm, the alternators would not produce enough current to feed both converters without the starting-battery voltage dropping, turning the converters off. Then the voltage will rise, the converters turn on again, drop the voltage, turn off…over and over. Staggering the input voltage cut-in, hopefully starting the converters one at a time, will more smoothly supply power to the house bank across the engine/alternator rpm range.”

OceanPlanet Energy specified the DC system including DC/DC converters and hefty battery banks to power house loads and critical electronics.

There are two 4,500-watt 240V split-phase engineroom-ventilation fans connected to two Victron Quattro 5-kW 24V inverter-chargers configured for 240V/120V split-phase AC loads. They can accept AC inputs from two sources (shore power or generators) and automatically connect to the available source. “In the event of a grid failure or power disconnect, they take over the supply to the connected AC loads by inverting from the Lithionics house-battery bank,” Schwab said.

“It’s more complicated than that,” according to Herrin. “Typically, we’re going to be operating with the A-bus and the B-bus tied together, so we can power everything with one generator. The B-bus actually passes current through the Victron inverter-chargers on its way to the load. We have the ability to split the A-bus and the B-bus and run the A-bus on one generator and the B-bus on the other in the few instances we’re exceeding the capacity of one of the generators. If we lose both generators, then the essential loads are still going to be carried,” meaning engine vents or water pumps.

Redundancy and emergency backups also figured largely in the deliberations of John McKay, manager of the Switchgear Systems Division at Ward’s Marine Electric and point man for this project.

One of his challenges was limiting the voltage drop in the estimated 53 ‘ (16.2m) cable run between engines, which in an emergency allows the starboard engine to be started from the port battery and vice versa. “For a starter group, you can allow a 20% voltage drop,” McKay said and noted that starting the engines requires 720 amps, while the gensets needed only 200 amps. “I was keeping the 720-amp current between 7% and 11% voltage drop, getting up to some pretty good-sized copper. Some sections of the run were 240mm2 [500MCM] cable.” Knowing that the boat is capable of going to high latitudes, McKay recalled his youth and the frigid winter mornings in Massachusetts, “where you can crank a diesel all day long at a low rpm, and it’ll never start. You just need to turn it over one or two times at a higher rpm, and it’ll be running. So, I was making certain that the starter was going to crank at the highest rpm possible and not lose it all to voltage drop.”

Protecting Assets and Finishing the Job

No matter how fast or how far H-2 will travel, corrosion caused by galvanic current between dissimilar metals, by stray currents or by electric fault, is an enemy that needs to be kept in check. That’s the calling of Ted Schwartz, who runs Electro-Guard (Mount Shasta, California). He’s one of the country’s foremost experts on cathodic protection, and also served on ABYC’s E2 Cathodic Protection Project Technical Committee.

“We designed the system and supplied all the equipment and steered them through the installation,” Schwartz said. It’s a 15-amp impressed-current-cathodic-protection (ICCP) system, model 715 A-2, with three anodes and two reference cells. Regarding the boat’s Evolution shaft system with driveshafts running inside an oil-filled tube, Schwartz said: “It was a real challenge because you can’t actually make contact with the propeller shaft on the inside of the boat.” He consulted with Soundown and found a solution. “At the coupling on the inboard end of the tube, a bit of the shaft stuck out through the seal,” Swartz said. “There’s this coupling that Soundown built that fastens to the shaft, and we asked them to provide a surface on that coupling where we could put our silver slip rings on [to provide an electrical connection] to protect props and shafts.”

Every anode can deliver up to 5 amps of current using its own current controller that receives a signal from the main controller, which determines exactly how much current each anode will put out. The entire system consists of three anodes, three current controllers, the main controller, and a separate monitoring station connected to the controller by signal cable. Later, Schmitt also ordered a backup system employing aluminum sacrificial anodes.

On catamarans, the company installs a reference cell aft near the prop of each hull, and an anode on the aft section of each hull, and one anode amidships on the inboard side on one hull.

Chromate, two layers of epoxy, copious amounts of fairing compound, and various primers rendered the surface fair and ready for a yacht-quality paint job.

At the time of this writing, the vessel had been shot with chromate and two layers of epoxy before approximately 500 gal (1,893 l) of fairing compound and 325 gal (1,230 l) of various primers rendered the surface fair and ready for a yacht-quality Alexseal paint job with 35 gal (132.5 l) light ivory, 24 gal (91 gal) stark white, and 2 gal (7.6 l) cordovan gold. Parallel to the exterior, construction was on the home stretch with installation of the crew quarters and the saloon overhead. On the systems side, pressure checks were performed for hydraulics and plumbing.

Since H-2 is a much larger and more complex vessel than the original Hippocampus , with a multitude of systems that need to be managed, monitored, and maintained, I was curious how many crew Schmitt was planning to hire to help run his new boat. He said he consulted with captains and headhunters, and “the consensus is three or possibly four at most. I just completed my 100-Ton Masters and will build time on the new boat as well. We won’t charter and are not accustomed to being cooked for or served or having our beds made and all that. So mostly I’m looking for a qualified captain and engineer to maintain the systems.”

Little surprise that a hands-on operator like Schmitt does not want to cede too much of the game he loves to play. But as big, bold, and broad-shouldered as H-2 will be when she finally emerges from the old Gunboat shed in Wanchese, the proud owner is quick to remind anyone that it’s still “a vehicle to get the toys wherever.”

H-2 : The Designer’s View

H-2 ’s owner, the adventurous Brian Schmitt, has dived into deep caves to see submerged caverns, hand-fed large sharks that would normally view him as food, and spent years in his off-time exploring Caribbean archipelagos in Hippocampus, his current 19-year-old 57 ‘ (17.4m) power catamaran. Nearing retirement age, he gave the order for his “ultimate” yacht.

The foldable hydraulic deck crane to launch and retrieve a two-man electric submarine or an all-terrain vehicle required cutting a slot in the helicopter deck for the lifting bridle.

The first talk about the new design was between the owner, the builder, and me. As we discussed the mission of the boat, it became clear that it would fall into the category of expedition vessel with more guest staterooms, more range, and more room for equipment than his old boat. Brian defined the function of the vessel as a carrier for a 26 ‘ (7.92m) twin-outboard catamaran, an outboard skiff, a small car, and a small helicopter, which needed a flight deck. This vessel was to be used with family and guests while also serving as an operations base for outbound travel by air, land, or sea.

Aside from commodious accommodations, a key requirement was comfortable motion on rough seas. This was to be a catamaran, like his current boat, which offers extensive real estate afloat in a seagoing vessel. The only restriction for the new design was a beam no greater than 35 ‘ (10.6m) to fit the largest Travelift.

The trade-off for overall beam width involves room versus roll motion. A wider catamaran responds more quickly to roll in seaways but with less amplitude, whereas a narrower beam rolls more slowly with slightly more amplitude. The slower roll is preferable as long as overall roll stability is maintained. Roll in catamarans is unlike roll in single-hulled vessels. Because the vessel is supported by two buoyancy chambers (hulls) with distance between them, motion has little to do with roll inertia, but rather with response of the hulls to the seaway. Each hull responds to a passing wave independently by heaving (up/down) and rolling, which is a circular motion around the center of gravity (CG) that translates to lateral motion when standing above the CG, especially high up on the bridge. Power catamarans, unlike sailing catamarans, do not require wide hull spacing to generate righting moment (to support a sail plan), so they can have closer hull spacing, which still preserves sufficient stability, slows wave-response roll characteristics, and takes up less space in port.

One of the expected routes for this vessel is the Northwest Passage over the top of North America. Boats venturing there can expect floating ice, so we added thicker hull plating at the waterline and an ice-separation chamber on the cooling water intakes. We also designed the hull to give the propeller protection by positioning it behind a deep canoe-stern afterbody with no exposed shaft. A rudder horn, below the propeller extending aft from the hull, adds support for the rudder and protection for the prop. This configuration is useful as a hedge against the possibility of grounding. In fact, this boat can be careened on the beach between tides if necessary for repairs. The hull includes a strong, deep, vertical keel structure that allows for blocking anywhere along its length.

Speed and range became the largest determinates of the design. A maximum range of 4,000 miles at 15 knots (enough to cross the Atlantic Ocean) was proposed. Catamarans are easily driven at modest speeds due to lack of significant wave resistance by narrow hulls. A preliminary speed prediction analysis showed that we would be in the ballpark with about 1,400 hp (1,050 kW) and 5,000 gal (18,925 l) of diesel per hull. The final installed fuel capacity is 12,500 gal (47,313 l).

The general arrangement plan shows crew quarters in the hulls, three guest cabins, office, saloon, and galley on the main deck and owner’s suite on the bridge deck level.

A totally new design normally goes through a lengthy proposal and critique cycle between designer and client, especially if the client is knowledgeable and involved. The vessel’s first iteration started at 90 ‘ (27.43m) LOA, but it became evident that it needed more length to relieve a number of ills. After adding 10 ‘ (3.05m) we saw improvements, but it wasn’t until the 110 ‘ (33.5m) length proposal that we felt all the requirements had been satisfied: more slender hull shape, more open interior space, and better placement of machinery and tankage. The flight deck for the helicopter became larger, and the forward superstructure fairings gave the boat a sleeker look. And at 110 ‘ we achieved an efficient length versus waterline beam ratio that reduced wave drag and fuel consumption at the target cruise speed.

While beam remained at 35 ‘ , lightship displacement increased significantly to 230,000 lbs (104,190 kg). Accommodations now include crew quarters for four persons in the bows; three double guest cabins and a ship’s office forward; a large saloon amidships with adjacent galley, and a dive and a storage locker aft on the main deck. The upper deck is arranged with a full-width-bridge steering station forward, protected by a Portuguese bridge, and a master stateroom with en suite bathroom aft. The flight deck extends aft of the master stateroom. Access to the upper deck is by either a staircase from the foredeck, an interior staircase adjacent to the ship’s office, or by stairs from the starboard side deck.

The largest variable weight on the boat is fuel, so the tankage is located amidships to minimize its influence on trim. Engine and machinery rooms aft of the tankage take up the remaining spaces all the way to the transoms. Other amenities include a utility area aft of the crew quarters port side with storage and washing machines, and a walkway through the tank spaces and enginerooms to the boarding decks at each transom. Another late addition is the flying bridge to aid with shallow-water operation by improving the vantage point to see coral heads and other obstructions. Its protective bimini serves as a mounting platform for lights and antennae.

—John R. Marples

Read more Construction , Design , Drawing Board , Yards articles

- Van der Werff’s Curved Wood

A Dutch yard adopts composite panel molding technology to build boats from preshaped wooden hull sections.

- Departures: Carl Chamberlin

Passionate, competent, considerate, modest, and thoughtful is how designer and boatbuilder Carl Chamberlin is remembered by those who knew him. He died last November at age of 75 in Port… Read more »

- SAFE Boats Regains Small-Business Status with Employee Ownership

More than 20 years ago, Professional BoatBuilder ran a feature titled “God, Country and Fast Boats” (No. 85, page 64) about SAFE Boats International (SBI), a Bremerton, Washington–based manufacturer of aluminum boats…. Read more »

Recent Posts

- Find out how 3D printing can help your boatbuilding with MASSIVIT

- SNAME Powerboat Symposium Is Back

- Companies (85)

- Construction (106)

- Design (161)

- Drawing Board (10)

- Education (25)

- Environment (16)

- Events (21)

- Materials (50)

- Obituary (18)

- People/Profiles (49)

- Products (16)

- Propulsion Systems (32)

- Racing (16)

- Repair (37)

- Rovings (317)

- Short Cuts (3)

- Sponsored Partner News (14)

- Systems (80)

- Task Sheet (1)

- Uncategorized (26)

- Wood to Glass (7)

ProBoat.com Archives

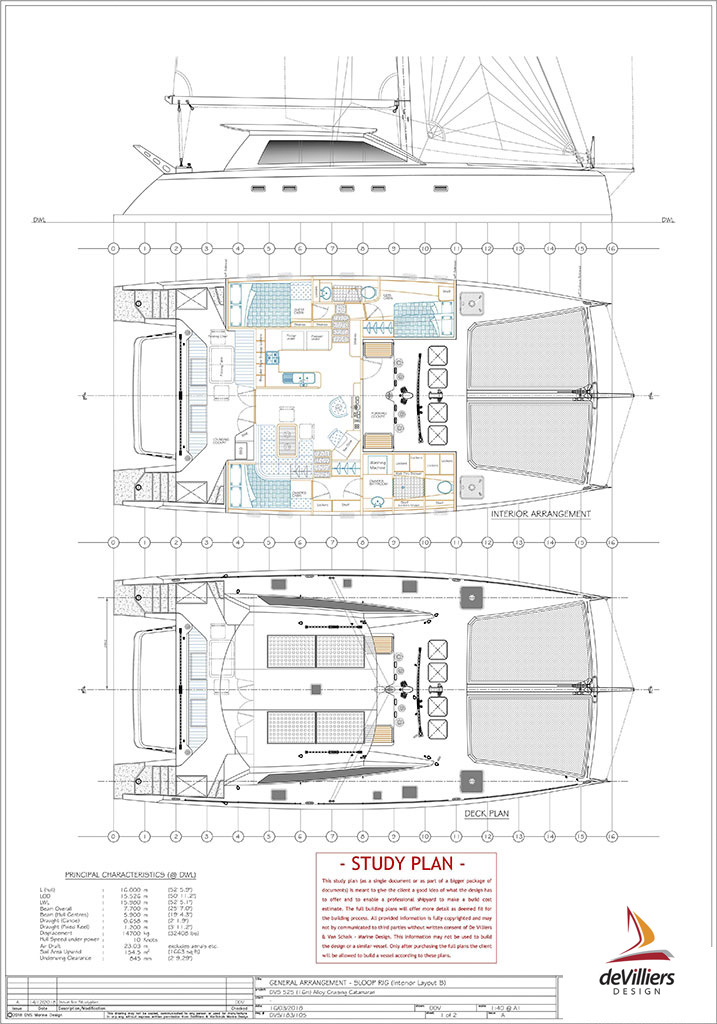

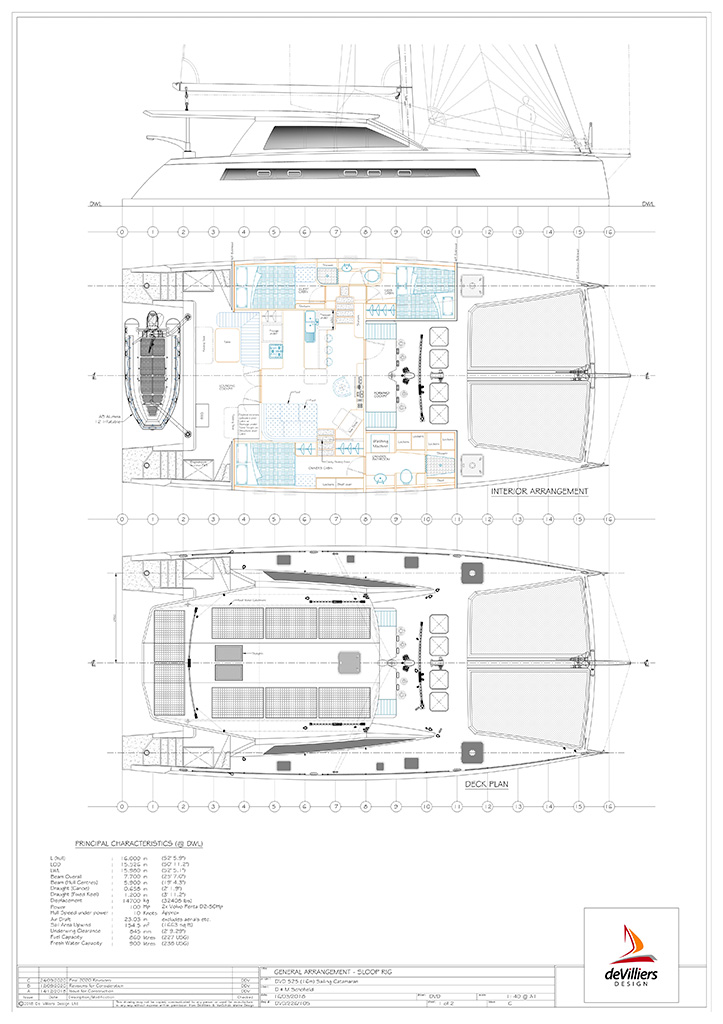

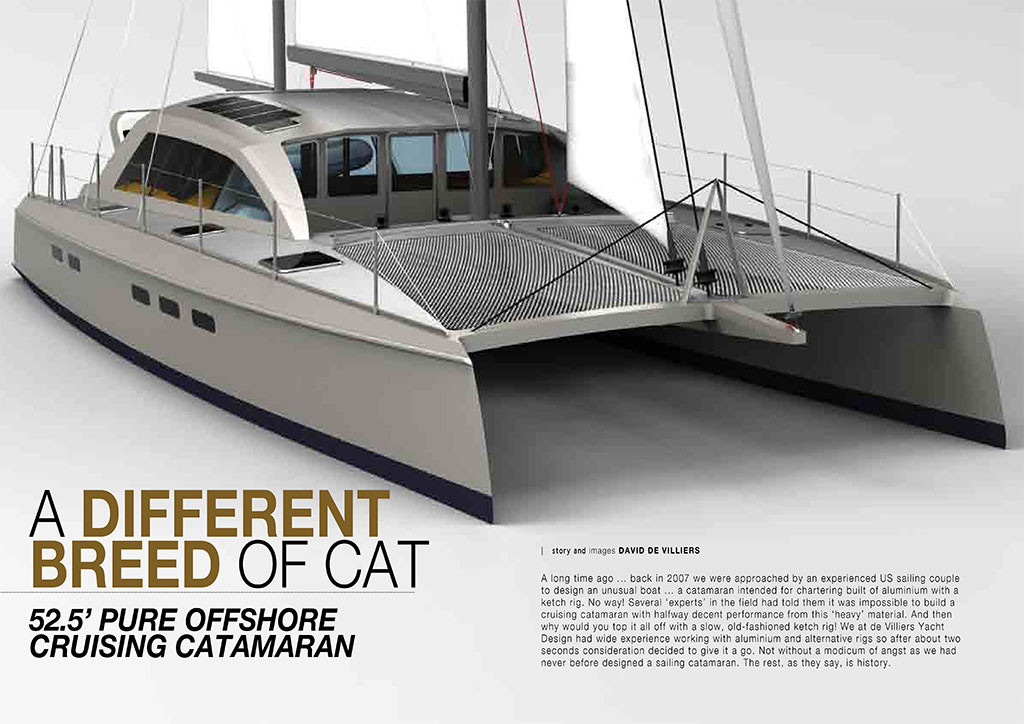

DVD 52 foot Aluminium Cruising Catamaran – Design #163 / #183 /#226

This is the smallest design in our range of Aluminium Sailing Catamarans. The philosophy and basic features of this design are firmly rooted in our earlier, successful 62ft Alloy Ketch Cat design which has covered over 100000 nautical miles as an expedition charter boat.

The 525 Cat is obviously smaller and more manageable than the 62ft older sister . We have developed 2 distinct versions of the design ie. a ketch rig as well as a sloop rig and lately there is a 3 rd iteration which is essentially the sloop version with a stretched deckhouse roof for an increased solar array plus other minor modifications.

Early concepts of this design reflected a more performance-oriented optimisation for the design. In developing the full construction plans we have chosen to accentuate capacities and features which will have more mainstream appeal to a broader spectrum of cruising sailors.

Make no mistake this design remains well above average in terms of sailing performance. Performance can be further enhanced by the sailor willing to compromise by not overloading the boat.

Having said all that what we have here is a durable, rugged alloy cruising boat with inherent safety features (6x watertight compartments, skeg protected rudders and props, exceptional underwing clearance, easily-managed ketch rig etc) which will appeal to anyone wanting to cruise far and wide.

Our plan packages are carefully detailed and together with the comprehensive build kit information (assembly drawings and nested CNC cutting files) most skilled yachtbuilders will have no trouble putting together your perfect cruising home.

We are available to discuss any of the questions you have. Please contact us for further information on this design.

DIMENSIONS & SPECIFICATIONS

Design #163

Design #183

Design #226

REQUEST INFORMATION AND PLANS

STUDY PLANS: – See Pricing and Stockplans BUILDING PLANS & KIT: – See Pricing and Stockplans

F I R S T I N C A T A M A R A N S

- 1-360-457-5752

- RecPro | Recreational

- PaxCat | Passenger

- LabCat | Survey

- Landing Craft

move beyond ordinary with brix marine

LIMITED AVAILABILITY – BOOKING 2025 DELIVERIES NOW

join the legacy

FEATURED BOAT

3814-ctc offshore, latest brix videos, safety. stability. speed., efficient. spacious. safe., stable. strong. ergonomic., 4wd of the sea, first in catamarans, discover our boats.

RECREATIONAL

Walk-around or full width cabin

Join the BRIX legacy with a recreational cat built to professional standards. Be it for fishing or cruising, each custom RecPro is distinctly tailored for adventure.

TOUR, FERRY, DIVE

Customize For Diving, Whale Watching Or Luxury

BRIX Marine’s PaxCats deliver reliability and comfort for the most memorable excursions. Choose the sweetest ride on the water for up to 49 passengers and beyond.

SURVEY, RESEARCH

Workboat’s Top-10 Significant Boats Of 2019

BRIX provides the most capable boats under 50′ in the marine science industry. Outfit with equipment such as a knuckle boom crane, an A-frame, or the versatile BRIX HYPR-Arm.

ABOUT BRIX MARINE

has earned a solid reputation for pioneering and crafting the world’s most rugged aluminum catamarans and workboats since 1991.

The company was founded in Canada and moved to Port Angeles, WA in 2001. We gained new ownership under Bryton Marine Group in 2017, which fortified the company’s focus on our Core Values and strategic plan for our future.

“Our team has developed strong momentum with our boat portfolios and customers. As we look to the future, BRIX Marine will honor the legacy we have built and move beyond to deliver exceptional custom boats,” said Perry Knudson, Managing Director.

BRIX literally means the scientific measure of sweetness in liquid. This translates well to the high-performance boats the company is known for. “BRIX is more than a sweet riding hull,” said Knudson. “Our custom projects begin with the first communication and the relationship continues after the boat is delivered. BRIX is committed to an owner-centric approach.”

BRIX Marine has another important target. “We want to be the best place to work in our community,” said Knudson. BRIX employs master level craftsmen in the disciplines required to build welded aluminum boats. The company invests in defining career paths and training employees to gain the skills needed to advance in their fields.

The BRIX team will broaden and diversify its portfolio of welded aluminum boats, known as being “first in cats.” The newly redefined custom recreational portfolio is in high demand, and BRIX Marine is bringing this same innovative approach to other key markets.

“Our luxury water taxi designs are raising the standards for passenger vessels as seen with the recent launch for Liberty National Golf Club. The research vessel Bob & Betty Beyster we delivered in 2019 earned a Workboat Magazine award as a Significant Boat of the Year. That design is reshaping our research vessel line-up,” commented Perry Knudson. “We have a lot of exciting things on the horizon. This new identity represents who we are and where we’re going.”

Your Vision. Our Expertise.

We believe solutions exist to unique vessel demands, and we provide solutions to our clients every day, giving them the best possible opportunity to succeed on the water.

Let’s build your boat.

Our Core Values

- Quality Craftsmanship

- Financial Responsibility

- Accountability

SOME OF OUR VALUED CLIENTS

- Aluminum Boat Plans

Aluminum Catamarans

SPECMAR Aluminum Catamaran Hulls are either symmetrical or asymmetrical in design. A symmetrical hull consists of two basic V-bottom hull structures. Asymmetrical hulls are basically a monohaul craft split down the middle and spread apart. A fOIL assisted cat has a lifting foil between the two hulls to increase performance. One of the advantages of our aluminum catamaran is high initial stability.

Prices shown on this website are for plans and for a one time use of CAD cutting files.

DIY Cruising Catamaran: Complete Building Guide

As an Amazon Associate, we earn from qualifying purchases. We may also earn commissions if you purchase products from other retailers after clicking on a link from our site.

A brand-new cruising catamaran can set you back a hefty amount of money. However, a DIY cruising catamaran provides a more affordable way to own your own boat. While building a large boat can be an extremely challenging and time-consuming experience, nothing beats the pleasure of bringing your own boat to life.

To build a DIY cruising catamaran, buy good design plans, determine your budget and find a working space. Next, choose your hull material, buy supplies and start building the mast beam. Build and sheathe the hull, install bulkheads, the interior, and finally, launch the catamaran boat.

In this article, you will find a complete guide to building your own catamaran. You will also find detailed information on why you may want to consider building your catamaran and approximately how much this project would cost. Finally, we will explore the advantages and disadvantages of building a catamaran from scratch.

Why You Might Want To Build Your Own Catamaran

Most people might think that purchasing a used boat to repair and fix it up would be cheaper than a DIY cruising catamaran. But while building your own catamaran could be an enormous undertaking, it also comes with many advantages over buying something used.

Other than the unique opportunity to create beautiful memories and experiences while cruising, sailing, and exploring beautiful coastlines, there are a number of benefits that come along with the DIY approach.

Knowing Your Boat

Building your own catamaran provides you with intimate knowledge of your boat. You will know every corner, including where to find every bolt, wire, bulkhead, rib, hose, and support as you installed them yourself. This knowledge will enhance your confidence while at sea since you will have entrusted your life to a boat whose history you are aware of and deeply connected to.

Pride of Ownership

The satisfaction you get from crafting something with your own hands is immense. As a result, the knowledge that you built your boat from scratch will fill you with absolute pride and an immense sense of achievement. Furthermore, as an owner-builder, you get to keep and enjoy the boat for as many years as you wish.

Substantial Cost Savings

Building your catamaran will work out cheaper than buying a new or even gently used boat. Though you will likely require some additional labor since doing some things will require an extra pair of hands, if you are particularly good at DIY, you will save a significant amount of money on labor costs as a whole.

Freedom To Create Your Own Designs

If you decide to buy a catamaran boat, it might not be easy to find one that meets your unique needs. However, instead of choosing from production boats that bear traditional and outdated designs, you can come up with an ultra-modern design or style for your catamaran. You also get to pick your layout, size, and equipment based on your taste and budget.

Great Learning Experience

Building your own boat will help you pick up numerous skills that will come in handy later when sailing your boat. As much as you might still require an expert to help you with specialized skills like carpentry or wiring, your new skills will serve you well. This will also be beneficial when it comes to your boat’s maintenance and fixing things for yourself.

What To Look For in Catamaran Boat Designs

When deciding on the type of catamaran boat to build, you may want to choose a design that’s simple and easy to build. This is because doing so will allow you to spend a shorter time building the boat.

You also need to have a set of requirements to guide you in choosing your design or what you might call an ideal cruising catamaran wish list. This is essential because, ultimately, you want to build a boat that offers outstanding qualities such as:

- Delivers good speed

- Affordable to own and operate

- Agile, strong, and easy to maintain

- Has a high resistance to capsizing

- Great for sailing and cruising

- Delivers a comfortable and easy motion underway

- Good handling ability and high performance under sail

- User-friendly embarking and disembarking

- Provides ample living and accommodation space

- Presents a reasonable resale value

It’s worth noting that, in general, catamaran boats tend to offer a fair resale value mainly because of scarcity and the high price accorded to production models. So, if you build a well-constructed catamaran, you are bound to get a return that’s much higher than the cost of materials upon resale.

It’s also good to consider whether the design you settle on is from an established designer. This is significant because documentation of the building process is just as valuable when it comes to selling the boat.

How Much Would It Cost To Build Your Own Catamaran?

The cost of building your cruising catamaran will depend heavily on the size of the boat you plan to build and the skills you bring to the table. To give you an idea of probable costs, a professionally built 40 foot (12.1 m) long cruising catamaran could go for up to $300,000.

Though building it yourself will undoubtedly be cheaper, most DIY boatbuilders tend to underestimate the expected costs. Your final costs should cover not only the cost of material and equipment but also the labor and time it would take to come up with the final product.

If you were to build a 40-foot (12.1-meter) catamaran, your cost of materials would range between 20-30% of the total cost. Therefore, for $300,000 total, the boat’s materials would range between $60,000 and $90,000. The hull tends to range between 15-35% of the total build. Again, this depends on the finish and furniture.

But before you even start working on the DIY project, you will need to figure out where to do the work. If your home has ample space, then you can opt for a backyard building. But if you live in a small apartment, then you might want to consider renting a small garage at first and then move on to a boatyard later. This is one of the significant costs involved in building your multi-haul.

What You Will Need

To get a clearer picture of how much the entire project would cost, let’s have a look at what else you will need to purchase.

- Good design plans

- Working space

- Ground tackle

- Matting and roving

- Equipment such as the engine, windows, rudders, deck fittings, mast, and rigging

In addition to the above, you also need to install plumbing and electricals. You may also want to consider going electric rather than using diesel. Not only will this drastically reduce your maintenance costs, but you get to use the regenerated power for all of your housing needs while sailing.

Some catamaran boat designs help you save costs by advocating the use of less expensive corpus materials. Most of the material goes directly into making the boat, which means there is hardly any wastage on vacuum bagging . With this method, there are few molds and temporal building forms and fewer fillers to grind off as waste. All these factors reduce the time and cost it takes to build your catamaran boat.

That said, building a boat of any kind is a huge financial undertaking. As such, you still need to have the financial ability to keep building; otherwise, your project will stall or take much longer than anticipated. Instead of enjoying yourself and making memories cruising to faraway lands, you might end up spending all your time building a seemingly never-ending boat.

To reiterate, this project is more of a labor of love, given that it involves a tremendous amount of manual work. Calculating an hourly rate on the time spent building the boat and adding this cost to that of materials may make it seem a very pricey exercise. However, it is vital to understand that your time matters, and every hour you spend working for “free” should be included.

With that in mind, you need to ensure that you are fully devoted to the boat construction project and are sure you want to do it before you begin. Stopping halfway because it seems like too much work would be incredibly costly.

How To Build a Catamaran

When it comes to building a cruising catamaran, you have 3 main options:

- You can buy an old boat and refurbish it.

- Purchase a bare hull plus deck molding for a home-boat building.

- Start from scratch and build everything, including the hull, on your own.

As mentioned above, renovating an existing boat may end up being more costly than starting from scratch. To build a catamaran boat from scratch, follow the below step-by-step guide.

Prepare the Essentials

Before you jump into such a large project, there are several important aspects to consider:

- Buy your plans from an established catamaran designer. You can also get inexpensive, easy-to-build catamaran designs online.

- Get access to a large working space or build a shed . Depending on your climate, you may need to opt for climate control to avoid an excess of moisture in humid areas.

- Decide on your choice of hull material. This could be fiberglass, aluminum, steel, wood, or ferroconcrete.

- Start working on a bill of materials estimate. Include everything that you think you need to get a better idea of the initial costs.

Build the Mast Beam

Using wood and epoxy, cut and glue together the pieces of wood that will form the mast beam. Most of the work at this stage can occur in a garage since it involves building small parts. Still, the work could take up to 4 months, so be prepared to put in long hours.

Build the Boat Hull

Now, it’s time to build the boat’s hull. A catamaran comprises two hulls which are connected with a deck. Below is a short video showing how to build a hull mold:

This work requires a larger facility, so you might need to move out of the garage and into a boatyard. If you don’t have access to a larger workshop, consider building a shed where you can work as you do the construction. Make sure there’s enough room to fit the boat and also allow you to work comfortably. To cover the shed, you can use opaque white tarps.

Sheathe the Hull

Get all the materials you require for this stage in the construction, such as lots of resin, fiberglass, and foam for use in the hull cores. You’ll also require matting and glass roving to sheath the hull .

Sheathing helps to make the hull impervious to water and other marine borers. But first, you need to prepare the hull using a rotary sander. To make it as smooth as possible, use light, sweeping strokes. This is a very dusty task so be prepared to wear a facemask and safety goggles.

Install the Bulkheads

Next is installing the plywood bulkheads . You might need to call in friends to help turn the hulls or use a crane. In this step, you will need to laminate the hull sides on the molded hull panels and bond them above the bulkheads. Ensure the bulkheads are snug and sealed in place.

Construct the Interior Structure

Over the next couple of months, the boat work will involve joining the hulls together with the beams that you had made back in the garage. Then, install the cuddy cabin, decks , and the cockpit . Soon the boat will start to take the shape of a catamaran.

Next, proceed to construct the major structural components such as stairs, hatches, mini-keels, and the interior. Then comes the work of fairing the boat, which is quite labor-intensive.

Finally, it’s time to apply primer on the catamaran boat and start the paintwork. Before painting the boat, you will need to do additional sanding to finish off the two layers of primer as well as fill all the pinholes. Since it’s a large boat, the catamaran has lots of surface area; thus, the sanding could get extremely exhausting—mentally and physically—at this point.

The painting can take a while, too. The hulls are the easiest to paint, but the topsides, non-skid, as well as masking and prepping could seem never-ending.

The final stretch involves working on the center bridge deck cabin and other final touches like installing the engines, electricals, and plumbing. This is also the time to fix the rudders, rigging, mast, windows, and deck fittings.

Launch Your Cruising Catamaran

After many months or years of hard work, your cruising catamaran is finally ready to test the waters. After lowering the boat into the water, check carefully in case there are leaks. If none, you can set up the sails and take your catamaran out for your first cruise.

Below is a short video that takes you through the entire boat-building process:

If you don’t have deep pockets, don’t despair. It’s also possible to build an inexpensive catamaran boat, as shown in this post from the coastal passage .

The Pros of Building a Catamaran

Though it will be a costly endeavor, there are so many things to look forward to should you decide to build your own catamaran:

- It can be lots of fun.

- You get to have a new boat.

- It’s an excellent hobby for DIY enthusiasts.

- The effort is rewarding.

- It offers a great learning experience.

- You get the exact kind of boat you want.

- You can alter building plans and tailor the boat to suit your specific needs.

- It might be cheaper than buying a new boat.

The Cons of Building a Catamaran

Though there are a number of positive aspects to a DIY build, it is just as important to keep in mind that it won’t always be easy:

- Maintenance costs can be quite high.

- It’s both mentally and physically exhausting.

- It might require some technical know-how.

- It can take many months or even years to complete.

- It requires a lot of commitment to finish the DIY project.

- It might be challenging as well as expensive to get insurance.

- You will spend almost all your free time building the boat.

DIY Cruising Catamaran Tips and Tricks

If you are new to boat building, it would be a good idea to build a small boat first. This would give you a good indication as to whether you’d enjoy tackling a more extensive project like building a catamaran. Again, if you are the handy type, fixing your own electronics could also save you a significant amount of money.

Here are more tips and tricks to get the most out of your DIY cruising catamaran:

- Lower your costs. Bring down your costs even further by sourcing for parts and supplies at marine surplus outlets, Craigslist, eBay, or wholesale suppliers.

- Enhance your resale value. Most home-built boats are not easy to sell since they tend to be too customized. To enhance your resale value, it’s advisable to work with a standard design from a well-established naval architect.

- Follow the design instructions. Make sure to follow the designer’s instructions regarding the type of materials and tools to use during the build to avoid making costly mistakes.

- Maintain your original budget. Avoid any additional customizations once you have started building the boat. Using good plans and sticking to them ensures that your budget doesn’t spiral out of control.

Final Thoughts

Building a catamaran is about more than saving money. It’s fun, exciting, fulfilling, and can be a great learning experience. While it might take many months of back-breaking work, comparative shopping and sourcing for materials will help you save a lot of money. Still, at the end of it all, you’ll have a beautiful catamaran boat, all ready for your first cruising adventure.

However, if you have neither the time nor the energy to build your own catamaran from scratch, refurbishing an existing hull might prove faster and easier. It also works out much cheaper than buying a new boat.

Owner of CatamaranFreedom.com. A minimalist that has lived in a caravan in Sweden, 35ft Monohull in the Bahamas, and right now in his self-built Van. He just started the next adventure, to circumnavigate the world on a Catamaran!

One thought on “ DIY Cruising Catamaran: Complete Building Guide ”

Hello, I am a French Quebecer who is original, imaginative, creative and who finds that all boats and catamarans have a huge flaw and a very big lack of logic. I would have a brand new concept…. I am sending this message to any catamaran creator – designer to make those who have the opportunity and the intelligence to want to know about my innovative idea which will finally upset the market much richer. An idea that will totally change the concept of sailing, navigation and save so much worry!! All I would ask for is a small percentage of each sale of the new product. To be able to make me produce one when I have enough!! It is certain that like that, you just want to tell me: come on Mr. Lessard give us your idea but do not take your word to help me in return! But, if you are the kind of man to have only one word and maybe have a proof of your good faith if the realization of the project would make it… I will be very happy!! Giving it to everyone wouldn’t bother me either…. all I would like is to be able to find flax fiber (too expensive carbon) to be able to try to make my catamaran myself. Because not rich! Have a nice day and looking forward to having a message!!

Leave a Reply Cancel reply

Your email address will not be published. Required fields are marked *

Save my name and email in this browser for the next time I comment.

Recent Posts

Must-Have Boat Gear for Catamaran Sailors!

Sailing is probably the most gear-intensive activity I've ever done; there are so many decisions to be made about what gear to buy now, for tomorrow, and what to definitely never buy. The gear on...

6 Best Trailerable Trimarans For Bluewater and Coastal Sailing

Having a boat costs a lot of money, even when you are not using it, marina fees, etc. And once it is in the water most sailors never go very far from their "home marina" and sailing will be somewhat...

Yachting World

- Digital Edition

First look: Ovnicat 48 aluminium multihull

- Rupert Holmes

- April 26, 2022

The inevitable combination of both the trend for aluminium yachts and towards multihulls, the Ovnicat 48 is a new go anywhere catamaran, Rupert Holmes reports

It’s easy to assume that all rugged metal yachts are very heavy. While that was the case at one time for steel designs, it’s a different matter for aluminium which, before carbon fibre became feasible, was frequently used for competitive racing yachts and from which the Ovnicat 48 is built.

This means it was almost inevitable that two of the biggest trends in cruising yacht design – expedition yachts and multihulls – would merge at some stage. The Garcia Explocat 52 , launched late in 2020, wasn’t the company’s first aluminium catamaran, but it brought the concept to a bigger audience.

At the same time Ovni, which has built 1,500 shoal draught aluminium monohulls over the past 50 years, was also developing a multihull concept with a 48 design. The first two have already been sold, with one scheduled to launch in 2024.

We don’t yet have many details, but it looks like an enticing design by Mortain and Mavrikios, with more of an emphasis towards warm water sailing and temperate climates than the other yachts in this selection.

Despite the boat’s rugged nature, laden displacement is lower than that of most cruising catamarans of similar size, giving the promise of brisk and enjoyable sailing without the worries of a more fragile fibreglass construction.

Ovnicat 48 specifications

LOA: 14.50m / 47ft 6in Beam: 7.75m / 25ft 6in Draught: 1.35m / 4ft 5in Base price: €1,200,000 ex VAT Builder: alubat.com

If you enjoyed this….

Yachting World is the world’s leading magazine for bluewater cruisers and offshore sailors. Every month we have inspirational adventures and practical features to help you realise your sailing dreams. Build your knowledge with a subscription delivered to your door. See our latest offers and save at least 30% off the cover price.

Built for a lifetime

Aluminum boats built with every detail engineered, designed, and executed with dedication. ACI Boats builds welded aluminum catamarans and monohulls for recreational and commercial use. Our boats are built to last a lifetime.

We are founded on generations of boat building experience. ACI Boats is owned and operated by Cory Armstrong, and backed by a team of skilled craftsmen and women. When choosing a boat builder, quality and trust is everything– ACI boats delivers with a safe, and comfortable vessel that you can rely on.

Pybus Point Lodge is proud to announce the official launching of two brand new, catamaran style, fishing and touring boats from ACI Boats. This is the second time we’ve had the pleasure of working with ACI and once again, they exceeded our expectations. Since we run a premium fishing and adventure lodge, we don’t just have to worry about our boats being safe and functional–we also have to make sure that our boats have the style and comfort that our guests expect.

ACI Boats is thrilled to announce the official award of a $3 million dollar contract with American Samoa’s Departmant of Commerce for four “Super Alia” commercial fishing vessels. All four boats will be manufactured at ACI Boats’ facility in Port Townsend, WA. The vessels themselves will be 38’x14’ semi-displacement catamarans, designed by ACI Boats and Coastwise Marine Design. The first of the four vessels, to be completed in Fall/Winter 2022, will be used as a training platform for boat owners, captains, and deckhands. The following three boats, will be completed over the course of 18 months and will then be available for lease by the American Samoa Dept. of Commerce, intended to support the growth and safety of the local fishing fleet.

ACI Boats launches it’s first CatLander in it’s line of CatLander landing crafts. Built for the Jamestown Sklallam tribe in Washington State, the CatLander7500 will be used as a spill response support vessel by the tribe.

ELEVATE YOUR EXPERIENCE

BEST OF BOTH WORLDS, HYBRID SOLUTIONS, FUEL SAVINGS

This equilibrium maintains speed when needed, ensuring secure passages, optimal operational economy, unwavering reliability, and zero-fuel serenity at anchor.

The ocean connection bestows tranquility, adventure, and sustenance, fostering personal well-being and a vibrant lifestyle.

CUSTOM CATAMARAN ALUMINIUM YACHTS

Discover the ultimate in custom catamaran aluminium yachts with Cosmopolitan Yachts. Our passion for excellence shines through in every detail, from the cutting-edge hybrid diesel/electric propulsion system to the meticulous construction using top-grade materials and state-of-the-art technologies.

At Cosmopolitan Yachts, we take pride in delivering superior build quality and attention to every detail, ensuring unmatched durability, performance, and luxury. Our custom catamaran aluminium yachts are designed to excel in any environment, with marine-grade aluminium construction that provides strength, sturdiness, and resistance to corrosion for sailing in any water conditions.

Whether you’re looking for a silent electric boat or speeds of over 26 knots, our custom catamaran aluminium yachts offer ultimate flexibility in power and fuel efficiency. And with advanced hull forms and superior bow height, you’ll enjoy comfortable sailing even in seas exceeding 1.75m.

Embark on a journey of a lifetime with a custom catamaran aluminium yacht from Cosmopolitan Yachts. Let us help you bring your dream yacht to life with our superior build quality, attention to detail, and passion for excellence. Contact us today to start creating the perfect yacht for your needs and make unforgettable memories on the water.

HYBRID-ELECTRIC, HYDROGEN AND FUTURE BIOFUEL AND BIOGASES

At Cosmopolitan Yachts, we’re committed to creating custom catamaran yachts with the latest in propulsion technology. Our hybrid diesel/electric propulsion system offers ultimate flexibility in power and fuel efficiency,but we don’t stop there. We’re also exploring the use of hydrogen and biofuels as a more sustainable alternative for yacht propulsion and all our yachts are classified as “Hydrogen-Ready”. Hydrogen yachts or the use of biofuels and biogas could be the future of yachting, offering an even cleaner and more sustainable, self-sufficient energy source for powering your yacht.

Our dedication to sustainability and innovation means that we’re always looking for ways to reduce our impact on the environment while still delivering unparalleled performance and luxury. With the combined integration of the most advanced electric and hybrid technologies and, with the use of the next generation of fuels such as hydrogen, solar, biogas or biofuels,we can offer the perfect propulsion system to meet todays.

DISCOVER OUR YACHTS

New journeys await.

Discover the ultimate in durability and performance with our catamaran yacht range, designed to excel in any environment. with a robust aluminium construction and hydrid diesel/electrical propulsion system to make the most of the best technological advancements without any compromises.

THE WAY FORWARD

Equipped with either a conventional diesel or a hybrid diesel/electric propulsion system installed in both hulls, each with dual power inputs. This grants Cosmopolitan Yachts the ability to operate silently and emission-free as an electric boat at lower speeds, while still achieving speeds of over 26 knots. Complete redundancy and future proof.

A MAJOR IMPROVEMENT

To create the ultimate catamaran yacht, we have meticulously crafted every aspect with a keen eye for detail, to provide unparalleled performance and luxury. Our yachts are constructed using top-grade materials and state-of-the-art technologies, ensuring durability, comfort, and efficiency.

SUPERIORLY BUILT

The use of high-quality marine aluminium in our yachts not only provides strength and sturdiness but also ensures resistance to corrosion, making it perfect for sailing in various water conditions.

EXCEPTIONALLY DESIGNED WHIT A MAJOR IMPROVEMENT

We believe that every yacht should be a masterpiece, crafted with passion and dedication. Our commitment to quality and attention to detail is reflected in every yacht we build.

UNMATCHED COMFORT

The most spacious interiors, complete with luxurious to create an unforgettable sailing experience. The modern exterior design pays meticulous attention to every detail, including the placement of windows and other features that provide maximum comfort and offer breathtaking views of the surrounding water.

The yacht’s advanced hull form and superior bow height work in tandem to ensure comfortable sailing, even in seas exceeding 1.75m.

- News & Events

Handcrafted. Custom. Catamarans.

Island Hopper

NEW MODEL - The perfect family boat is here. Doesn’t matter if you like pulling up to sandbar parties, cruising around a lake, or nosing up on an island, the Island Hopper will provide everyone with a fun time on the water.

NEW MODEL - This shallow draft Bay Boat will get you everywhere you want to go. With an in-class leading amount of deck space, there is more than enough room to carry duck decoys, beach bags, and comfortably enjoy the water with your whole crew.

22SF Catamaran

A popular model throughout the Southeast, these smooth-riding catamarans are equally capable of taking the family for a joy ride or cutting through some chop in the ICW.

25SF Catamaran

Available with single or twin motors, the 25SF can make getting offshore a breeze. A spacious boat that is easy to maneuver and capable of going anywhere on the water.

29SF Catamaran

This catamaran can be customized for any boater. If you prefer a sunset cruise in the river, or you want to spend all day bringing in Wahoo, this cat can be customized for whatever you desire.

32SF Catamaran

Used by fishermen and fire departments in the Southeast, our 32’ catamaran gives you plenty of space for all your charter guests.

35SF Catamaran

Our largest boat gives you the size and range for any type of fishing, anywhere you want to go. Customize this with an upper station and a huge coffin box.

Aluminum Hulls

At twice the strength of fiberglass, our lifetime guaranteed aluminum hulls will provide you with a supremely maneuverable boat that can travel faster and with less draft, all while providing a safe boating experience.

Catamaran Design

Catamaran hulls provide a softer, more stable ride with exceptional efficiency all while providing optimal deck space due to wider beams. The lower center of gravity will give you a ride with the least impact.

2 Decades of Experience

A track record of over two decades of building custom aluminum boats ensures that you will be getting the boat you deserve. Boats built by artisans dedicated to delivering the perfect vessel for you.

Built by Artisans

The Cape Fear Cats team of artisans is invested in seeing your boat all the way through from design to delivery. Our in-house welders, fabricators, riggers, and painters are able to build your boat 100% on site.

We craft all of our 100% aluminum boats to your specific design. Our commercial strength hulls will provide you a top of the line boating and fishing experience.

Adventure to feel free

The future of sailing

Comfort & Luxury

Eyecat offers everything that a true sailor's heart needs! But it also has all the luxury and comfort for friends and family. So together you can sail over the horizon in style.Why settle for a five star-hotel if you can sleep under a thousand star sky on the open ocean. Imagine waking up on your own boat and fully enjoying a 360 degrees view and fully enjoying all the luxuries you can imagine. With our Sailing Island package you'll have a spacious cabin that can be customised to all your wishes and needs.

Performance

The Eyecat is a catamaran built in aluminium, a material that is the future of boat building. The light weight and strength of aluminium will last longer and is strong enough for off-the-beaten path sailing, giving you a sailing experience as closed to a performance monohull as you can get. We've taken into consideration the environmental challenges of our planet and made the eyecat as future proof as possible without compromising on quality, materials and performance. With two electric motors, an aluminium hull, solar panels and a water maker you can sail with peace of mind on the free energy of the wind.

Adventure & Fun

Most important thing on the water is: enjoying the ultimate feeling of freedom! With your friends and family, surrounded by nature, breaking all the limits.

“After 40 years of sailing in a monohull, I wanted a boat with the same sailing performance, but with more comfort and at the same time a smaller footprint. Eyecat 55 is the result: exploring the world in luxury and in a sustainable way!”

We are Eyecat

Latest news

Video update: transport to the harbor

Call us on +31 (0)6 36543848 , or write your name and email address below and we'll be in touch with you

Explorer Catamarans

Custom design and construction of sturdy sailing and motor catamarans from certified aluminium. Homogeneous, torsionally rigid and extremely strong structure, without annoying creaking noises. Good sailing characteristics for worldwide ocean cruises. 55 - 78 ft., made in Holland.

Sailing Yachts

Motor Yachts

WEST COAST TOUGH

Aluminum catamarans.

JR Marine builds top-of-the-line welded aluminum catamarans. We build vessels for every imaginable purpose including sport fishing, commercial fishing, commercial transport and research vessels.

BOAT MODELS

16′ monohull, 20′ monohull, 26′ catamaran, 30′ catamaran, 36′ catamaran, jr marine – the metal manipulators.

AT JR MARINE, we love a challenge. Primarily fabricators of aluminium catamarans, monohull and structural boat accessories, we are also experienced in the production of a wide range of custom aluminium products.

JR Marine is considered one of the best aluminum catamaran boat builders due to our focus on innovation, design, and performance. We use advanced materials and manufacturing techniques to create catamarans that are lightweight, strong, and efficient. Our company places a strong emphasis on customer satisfaction, ensuring that each boat is designed to meet the specific needs of the customer. With a commitment to excellence, JR Marine’s boats are known for their superior ride, handling, and reliability.

TRIED, TESTED & TRUSTED

Excellence on the water.

Our vessels are trusted by fisherman, charters and recreational boaters. Boats by JR Marine will give any operator confidence on the water.

West Coast Tough

We build aluminum catamarans that can handle the rugged conditions of any marine situation.

DESIGNED & BUILT TO LAST

Our designs are engineered to carry more payload with greater fuel efficiency, while maintaining maximum stability.

We love a challenge

We specialize in customized aluminium catamarans, monohull and structural boat accessories.

SUPERIOR HULL DESIGN

Why catamarans.

Catamaran hull designs are superior because they provide stability, speed, and comfort. They have a wider beam, reducing roll and providing a more stable platform. The two hulls also increase surface area, reducing drag and resulting in higher speeds. Finally, the separation of the hulls provides more interior space, leading to greater comfort for passengers.

250-857-2782

© Copyright 2023 - 2024 | JR Marine Website by DOC Media | All Rights Reserved |