Your Vision. Your Burger.

Creating a custom-built yacht is a journey unlike any other. Conceiving your yacht alongside Burger’s engineers and design team is a remarkable experience: developing the specifics, reviewing the plans and making decisions as you watch your dreams materialize before your eyes. Burger welcomes all clients to enjoy the progression of their journey while your custom creation evolves.

The first step in delivering the yacht of your dreams is to share your vision with the Burger design team and engineering staff. Our in-depth design brief helps define your priorities for a yacht. We recommend touring the Burger shipyard where you can meet our exceptional team, learn how your yacht will be constructed and to witness the true value of Burger’s experience and craftsmanship.

After defining your vision, your dreams will begin to take shape in dramatic conceptual designs, renderings and cost estimates, presented for your direction and approval before moving forward.

Conceptual designs and renderings include:

- Hull designs

- Exterior styling and interior floor plans

- Interior elevation renderings

- Engines, propulsion and electric generation equipment selection

- Special requirements, including recreational and/or shore tenders and storage options

- Navigation electronics and entertainment system descriptions

Once you’ve approved the design, Burger will prepare a detailed design and specification breakdown with descriptions of every step in your yacht’s construction; from its development milestones to key points of approval. With a finalized and signed contract, your yacht is on the way to fruition. Each step of the build is documented before work begins, with a detailed timeline that describes each step of the process, so that you remain involved and aware of our progress, every step of the way.

Months of careful planning and construction culminate when it’s time to launch your new Burger yacht. Along with the Burger team, you and/or your captain take your new Burger yacht through various sea trials, including at-sea observations and detailed walk-through inspections. At this stage, final modifications and refinements are made.

Congratulations; owning a Burger built for you also means you’ve joined the most exclusive fleet of yachts in the world. Our craftsmen share your pride in seeing your new yacht launched, and value each customer relationship that endures long after delivery. Bringing your dreams to reality is what makes every Burger yacht unique and extraordinary.

With your Burger set out into open waters, a new journey begins.

Custom Yachts

View Burger's full fleet of custom yachts, uniquely crafted to each owner's vision of limitless luxury.

Design Concepts

Explore Burger's newest design concepts and yachts under construction — and bring your ideas to their design.

The Ultimate Guide: How to Make a Sailboat – A Step-by-Step Tutorial

Alex Morgan

Making a sailboat can be an exciting and rewarding project for those who love the thrill of the open water. Whether you’re an experienced sailor or a beginner, building your own sailboat allows you to customize the design and create a vessel that suits your needs. This guide will take you through the step-by-step process of making a sailboat, from gathering materials and tools to launching and testing the final product.

Introduction to Making a Sailboat

Building a sailboat is a complex and intricate endeavor that requires careful planning, attention to detail, and a love for craftsmanship. In this article, we will explore the various steps involved in making a sailboat, including gathering materials and tools, designing and planning the sailboat, constructing the hull, building and rigging the sail, adding finishing touches, and finally, launching and testing the sailboat.

Gathering Materials and Tools

Before diving into the construction process, it is essential to gather all the necessary materials and tools. We will discuss the essential materials required for building a sailboat, such as wood, fiberglass, epoxy resin, and fasteners. we will explore the various tools needed, including saws, drills, clamps, and measuring instruments. Having the right materials and tools is crucial for a successful sailboat-building project.

Designing and Planning the Sailboat

When it comes to designing a sailboat, there are several factors to consider. We will delve into these considerations, including the type of sailboat, its intended use, and the desired performance characteristics. We will discuss how to create a blueprint or design plan that outlines the specific dimensions, layout, and structural details of the sailboat.

Constructing the Hull

The hull is the foundation of any sailboat, providing buoyancy and stability on the water. We will explore the process of building the framework of the hull, including shaping and assembling the different components. we will discuss the techniques used for planking the hull, such as carvel planking or cold-molded construction.

Building and Rigging the Sail

The sail is a vital component of a sailboat, harnessing the power of the wind to propel the vessel forward. We will discuss the materials required for constructing the sail, including fabric, battens, and hardware. we will cover the steps involved in assembling and attaching the sail to the sailboat, ensuring proper rigging for optimal performance.

Finishing Touches and Final Steps

To add the finishing touch to your sailboat, there are several details to consider. We will explore how to add decorative elements and functional accessories to enhance the overall appearance and functionality of the vessel. we will discuss the steps involved in painting and varnishing the sailboat, protecting it from the elements and giving it a polished finish.

Launching and Testing the Sailboat

After months of hard work and dedication, it’s time to launch your sailboat and test its performance on the water. We will guide you through the necessary preparations before the first launch, including ensuring the boat is properly balanced and rigged. we will discuss the safety precautions to follow when testing the sailboat, ensuring a smooth and enjoyable sailing experience.

By following this comprehensive guide, you will gain the knowledge and confidence to embark on your sailboat-building journey. So, let’s set sail on this exciting adventure of creating your very own sailboat.

Key takeaway:

- Making a sailboat maximizes creativity: Building your own sailboat allows you to express your creativity and create a unique vessel tailored to your preferences.

- Gathering essential materials is crucial: To build a sailboat, you need materials such as wood, epoxy, fiberglass, and marine plywood, which are vital for constructing a sturdy and seaworthy vessel.

- Proper planning ensures a successful build: Designing and planning a sailboat involves considering factors like stability, weight distribution, and sail area to ensure the boat performs well in various conditions.

Gathering materials and tools is crucial when it comes to making a sailboat. Follow these steps:

1. Begin by researching the type and size of sailboat you wish to build. Gather information on the required materials and tools.

2. Create a comprehensive list of all the necessary materials including marine-grade plywood, fiberglass, epoxy resin, screws, and hardware.

3. Make a separate list of all the tools that you will need such as a circular saw, jigsaw, drill, sander, clamps, and measuring tape.

4. Take the time to find reliable suppliers for the materials. Compare prices and quality to find the best options available.

5. Once you have identified the suppliers , go ahead and place orders for all the materials you need. Make sure to order sufficient quantities.

6. If you don’t already have the required tools in your workshop, consider purchasing or borrowing them from someone reliable.

7. It is important to set up a dedicated workspace that provides enough room for you to work comfortably and store both materials and tools.

8. Ensure that your workspace is clean and well-organized. Pay special attention to proper lighting and ventilation.

9. As soon as you receive the materials , inspect them thoroughly for any signs of damage or defects. If you find any issues, contact the supplier immediately.

By following these steps, you will be able to successfully gather all the necessary materials and tools to begin building your sailboat.

What are the Essential Materials for Building a Sailboat?

What are the essential materials for building a sailboat? The necessary materials for constructing a sailboat include high-quality marine-grade plywood for the hull and deck. To reinforce the structure, fiberglass cloth and epoxy resin are employed. As for the assembly, stainless steel hardware is utilized, along with various types of sailcloth for the sails. The rigging is composed of stainless steel mast, boom, and rigging wires . To protect the wooden surfaces, marine-grade paint and varnish are applied. Joint sealing is achieved by utilizing adhesive, sealant, and caulking . Finishing touches are made with bungs, plugs, and filler materials . By using these materials in conjunction with the appropriate tools, one can build a sailboat that is robust and dependable for countless enjoyable hours on the water.

What Tools are Needed for Building a Sailboat?

To successfully build a sailboat, you will require a number of essential tools. Below is a comprehensive list of the necessary tools needed for the construction process:

1. Measuring tools: To accurately measure and mark the boat’s dimensions, you will need a tape measure , ruler , and protractor .

2. Saws: In order to cut materials, both a hand saw and a power saw, such as a jigsaw or circular saw , are indispensable.

3. Drill: A drill with various sizes of drill bits is crucial for creating holes in the boat’s structure and attaching components.

4. Screwdriver: To tighten screws and fasten hardware, you will need both flathead and Phillips head screwdrivers.

5. Clamps: Clamps are necessary to hold components together while they are being glued or screwed.

6. Sanding tools: To achieve smooth surfaces and eliminate imperfections, you will require sandpaper and sanding blocks .

7. Chisels: Chisels are essential for shaping and carving wood for intricate details or joints.

8. Planer: A planer is necessary to level surfaces and reduce the thickness of wooden components.

9. Painting tools: Brushes and rollers are indispensable for the application of paint or varnish, which serves to protect and enhance the sailboat’s appearance.

10. Safety equipment: Make sure to have safety goggles , gloves , and a dust mask to ensure your protection while working.

By utilizing these tools effectively, you will be able to successfully and safely complete your sailboat building project.

When designing and planning the sailboat, it is important to follow these steps:

1. Research different sailboat designs and hull types to gather information and ideas.

2. Determine the size and dimensions of your sailboat based on your needs and the resources available to you.

3. Create a detailed blueprint or design that includes important aspects such as hull shape, rigging, and deck layout.

4. Select materials for the construction of your sailboat based on factors like durability, weight, and cost.

5. Ensure the inclusion of safety features and necessary equipment, such as navigation instruments and life jackets.

6. Calculate the sail area and carefully choose the appropriate sails for optimal performance.

7. Evaluate the stability and balance of the sailboat to ensure safe sailing.

8. It is always helpful to consult experts for advice and guidance throughout the designing and planning process.

To guarantee success, it is crucial to consider your needs, seek expert opinions, and give utmost importance to thorough research, attention to detail, and careful planning.

What Factors to Consider when Designing a Sailboat?

When designing a sailboat, there are several factors to consider for a successful and efficient vessel. These factors include the intended use, hull design, sail plan, structural integrity, and ergonomics and comfort.

Firstly , the intended use of the sailboat must be determined. This involves deciding whether the sailboat will be used for racing, cruising, or both. The intended use will determine the size, shape, and necessary features for optimal performance.

Next , the hull design plays a crucial role in sailing performance. Factors such as stability, speed, and maneuverability should be considered when choosing a design.

The sail plan is another important aspect to take into account. The type and configuration of the sails will depend on the boat size, intended use, and sailing conditions. Factors like ease of handling, sail material, and the number and size of sails should be considered.

Structural integrity is essential for safety and longevity. It is important to consider the materials and construction techniques that can withstand water and wind forces.

Lastly , the sailboat should be designed with ergonomics and comfort in mind. This involves considering factors such as seating arrangements, control access, and storage space.

To ensure the best sailboat design, it is advisable to consult naval architects or experienced sailors for expert advice and guidance. Their knowledge and expertise will help in creating a well-designed and functional vessel.

When designing a sailboat, it is important to consider these factors to ensure a successful and efficient vessel that meets the specific needs of the owner.

How to Create a Blueprint or Design Plan?

When creating a sailboat blueprint or design plan, follow these steps on how to create a blueprint or design plan:

- Research sailboat designs based on sailing conditions and intended use.

- Measure and calculate sailboat dimensions, including length, width, and height.

- Create a detailed sketch, indicating parts like the hull, mast, keel, and rigging.

- Specify durable, lightweight, and cost-effective materials for each part.

- Develop a comprehensive list of materials and resources required, including quantities and specifications.

- Add precise measurements and dimensions to ensure accuracy and alignment.

- Annotate the blueprint with construction notes and instructions, including specific techniques.

To create an effective blueprint or design plan, consult experienced boat designers or naval architects for structural integrity and functionality. Utilize software or online tools for enhanced precision and efficiency. Careful planning and considering all aspects of the sailboat’s design will lead to a successful construction process.

To successfully construct a sailboat hull, it is important to follow these steps:

1. Begin by designing the hull, taking into consideration factors such as size, shape, and the materials that will be used.

2. Gather all the necessary materials for the construction process, including fiberglass, wood, or aluminum, depending on your preference.

3. Prepare the mold if fiberglass is the chosen material. Create a mold that matches the desired shape and apply a release agent to ensure easy removal.

4. Once the mold is prepared, start applying layers of fiberglass sheets and resin smoothly, making sure to avoid any air bubbles.

5. After the fiberglass has cured, carefully remove the hull from the mold and use sandpaper to smooth out any rough edges or imperfections.

6. To strengthen the hull, consider adding reinforcements such as bulkheads or ribs to provide structural support.

7. Install any necessary fittings according to the design, including cleats, ports, and drains.

8. For added protection and to enhance the appearance, apply a suitable coating or paint to the hull.

9. Prior to completing the construction process, it is important to thoroughly inspect the hull for any defects or leaks. Test the sailboat in water to ensure its proper performance.

To ensure a successful sailboat hull construction, it is crucial to plan properly, paying attention to detail, and following safety standards. If needed, consult professional boat builders or utilize resources that offer specific guidance tailored to your project. Happy sailboat construction!

How to Build the Framework of the Hull?

To learn how to build the framework of the hull, follow these step-by-step instructions. First, measure and mark your desired hull length on the building board. Next, cut long, straight pieces of lumber that match the hull length. Place these pieces parallel on the building board, making sure there is equal spacing. Secure the lumber to the building board using clamps or screws. Then, measure and mark the desired hull width on the lumber pieces. Cut shorter pieces of lumber that match the hull width. Attach these shorter pieces perpendicular to the longer ones, using screws or nails. Add any additional shorter pieces needed to complete the framework, ensuring even spacing. It’s important to check the framework for accuracy and make any necessary adjustments. Secure all connections with extra screws or nails for added stability.

Building the framework of the hull is a crucial step in sailboat construction. It provides the necessary structure and shape for stability and functionality in the water. By following proper measurements and securely fastening the lumber together, builders create a strong foundation for the rest of the sailboat. The framework acts as the backbone of the sailboat, allowing it to withstand wind and waves while providing structural support for other components. A sturdy framework ensures a well-built and seaworthy sailboat, enhancing the thrill of sailing.

What Techniques to Use for Planking the Hull?

To plank a sailboat’s hull , it is important to use the following techniques:

– First , prepare the planks by cutting them to the desired dimensions. Make sure they are smooth and free of defects.

– One effective technique is steam bending . Heat the planks in a steam box until they become pliable, and then shape them to fit the curvature of the hull.

– Next , fasten the planks securely to the hull’s framework using screws or nails. Ensure proper spacing and secure penetration.

– To prevent water from entering the hull through the seams, it is crucial to seal them. Apply a waterproof sealant like epoxy or polyurethane.

– After the sealant dries, sand the planks for improved appearance and performance.

Pro Tip: When planking the hull, take precise measurements and cut the planks carefully to achieve a tight fit. Properly securing and sealing the planks will result in a strong and watertight hull for your sailboat.

Building and rigging the sail is a crucial skill in sailing. Throughout history, civilizations like the Egyptians and Phoenicians utilized unconventional materials such as papyrus and animal hides to construct sails. In modern times, sailmaking has advanced using innovative techniques and high-quality materials. Today, the process of building and rigging sails involves precise measurements, intricate designs, and the utilization of high-performance materials. Sailmakers play a critical role in providing sailors with sails that are both durable and efficient, enabling them to harness the power of the wind and navigate through open waters.

To successfully build and rig a sail , follow these steps:

1. Choose the appropriate sail material: Begin by deciding on the type of material you wish to use for your sail, such as Dacron , nylon , or laminate .

2. Measure and cut the sail panels: Use a sharp fabric cutting tool to accurately measure and delineate the dimensions of the sail panels on the chosen material. Then, cut along the marked lines.

3. Assemble the panels: Arrange the sail panels in the desired order and position. Employ a sewing machine to securely stitch the panels together, ensuring that you follow the specified seam allowance.

4. Add reinforcements: Affix reinforcements, like corner patches and reefing points, to the relevant areas of the sail. These reinforcements enhance the sail’s strength and durability.

5. Install the sail hardware: Attach the necessary hardware, such as grommets, luff tape, and battens, to the sail. These components facilitate rigging and effective control of the sail.

6. Rig the sail to the mast and boom: Connect the sail to the sailboat’s mast and boom using suitable connectors, such as hanks or slides, securing the sail firmly in place.

7. Tune the sail: Adjust the sail’s tension by tightening or loosening the halyard and other control lines. This ensures optimal performance and shape during sailing.

What Materials are Required for Constructing the Sail?

To construct a sail for a sailboat, you will need several materials. First, you will need a durable and lightweight sailcloth made from materials such as Dacron or Nylon . This will provide strength and resistance to tearing. Next, you will need high-quality UV-resistant thread to sew the sail together, ensuring it can withstand the elements and maintain its integrity.

To strengthen areas of the sail that experience higher stress, such as corners and reef points, you will need adhesive-backed polyester tapes or webbing. These reinforcements will help keep the sail in good condition during use. You will need grommets or eyelets to create attachment points on the sail for halyards, sheets, and other lines. These can either be made of metal or plastic fittings.

It is important to insert battens into pockets on the sail to provide shape and stability. These thin and flexible strips can be made of fiberglass, carbon fiber, or wood, depending on your preferences. You will need hardware such as shackles, blocks, and cleats to attach and adjust the sail on the sailboat.

When constructing your sail, make sure to choose materials that are suitable for the size and type of sailboat you have, as well as the intended use of the sail. The materials should be durable, resistant to UV damage, and able to withstand the forces and conditions encountered while sailing.

How to Assemble and Attach the Sail to the Sailboat?

To learn how to assemble and attach the sail to the sailboat, follow these steps:

1. Prepare the sail and sail track: Lay out the sail, check for damage/debris, and ensure the sail track on the mast and boom is clear and in good condition.

2. Attach the halyard: Connect the halyard to the head of the sail and hoist it up the mast securely.

3. Attach the luff and tack: Slide the luff (front edge) of the sail into the sail track on the mast. Attach the tack (bottom front corner) of the sail to the fitting on the boat’s bow.

4. Attach the leech and clew: Slide the leech (back edge) of the sail into the sail track on the boom. Attach the clew (bottom back corner) of the sail to the fitting on the boom.

5. Tension the sail: Thoroughly tighten the halyard to remove any wrinkles or flapping in the sail. Ensure the sail is evenly tensioned along its edges.

6. Secure the sheets: Attach the sheets (lines that control the angle of the sail) to the clew and route them back to the cockpit, ensuring they are free from obstructions.

7. Test the sail: Adjust the sheets and the angle of the sail for optimal performance. Ensure the sail is properly trimmed and responding to the wind.

By following these steps, you can successfully assemble and attach the sail to your sailboat. Remember to always prioritize safety and seek guidance from experienced sailors if needed.

When applying the finishing touches to a sailboat, there are important final steps to consider:

1. Apply a final coat of paint or varnish to protect the wood and enhance appearance.

2. Securely install the rudder and tiller for smooth steering.

3. Tighten the attachment of the mast and rigging for optimal sailing performance.

4. Properly install the boom and attach the main sail .

5. Efficiently attach the jib sail to the forestay to capture the wind effectively.

6. Rig the halyards and sheets for easy sail control.

7. Securely mount any additional equipment.

8. Double-check all connections, fastenings, and fittings.

9. Thoroughly inspect the sailboat for any defects or issues.

10. Launch the sailboat and enjoy your completed creation.

How to Add Finishing Details to the Sailboat?

When it comes to adding finishing details to a sailboat, many people wonder how to do it correctly. Fortunately, I can guide you through the process step-by-step. By following these instructions, you will be able to achieve a polished final product that is both beautiful and functional.

Step 1: Sand

To start, you need to sand the entire surface of the sailboat. This will create a smooth texture and prepare it for the varnish or paint that you will be applying later.

Step 2: Clean

After sanding, it is important to clean the surface to remove any dust or debris. You can use a damp cloth for this task. Make sure the surface is completely clean and dry before proceeding.

Step 3: Prime

To protect the sailboat against water damage and create a smooth base, apply marine-grade primer. This step is crucial for the longevity of the finishing details. Allow the primer to dry completely before moving on to the next step.

Step 4: Varnish or Paint

Now comes the fun part – applying the varnish or paint. For a natural wood look, use multiple coats of marine-grade varnish. If you prefer some color and design, opt for marine-grade paint instead. Make sure to apply each coat evenly and allow enough time for drying between coats.

Step 5: Add Hardware

Once the varnish or paint has dried, it’s time to install any necessary hardware on the sailboat. This includes items such as cleats, handles, or hinges. Ensure that they are securely attached and in the correct positions.

Step 6: Detail

To enhance the aesthetic appeal of the sailboat, consider adding some decorative elements. Pinstripes, decals, or other decorative touches can really make a difference. Get creative with this step and add your personal touch to the sailboat.

Step 7: Inspect

Before you launch the sailboat, take the time to thoroughly inspect all the finishing details. Check for security and quality. If any adjustments or touch-ups are needed, make sure to address them before hitting the water.

By following these steps, you will be able to successfully add the finishing details to your sailboat. The end result will be a beautiful and functional watercraft that you can be proud of.

What Steps are Involved in Painting and Varnishing the Sailboat?

The steps involved in painting and varnishing a sailboat are:

- Clean the sailboat’s surface using a mild detergent and water to remove dirt and debris.

- Sand the surface with fine-grit sandpaper to create a smooth base for painting and varnishing.

- Apply a primer coat evenly to create a strong base.

- Let the primer coat dry completely as per instructions.

- Use a brush or roller to apply the desired paint color , starting from the top and working down.

- Allow the paint to dry between coats and apply more coats if needed.

- To varnish the sailboat, apply a thin and even coat in the direction of the wood grain.

- Let the varnish dry between coats and apply more coats for desired shine and protection.

Suggestions for painting and varnishing the sailboat:

- Use high-quality marine-grade paint and varnish for durability and protection against the elements.

- Consider using a marine-grade polyurethane varnish for a glossy finish.

- Take your time and ensure proper preparation and application techniques for a professional result .

- Follow safety precautions such as wearing gloves , goggles , and a mask to protect against fumes.

- Regularly inspect and maintain the painted and varnished surfaces for longevity.

When I launched and tested my newly built sailboat, I felt excitement and anticipation . Launching and testing a sailboat involves important steps to ensure functionality and safety. The calm waters were perfect for my maiden voyage. As I hoisted the sails and caught the wind, I tested the sailboat’s functionality by adjusting their angles to catch the wind. The sailboat glided effortlessly, showcasing the successful launch and testing process. The boat’s responsiveness and stability were remarkable, proving that launching and testing the sailboat properly resulted in optimal performance. I knew that my hard work had paid off. The sailboat performed flawlessly , and I felt proud as I navigated the open waters. It was an exhilarating experience , marking the successful launching and testing of my sailboat and the beginning of many memorable adventures.

How to Prepare the Sailboat for its First Launch?

To prepare the sailboat for its first launch, follow these steps:

- Check the hull: Inspect for damage or cracks. Ensure proper sealing and no leaks.

- Verify essential equipment: Have necessary safety equipment on board, including life jackets, flares, and a first aid kit.

- Secure the rigging: Check the mast, boom, and rigging lines for wear or damage. Tighten and secure them.

- Check the sails: Examine for tears or fraying. Ensure proper attachment to the mast and boom.

- Test the navigation equipment: Ensure proper functioning of the compass, GPS, and other navigational instruments.

- Inspect the engine: Check oil, fuel, and coolant levels. Start the engine to ensure smooth operation.

- Verify the bilge pump: Test to ensure it functions correctly and can remove accumulated water.

- Fuel and water: Ensure sufficient fuel and freshwater on board.

- Inform someone: Share sailing plans, including estimated time of departure and return, with someone onshore.

- Perform a safety briefing: Gather passengers and explain safety equipment location and emergency procedures.

Pro-tip: Before longer trips, it’s recommended to have a practice sail near shore. This will build confidence in handling the sailboat and verify proper functioning.

What Safety Precautions to Follow when Testing the Sailboat?

When testing a sailboat, it is important to follow safety precautions for a successful and safe experience. Here are some steps to consider:

1. Check the weather forecast: Before testing the sailboat, check the weather to avoid severe conditions like high winds or storms.

2. Inspect the sailboat: Thoroughly check the sailboat for any damages or issues with the hull, rigging, and sail.

3. Wear appropriate safety gear: Always wear a life jacket and suitable footwear.

4. Inform someone about your plans: Let someone know your plans, including location and duration, as a safety precaution.

5. Use proper navigation equipment: Have a compass and charts for safe navigation.

6. Start with calm waters: Choose calm and shallow water, especially if you are a beginner, and avoid strong currents or heavy boat traffic.

7. Be cautious of capsize risks: Understand the risk of capsize and practice self-rescue techniques.

8. Be aware of other boats and obstacles: Watch out for other boats, objects, or obstacles in the water to avoid accidents.

9. Follow boating regulations: Familiarize yourself with local regulations and follow them for a safe and legal experience.

10. Stay alert and maintain control: Always stay alert and in control of the boat, adjust to changing weather conditions.

Remember, safety should always be the top priority when testing a sailboat. By following these precautions, you can enjoy a safe and enjoyable sailing experience.

Some Facts About How To Make A Sailboat:

- ✅ Building a wood sailboat takes approximately 100 hours over a span of 3 months. (Source: www.instructables.com)

- ✅ The cost of building a wood sailboat is around $1,000, excluding tools. (Source: www.instructables.com)

- ✅ A wood sailboat requires materials such as oak plywood, brad nails, epoxy resin, etc. (Source: www.instructables.com)

- ✅ An origami paper boat can be made by folding a sheet of paper in a specific pattern. (Source: www.wikihow.com)

- ✅ Aluminum foil can be used instead of paper to make a waterproof origami boat. (Source: www.wikihow.com)

Frequently Asked Questions

1. how long does it take to build a wood sailboat.

Building a wood sailboat typically takes around 100 hours over a span of 3 months.

2. How much does it cost to build a wood sailboat?

The cost of building a wood sailboat is estimated to be around $1,000, excluding tools.

3. What materials are needed to build a wood sailboat?

To build a wood sailboat, you will need boat building plans, oak plywood, pencils, ruler, tape measure, brad nails, epoxy resin, epoxy hardener, silica thickener, wood flour thickener, masking tape, Japanese pull-saw, table saw, router, sanding discs, jigsaw, combination square, drill, wire or zip ties, C-clamps, mixing cups, mixing sticks, gloves, wax paper, fiberglass cloth, plastic spreader, waterproof glue, screws, fasteners, blocks, pad eyes, gudgeon & pintle, patience, and elbow grease.

4. How do you make a paper boat?

To make a paper boat, start by folding an 8 ½ in x 11 in sheet of paper in half. Follow the step-by-step instructions outlined in the reference to create the boat shape.

5. What materials are needed to make a paper boat?

To make a paper boat, you will need a sheet of printer paper or origami paper. Additional materials such as clear tape, waxed paper, or a crayon can be used to reinforce or waterproof the boat.

6. How do you increase the water resistance of a sailboat?

To increase the water resistance of a sailboat, you can use an outdoor craft sealant. Spray the entire boat with the sealant and let it dry before using.

About the author

Leave a Reply Cancel reply

Your email address will not be published. Required fields are marked *

Save my name, email, and website in this browser for the next time I comment.

Latest posts

The history of sailing – from ancient times to modern adventures

History of Sailing Sailing is a time-honored tradition that has evolved over millennia, from its humble beginnings as a means of transportation to a beloved modern-day recreational activity. The history of sailing is a fascinating journey that spans cultures and centuries, rich in innovation and adventure. In this article, we’ll explore the remarkable evolution of…

Sailing Solo: Adventures and Challenges of Single-Handed Sailing

Solo Sailing Sailing has always been a pursuit of freedom, adventure, and self-discovery. While sailing with a crew is a fantastic experience, there’s a unique allure to sailing solo – just you, the wind, and the open sea. Single-handed sailing, as it’s often called, is a journey of self-reliance, resilience, and the ultimate test of…

Sustainable Sailing: Eco-Friendly Practices on the boat

Eco Friendly Sailing Sailing is an exhilarating and timeless way to explore the beauty of the open water, but it’s important to remember that our oceans and environment need our protection. Sustainable sailing, which involves eco-friendly practices and mindful decision-making, allows sailors to enjoy their adventures while minimizing their impact on the environment. In this…

How Much Does It Cost to Build a Sailboat?

If you're on a tight budget, there are ways to build a sailboat affordably and still end up with a seaworthy boat. You can choose to start completely from scratch or consider using a self-build kit. If you want to hop on a sailboat project, let me help you break down the costs of building one.

The average price range for building a sailboat from scratch is between $10,000 and $20,000. A self-build kit for a 17' sailboat can be purchased for $2,500, while a sail-away Puur 17 kit can cost between $14,000 and $18,000. Meanwhile, building a 21ft gaff-rigged cutter can cost between $33,000 and $35,000.

If you're building dinghies, you can expect to spend anywhere from $1,500 to $10,000, depending on the size and materials used. Let's look at the estimated costs of building other types of sailboats and what factors can affect these costs.

- If you are on a tight budget, you can try starting to build a basic dinghy, which only costs around $1,500.

- If you're building a smaller boat, try to use less expensive materials, such as plywood or fiberglass, to keep costs down.

- You can save a significant amount of money on labor costs—around $10,000 if you do all the building yourself.

- A plan includes information on the materials needed for construction, as well as step-by-step instructions for assembling the boat.

- A catamaran with a more complex design or more advanced features costs around $50,000–$500,000 to build.

On this page:

Breakdown of costs in building a sailboat, average cost of building different types of sailboats, how to build a sailboat on a budget.

The average price range for building a sailboat from scratch is between $10,000 and $20,000 , but this can be much higher if you want to build an extremely high-quality craft or if you live in an area that is especially expensive.

Below is a table showing the estimated range of costs when building a sailboat:

Consider the materials you will use and the amount you need

Some common materials used in sailboat construction include fiberglass, wood, aluminum, and steel. The estimated cost of each material is as follows:

If you plan to build an aluminum sailboat, you might want to check out its pros and cons .

Factor in the costs of equipment

Building a sailboat requires a variety of specialized tools and equipment, such as saws, sanders, drills, and clamps. In addition to these basic tools, there are also more specialized pieces of equipment that may be necessary, such as a planer, a router, and a jointer. The table below shows how much each of these equipment costs:

Take into account the costs of labor

If you have the skills and experience to build the boat yourself, you can save a significant amount of money on labor costs. However, building a sailboat is a time-consuming process, and you should factor in the value of your time when calculating the overall cost of the project.

If you hire a professional boat builder, the cost of labor can be quite high, based on the complexity of the boat and the builder's experience and expertise. Although hiring a professional builder can be more expensive, it can ensure that the boat is built to high standards and is seaworthy.

Budget for purchasing a plan

If you are building a sailboat from plans, you will need to purchase the plans themselves. A plan refers to a set of detailed instructions and diagrams for building a specific sailboat design. It includes information on the materials needed for construction, as well as step-by-step instructions for assembling the boat.

Plans for a smaller, simpler sailboat may cost a few hundred dollars, while plans for a larger, more complex sailboat may cost several thousand dollars. The plan also includes the estimated timeline for completing the boat construction process. Building a sailing yacht can take at least 10 - 24 months to complete .

Carefully evaluate different sailboat plans before making a purchase to ensure that they are suitable for your needs and skill level. You may also want to consult with a professional boat builder or designer to help you choose the right plans and provide guidance during the construction process.

Account for miscellaneous expenses

There are a variety of other expenses which can add up quickly and should be factored into the overall cost of the project, such as the following:

- Permits: Depending on the location where the sailboat is being built, there may be permits required for construction.

- Insurance: Sailboats are valuable assets and require insurance coverage to protect against damage, loss, or theft. Insurance premiums can be a significant expense, especially for larger sailboats. Read this article to see the current costs of sailboat insurance.

- Transportation: If the sailboat is being constructed in a location that is far from the water, transportation costs may be incurred to move the boat to the water. This can include fees for a trailer, a truck, or a professional boat transport company.

- Miscellaneous Materials: There may be other materials required for the project that are not included in the initial cost estimate, such as hardware such as screws, bolts, and fittings, which may need to be purchased separately.

Sailboats come in various types, each designed with different features and purposes. The type of sailboat you choose will affect the cost of building it. Here are some common types of sailboats and their average costs:

The cost of building a dinghy

Dinghies are small sailboats that are typically used for racing or leisure sailing. They are usually less than 20 feet long and are designed to be sailed by one or two people.

For a basic dinghy, the cost can be as low as $1,500. This would typically involve using plywood or fiberglass for the hull, and basic rigging and hardware. However, for a more high-end dinghy, the cost can be as much as $10,000 or more. This would typically involve using high-quality materials such as carbon fiber or Kevlar for the hull, and more advanced rigging and hardware.

The cost of building a daysailer

Daysailers are slightly larger than dinghies and are designed for sailors who want to enjoy a day on the water without the expense and maintenance of a larger boat. Daysailers come in a variety of designs, from traditional wooden boats to modern fiberglass models. Some popular brands of daysailers include the J/Boat, the Laser, and the Sunfish.

These types of sailboats can accommodate up to six people and are usually between 20 and 30 feet long. A basic daysailer can be built for as little as $10,000, while a more luxurious model can cost upwards of $30,000. The most common materials used for building daysailers are wood, fiberglass, and aluminum.

The cost of building a cruiser

Cruisers are larger sailboats that are designed for long-distance sailing. The best-size cruiser usually ranges from 30 - 40 feet long.

Building a cruiser can cost between $30,000 and $100,000. Some cruisers may have additional amenities such as a kitchen, bathroom, and sleeping quarters, which can increase the overall cost.

The cost of building a racing sailboat

Racing sailboats are designed for speed and agility. They are usually between 20 and 30 feet long and are built with lightweight materials.

Building a racing sailboat can cost between $20,000 and $50,000, depending on the size and materials used. Since these sailboats are designed to be as lightweight as possible, it means that high-performance materials such as carbon fiber may be used, which can increase the overall cost.

The cost of building a catamaran

Catamarans are sailboats with two hulls. They are designed for stability and speed and are usually between 30 and 50 feet long, but the perfect size for sailing is around 37037 feet . Building a catamaran can cost between $50,000 and $500,000.

The larger the catamaran, the more expensive it will be to build. The materials used in the construction of the catamaran can also impact the cost, so if a catamaran is made of fiberglass, it will be less expensive than one made of carbon fiber. A catamaran with a more complex design or more advanced features will generally cost more to build.

The cost of building a trimaran

Trimarans are sailboats with three hulls, which are usually between 30 and 50 feet long. The cost of building a trimaran ranges between $50,000 and $500,000.

Since trimarans are generally larger and more complex than monohull boats, they require more materials and labor to build. Additionally, trimarans often require specialized equipment and expertise to construct, which can drive up the cost of the project.

Trimarans are also often built using high-quality materials like carbon fiber, Kevlar, and other advanced composites, which can be quite expensive. These materials are chosen for their strength, durability, and lightweight, which are all important factors for a high-performance sailing vessel.

Below are some tips to help you build a seaworthy sailboat without breaking the bank:

Consider a self-build kit : If you're handy with tools and have some building experience, you might want to consider a self-build sailboat kit. These kits come with everything you need to build a sailboat, including plans, materials, and hardware. Self-build kits can be a cost-effective way to build a sailboat, with prices ranging from $2,500 for a 17' sailboat kit to $14,000 to $18,000 for a Puur 17 kit, whichever you'd like to choose.

Choose your materials wisely : You don't want to skimp on quality, but you also don't want to overspend on expensive materials. With this, perhaps consider using plywood instead of solid wood for the hull, as it's more affordable and easier to work with. You can also look for deals on used materials, such as sails, rigging, and hardware, to save money.

Keep it simple : The more complex the design, the more expensive it will be to build. A simple design with a basic rig can be just as seaworthy as a more complex design, and it will be easier and cheaper to build.

Do it yourself : If you have the skills and experience, try doing as much of the work yourself as possible. This can include everything from building the hull to installing the rigging and hardware. Doing the work yourself can save you a lot of money on labor costs, and it can be a rewarding experience to build your own sailboat from scratch.

Leave a comment

You may also like, how long does it take to build a yacht (7 types).

Building a yacht requires time, effort, and dedication. Factors such as customization, size of the yacht, design complexity, material availability, and shipyard …

pros-and-cons-of-aluminum-sailboat

What's the Best Size of Sailboat for Coastal Cruising?

13 Best Beginner Sailboats with Cabin (For Any Budget)

The Best Sailboats for Rough Sea Conditions (13 Examples)

Own your first boat within a year on any budget.

A sailboat doesn't have to be expensive if you know what you're doing. If you want to learn how to make your sailing dream reality within a year, leave your email and I'll send you free updates . I don't like spam - I will only send helpful content.

Ready to Own Your First Boat?

Just tell us the best email address to send your tips to:

Building a Yacht: Top Things to Know About the Yacht-building Process

Owning a yacht and having the freedom to explore our beautiful planet by boat is a dream shared by many. But building a yacht is a long and complex process. Should you be one of the fortunate ocean explorers who will get the opportunity to have your semi custom yacht built from scratch, you will undoubtedly require the services of an experienced and knowledgeable boat builder.

Knysna Yacht Company is a boutique yacht-building company based in the picturesque coastal town of Knysna on South Africa's world-famous Garden Route, and crafting beautiful, artisan-made semi custom yachts for clients around the globe is what we do best.

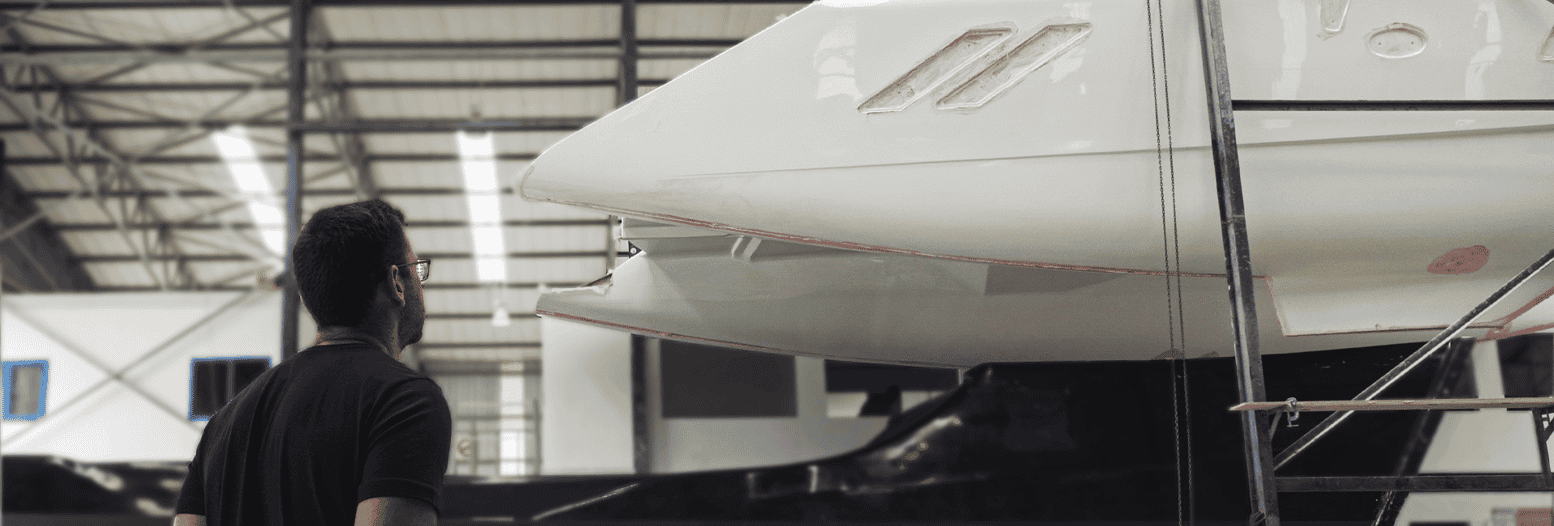

Having your yacht designed and built by a professional, acclaimed yacht builder like KYC will not only see you sailing off in a unique boat that was built to the highest standards. It will also ensure that you are a pivotal part of your yacht's design and construction process, right from the very outset.

While KYC builds your yacht, your input will not only be valued, it will be sought out and encouraged, with your particular tastes and preferences incorporated in every aspect of your boat's construction.

Continuous consultation and communication with the KYC team of expert yacht builders will see you taking to the seas in a boat that not only complements your personal style, but one that can truly be your home on the high seas.

Read on as we take a closer look at the various aspects of the semi custom yacht building process.

#1: What are the trademarks of a semi custom yacht?

When you first start to do your yacht-buying research, you'll no doubt come across various types of yachts available for purchase. Most of these will be standard, production yachts.

With a production yacht, what you see is truly what you get. There are virtually zero customizations that you can make to the layout or interior of an off-the-shelf production yacht,

A semi custom yacht, however, will afford you much more opportunity to add all those little touches that will make your boat a true extension of your personal style and tastes.

Even though semi custom yachts are built on a standard hull, when it comes to trims and finishes, appliances and the interior layout, that is all up to you.7The planning and design of a semi custom yacht can be compared to working with a home builder. Many larger home building companies have several base floor plans to select from, with the selection of cabinets, finishes, layout, and other details entirely up to the owner. It's the same with the design of a semi custom yacht.

#2: The advantages of a semi custom yacht

You might be wondering if a semi custom yacht is a better option than a standard production yacht. Buying a production yacht may save you money, but going for the cheapest option is not always the best choice.

There are clear advantages to having your own semi custom yacht built by professional yacht builders. One of those advantages is that you will personally be involved in the entire process of your yacht's construction.

A semi custom yacht build takes around 12 months to complete, allowing you ample time to really get stuck into the various design, building and finishing aspects of your boat.

In addition, you will almost certainly be cementing a long-lasting relationship with the dedicated team that is building your boat. Should you choose KYC as your yacht builder, this relationship will continue long after your boat's build is complete.

With a semi custom yacht, the price may be higher than what you'd pay for a standard production yacht (although the costs of KYC's boutique semi custom yachts compare very well with some new production yachts on the market).

But, if you choose to go for a semi custom yacht, you'll be getting much more than just a boat.

You'll be setting sail in a vessel you can take immense pride in, because you would have played a central role in crafting your boat to your exact tastes and specifications. If you select KYC as your yacht builder, you can also look forward to the many benefits of becoming a member of the KYC family of yacht owners.

This means you'll enjoy the support and expertise of an experienced team of yacht-building professionals for many years to come.

#3: Semi custom vs. production yacht

The advantages of having your own semi custom yacht built for you may be clear, but how do these boats compare to standard production yachts ?

Well, one major difference is alterations. When you're having a semi custom yacht built, you can make changes as you go. With a standard production yacht, you are buying the boat pre-made. Alterations to a production yacht after the fact can cost a lot of money, and may not be that simple – or safe – to execute.

Why would altering a production yacht post-sale be a safety risk? A production yacht's design and aesthetics may hide pre-existing flaws in the boat's construction. In itself, this could already pose potential safety risks. Making further changes or additions to a yacht that may already contain pre-existing design flaws would not be a wise course of action, and could be very dangerous indeed.

If you're involved in every step of the build of your semi custom yacht, you will have the opportunity to closely inspect your boat at every stage of its construction. This is a valuable advantage that could potentially allow you to avoid safety issues and layout problems relating to your boat.

#4: Building a semi custom yacht

If you choose to have yacht builders build your semi custom yacht from scratch, you'll be involved in every step of the process. For this reason, it will be in your interest to know as much as possible about your boat's building process.

So, what is the actual process of building a semi custom yacht?

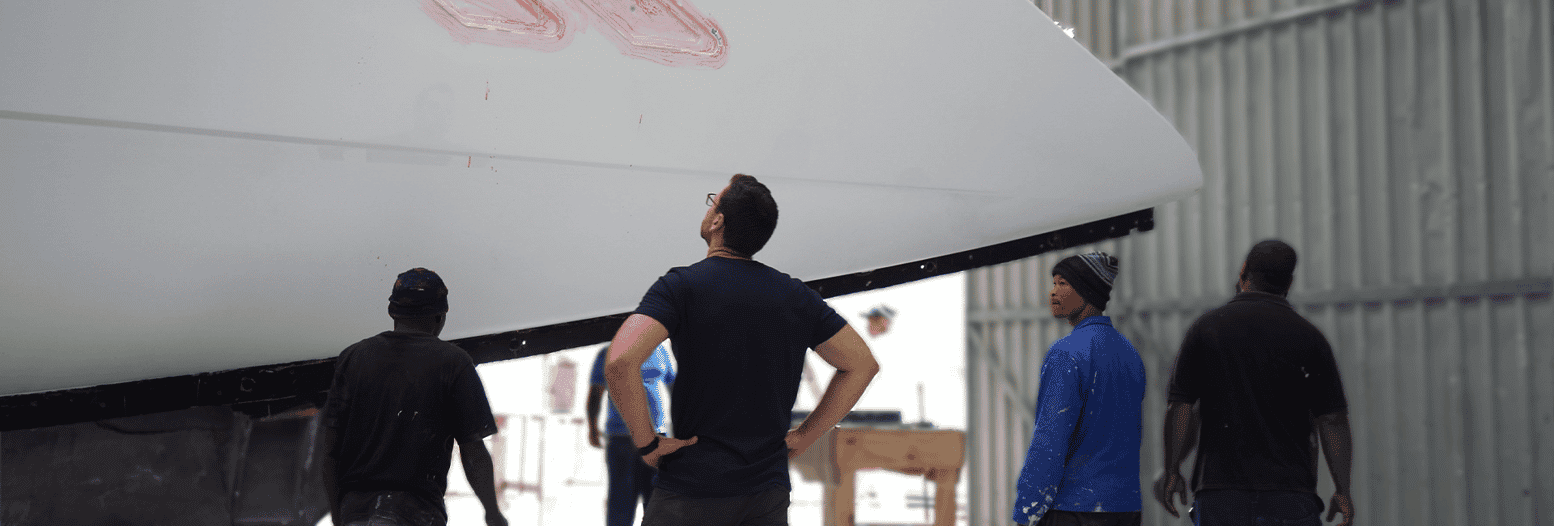

Building the hull

The first stage of the yacht-building process involves the "bones" of your yacht. During this stage, your yacht's hull and superstructure are made.

Unless they have commissioned a completely custom yacht to be built from the ground up, boat owners typically aren't involved in the selection of their boat's hull. However, it is important to know what this process involves.

Constructing a boat's hull is a process that takes four to six months to complete and takes place in a boat builder's aluminium or steel workshop. A steel yacht hull is extremely durable, but it will add a lot of weight to the overall weight of your boat.

Steel is one of the most common hull-construction materials, as it can be constructed and maintained with low technology, and at a relatively low cost.

Aluminium or alloy hulls are one of the better options available for hull construction, as they are so much lighter. These hulls offer the durability and longevity of steel hulls, but add only a fraction of the weight of a steel hull to your yacht.

After your yacht's hull is complete, it will have to go through a rinsing and priming process before your boat will be ready for the next step in its construction: finishing.

Finishing the yacht

Once your yacht's hull is complete, the second stage of your yacht's build can commence. This is the part where you'll start to see your boat "come to life".

The finishing process of your yacht is made up of several stages, including:

- Installing the yacht systems

- Interior and exterior carpentry

- Insulating the yacht

- Varnishing the yacht interior

- Spray painting the hull/superstructure

- Installing the mast

Semi custom yachts are beautiful machines. And, under such a boat's surface, a lot goes on to keep that beautiful machine moving and functioning as a self-contained living unit on the water. A large network of wiring and systems will be expertly installed to keep your yacht running smoothly and safely.

Yacht systems

It takes several systems for your new boat to run, including a navigation system, anchoring system, electrical system, propulsion system, air conditioning system, water systems, and more.

Each of your yacht's systems requires an expert team possessing the necessary knowledge and expertise to install it correctly and efficiently. Some people set sail with a yacht engineer as part of their crew team, to keep everything running smoothly onboard. However, KYC offers all new Knysna yacht owners a complimentary, 2-week training period during which they are shown and taught everything they need to know in order to maintain their yacht's systems themselves.

Gel coating & interior and exterior carpentry

A yacht's gel-coating process is done with a resin that bonds with the fibreglass surfaces throughout your boat. Gel coating ensures no leaks and cracks on a yacht's surface, but it can also be applied to add more colour to your boat.

Since most yacht hulls and exteriors are finished in fibreglass, gel coating becomes an extremely important part of the yacht-building process.

After gel coating, the interior of the yacht receives a protective varnish. The yacht exterior is also gel-coated and waterproofed to prevent leaks and ensure the boat is completely sealed.

Carpentry is also an essential component of your new yacht. Marine carpentry experts are required for both the interior carpentry (think bathroom cabinets, kitchen counters and seating), as well as the decks and other carpentry aspects on the boat's exterior.

Yacht builders and their teams

If you select to have your yacht built by a big yacht-building company, a project manager will be appointed to oversee your yacht's construction, making sure the entire process runs smoothly. Project managers are typically the face of a boat-building company, and clients will deal with their boat's project manager as their point of contact throughout their yacht's construction process.

Underneath the project manager, you'll likely have a team of engineers, systems installers, artisans, an interior designer, and a few legal team members.

Should you choose to have your semi custom yacht built by KYC, you will be dealing directly with KYC’s owners. You will also have access to your under-construction yacht at all times, ensuring that the lines of communication remain open and that your needs are being met.

Selecting the right yacht builder

It's essential to choose the yacht builder best suited for your particular project. There are several questions you should ask yourself before selecting a company to build your yacht.

First, you will have to decide on the type of vessel you want. Many boat builders specialise in certain types of boats. Knowing what type of boat you want will be the first step toward deciding which yacht builder is right for you.

Next, you'll want to figure out how far you'll typically be sailing. This is known as your yacht's range. If you're only planning on doing shorter sailing trips, that will require a specific type of boat. If you want to sail out on the ocean for weeks or months at a time, that will require a different kind of boat entirely.

Finally, ask yourself how long you're willing to wait for your new boat . This wait is known as your lead time. If you're okay with waiting 2-4 years for your yacht to be built, then you can consider selecting a fully custom yacht.

Semi custom yachts, including KYC’s artisan-built Knysna 500SE and Knysna 550 yachts can be completed much faster. This will vary from builder to builder, but most semi custom yachts have a much shorter lead time than a fully custom boat that is built from scratch.

Financing a semi custom yacht

Financing a boat that is yet to be built is notoriously difficult, with most banks and financial institutions only willing to provide loans for completed boats. At KYC, we offer clients a Yacht Construction Financing Option, allowing them full flexibility to pay off building costs over the boat's complete building timeframe.

Become a yacht owner faster

Let us answer your yacht-building questions!

Read our blog article on yacht financing and learn more about KYC's unique Yacht Construction Financing Option.

Let us answer your yacht-building questions

There are lots of points to consider when you're thinking of having a boat built.

Our team of KYC yacht-building experts will help you navigate the yacht-building process to ensure that your journey towards ultimate freedom is smooth sailing every step of the way.

Don't hesitate to send us a message at [email protected] and let us know how we can help.

Yacht Maintenance - Top Tips for Protecting Your Investment

Essential things to know about boat insurance, top things to know about yacht solar power, get all the latest to your inbox, discovery awaits.

- Types of Sailboats

- Parts of a Sailboat

- Cruising Boats

- Small Sailboats

- Design Basics

- Sailboats under 30'

- Sailboats 30'-35

- Sailboats 35'-40'

- Sailboats 40'-45'

- Sailboats 45'-50'

- Sailboats 50'-55'

- Sailboats over 55'

- Masts & Spars

- Knots, Bends & Hitches

- The 12v Energy Equation

- Electronics & Instrumentation

- Build Your Own Boat

- Buying a Used Boat

- Choosing Accessories

- Living on a Boat

- Cruising Offshore

- Sailing in the Caribbean

- Anchoring Skills

- Sailing Authors & Their Writings

- Mary's Journal

- Nautical Terms

- Cruising Sailboats for Sale

- List your Boat for Sale Here!

- Used Sailing Equipment for Sale

- Sell Your Unwanted Gear

- Sailing eBooks: Download them here!

- Your Sailboats

- Your Sailing Stories

- Your Fishing Stories

- Advertising

- What's New?

- Chartering a Sailboat

How to Build a Boat

If you want to know how to build a boat you've come to the right place, because that's what we did, learning as we went. She's called Alacazam , and you can see her in action in the picture above, charging through the Caribbean Sea off Montserrat. And we're going to take you through the entire sailboat construction process...

Jumping forward several years...

She was called 'Alacazam' , from the great Nat King Cole's song Orange Coloured Sky, and these are her vital statistics...

- Length overall: 11.5m (37.5 feet)

- Waterline length: 10.6m (34.5 feet)

- Beam: 3.9m (12.5 feet)

- Draft: 2.2m (7 feet)

- Displacement: 7,023kg (7.75 tons)

- Displacement/length ratio: 159

- Sail area/displacement ratio: 18.28

Of course you don't have to start from scratch as we did; there are a few other boat building options available that could save time and maybe cash too.

Whichever option you choose it's a very good idea to think the whole project through from beginning to end, as nothing can cause more disruption and additional cost than changing your mind halfway through a boat construction project.

It's an inescapable fact that cost and size are closely related, but not in a linear fashion as you might assume. If you double the length of the boat you're likely to increase the costs by a factor of four; and not just the build costs, but owning and operating costs too. Just wait until anti-fouling time comes around and you'll see what I mean.

Berthing costs seem to take a hike at around 12m (40ft) overall, and another at 15m (50ft), which was the final compelling factor in sizing our self-build cruising sailboat at 11.5m (38ft) on deck. This allowed for the anchor poking out at one end and the self-steering gear at the other, just in case any marina employee should get overzealous with the tape measure.

But where do you want to start? Here are your three main options:

- Buy an old, tired boat and completely refurbish her, or

- Buy a bare hull and deck moulding for home completion, or

- Start from scratch, and build the hull yourself.

We'll take a look at these three options in turn:

1. Starting With a 'Fixer-Up'

This can be a great option, particularly if you can get your hands on an old but tired pedigree boat with a proven reputation like the Ted Brewer designed Morgan 28 shown here - and you might just get it at an absolute knockdown price.

With luck, much of the interior will be salvageable, but you'll probably want to bring the instruments and electronics up to date, replace the rig and all the rigging, install a new engine and stern gear and replace the hatches and much of the deck equipment.

But you really should get a professional surveyor involved before you take up such a project. Explain to him carefully what your intentions are, and ask him to prepare his report with that in mind; it could save you a whole heap of time and money.

2. Starting from a Bare GRP Hull

This approach will get you off to a flying start, particularly if the hull comes with the deck moulding already fitted and the bulkheads bonded in. The problem will be in finding one, as few manufacturers seem to offer this once popular option these days.

3. Starting from Scratch

You need to take a very deep breath before setting off along this route - and believe me, I know, because this is how we built our custom designed sailboat Alacazam .

Unless you're building from an established set of boat plans, you'll be well advised to get a yacht designer involved at the outset.

And one of your first decisions will be the choice of hull material - fibreglass, steel, aluminium, ferro-concrete or wood - but which one, and why?

The Outline Requirements for our 'Ideal Cruising Sailboat'

My current boat at the time was a Nicholson 32 Mk10. Jalingo was a narrow hulled, heavy displacement, long keeled cruiser that I'd sailed thousands of miles - much of it singled handed (until I met Mary, who put paid to all of that self indulgence) - off the shores of the UK, France, Spain and Portugal, and to the Mediterranean and back.

Her hull shape and displacement ( Jalingo's , not Mary's) meant that she was comfortable in a seaway and great in a blow, but sluggish in light winds - and that keel meant she was a nightmare to handle in the confines of a marina.

Like all long-distance sailors we had a good idea as to what our 'ideal cruising sailboat' would be. I've always thought that a cutter rigged sloop is the ideal the ideal rig for a cruising boat, with a roller furling jib , a hanked-on staysail (easy to replace with a storm jib when necessary) and a slab-reefing mainsail with lazy jacks , as I don't trust either in-mast furling or in-boom furling .

Additionally she would:~

- have high resistance to capsize;

- be robust and easy to maintain;

- have good performance under sail;

- have a comfortable, easy motion underway;

- be easily manageable by a small crew;

- have sufficient internal volume for comfortable living aboard;

- be affordable to own and operate.

Did we know how to build a boat with these desirable characteristics? No, but we knew a man who did. Enter Andrew Simpson, yacht designer, surveyor and shipwright - and one of my best chums...

The Designer's Proposals for our Ideal Cruising Sailboat

We discussed all this at length, and made a number of sketches of both the interior layout and an efficient, workable cockpit .

Andrew did the number crunching and came up with an outline design for a 38ft (11.5m) cutter rigged wood/epoxy (cedar strip) water-ballasted cruising boat.

"She'll be light, quick, robust and comfortable" he said

"And seaworthy?" we asked

"Eminently so" he replied

"Right" we said, "Let's do it!"

And so we did...

So How Did We Build Alacazam ?

Here's the whole story, in words and pictures.

How to Build a Boat:

- Part 1: The All-Important Preparation

- Part 2: How to Build a Boat Hull in Western Red Cedar

- Part 3: Sheathing the Hull in Woven Glass Rovings

- Part 4: Cutting and Installing the Plywood Bulkheads

- Part 5: Building the Interior Structure

- Part 6: Constructing the Deck and Coach Roof

- Part 7: Moulding the GRP Cabin Top

- Part 8: Fitting the Bulb Keel

- Part 9: Making the Rudder

Next: How to Build a Boat, Part 1

Recent Articles

'Hitchcock', an RM1260 Sailboat for Sale

Mar 27, 24 09:53 AM

'Natalya', a Jeanneau Sun Odyssey 54DS for Sale

Mar 17, 24 04:07 PM

'Wahoo', a Hunter Passage 42 for Sale

Mar 17, 24 08:13 AM

Here's where to:

- Find Used Sailboats for Sale...

- Find Used Sailing Gear for Sale...

- List your Sailboat for Sale...

- List your Used Sailing Gear...

Our eBooks...

A few of our Most Popular Pages...

Copyright © 2024 Dick McClary Sailboat-Cruising.com

The global authority in superyachting

- NEWSLETTERS

- Yachts Home

- The Superyacht Directory

- Yacht Reports

- Brokerage News

- The largest yachts in the world

- The Register

- Yacht Advice

- Yacht Design

- 12m to 24m yachts

- Monaco Yacht Show

- Builder Directory

- Designer Directory

- Interior Design Directory

- Naval Architect Directory

- Yachts for sale home

- Motor yachts

- Sailing yachts

- Explorer yachts

- Classic yachts

- Sale Broker Directory

- Charter Home

- Yachts for Charter

- Charter Destinations

- Charter Broker Directory

- Destinations Home

- Mediterranean

- South Pacific

- Rest of the World

- Boat Life Home

- Owners' Experiences

- Interiors Suppliers

- Owners' Club

- Captains' Club

- BOAT Showcase

- Boat Presents

- Events Home

- World Superyacht Awards

- Superyacht Design Festival

- Design and Innovation Awards

- Young Designer of the Year Award

- Artistry and Craft Awards

- Explorer Yachts Summit

- Ocean Talks

- The Ocean Awards

- BOAT Connect

- Between the bays

- Golf Invitational

- Boat Pro Home

- Pricing Plan

- Superyacht Insight

- Product Features

- Premium Content

- Testimonials

- Global Order Book

- Tenders & Equipment

Six facts about the build of Sailing Yacht A

One of the largest superyachts in the world , the 142.81 metre Sailing Yacht A has pushed the boundaries of yacht building. We reveal some of the most amazing facts about how this boat came to be.

The construction of Sailing Yacht A

This incredible superyacht was commissioned by Andrey Melnichenko. As owner of Motor Yacht A , we knew Sailing Yacht A would be anything but conventional. Melnichenko is one owner who delights in challenging the status quo and moving the game on, introducing new techniques and technologies in his yacht projects. Sailing Yacht A ticks both boxes: at 142.81 metres LOA, the “sail-assisted motor yacht” is one of the largest superyachts in the world.

Working once again with Philippe Starck on the design, Melnichenko assembled his own team to take the project from concept to completion. He chose Dirk Kloosterman, a veteran project manager of superyacht builds, to lead it. Kloosterman was involved in the build of Larry Ellison’s Rising Sun before taking on Motor Yacht A for Melnichenko.

Sailing Yacht A is his biggest undertaking. Kloosterman’s first challenge was to find a shipyard with the capabilities to build such a vessel. Few major deep-water shipyards wanted to take on the risk of such a radical project, but Nobiskrug’s purchase of part of the HDW yard in Kiel, Germany, presented an opportunity.

“This was an excellent facility, with its large docks and the draught needed for the project,” Kloosterman says. “In March 2011, we signed the deal for pre-engineering to start. It was made clear to the yard that the team wanted large input and control over the build so the standard tender-and-bid process, with the yard supplying subcontractors, was scrapped. Cost control for an eight-deck motor yacht, with the added dimension of sailing, was going to prove challenging.”

Sailing Yacht A's imposing scale

Sailing Yacht A is a sharp, three-masted motor yacht with sailing potential, constructed mostly in steel incorporating composite and carbon fibre to keep weight down. In profile from her high bow, the sheerline climbs aft, before dropping down to an almost retroussé stern. The line is seamless, without interruption or sight of any deck equipment, anchors, balconies or openings of any kind, but they are all there, cleverly hidden away. Astonishingly, there are 24 shell doors in the hull.

The windows, which are all oval, look small from a distance, but all have a magnifying effect, making them seem huge from the inside. A special one-way film covers the exterior of the glass for privacy and helps to blend them into the custom metallic paint finish by Alexseal.

Her scale is extraordinary: 142.81 metres LOA, with a maximum beam of 24.88 metres and a draught of eight metres. She has eight decks, connected by multiple elevators and free-floating spiral staircases, garages for four tenders and a submarine, as well as a touch-and-go helipad on the bow. Every part of her interior has been designed to be flowing and organic.

Inside, up to 54 crew will run a professional galley large enough to serve a hotel and a powerplant and hotel services, stretching uninterrupted across two decks. In contrast to the volume of the everyday living accommodation is arguably the most incredible feature on board, occupying the smallest space: an underwater viewing pod moulded into the keel, offering a view of the props.

To make sure it all worked, hydrodynamic research facility HSVA in Hamburg performed towing tests for the hull, and the Wolfson Unit at the University of Southampton carried out wind tunnel tests to determine aerodynamic loads. This phase of the project revealed the optimal combination of sailing characteristics, seakeeping behaviour and performance under power. MARIN, in the Netherlands, conducted final tests of the model with keel and rudders.

With simulated aerodynamic loads applied, results concluded that the yacht’s heeling angle when under full sail would be a maximum of 12 degrees at 20 knots true wind-speed upwind and 35 knots downwind.

The rig and sail plan of Sailing Yacht A

Three colossal unstayed masts – the largest carbon masts in the world – define Sailing Yacht A . The mainmast towers 100 metres above the waterline – taller than Big Ben. An enclosed electric gimballed crow’s nest is incorporated, to whoosh a crew member 60 metres up the mast for what will surely be one of the most amazing views on the water. Dykstra Naval Architects , the Dutch naval architect that designed the rig for Maltese Falcon , was the obvious choice to develop an easy-to-use and safe sailing system.

Being “sail assisted”, the ratio between sail area and the yacht’s displacement is somewhat lower than would be found on a pure sailing yacht. Dykstra optimised the sailplan with full roach sails and freestanding aerodynamically efficient masts that can be rotated a total of 70 degrees to increase lift-drag characteristics.

Curiously, the masts are curved. “When we started to design this rig,” explains Mark Leslie-Miller from Dykstra, “the distinct feature of the freeboard sloping up towards the stern was already defined. For styling reasons, we wanted the foot of the sails [thus the booms] to align with the sheerline.” Sails this big would need to furl rather than flake when not in use. Furling booms, however, have to be at 90 degrees to the mast in order to work. Rather than tip the entire mast forward to preserve the right angle, Dykstra designed in the curve to keep the design aligned.

Magma Structures in Portsmouth, UK, developed the unique freestanding spars in carbon fibre, the only material that could cope with the stresses involved; masts this size cannot, in fact, be built using metals, according to Magma’s Damon Roberts, and they posed quite a challenge for the team. “Since the rig concept is unprecedented on this scale, there were no easy answers or standard solutions for any of the challenges that the rig design posed,” he says.

The sail and booms on Sailing Yacht A

With the masts designed to carry the whole load, they were able to calculate the maximum bending-force load on the lower bearing by using the predicted upper wind speed limit. “Allowable material stresses and safety factors then clearly led to the structural requirements for the design,” Roberts adds. The bending load at deck on the main mast, for instance, is about two-and-a-half times that of a Dreamliner aircraft wing and about two times that on Maltese Falcon , which has the highest-loaded freestanding masts to date. To put it another way, the masts can withstand 90 knots of wind with full sail up (equivalent to a Category 2 hurricane), or two double-decker buses hung from the tip of each.

Magma built the masts using high-strength carbon/epoxy prepreg laminate. Each mast was produced in four large sections: top and bottom, port and starboard. In the lower sections, 370 layers of carbon were laid up in open moulds. For the curing, Magma designed and manufactured oven software to monitor and control the cook cycle over a three-day period. Embedded in the masts is a network of fibre-optic sensors to give real-time comprehensive load data for safety, historical data, condition monitoring and sail performance optimisation.

The total sail area of 3,747 square metres is equal to the size of half a football pitch, and is 67 per cent larger than Maltese Falcon’s 2,370 square metres. Unlike the many small sails that deploy from Falcon’s mainmast, Sailing Yacht A’s fully battened mainsail, at 1,464 square metres, is a single piece and furls on a carbon-fibre mandrel inside a U-shaped boom at the press of a button; no crew are required. The total length of fibre used in the sail is 754 miles, or long enough if pulled straight, to stretch from the shipyard in Kiel to Monaco.

The sails, by Doyle Sailmakers of the US, are a combination of carbon and Technora fibres and covered with taffeta to protect them from UV. The trick was determining compression loads on the battens and then engineering a soft inboard end capable of furling reliably but, at the same time, handling the forward thrust of the battens without tearing. Future Fibres, in Valencia, constructed the carbon-fibre booms, which measure 25 metres (foresail), 27.5 metres (mainsail) and 23.6 metres (mizzen).

Glass technology on Sailing Yacht A

Germany’s GL Yachtverglasung (GLY) developed the yacht’s glass, including the longest piece of curved glass ever made: a 1.8-tonne, 15 metre bulwark forward on the bridge deck. “The designer wanted to make the look as clean as possible and preferably without railings. The only way to make invisible railings was to make them out of glass,” explains Kloosterman.