How To Use Your Mainsheet Traveler (The Right Way)

The mainsheet traveler is one of those things it pays off to master as it can add knots to your speed. In this article you will learn how to use it well so that you leave others in the dust. Or waves. You get my point.

So how to use your mainsheet traveler?

- When close-hauled, use the mainsheet traveler to keep the boom centered

- Use the mainsheet traveler to pull the boom down to tighten the mainsail

- Reduce the boat's heel by lowering the traveler

On this page:

How to use the mainsheet traveler, what is a mainsheet traveller, a valuable helper.

Look, I get that tweaking your sails with all those ropes and rollers and telltales and whatnot can get a bit daunting at first. But luckily, the mainsheet traveler is not a complicated matter to understand, since its use is relatively straightforward. And it really can help you sail much faster and easier. So let's go through the points above in detail.

Before we get into the specifics of the use, let's close our eyes and shed a tear in respectful silence for all the unused main travelers. You see, sadly, it is one of the most underused parts of the whole sailing rig, especially on charter cruisers.

More often than not, you see sailors lock the traveler in the central position at the beginning of their stay on board and not move it during the whole journey. That is unless they want to reposition the boom so that the swimwear that is drying on it doesn't drip into the cockpit.

Heart wrecking, I know.

Though sailing without using the main traveler is possible, you are robbing yourself of speed, comfort and, believe it or not, you are actually doing more work than you would have to do if you took advantage of this thing.

So why is this? What good does it do to move these travelers around? As mentioned:

1. Use The Traveller To Center The Boom When Close Hauled

Especially when going upwind (or close-hauled), you want to make sure your sails are in the correct position. Going into the wind is one of those points of sail that require quite a bit of attention as if you don't get the sails right, you just won't go.

As for your boom, it needs to stay centered in such a situation. While traveling upwind, there will be quite a lot of force exerted on the mainsail by the apparent wind, pushing it away from the wind direction, which could mess up your set up. Since the connection between the traveler and boom are flexible ropes, you might need to move the traveler slightly upwind to keep the boom centered.

So keep playing with it until the boom is nicely set in the middle and tighten the ropes so that it doesn't move around.

If you want to learn more about sailing into the wind , I've written a 7-step guide on how to do it effectively. You can read it here .

2. Use The Traveller To Pull The Boom Down To Tighten The Mainsail

Especially when the wind gusts a lot, you might want to keep the sail more firm so that it doesn't 'belly out' since that would often mean a loss of power.

During those moments it pays off to pull the boom down to make sure the sail holds its form even if you are getting punched by the Anemoi themselves.

Fun fact, Anemoi are the Greek gods of wind. I thought it was Poseidon but upon googling him to find whether you write two 's' or just one, I found out he only takes care of the sea. Winds are not his department.

Anyway, to those of you thinking 'but man, pulling the boom down, that's what the boom vang is for!' yes, you are right, but boom vang works better when sailing downwind and thus the boom is wide open. On the other hand, when going upwind, when the boom is more centered, doing this with the mainsheet traveler ropes is easier and more effective.

3. Lower The Traveller To Reduce The Boat's Heel

This is a big one. The main traveler can save you tons of work and time.

A heeling boat is an inevitable part of sailing, and it looks hella cool, (or at least I'd like to think so) but once you go over a certain point, you are losing power and speed. So to reduce the risk of that or to provide your crew with a bit of comfort - since it is quite tricky to cook or use the heads when the boat is sideways - if you find it heeling too much, let the traveler out a bit.

This will reduce heeling and the weather helm. To those who haven't heard about this before - weather helm is the tendency of boats to turn into the wind and is a result of too much heeling. While you can still keep your direction, to do that, you have to steer more, thus there is more drag on the rudder, which slows your boat down quite significantly.

So that was speed - now let's explain where exactly are you saving energy.

Use the traveler instead of reefing

Using the traveler this way is much easier and faster than depowering. If the wind gets too rough, instead of reefing, you can let the traveler out. This of course does not go all the way and you will likely need to reef eventually, but the main traveler can buy you some time before you have to.

This is valuable especially in cases when there is a chance of the wind slowing down soon, thus a chance you would have to reef and then open the whole sail up soon after.

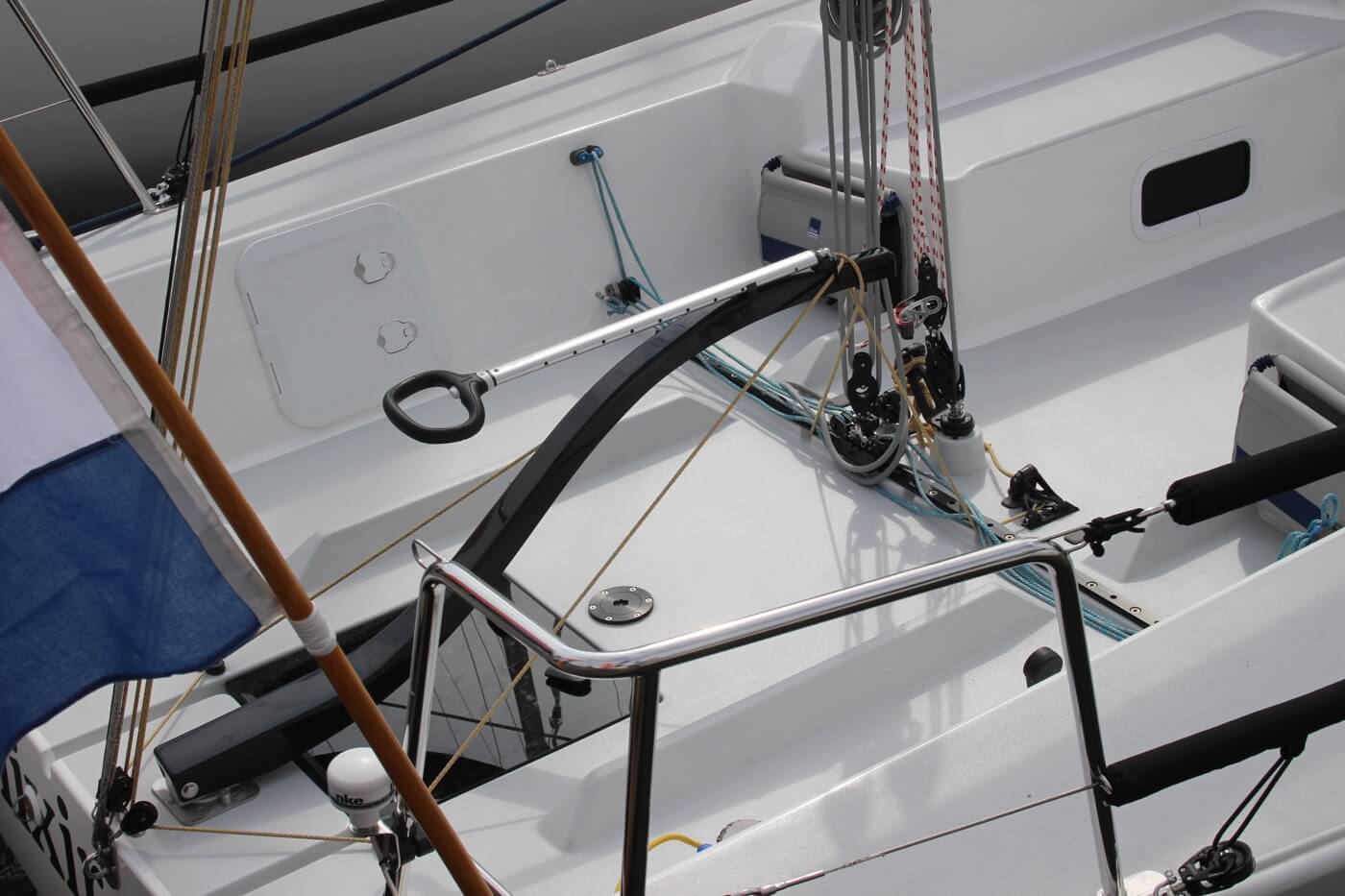

Let's make sure we all understand what this piece of equipment is. Look at a picture of most sailboats and you will find a bunch of ropes and shackles and blocks that go from the boom down, connecting it with the boat. They are usually connected either to the roof of the salon or back of the cockpit, mostly depending on the size of the boat. At the bottom, they are joined to a wheely thing that can travel horizontally left and right on a rail, taking the boom with it.

Sometimes there is not a wheely thing, but two roller systems, connecting the boom with the left and the right side of the boat. Tightening the left one and loosening the right one will bring the boom to the left and vice versa. Thus it serves the same purpose, it just takes up a bit more space.

These systems come in a variety of forms and alternatives, and sometimes there is nothing at all and the boom is simply locked in a central position. Usually, though there is something , all with the same purpose - to position the boom and lock it in place.

So you see, it isn't at all complicated. Once you get on a boat to test this out, you will find that operating the main traveler is rather intuitive, most of the time very simple, regardless of what system is in place. It is not a complicated piece so it should be relatively straightforward how to manipulate with it, even without a manual. And as apparent, it can make your journey quite a bit more effective and fun.

It is exactly this type of little skills you can have that make all the difference between a weekend cruiser and a sailor. Don't get me wrong, there is nothing wrong with leisure sailing even if you are a bit lazy about it. After all, sailing is about fun, passion for the seas and boats - that should be on top of the hierarchy.

That being said, I strongly encourage anyone half interested in sailing to learn as much as possible about operating a sailboat. Most sailors use perhaps one-third of the boat's equipment, the bare minimum that makes their vessel move. And while the basic setup is not that complicated, this should only be good news for those without many skills, since they can go and sail even if they are in a relatively early stage of their learning process.

But once you are familiar with the basics, knowing how to trim correctly, shape the sails in the right way and select the proper course adds a lot even to a leisure cruise and most importantly can save your boat and keep you safer when the seas get rough. Which will happen sooner or later?

In short, there should not be a single rope on board that you don't know the function of and aren't using unless that is your deliberate choice. Luckily enough, these days the internet is full of articles and videos about sailing and you can learn quite a lot from the comfort of your home. This site is an example of this. So go ahead, skim through the Improve Sailing guides and become the best you can be.

To cite Sir Francis Bacon, “Knowledge is power.” In our case, knowledge is speed, comfort, and safety.

Fair winds and safe travels to you all!

DAVID DONNELLY

Thank you for all your efforts in putting these materials together. For a neophyte like myself, I have found the information to be not too complex, but with lots of links to explain matters more fully. Much appreciated and, again, thank you.

Leave a comment

You may also like, how to sail into the wind (in 7 simple steps).

Sailing into the wind seems like Poseidon's magic, but once you learn how to set up your sails and hold the correct course, you can do it. This article explains the …

What is the Ideal Wind Speed for Sailing?

Own your first boat within a year on any budget.

A sailboat doesn't have to be expensive if you know what you're doing. If you want to learn how to make your sailing dream reality within a year, leave your email and I'll send you free updates . I don't like spam - I will only send helpful content.

Ready to Own Your First Boat?

Just tell us the best email address to send your tips to:

What is a Sailboat Sheet?

Last Updated by

Daniel Wade

June 15, 2022

A sailboat sheet is a rope or line used to pull the sail in and out. Sailors use sheets to control the speed of the boat and the trim of the sails.

Using the term "sheet" to describe a rope seems counterintuitive. As a result, the term is often confused with the sail itself. Sailboat sheets are connected to one corner of the sail (clew) or boom and control its lateral position. Sheets are an integral part of sailboat rigging.

Table of contents

A sailboat sheet is a rope or line connected to the clew of a sail (in the bottom corner) or the boom. From the boom or clew, the sheet often runs down to a series of blocks and winches on the deck. Sailors control the sheets from these winches and blocks.

The mainsheet controls the lateral movement of the boom and the mainsail. This is often the most important sheet onboard a sailboat. It's also the closest, as the boom hangs over the cockpit of the sailboat.

The jib sheet controls the front triangular sail. It runs across the length of the deck and often includes two separate lines. When changing direction, sailors release the cleat and winch, securing one side of the jib sheet, and engage the other, allowing the jib to swing to the other side.

Basic Sailboat Sheet Rigging

Small sailing dinghies use the simplest forms of sheet rigging. In many cases, the sheet of a small sailboat is simply a section of rope hanging from the boom, which the sailor holds on to and pulls in and out.

Other small vessels have a simple block system mounted to a fixed point on the deck, which allows the operator to tether the sheet in place. Small boats often avoid these systems as they're sensitive to minute wind changes.

Block and Tackle

The mainsheet feeds through a complex system of blocks (pulleys), cleats, and winches. These rigging systems allow the boom to swing to either side, which is especially useful when tacking quickly. Here are two common types of mainsheet rigging, otherwise known as 'tackle' systems.

Gun tackle is one of the simplest block and tackle systems used on sailboats. It requires only two blocks, which are usually positioned towards the end of the boom on the stern of the vessel.

Gun Tackle only utilizes two sections of rope in the blocks, which provides the lowest level of force reduction. As a result, this block and tackle system is typically found on smaller sailboats where the size of the sail plan requires less effort to manage.

Luff Tackle

Luff tackle is much more common on cruising sailboats , and it's still fairly simple to operate. Luff tackle is easier to pull (requires less force) than gun tackle, as it includes three sections of rope instead of two. Remember, each section of rope reduces the force required to pull in the sheet.

The main disadvantage to luff tackle (and other high-ratio block and tackle systems) is increased sheet length. Longer lines increase the chances of tangling, which can be a nightmare at sea. However, a properly-rigged sailboat and a trained crew can reduce the chances of fouling up the mainsheet.

Mainsheet Travellers

Travelers are extremely useful for trimming the sail. The system allows sailors to adjust the "twist" of the mainsail , which helps control the speed more precisely. The mainsheet block mounts to the sliding traveler and moves side to side.

Mainsheet Bridle vs. Mainsheet Traveller

A bridle is a simple alternative to a traveler, and it comes in many configurations. A standard dinghy-style bridle feeds the mainsheet through two deck-mounted blocks, which allows the operator to center the boom. Other vessels use a single block on a sliding rail, which serves the same purpose.

Travelers are more complex, but they offer superior power and trim control on larger boats. The primary advantage of a traveler is the ability to precisely adjust the twist of the sail, which is especially important in windy and stormy conditions.

Sailboat jib sheets utilize more than one section of rope or line. Instead of a single line connected to the boom, the jib uses one line on either side of the sail. Jib sheets connect to the jib through a clew located at the bottom corner of the canvas.

The jib sheet works in a similar way to the mainsheet. Tightening one side of the sheet pulls the bottom corner of the jib in that direction and helps control the boat. When one side of the jib sheet is taught, the other side is loosened.

The jib sheet utilizes two separate sections of the rope that run along the port and starboard side of the deck. The advantage of using two lines is that there's no need to unwrap the sheet from the mast when changing direction.

The sheets travel from the clew of the jib to a set of blocks towards the bow of the boat. From there, the lines often run through a set of cam cleats and to their respective winches.

When changing direction to the wind, sailors loosen one section of the jib sheet and release tension from the cleat and the winch. Then, they feed the opposite line into the cam cleat and tighten the winch. This process prepares the jib to switch sides.

Sailboat Sheet Winches

Sailboats utilize winches for the mainsheet and the jib sheet. Winches allow sailors to increase and decrease line tension by winding around a cammed drum. Winches include a removable winding crank or a motor.

The cam inside the winch works like a socket wrench or a bicycle sprocket, allowing sailors to wind against pressure and lock one direction of travel. Sailors can switch the direction of the cam for winding and unwinding.

Manual Winches

Manual winches are common on sailboats of all sizes. These winches are wound manually using a removable crank or 'key,' which fits into the top of the drum. Manual winches are sometimes difficult to wind by hand, especially in windy conditions.

Power Winches

High-end modern sailboats often utilize motorized winches. These electrified systems allow sailors to wind heavier loads. Additionally, electric winches can be controlled from a protected pilothouse. Advanced electric winch systems allow the sail to be trimmed without stepping foot on deck.

Best Line for Sailboat Sheets

Sailboat sheets control the speed of the boat, so it's essential to choose a durable and long-lasting line material. It's also necessary to quickly replace aged and frayed sheet lines, as degraded lines can snap, tangle, and bind up without warning. Here are the best materials for sailboat sheet rigging.

Polyester Sheet Line

Polyester is an affordable and robust material for sailboat sheets. It's extremely common on all kinds of sailboats. Polyester is ideal because it's strong, resists decay, and it doesn't stretch easily. Polyester line is a trusted go-to for typical day-sailing activities.

Polyester has a few disadvantages. For one, it absorbs water readily and breaks more easily than high-strength lines. It's fine for most leisure sailing activities, but better alternatives exist for serious cruising.

Aramid (Kevlar) Sheet Line

Aramid (Kevlar) line is a high-strength alternative to polyester, and it's ideal for marine applications, including sailboat sheets. Kevlar line consists of tightly woven strands of ultra-strong aramid fiber, which is highly resistant to heat, weather, stretching and fraying. Aramid line is trusted onboard serious cruising sailboats all over the world.

Kevlar is stronger than polyester, sheds water better, and stretches less. But strength comes at a cost—kevlar lines aren't as flexible as polyester, and they tend to become brittle when exposed to the sun for too long.

HMPE Sheet Line

HMPE (High Modulus Synthetic Fiber) is a space-age material that solves most of the problems caused by polyester and aramid sheet lines. HMPE is a premium woven fiber material that is (quite literally) one of the strongest synthetic fibers available to sailors. It doesn't stretch, and it's highly resistant to weather and wear.

HMPE is the material of choice for competitive sailboats and blue water vessels. The primary downside of HMPE lines is cost, as this fiber is quite expensive when compared to relatively affordable aramid and dirt-cheap polyester.

Related Articles

I've personally had thousands of questions about sailing and sailboats over the years. As I learn and experience sailing, and the community, I share the answers that work and make sense to me, here on Life of Sailing.

by this author

Sailboat Parts

Learn About Sailboats

Most Recent

What Does "Sailing By The Lee" Mean?

October 3, 2023

The Best Sailing Schools And Programs: Reviews & Ratings

September 26, 2023

Important Legal Info

Lifeofsailing.com is a participant in the Amazon Services LLC Associates Program, an affiliate advertising program designed to provide a means for sites to earn advertising fees by advertising and linking to Amazon. This site also participates in other affiliate programs and is compensated for referring traffic and business to these companies.

Similar Posts

Affordable Sailboats You Can Build at Home

September 13, 2023

Best Small Sailboat Ornaments

September 12, 2023

Discover the Magic of Hydrofoil Sailboats

December 11, 2023

Popular Posts

Best Liveaboard Catamaran Sailboats

December 28, 2023

Can a Novice Sail Around the World?

Elizabeth O'Malley

4 Best Electric Outboard Motors

How Long Did It Take The Vikings To Sail To England?

10 Best Sailboat Brands (And Why)

December 20, 2023

7 Best Places To Liveaboard A Sailboat

Get the best sailing content.

Top Rated Posts

Lifeofsailing.com is a participant in the Amazon Services LLC Associates Program, an affiliate advertising program designed to provide a means for sites to earn advertising fees by advertising and linking to Amazon. This site also participates in other affiliate programs and is compensated for referring traffic and business to these companies. (866) 342-SAIL

© 2024 Life of Sailing Email: [email protected] Address: 11816 Inwood Rd #3024 Dallas, TX 75244 Disclaimer Privacy Policy

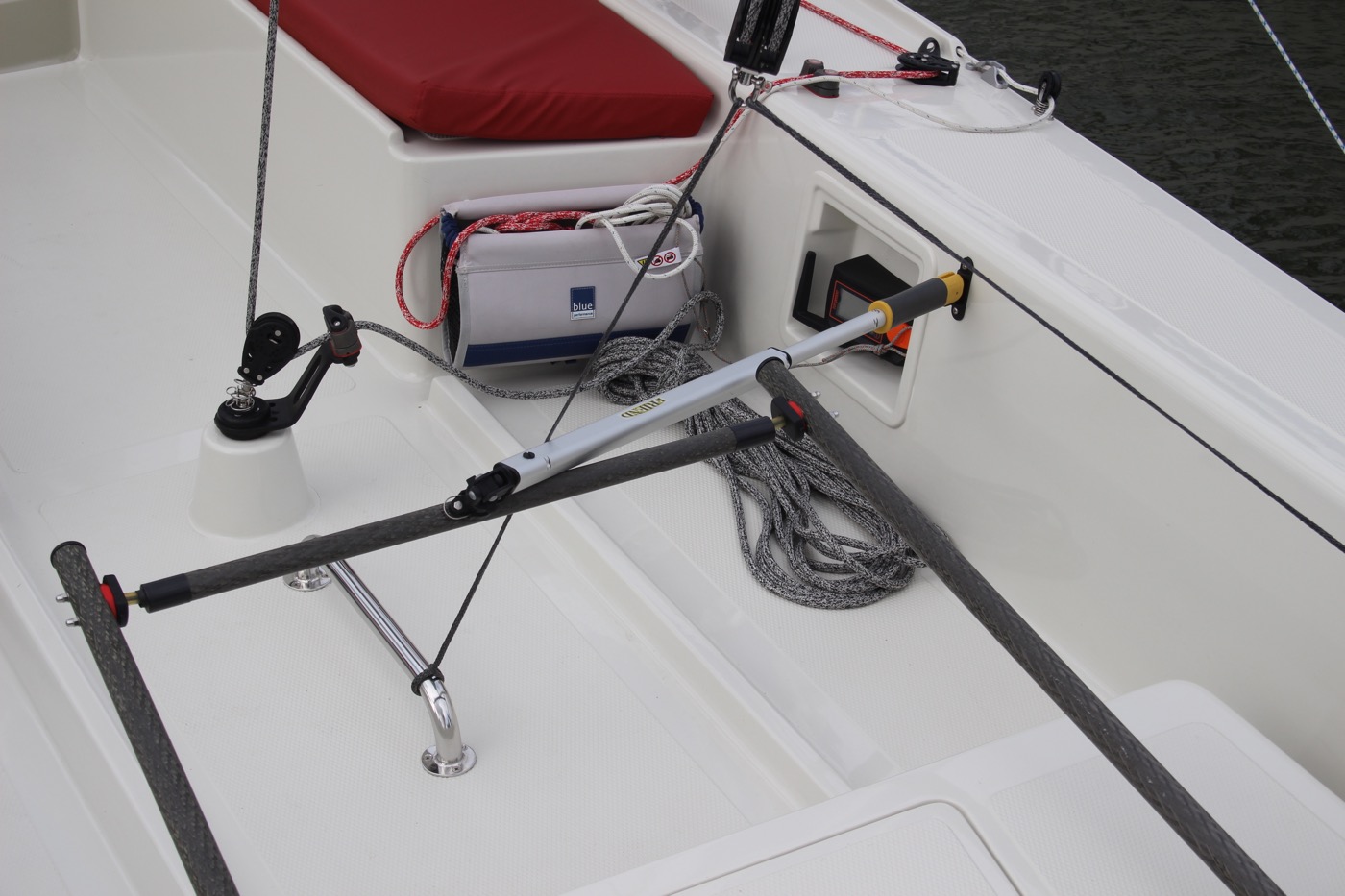

Mainsheet Management Tips

Does your mainsheet get knotted up at the most inconvenient time? Do you find it difficult to keep your boom out while going downwind? Do your feet get tangled up in your mainsheet while you are trying to tack? Here are some ideas that might help.

Mainsheet selection

First, repurpose or throw away your old, fuzzy, heavy mainsheet. Replace it with either a 6- or 7-millimeter Rooster or equivalent mainsheet. The 6-millimeter Rooster yellow is used by most of the World Cup and Olympians in all conditions. It is perfect for light winds and will allow you to keep your boom out while going downwind in light winds. Heavier mainsheets tend to pull your boom in and make the sail collapse in lighter wind.

For heavier wind conditions, I like the 7-millimeter Rooster black because it puts less strain on my hands. Your mainsheet should be at least 44 feet long. DO NOT CUT IT SHORTER!

Mainsheet preparation and installation

Put your mainsheet in the washing machine and run it through a cycle or two to wash the shine off the mainsheet. This will make it less slippery and easier to grip. Al Sargent goes a few steps further and suggests, “When I first get a Rooster mainsheet, I like to wash it on extra hot to get out all the slippery coatings. Then I like to run it through sandpaper, maybe 100 grit, a few times so that it’s slightly fuzzy and thus easier to grip. This extends the wind range in which I can use the thinner, yellow 6mm Rooster mainsheet.” He also suggests tossing your mainsheet into the wash regularly to ensure that it’s free of salt or grime that can make it stiffer.

I like to put two figure-eight knots about a foot apart at the cockpit end of the mainsheet. The knots prevent the mainsheet from running out through the mainsheet block. Not having the mainsheet attached allows me to throw the trailing end of the mainsheet into the water and drag it behind the boat to remove twists. I can also adjust the second knot to shorten the mainsheet in very high winds to prevent me from accidently letting out too much mainsheet which can cause an immediate death roll. When the wind gets up beyond 15 knots, I generally move the second knot up the mainsheet so that there is at least 3 feet between the knots. When the wind is light, I move the knot back down the mainsheet so that there is about 1 foot between the knots.

As an alternative, some people like to attach their mainsheet to the stern end of their hiking strap. There are some advantages and disadvantages to this approach. I will leave it up to you which system you prefer.

In between races and/or at the beginning of each starting sequence, get all of the kinks and twists out of your mainsheet. Carefully stack your mainsheet slack into the back of your cockpit. By doing this you will at least have one time during the race when your mainsheet is perfectly organized.

You should be using your mainsheet to control your sail shape. This is a dynamic process. You are continually sheeting in and out, even if it is only an inch or two. Consequently, don’t cleat your mainsheet into the deck cleats. If fact, get rid of the deck cleats. The vast majority of the top sailors don’t use them at all.

Before you begin a tack, make sure that you free up an arm’s length of mainsheet and lay it on the deck or on your lap. This will ensure that you are not stepping on or getting tangled in the mainsheet during your tack. Even better, free up an arm’s length of mainsheet after every tack. This will ensure that you are always ready to tack at a moment’s notice.

Clearing the mainsheet after a tacking in a Laser ILCA dinghy

Windward Mark Rounding

Free up a couple of arm lengths of mainsheet and lay them on the deck as you approach the windward mark. As you make the turn, raise your sheet hand with sheet in it high above your head and then drive your hand with the sheet toward the mainsheet block and then let the rest of the mainsheet slide through your hand. Do not loose contact with the mainsheet.

Downwind sail trimming is also a dynamic process. You should be constantly trimming to find the precise by-the-lee angle that gives your sail the most power. This is constantly changing as your boat speeds up or slows down and as you change your sailing angle to achieve best VMG.

Leeward Mark Rounding

This is where you mess up your mainsheet the most. As you round the leeward mark you need to sheet in just as fast as you possibly can at the appropriate moment. You can practice building your speed and managing where your mainsheet lands in the cockpit on dry land in your boat with a partner. Start by sheeting in a fully extended sail and boom in slow motion to ensure that your hands and arms are moving correctly. Slowly build up your speed while maintaining correct form. With just a few days of practice you will increase your speed and improve your mainsheet management significantly.

Mainsheet Storage

When you put your boat away, don’t coil up and tie up your mainsheet. Or worse yet, don’t just pile it up into a tangled mess in your cockpit. Instead, lay it out flat on your deck from bow to stern and let it dry straight, with no kinks or knots. I maintain that if you let your mainsheet live most of its life straight, untwisted and untangled that it will be more likely to stay that way during a race. So far, I’ve had pretty good results with this approach.

If you have to coil up your mainsheet, Al Sargent and Tom Vollbrecht both recommend using a butterfly coil. This a technique that rock climbers use to coil up their ropes so they don’t have kinks: https://www.petzl.com/US/en/Sport/How-to-coil-the-rope-?ActivityName=Multi-pitch-climbing

Good luck and sail fast, UNTANGLED!

Paul has a Ph.D. in human performance technology. He works with the ISA coaches to analyze, break down and effectively teach the cutting-edge techniques of the world’s top Laser sailors to ISA clients using powerful instructional strategies and technologies.

3 Responses to “Mainsheet Management Tips”

August 15, 2020 at 4:36 pm , Dejan said:

Hi Paul, happy to read your article because it gave a lot advice for problems I meet in “daily life”.

Can you be so kind to clarify: I like to put two figure-eight knots about a foot apart at the cockpit end of the mainsheet. Are those two knuts beside each other or?

Thanks for nice assistance in La Cruz

Best regards Dejan

August 17, 2020 at 10:42 am , Al Sargent said:

Thanks for the post! Some other ideas for mainsheet management:

1) When you do have to coil up your mainsheet, use a butterfly coil. This a technique that rock climbers use to coil up their ropes so they don’t have kinks: https://www.petzl.com/US/en/Sport/How-to-coil-the-rope-?ActivityName=Multi-pitch-climbing

2) When I first get a Rooster mainsheet, I like to wash it on extra hot to get out all the slippery coatings. Then I like to run it through sandpaper, maybe 100 grit, a few times so that it’s slightly fuzzy and thus easier to grip. This extends the wind range in which I can use the thinner, yellow 6mm Rooster mainsheet.

3) Toss your mainsheet into the wash regularly to ensure that it’s free of salt or grime that can make it stiffer.

Hope this helps.

November 05, 2020 at 5:48 am , Tad Gruchalla-Wesierski said:

Good article Paul! I’ve also been told that on tacking it’s good to have the mainsheet at the back of the cockpit but threaded between your legs. That way when you change sides on a tack it stays between your legs. When I’ve tried this I end up getting my feet caught in the bag of snakes. In fact my feet are prone to getting caught like that no matter what I do. So I try to stack the mainsheet at the front of the cockpit so it is clear of my feet on tacking. On windward mark roundings I sometimes get it knotted up which leads to a bad rounding as you might suppose. Any thoughts?

Leave a Reply

You must be logged in to post a comment.

Send Us a Quick Message

We're not online to chat, but send us a message below, or use our booking form to reserve your spot now.

- LEARN ONLINE

- Virtual Coaching

- Clinic Dates

Yachting Monthly

- Digital edition

Easy ways to power up your mainsheet

- Duncan Kent

- May 7, 2021

The mainsheet is the most worked item of deck gear, so it's vital to choose the right system and set it up correctly for your boat

Making tweaks to your mainsheet system can prevent breakages and wear to fittings. Credit: Graham Snook

New production yachts often come with systems that have been designed more for convenience while moored than with a sensible engineering solution in mind, resulting in significant loads placed on the boom, kicker, boom-end fittings, mainsheet tackle and crew.

Duncan Kent is a technical writer for marine publications and websites

Making a few tweaks to how your mainsheet system is set up makes handling easier for you and prevents breakages and wear to your fittings.

Keeping complex sail control mechanisms away from vulnerable areas of the boat is paramount, which is why cruising boatbuilders often position the mainsheet up on the coachroof ahead of the main hatch garage.

Though this effectively keeps it ‘out of the way’, it’s often not ideal from an engineering point of view in that it invariably means the mainsheet is attached halfway along the boom, when best mechanical advantage is offered at the aft end.

When connected further forward on the boom, the load on the mainsheet is greatly increased, so too the amount of human effort required to operate it.

If it really must be on the coachroof, then it should be mounted directly under the first leech reefing point, giving you the same mechanical advantage when the wind is up and you’re reefed .

Mainsheet blocks

The key to any sail control system is to keep friction to a minimum, which means the dimensions of the blocks, sheaves and lines are all important, as well as the type of bearings they have.

In principle, you should choose a sheave diameter of at least six times the diameter of the sheet, within the safe working load of the system.

Upgrading the line to one with superior strength, such as Dyneema, and lower stretch can result in you being able to drop a couple of sizes in line diameter, reducing costs, effort and wear.

The type of bearing a block has makes an enormous difference to the friction in any high-load tackle.

Standard plain bearing models are strong, but hard to turn, whereas ball-race and roller types require far less effort.

However, though ball-race bearings reduce friction, they also reduce the working load capacity as Delrin balls (most common) can distort under load long before a plain metal bearing would.

For this reason, the more popular choice for larger yachts are blocks with roller bearings, that have the low-friction of the balls, but the load capacity of plain bearings.

Specialist Rutgerson supplies a range that’s even maintenance-free, thanks to clever ‘roll- links’ between the rollers that keep out dirt and salt.

Mechanical advantage

A 6:1 tackle theoretically reduces sheet loads to 1/6th, but in real terms it’s closer to a quarter due to the friction in the block bearings.

Upwind the average load on the mainsheet for a 35ft cruising yacht with the mainsheet attached at the boom end is said to be around 150kg in 16 knots of apparent wind.

This would result in an actual hand load of roughly 37kg (including friction) if you were to sheet her hard in at this point with a 6:1 tackle, dropping to a more manageable 15-20kg in 12 knots apparent wind.

Whilst it’s useful to have an idea of how these items are rated, most manufacturers will recommend which size line and block you should use for your set-up.

Overhead mainsheet tracks retain the mainsheet’s mechanical advantage while keeping the track out of the cockpit. Credit: Graham Snook/Yachting Monthly

You can make the main easier to sheet in by increasing the mechanical advantage via an additional purchase (more turning blocks) or, if possible, moving the attachment point further towards the end of the boom.

Remember, though, that the more parts a tackle has, the more line is required, which, when close-hauled, has to go somewhere in the cockpit!

Alternatively, you could use a two-speed, double-ended tackle such as Harken’s self-contained system.

Pulling on both lines sheets it in quickly but requires more effort, whereas pulling just on one line doubles the mechanical advantage, halving the effort needed.

This method uses far less line than a traditional multi- way block arrangement and doesn’t introduce dangerous ‘flying’ blocks where a ‘fine trim’ block is positioned halfway up the mainsheet – just about at head level when tacking.

A widespread problem with any mainsheet system that incorporates a cam cleat can be difficulty with releasing the sheet under load.

Many folk don’t realise that on almost all blocks with a cam cleat attached the lead angle can be adjusted to suit the set-up, which can make life a whole lot easier and avoid you having to use your foot on the sheet to release it.

Sit in the cockpit where you normally would when sailing upwind and check that the cam cleat is in line with or just above where your hands are.

Twist can also be a problem on multi-part mainsheets due to the natural twist in the line, often exacerbated by having two swivels or the line being incorrectly reeved.

The former is simply cured by ensuring there is only one swivel, which is attached to the traveller end so that the lead angle can be changed easily when changing tack.

Some blocks, such as those from Selden, have lockable swivels.

Continues below…

How to reef to sail safely through any weather

Pete Goss delivers his masterclass on when to reef, and explains why it is critical to keeping control of your…

Mainsail furling systems: an expert guide

Some sailors swear by mainsail furling systems, others swear at them. Graham Snook looks at way to keep your furling…

How to repair a sail – video guide

Knowing how to patch up a sail can get you home safely, extend your cruise and save you money. Rob…

Rope, rigging & deck gear: how to choose the right rope

Rope continues to develop every year. We take a look at the plethora of options on the market

Reeving is an art form in itself and is by no means obvious.

Very often a multi-part tackle is mis- reeved causing two parts of the sheet to chafe against each other creating friction and the whole set-up to end up twisted.

Correct reeving (if in doubt ask the supplier) eliminates crossed lines and ensures load is balanced evenly across all of the sheaves.

Finally, some mainsheet tackles have a ratchet sheave, although they don’t really help much on a cruising yacht.

They do relieve some sheet load, but a larger mainsheet tackle needs a quick- release jammer to be safe and the faceted V-grooved rope channel simply puts extra wear on the sheet.

Sail control: Getting the most from your mainsail

The traveller.

- The traveller is one of the most important aspects of mainsail trim, yet I have been on numerous yachts where the traveller has been ignored all its life. Not knowing its purpose, many owners leave it fixed permanently in the centre. On one boat I sailed it was even screwed down!

- The reason for having the mainsheet attached to a traveller on a track is to enable it to be used to control the position of the boom under sail. Letting the traveller run down the track ‘spills’ the wind in the mainsail and reduces heeling momentum instantly, without affecting the shape or trim of the mainsail itself. When the gust has gone through all you need do is haul it back up the track to put the power back on, knowing the sail will be set as before.

- If you have an old boat with spring- release locking pins on the traveller, I would advise you modify it or replace it with a purpose-made system. If this isn’t possible, then you’ll need to rely much more on the kicker (see above) for controlling the sail shape when sheeting in and out.

The mainsheet track

- The position of the track is also important. The closer to the mast the mainsheet is attached to the boom, the shorter the track needs to be (as the outboard end of the boom moves in a much wider arc than the inboard end). However, mounting it ahead of a spray hood makes it extremely difficult to adjust the position of the traveller in a hurry.

- Tracks that are mounted overhead on a gantry, like those on the Hunter Legend range of yachts offer something of a compromise. To my mind their good points – long track right across the boat, mainsheet attached at the end of the boom, tackle kept well clear of the cockpit – are somewhat negated by the need for another turning block in the traveller adjusters, increasing friction and making them harder to adjust quickly.

- It makes sense to have the mainsheet track within reach of the helmsman with the mainsheet tackle as close to vertical below the boom end as possible. In some cases, especially on smaller boats, this will mean the mainsheet track is in the cockpit and can restrict access when not sailing. It is possible to install a removable track mounted across the centre of the cockpit well, for example, but quickly detached in port or at anchor to free up the space for relaxing. UK deck gear specialist, Barton produces a range of these for yachts right up to 36ft LOA, complete with traveller adjustment blocks mounted on the end-stops.

- Sometimes (particularly on coachroof- mounted tracks) the track has been ‘contoured’ to suit the curved cabin top. I’d strongly recommend replacing it with a straight, flat piece of track. A curved track encourages the traveller to remain in the centre. If you force it to the end using a powerful adjuster tackle it will simply pull the boom down.

The kicker is almost as important as the sheet for controlling the mainsail. Credit: Graham Snook

- The kicker (aka vang) is almost as important as the sheet for controlling the mainsail but is often ignored. The kicker’s primary purpose is to keep the boom from rising up when the mainsheet is eased. It is especially vital if you have a single-point mainsheet fixing or a bridle, rather than a track and traveller, as the former allow the boom to lift as soon as the

- mainsheet is freed.

- Because of the extreme loads it has to undergo, the non-boom end of the kicker should ideally be attached to a reinforced pad eye on the deck or to a stout collar around the mast, rather than a simple, riveted mast fitting.

- A gas-sprung or hydraulic kicker enables you to do away with the topping lift as, when the kicker is released, the spring-loaded vang pushes the boom upwards. It’s sensible to put the main halyard on the boom end to act as a topping lift when leaving the boat to take the permanent load off the spring.

Safety first

- Mainsheet tackles, tracks and travellers, kickers and boom fittings are all subjected to massive loads in heavy conditions, but should the yacht undergo an accidental gybe these loads can increase tenfold. For this reason, it can pay dividends to fit a boom brake of sorts. These ‘adjustable preventers’ not only allow for more control during an intentional gybe, but also stop the boom crashing over and possibly taking the rig down in the event of an accidental gybe. There are several on the market, including the Scott Boomlock, Wichard’s Gyb’Easy, Walder Boombrake, which can really offer peace of mind, particularly when sailing dead downwind.

Leech control

Leach control is important for gust response, adapting to conditions and preventing excessive heel. Credit: Graham Snook

Jeremy White of Elvstrom Sails shares his tips

- Traditionally you’re taught to pull in the mainsheet until you get the desired amount of twist (and so power in the sail), then take the slack out of the kicker, which will lock in that twist setting.

- The problem with mainsheet systems located forward on the boom, is you can’t get the leech tension you need. In this situation you’re forced to use the kicker alone to shape the leech. It is rare you are able to get as much tension via the kicker as you are via the mainsheet without using a winch and when cruising few of us are likely to do this.

- That is not to say it is always a negative outcome. The bonus to plenty of mechanical advantage is that when you ease the main, the leech remains tight which, in turn, gives more finite control. However, I often think the twist that develops in a mainsail when easing a mainsheet with less load in the kicker functions as a very effective safety valve. Racing sailors might want to have very specific control if someone is constantly trimming, but being able to lose a lot of power quickly by easing a small amount of sheet does have its appeal.

- If you are using your traveller then your leech will keep the same shape as you let the traveller down to depower in a gust anyway, so using this most of the time, there is no harm in being set up with less kicker than desirable as this will act as a macro adjustment in a really big gust.

Power up your purchase

- Consider an upgrade. Make sure your traveller is able to move easily while under load, and if possible can be adjusted from the helm. Consider upgrading your mainsheet track. Moving this to the cockpit will increase sail control and you can fit a removable track. At the same time, adding a purchase to adjust the traveller under load will also make sail adjustment much easier.

- Keep a clean sheet. Ensure your mainsheet system is free of twists, is correctly reeved and has the right rope and sheave sizes. Any unwanted friction in the system results in more effort for the crew, so make sure your mainsheet is reeved through the blocks correctly. You can also lock the top set of blocks so they can’t swivel, which will help keep the twists out.

- Here’s the kicker. Use your kicker. This is increasingly vital on those boats without a traveller or on those boats with a mainsheet system located mid-way down the boom. The kicker controls leech twist and gives you better control of power in gusty conditions and downwind.

- Increase the power . Move the adjustment point of the mainsheet further aft along the boom if possible, or add more purchase to your mainsheet system, or opt for a speed-sheet system to reduce sheeting loads. Consider adding more purchase to your kicker system too, to give you more control over the leech shape, though you may need to reinforce or change its mast attachment point. Adjust the angle of your cam cleat to make cleating and uncleating easier.

- Block busters. Get the blocks and cleats set up correctly to reduce friction and make it easier to use. Ratchet blocks are generally unnecessary on cruising boats and add friction, so get rid of these if you have them. Check the bearings of the blocks run freely under load – they may need replacing. Just washing the blocks out with fresh water and spraying with dry lubricant can work wonders with friction.

German mainsheets

German mainsheets that run to the end of the boom offer good control and minimise rope in the cockpit, but the sheet needs working. Credit: Graham Snook

The double-ended, or single-piece mainsheet has become known colloquially as the ‘German’ mainsheet.

Often the sheet will come back to a pair of primary winches, one either side of the cockpit.

With this system a crewmember can sit on the windward side with full access to the traveller and mainsheet winch.

It is a workable solution too for shorthanded sailing on dual-helm yachts, in that the helmsman can control the mainsheet from either helm.

A key disadvantage is that often you end up with all the sheet on one side, unless you constantly even out their use as you go.

To counter this, splicing the ends together makes a continuous loop, but this does make it harder to neatly coil and tidy away.

Increasingly these systems return to a cabin-top winch.

Though this does free up cockpit space, and means there is no mainsheet to catch an unwary crewmember in a gybe, it significantly reduces ease of use and accessibility significantly.

Enjoyed reading Easy ways to power up your mainsheet?

A subscription to Yachting Monthly magazine costs around 40% less than the cover price .

Print and digital editions are available through Magazines Direct – where you can also find the latest deals .

YM is packed with information to help you get the most from your time on the water.

- Take your seamanship to the next level with tips, advice and skills from our experts

- Impartial in-depth reviews of the latest yachts and equipment

- Cruising guides to help you reach those dream destinations

Follow us on Facebook , Twitter and Instagram.

By Product Categories

Small Boat Blocks

Big Boat Blocks

Complementary Hardware

Travelers & Genoa Leads

Mainsail Handling

Headsail Handling

Mooring Solutions

Spare Parts

Accessories

Harken Canvas

Fly Soft-Attach Blocks

Carbo Air Blocks

Small Boat Classic

Flip-Flop Small Boat

GP Catamaran Ceramic Mainsheet Systems

Protexit™ Exit Blocks

Through-Deck

Wire High-Strength

Dinghy Vang

Small Boat Deck Organizers

Midrange Classic

Midrange Deck Organizers

Zircon Blocks

Element Blocks

Black Magic Air Blocks

Cruising ESP Blocks

Megayacht Blocks

Stainless Steel Blocks

Black Magic Air Runners

FlatWinder Powered Blocks

Mastbase Blocks

Over-the-Top

Crossover Blocks

Big Boat Deck Organizers

Cam Cleats & Kits

Cam Cleat Accessories

Cam Cleat Bases

Stand-Up Bases

Deck Organizers

Spinnaker Pole Cars

Soft Attachments

Fixed Padeyes

Removable Padeyes

Bolt-Down Fairleads

Grand Prix Jib Leads

Halyard Tensioners

Tiller Extensions

Peter's Desk Drawer

Dinghy Jib Leads

Crossbow Pivoting Self-Tacking Jib Traveler

13 mm Micro

22 mm Small Boat

27 mm Midrange

32 mm Big Boat

Windward Sheeting

42 mm Mini-Maxi

T-Track Genoa Lead

Access Rail System

13 mm AA Battcar System

22 mm A Battcar System

27 mm B Battcar System

32 mm C Battcar System

18 mm Switch Battcar System

26 mm Switch Battcar System

26 mm Trysail Switch

32 mm Switch Battcar System

32 mm Trysail Switch

40 mm Switch Battcar System

40 mm Trysail Switch System

Furling Mainsail Outhaul Systems

Single Line Reefing

Harken Vang-Master

Carbo Racing Foil

Small Boat Furling

Small Boat Underdeck

Reflex Furling

MKIV Jib Reefing & Furling

MKIV Underdeck Jib Reefing & Furling

Furling Accessories

Powered Furling

MKIV Ocean Furling

SnubbAir (Not a Winch)

Grand Prix Winches

Air Winches

Circuit Breakers

Analog Switches

Digital System Switch

Aluminum, Chrome & Bronze Winch Handles

Carbo OneTouch Locking Winch Handle

Service Kits

CLR Mooring Winches

Electric Captive Reel Winches

Hydraulic Captive Reel Winches

UniPower Radial

Single-Acting Integral Backstay Adjuster

Single-Acting Cylinders

Locking Cylinders

Double-Pull Cylinders

Grand Prix Cylinders

Hydraulic Cylinder Rod End Blocks

Hydraulic Cylinder End Fittings

Control Valves

Control Manifolds

Control Panels

Compact Control Panel

Rotary Pumps

Hydraulic Pump Handles

Power Systems

Repair Kits

Ball Bearings

Block Spare Parts

Traveler Cars

Furling Spare Parts

Winch Spare Parts

Winch Service Kits

Blockheads Gear

Promo & Gifts

Marine Grip

harkengear.com

Jeep/Truck tops

Garage storage

One-design Covers

Boat accessories

Canvas bags

By Type of Sailing

Dinghy / One-Design

Offshore Racing

Coastal / Day Cruising

Bluewater Cruising

Megayachts / Custom

Service Guide

Tech/Service

deck layouts

Data Sheets (SDS)

How to choose

System diagrams

Calculators

Reeving diagrams

Traveler Purchase Selection Guide

How to Choose

Testimonials

Hoister Videos

Request a Quote

Request Samples

Fabric details

Cover Styles

Canvas Videos

Contract Services

Materials and Components

Our Equipment

Contract Cut-and-Sew Project Spotlight

- Harken at the front

- Safety & Rescue

Support / Selection tools / System diagrams

Mainsheet Systems

Mainsheets are simple hardware systems, but are among the most important as they are in almost constant use.

Typical boat length: Small Boat: 22' - 28' (6.7 - 8.5 m) Midrange: 29' - 34' (8.8 - 10.4 m) Big Boat: 35' - 42' (10.7 - 12.8 m)

This 4:1 tackle is the most common system on boats under 8.5 m (28 ft).

6:1 Reeved Right Angle

Boats with mainsails to 35 m² (375 ft²) often use a 6:1 system.

8:1 Beachcat

This 8:1 purchase handles high mainsheet loads on Beachcats up to 6 m (20 ft).

4:1 Swivel Base

Position the swivel base block off the traveler car to allow mainsail adjustment without dragging the car to windward in light air. To avoid tightening the leech, curve the track ends up.

4:1/16:1 Gross/Fine

This powerful gross-trim/fine-tune cascading system allows crew to use the 4:1 gross-trim for most trimming and the 16:1 fine-tune for precise adjustments.

4:1/16:1 Double-ended Fine Tune

This 4:1/16:1 system uses a dinghy-like double-ended tackle that locates the sheet ends on the cockpit sides.

6:1/24:1 Gross/Fine

This 6:1/24:1 cascading system is used on boats with end-boom sheeting and mains as large as 25.5 m² (275 ft²) and end-boom sheeting.

6:1/24:1 Cascaded

This 6:1/24:1 system is used on boats with mains as large as 25.5 m² (275 ft²) and end-boom sheeting.

7:1/28:1 Gross/Fine

This gross trim/fine tune system is found on racing multihulls where it is desirable to split the gross trim from the fine tune. Placing the fine tune in the boom provides a very clean system that the trimmer can get a hold of and put his weight into it. The powerful cascading fine tune portion is used to haul the boom in that last little bit.

4:1 with Dedicated Winch

This system moves the traveler over the companionway to clean up the cockpit. A favorite on cruising boats.

5:1 with Dedicated Winch

This system is popular on cruising boats with cabintop travelers. The sheet leads forward to the gooseneck and then down and back to a winch on the aft edge of the cabintop.

2:1 with Dedicated Winches

This simple double-ended system lets the mainsheet run freely through the blocks which allows the traveler car to move easily. The trimmer makes sail adjustments from the high side.

Admiral's Cup 2:1 with Dedicated Winch

In this system, the traveler is independent of the mainsheet so it rolls freely. The sheet leads forward along the boom before it turns down and aft to winches. Used on race boats like the Farr® 40.

Farr is a registered trademark of Bruce K Farr.

3:1 with Dedicated Winch

Many large boats use this simple 3:1 system. A block on deck turns the sheet to a winch.

Product Categories

- United States

- New Zealand

- United Kingdom

- New Sailboats

- Sailboats 21-30ft

- Sailboats 31-35ft

- Sailboats 36-40ft

- Sailboats Over 40ft

- Sailboats Under 21feet

- used_sailboats

- Apps and Computer Programs

- Communications

- Fishfinders

- Handheld Electronics

- Plotters MFDS Rradar

- Wind, Speed & Depth Instruments

- Anchoring Mooring

- Running Rigging

- Sails Canvas

- Standing Rigging

- Diesel Engines

- Off Grid Energy

- Cleaning Waxing

- DIY Projects

- Repair, Tools & Materials

- Spare Parts

- Tools & Gadgets

- Cabin Comfort

- Ventilation

- Footwear Apparel

- Foul Weather Gear

- Mailport & PS Advisor

- Inside Practical Sailor Blog

- Activate My Web Access

- Reset Password

- Customer Service

- Free Newsletter

Ericson 34-2 Finds Sweet Spot

How to Sell Your Boat

Cal 2-46: A Venerable Lapworth Design Brought Up to Date

Rhumb Lines: Show Highlights from Annapolis

Solar Panels: Go Rigid If You have the Space…

Leaping Into Lithium

The Importance of Sea State in Weather Planning

Do-it-yourself Electrical System Survey and Inspection

When Should We Retire Dyneema Stays and Running Rigging?

Rethinking MOB Prevention

Top-notch Wind Indicators

The Everlasting Multihull Trampoline

What Your Boat and the Baltimore Super Container Ship May Have…

Check Your Shorepower System for Hidden Dangers

DIY survey of boat solar and wind turbine systems

What’s Involved in Setting Up a Lithium Battery System?

The Scraper-only Approach to Bottom Paint Removal

Can You Recoat Dyneema?

How to Handle the Head

The Day Sailor’s First-Aid Kit

Choosing and Securing Seat Cushions

Cockpit Drains on Race Boats

Re-sealing the Seams on Waterproof Fabrics

Safer Sailing: Add Leg Loops to Your Harness

Waxing and Polishing Your Boat

Reducing Engine Room Noise

Tricks and Tips to Forming Do-it-yourself Rigging Terminals

Marine Toilet Maintenance Tips

Learning to Live with Plastic Boat Bits

- Sails, Rigging & Deck Gear

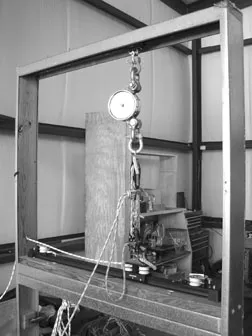

Midsize Mainsheet Traveler Test

Considerable evolution has taken place since our last traveler test. now, antal stands out for ergonomic design, functionality, and attention to detail, but lewmar is our choice due to its pricing..

A dozen years ago, in the July 1993 issue, PS reported on mainsheet traveler systems. Though we’ve kept up with developments in this realm during the interim, we haven’t offered a comprehensive evaluation of these important sailhandling systems since then. The time has come.

Properly installed and functioning mainsheet travelers are versatile devices, offering sailors a number of key advantages over simple mainsheet rigs traditionally used aboard sailing craft. These newer systems permit you to sheet to windward in light air to enhance your vessel’s pointing ability; they allow you to depower the sail in puffy conditions without touching the mainsheet; and they enable the mainsheet to be substituted for a vang when sailing upwind.

In that earlier article, we listed four reasons why mainsheet traveler systems are so appealing: “almost frictionless cars,” “modular system components that let you lead the mainsheet and control lines in virtually any configuration,” “installation so simple even a child can do it,” and, “almost unbelievably low prices.” Those observations also apply to today’s mainsheet travelers, and equipment evolution in the intervening years has rendered the bulk of these products even more efficient.

What We Tested PS gathered products from five of the six companies most recognized for fabricating or selling this kind of sailhandling equipment for midsized boats in the U.S.—Antal Marine (represented in the U.S. by Euro Marine Trading), Harken Yacht Equipment, Lewmar, Ronstan, and Schaefer Marine. The sixth, Garhauer Marine, opted not to send us a traveler because the company is in the process of introducing a new system that wasn’t available in time for our test. (We’ll evaluate that in a future issue.) Two other companies were considered—Frederiksen (now part Ronstan), which did send a car and track for a smaller size boat, and Rutgerson, of Sweden, which wasn’t able to provide products in time for our test. (We’ll also examine that later.)

From each company we requested a section of track, a car appropriate for that track on a sailboat 34 to 36 feet LOA, and equipment for a 4:1 control line. The track, we told them, should be four feet long and would have to span a 28-inch opening (as in a cockpit footwell or companionway application), unsupported. We will note here that those travelers set forward for mid-boom or three-quarter-boom mainsheet arrangements are thought to be subjected to greater loads than those set up for boom-end sheeting. Each of the manufacturers whose products we tested offer guidelines for various applications, including working load limits, and buyers should take care to purchase a system rated for their intended application.

Test Methodology For this test, instead of fitting our specimens to an actual boat, we built a jig to evaluate several parameters. We initially wanted to quantify how much force would be required to move the car along its track if the attached 4:1 mainsheet were under a 400-lb. load. We also wanted to know how much each manufacturer’s track would flex in this application. We also closely examined each unit with the following areas in mind: electrical isolation, sliding smoothness, track strength, flexibility of mounting, car control, mainsheet block attachment and support, center of effort angle (see sidebar), instructions, form and fit, and cost.

Each traveler system was secured to a 2 x 6 board on our jig using four points of attachment. We used a varying array of fasteners as required by the design of the track (some require countersunk machine screws and some hex-head bolts).

For our initial experiments regarding side force, we mounted a spare track and traveler car at the top of our jig and attached a Dillon dynamometer to it. The mainsheet purchase from the car and track under test was led up to the dynamometer. We put the mainsheet under a load of 400 lbs. and led the 1:1 traveler control line outside the jig via a hole bored in its side to a spring scale (see photo at right). Then, by way of repeated pulls, we quantified the force necessary to pull the car along the track. We learned early on that the force required, given this configuration, was almost inconsequential. In most instances it didn’t exceed 12 lbs. to start the car rolling, and once rolling, the force required to pull it was much less than that. This, we surmised, is a testament to the engineered efficiency of the bearing systems used in these travelers.

Then, using the dynamometer, we led the mainsheet to a point 16 feet above the traveler and forward by about three feet. This, we felt, would simulate the force vector, (but not the exact force) exerted on a traveler car with the mainsail let out on a close reach, essentially introducing a torsional component to the load. We then resumed our pull tests using the spring scale and learned that for all but one of the units we tested, there was little difference in the force required to move the car along the track.

To gauge track deflection under load, we led the mainsheet to a fixed point on the upper support of the jig, and using the dynamometer to measure, we again applied 400 lbs. of upward force with the purchase system. Using digital calipers, we gauged the deflection, first measuring the position of the tracks when unloaded and then when under load.

As a final evaluation, we attempted to determine smoothness by sliding each car back and forth on its track by hand through multiple cycles. Using this method we determined a ranking for that car and track assembly that seemed most smooth, and judged all others against it. This aspect of our test relates more to elegance of design than function, but a product that works more fluidly is likely to function well for a longer period of time than one that’s susceptible to binding or increased friction.

What We Tested Antal Marine’s 4113 traveler car ($652 including toggle) is milled from aluminum that is hardcoat anodized. The 4510 track ($140) is anodized as well. The system is rated for boats up to 36 feet LOA. Interestingly, we noted that this car represented the lone product in our test that is assembled with its aluminum parts isolated from its stainless parts by way of nylon bushings or washers. Galvanic corrosion with these products can occur when the anodized layer is compromised (through scratching, or cracking, which might be brought about by over-tightening a stainless fastener). This is a small, but important aspect, indicative of Antal’s attention to detail.

This car is also the only one in our test that utilizes two races of ball bearings to resist friction along the track. The lower layer bearings are Torlon balls, where the highest loading exists. The top bearings are Delrin. The car rides along the track with the bearings making contact with the track in two grooves. The lower groove with the Torlon balls sustains the upward forces, while the top groove with the Delrin bearings comes into play with side or torsional loads. This car prevailed in our smoothness test, principally because the second layer of bearings allows it to roll with minimal friction when under a torsional load. An additional feature we like is the fact that the car’s end caps are engineered in such a way as to keep the car on the track should the ball bearings fail.

The company engineers the system with an access port on each side of the car so that the bearings can be removed from the races and replaced simply by backing out a stainless Philips head machine screw. Three cars in our test allow the user to remove the bearings without taking the car off the track, and this one is the easiest. We think that facilitating this operation will promote better maintenance over time.

The toggle attaching the mainsheet block is fashioned from a bent stainless steel plate that surrounds a thick phenolic rubber bushing, which controls and buffers the fore and aft movement of the support. This toggle plate is connected to the car by way of a 7/16″ stainless steel pin. The car was fitted with double blocks for the control line (4740 $147 each).

Antal offers either plunger stops for this system, or 1:1, 2:1, 3:1 or 4:1 stackable control sheaves. Additionally, cam cleats can be mounted either at the track ends, or on the car carriage itself. The 4250 control sheaves ($184 each) Antal supplied are milled from aluminum and hardcoat anodized. They mount on a rectangular channel that fits over the track and has a soft but resilient urethane pad (4280 $11 each) to cushion the impact between car and end piece. On top is a broad aluminum plate with holes bored in it for the servo cam cleat (4410 $77 each) to be positioned at one of three angles. The only drawback of this assembly is that the channel piece has two lengths of stainless steel threaded rod set in it for securing to the boat, but these can’t easily be removed.

In our tests, the Antal track experienced the greatest deflection, but we acknowledge that it’s not meant to run unsupported across any expanse, and should be fastened every four inches via the pre-drilled holes. Euro Marine Trading told us the track should be installed with a support member like a stout section of teak to aid it in spanning any space.

Euro Marine Trading didn’t send any instructions with its traveler system because the company doesn’t ordinarily sell direct to the end user, but usually supplies its travelers to riggers for installation. Nonetheless, there’s nothing complicated about installing this system except that the cars are shipped on a short piece of loading track and installers must be careful to slide them onto the track without losing the bearings, because they are not captive. This system, with all its parts, can be purchased whole for $900.

Harken Yacht Equipment in Pewaukee, WI, offered its 1618 high beam track ($108) with a 1627 car and toggle ($196.30), and 1633 double sheave control end fitting with cam cleat ($265 each). These parts are rated for use on boats up to 34 feet. The track, car, and end fittings are all milled from aluminum that is thereafter hardcoat anodized. The track comes with eight rectangular washers (Harken calls them “bolt slides”) intended to fit over 1/4″ mounting bolts and slide into a channel in the bottom of the track (see photo pg. 14). The advantage of this approach is that the fasteners can be placed wherever it’s most convenient and appropriate, but Harken recommends spacing them no less than 4″ apart, with two on either side close to where the span begins.

The car rides along the track on recirculating Torlon ball bearings that are held captive by twin stainless steel clips so that the car may be removed from the track without worrying about the balls dropping out. The clips are made from 17-7 stainless that is heat-treated to improve strength. Having captive ball bearings is a handy feature for installation and we think it would enhance maintenance as well. With the car removed from the track, the bearings can be snapped out of the races one at a time if they require replacement, and new ones snapped back in. Harken’s car is the only one among those we tested that is engineered in this way.

To achieve the least friction, the Torlon balls bear on grooves in either side of the track. Harken’s advertising touts the car’s low-profile design, which means that the pivot point of the toggle attachment isn’t far above the surface of the track where the bearings sit. In fact, Harken’s car has the lowest center of effort angle (see sidebar) of all those PS tested, which means that it has a very efficient load transfer under side loading. This takes place when the boom is anywhere off centerline.

Though Harken’s car has end caps that will tend to keep it on the track should the bearings fail, these are not as large or as close-fitting as those on the Antal and Lewmar cars.

The 1627 car is fitted with a stout, stainless steel toggle to both support and connect the mainsheet blocks. This toggle is investment cast from stainless rather than bent out of a plate, but not unlike the Antal toggle, it surrounds a durable urethane support bushing that also limits and buffers the fore and aft travel of the toggle. The toggle has “ears” on either side which are formed to accept stainless steel clevis pins where control blocks (2638 $49.80 each) can be attached. Harken claims that attaching the controls to the toggle instead of the car reduces the loads on the car.

Harken’s 1618 track experienced the least deflection of all the ones tested, though it was essentially in line with that measured on Lewmar and Schaefer’s tracks. This track lacks the holes that would enable it to be fitted with pin-stop controls, though the company does offer those for this size traveler. It also offers single or double sheave control ends fabricated from its patented Carbo material, or single or double sheave controls built of stainless sides. These control units sit on an anodized aluminum base and mount with a single screw fastened to the track, so there’s no need to bore additional holes in the boat.

Harken also accompanies its products with detailed diagramed illustrations that enable DIY owners to install the equipment without confusion. And Harken is one of two companies that also sells its traveler system in kit form (car, control blocks, and end fittings), minus the track. The system we tested lists for $933.90.

Lewmar is revising its mainsheet traveler systems, and the new system is described by the company as an amalgam of the old Ocean and Racing systems, which are still available. The company sent us its track 29162315 ($114) and 29432300 car ($212), fitted with two double control line sheaves 29172012 ($65), and two end fittings 29472836 ($129 each). Each end fitting consists of an anodized aluminum base with two nylon sheaves, a Ronstan cam cleat, and a cast stainless becket. All these parts are rated for use on boats up to 36 feet.

The car body and end fittings are milled from aluminum and thereafter hardcoat anodized. The track is extruded and mounts in the same way as Harken’s, with 3/8 hex-head bolts meant to slide into a channel in the bottom of the track. Lewmar specifies mounting the bolts on 4″ centers, with at least three mounted on either side of the span. The bolts are to be mounted with washers underneath their heads, and washers should also be set underneath the track for each bolt. No fasteners were supplied, but the equipment arrived with the car already on the track and the end fittings in place as well.

Measuring 3.43″ wide by 1.56″ tall by 8.25″ long, Lewmar’ car is the largest one we tested. It’s nonetheless a low-profile car, which utilizes recirculating Torlon ball bearings that ride in grooves on either side of the track. The body of the car is complemented by twin tubes that contain the ball bearings as they rotate back toward the track, and twin end caps, which can be removed to service the balls. These end caps are also milled from aluminum alloy. On top of the car, six holes are tapped to accept the bolts that thread through the control sheaves and affix them to the car. The outermost holes on either end of the car are fitted with stainless inserts so that galvanic corrosion will not seize the bolts over time. PS wondered why the other two holes hadn’t been treated in the same manner. Lewmar does coat the bolt ends with a synthetic lubricant before assembly as a protective measure against seizing. The control sheaves themselves are made of a hard nylon and turn on bushings rather than bearings.

The mainsheet attaches to the car by way of a stout stainless steel D shackle contained by a pin held captive inside the car. (Lewmar also offers a forged stainless steel toggle not unlike the one on the Harken car.) The shackle articulates fore and aft, and twin urethane pads attached to the car keep the shackle from banging into and damaging the aluminum.

Lewmar accessories include friction stops that can be used on this track, which are activated by a winch handle. However, most sailors would likely opt for traveler controls with multiple part purchases, and for that reason the company offers one or two-sheave control end fittings, either with or without cam cleats. These fittings mount to the track by way of stainless steel Allen-head bolts that thread through holes tapped into the end fitting and simply tighten on the top of the track to lock the fitting in place. Lewmar treats them with Loctite to ensure that they won’t release. These bolts also serve as the axle for the sheaves’ bushings and to lock the cam cleats in place. Collectively, these end fittings represent engineering that uses the fewest number of parts for a number of functions.

Lewmar also sells its traveler system in kit form, with three sizes offered to accommodate boats up to 44 feet. The kit includes a different car and end controls from the one we tested, and because it’s intended for retrofits, no track is included. The system we tested sells for $669.

Ronstan provided its RC 12204 Series 22 low-profile car ($140), along with its RC 1224 Series 22 high-profile track ($93), which is rated for boats up to 33 feet. The company also sent its 12284 end fittings ($95 each). These have a single sheave and no cam cleats. Ronstan does offer double-sheave fittings—the RC00411 control sheave ($54 each)— with the option of a stainless steel arm, fairlead, and cam cleats, RC00421 ($72 each). We used all of that to calculate the price shown in our chart.

This is the lone track that we tested which didn’t come with pre-drilled mounting holes. Ronstan has other tracks that are pre-drilled, but feels that spanning applications require a degree of customization regarding the location of the mounting holes, and thus leaves the drilling up to the installer. The lack of holes also enhances the strength of the track for spanning purposes. Having the flexibility to drill your own holes can be an advantage for custom installations, but because properly countersinking a hole and getting it in the right location requires care and the precision of a drill press, we feel Ronstan’s strategy will have limited appeal for DIY owners. Ronstan also manufactures a high-profile track (no. 1225) for spanning greater distances.

Ronstan’s car and end fittings are milled from aluminum alloy and then hardcoat anodized. Like the majority of its competitors, the car also operates on recirculating Torlon ball bearings. Alloy end caps are screwed to each end of the car with stainless fasteners. The company claims these can be removed to service the ball bearings without having to remove the car from the track, but it’s not easy to do. Though these end caps would also tend to keep the car on the track if the bearings were to fail, they aren’t as beefy as those on the Lewmar and Antal cars, nor do they fit as closely to the track as the ones on those cars.

This car had the lowest profile of all those we tested—at just 1.01 inches high—and is also the lightest one at 8.1 oz. Like most of the other cars in our test, it’s versatile in that any of several control line attachments can be made. On either side of the mainsheet attachment shackle are tapped holes where a single or double control block could be attached. The mainsheet is attached to the car by way of a stout stainless steel shackle that pivots on a pin inside the car. This shackle articulates fore and aft, but there is no provision to keep it from hitting the side of the car. However, Ronstan does offer a stand-up spring kit to resolve this issue.

Ronstan’s end fittings fit over the track, and are pre-drilled for countersunk fasteners. Mounted atop by way of stainless bolts and nuts are alloy sheaves that turn on Torlon ball bearings, all kept in place by stainless plates. The inboard end of the fittings have urethane knobs installed that protrude out to accept the impact of the car should it slide all the way to the end unimpeded.

The system we tested sells for $675.

Schaefer’s traveler system arrived fully assembled, complete with two 12′ sections of 3/8″ braided control line. We’ll state right up front that this system is overbuilt for our test due to the fact that it’s rated for boats up to 45 feet in boom-end applications (up to 42 feet for mid-boom applications). The 72-92 ball bearing car with double stacked Delrin sheaves ($471.75) that is the heart of this system, is rated for a safe working load of 3,750 lbs., almost 1,500 pounds more than the other beefiest car in our test. Admittedly, this system is an apple among oranges for comparison purposes, but Schaefer’s next size down is only suitable for boats up to 27 feet long.

Schaefer’s 42-84 track ($180.75) was also the beefiest in our test. Fashioned from extruded aluminum alloy that is hardcoat anodized, it measures 1.5″ high by 1.5″ wide, and a four foot section weighs 4 lbs., 12 oz. This track, which is treated with a Teflon coating to reduce friction and wear, deflected fractionally more than Harken or Lewmar’s tracks, which are both similar in size. Schaefer’s track has countersunk holes (for 1/4″ fasteners) on 4″ centers. It also came with two 74-91 track end stops ($20.35 each), a 74-83 double control with cam ($120.60) and a 74-84 double control with cam ($120.60). A 78-49 stand-up adapter to connect the mainsheet is optional ($76.25).

Schaefer’s car, which is milled from aluminum alloy that is also hardcoat anodized, is almost 5.5″ long and weighs 2 lbs. 8 oz., making it the true heavyweight of our test group. Three stainless steel wheels are affixed on either of its inside surfaces. These wheels, which rotate around stainless axles on stainless steel ball bearings, run along the upper and lower ledges of the track as the car moves. The mainsheet connects to the car by way of a stand-up, spring-loaded adapter through which a clevis pin is inserted. (This piece we didn’t request, thus didn’t test.) The mainsheet can also connect to that same clevis pin, which pierces holes bored in the apex of a stout triangular bracket that is bolted to the top of the car with three stainless bolts. The outermost of these same fasteners are used to support the sheaves on the car for the traveler control system. The body of the car is not engineered (as are the others we tested) to remain on the track in case the axles or bearings fail, but in over 20 years of making this design, Schaefer says there’s never been a failure.

For traveler controls, Schaefer offers a combination of options including a dead-end bail, a single sheave, or a double sheave. These are mounted on track ends that fit over the track and are fastened to it by way of stainless machine screws that are threaded into holes tapped into the track. The track ends provided to us for our test had no buffering system, so car and end fitting will meet metal-to-metal, which isn’t a desirable arrangement.

The control sheaves are made of Delrin. Sandwiched between stainless steel plates, they roll on Torlon ball bearings. The track end controls include similar options, with the sheave-cam combination pre-drilled, allowing three different cam positions.

Though we deemed Schaefer’s car and track system nearly bulletproof, it does have one limitation. Two factors affect torsional loading: the width of the track, and the height of the car’s center of effort, defined as the pivot point of the cars toggle or shackle. Schaefer has a wide track and the highest center of effort angle (see sidebar) in our test. This means that when the boom is off centerline with the force vector extending along the mainsheet being other than vertical, Schaefer’s traveler system will experience higher torsional loads than its competitors.

The Schaefer system we tested retails for $934.40. Add the stand-up adapter ($76.25), and it totals $1,010.65

Conclusions All of the products we evaluated appear to be well-engineered and suited to the task of controlling the mainsheet orientation on a mid-size sailboat. We found their overall functionality and load capacities to be more than acceptable, and didn’t discover any flaws in concept or workmanship. That said, several of the products stood out from the others due to their engineering. Schaefer Marine’s wheel-bearing car appears to take the old-school approach, eschewing ball bearings in horizontal races and beefing up the car material. At its narrowest, the aluminum car is nearly a third of an inch thick (.323″), and on the sides, where the wheels are affixed, it’s almost a half inch (.414″). From a visual perspective, its engineering seems almost crude alongside its competitors, but there’s a lot to be said for the reliability of a stout, simple device when you’re well offshore in big winds and waves. And Schaefer likes to point out that Torlon bearings do degrade over time, whereas stainless ones last much longer.