Form Stability in Yacht Designers: Hull Design

Window treatments: enhancing yacht interiors with elegant designs.

- Fluid Dynamics: Performance Optimization in Yacht Design

Insurance Coverage for Yacht Design: Nautical Financing

Hull design: insights for yacht designers, rig design: performance optimization for yacht designers, textile choices in yacht designers interior design: the essentials, exterior finishing: a guide for yacht designers in exterior design, keel design in yacht designers: performance optimization.

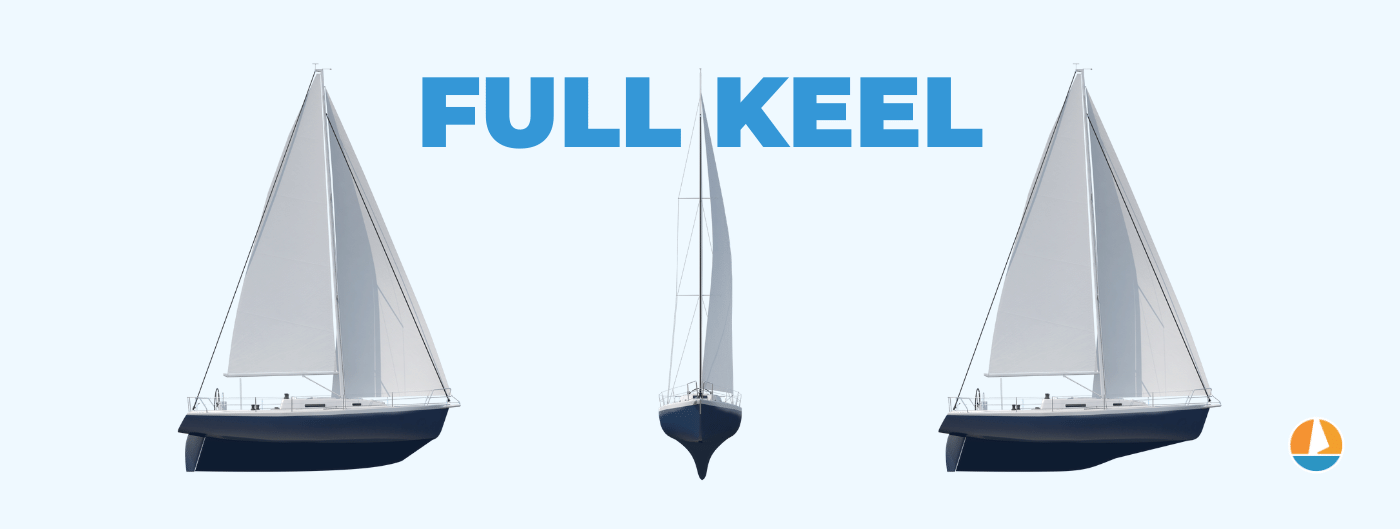

Keel design plays a crucial role in optimizing the performance of yachts. The shape and characteristics of the keel greatly influence a yacht’s stability, maneuverability, speed, and overall sailing capabilities. Through careful analysis and experimentation, yacht designers strive to develop innovative keel designs that enhance performance and ensure competitive advantages for their vessels. In this article, we will explore the significance of keel design in yacht performance optimization, focusing on its impact on various aspects such as hydrodynamics, aerodynamics, and structural integrity.

To illustrate the importance of keel design in enhancing performance, let us consider a hypothetical scenario involving two identical yachts competing in a prestigious offshore race. Yacht A is equipped with a traditional deep-draft fin keel commonly found in older designs, while Yacht B features a modern bulb-keel configuration. As they navigate through challenging wind conditions and varying sea states during the race, it becomes evident that Yacht B exhibits superior upwind performance compared to Yacht A. This advantage can be attributed to several factors influenced by the keel design, including reduced drag from the bulbous lead appendage below and improved righting moment due to better weight distribution along the hull. Such differences exemplify how keels significantly affect a yacht’s ability to sail efficiently and effectively in different conditions.

One of the key aspects influenced by keel design is hydrodynamics. The shape and profile of the keel determine how water flows around it, affecting drag and lift forces. A well-designed keel minimizes drag by reducing turbulence and creating a smooth flow of water along its surfaces. By reducing drag, the yacht can maintain higher speeds while expending less energy, resulting in improved performance.

Additionally, the keel plays a crucial role in generating lift, which helps to counteract heeling forces caused by wind pressure on the sails. Lift is generated as water flows over the curved surfaces of the keel, creating a force that opposes heeling and contributes to stability. A properly designed keel will maximize lift while minimizing induced drag, allowing the yacht to maintain a balanced and controlled sailing attitude.

Aerodynamics also come into play when considering keel design. The shape and position of the keel influence airflow around the yacht’s hull and rigging. A streamlined keel reduces wind resistance, allowing for smoother sailing and increased speed. Moreover, by optimizing the interaction between the keel and other components such as the mast and sails, designers can minimize turbulence caused by air passing over these structures.

Structural integrity is another critical consideration in keel design. The weight distribution of the keel affects how forces are distributed throughout the yacht’s hull. A well-balanced distribution ensures optimal stability and prevents excessive stress on certain areas of the boat. Furthermore, modern materials and construction techniques enable designers to create lighter yet stronger keels that enhance performance without compromising safety.

In conclusion, keel design plays a significant role in optimizing yacht performance across various domains such as hydrodynamics, aerodynamics, and structural integrity. Through careful analysis, experimentation, and innovation, designers strive to develop efficient and effective keels that deliver superior stability, maneuverability, speed, and overall sailing capabilities. By understanding the significance of keel design in yacht performance, sailors and designers can make informed decisions to achieve competitive advantages in the world of sailing.

The Importance of Keel Design in Yacht Performance

When it comes to yacht design, a crucial element that significantly impacts performance is the keel. The keel plays a vital role in maintaining stability and maneuverability on the water, making it an essential consideration for yacht designers. To illustrate its significance, let’s consider a hypothetical scenario where two identical yachts participate in a race. However, one has an optimized keel design while the other has a suboptimal one.

Firstly, an optimally designed keel contributes to improved sailing performance by enhancing stability. A well-designed keel provides sufficient resistance against lateral forces caused by wind or waves, preventing excessive heeling or rolling motions. In our hypothetical race scenario, the yacht with the optimized keel maintains better balance and stability compared to its counterpart with the suboptimal design. This advantage allows it to maintain higher speeds and more efficient sail trim throughout the race.

Secondly, the choice of keel design directly affects maneuverability during different sailing conditions. For instance, a racing yacht may require quick course changes or tight turns when navigating around buoys or avoiding obstacles. An intelligently designed keel can provide enhanced agility and responsiveness in such situations, allowing the yacht to change direction swiftly without losing momentum. On the other hand, a poorly designed or inadequate keel may hinder these maneuvers, reducing overall performance and competitiveness.

To further emphasize the importance of proper keel design in yacht performance optimization, consider the following emotional bullet points:

- Increased speed: An optimized keel design enables faster sailing speeds due to reduced drag.

- Enhanced safety: Appropriate weight distribution through effective keel design improves overall stability and reduces risks of capsizing.

- Improved comfort: Well-balanced yachts equipped with optimal keels offer smoother rides even in challenging sea conditions.

- Competitive edge: Yachts with superior keels have an advantage over their rivals in races by achieving higher speeds and maneuverability.

Additionally, let’s include a table that compares the characteristics of different keel designs:

In conclusion, the importance of keel design cannot be overstated when it comes to optimizing yacht performance. The hypothetical scenario and emotional bullet points presented highlight the significant impact an optimized keel can have on speed, safety, comfort, and competitiveness. In the subsequent section about “Factors to Consider in Keel Design,” we will explore key considerations that yacht designers must take into account to achieve optimal performance.

Factors to Consider in Keel Design

The Importance of Keel Design in Yacht Performance has been established, and now we turn our attention to the various factors that need to be considered during the design process. To illustrate these considerations, let us delve into a hypothetical case study involving two yacht designers who are tasked with optimizing the performance of their vessels through keel design.

When approaching keel design for optimal performance, designers must take into account several key factors. Firstly, hydrodynamic efficiency plays a crucial role in determining how well a yacht maneuvers through water. By carefully shaping the keel profile and considering its interaction with other components such as the hull and rudder, designers can achieve reduced drag and increased stability.

Secondly, weight distribution is another critical aspect to consider when designing a yacht’s keel. The position and size of the ballast within the keel greatly influence a vessel’s stability and ability to resist heeling forces caused by wind or waves. Achieving an ideal balance between weight distribution and overall boat trim ensures improved sailing characteristics, allowing for better control and handling.

Thirdly, sailors often encounter varying sea conditions while at sea. A well-designed keel should offer good seakeeping abilities by minimizing pitching motion and maintaining steady course-keeping even in rough waters. This not only enhances comfort on board but also contributes to safer navigation.

Lastly, it is essential to ensure structural integrity when designing a yacht’s keel. Factors such as material selection, construction techniques, and reinforcement play vital roles in ensuring durability under heavy loads and potential impacts from grounding or collision scenarios.

- Hydrodynamic efficiency: Optimizing shape for reduced drag.

- Weight distribution: Balancing ballast position for enhanced stability.

- Seakeeping abilities: Minimizing pitching motion for comfort at sea.

- Structural integrity: Ensuring strength against heavy loads or impacts.

Additionally, presenting information visually can evoke an emotional response and aid in understanding. Here is a table that highlights the different factors to consider:

With these considerations in mind, we can now transition into the subsequent section about “Different Types of Keels and Their Advantages.” By examining various keel types and their respective advantages, designers gain valuable insights into selecting the most suitable design for optimizing yacht performance.

Note: The information provided in this section is hypothetical and serves as an example to illustrate key considerations in keel design.

Different Types of Keels and Their Advantages

In the previous section, we explored the various factors that need to be taken into consideration when designing a keel for a yacht. Now, let’s delve deeper into the different types of keels and their advantages.

To better understand the practical implications of keel design choices, let us consider an example. Imagine a hypothetical scenario where two identical yachts are racing against each other. The only difference between them is their keel design – one has a fin keel while the other has a bulb keel.

When it comes to performance optimization, there are several key factors that designers must address:

- Stability: A well-designed keel provides stability by lowering the center of gravity and resisting heeling forces from wind or waves. This allows for smoother sailing and reduces the risk of capsizing.

- Balance: The placement and shape of the keel play a crucial role in achieving balance on a yacht. Proper balance ensures that the boat tracks straight without excessive weather helm or lee helm.

- Lift: Keels generate lift as water flows over them, countering leeway (sideways slipping) and contributing to upwind performance.

- Drag: While generating lift is important, minimizing drag is equally critical for optimal speed. An efficient keel design should minimize resistance through careful shaping and reducing turbulence.

Let’s now examine these factors in relation to different types of keels using the following table:

As seen in this table, both fin and bulb keels offer distinct advantages depending on specific requirements such as desired performance characteristics and sailing conditions. It is essential for yacht designers to carefully evaluate these factors in order to optimize the keel design for their specific vessel.

In the subsequent section, we will explore the role of keel design in stability and balance, further emphasizing the significance of this aspect in yacht design. By understanding how different keels impact a yacht’s performance, designers can make informed decisions that enhance both safety and speed on the water.

The Role of Keel Design in Stability and Balance

Having explored the different types of keels and their advantages, it is now important to understand the role that keel design plays in ensuring stability and balance. To illustrate this further, let us consider a hypothetical scenario where two yachts with different keel designs encounter rough sea conditions.

In this case study, Yacht A features a deep fin keel while Yacht B has a shoal draft keel. As they navigate through choppy waters, Yacht A’s deep fin keel provides greater resistance against sideways forces, resulting in improved lateral stability. On the other hand, Yacht B’s shoal draft keel offers reduced drag but compromises on lateral stability due to its shallower depth.

To better comprehend the significance of keel design in yacht stability, below are four key factors to consider:

- Weight Distribution: The placement of the keel influences how weight is distributed throughout the yacht. A well-designed keel ensures optimal weight distribution for enhanced stability.

- Center of Gravity: The position of the center of gravity relative to the waterline greatly affects a yacht’s overall balance. Keels play a crucial role in determining and maintaining an optimal center of gravity.

- Righting Moment: Keels contribute significantly to a yacht’s ability to resist heeling or tipping over. By increasing the righting moment, proper keel design improves overall safety during sailing.

- Performance Optimization: Different keel shapes and configurations can impact a yacht’s speed and maneuverability. Properly designed keels minimize drag and maximize performance potential.

- Enhanced Stability

- Increased Safety

- Improved Speed

- Optimal Weight Distribution

Table (3 columns x 4 rows):

Considering the significance of keel design in stability and balance, it is evident that a well-designed keel contributes to safer and more efficient sailing experiences. Understanding the impact of various factors such as weight distribution, center of gravity, righting moment, and performance optimization aids yacht designers in creating vessels that excel in challenging sea conditions.

As we have now explored the role of keel design in stability and balance, let us delve into how it affects maneuverability by examining different aspects of yacht control.

How Keel Design Affects Maneuverability

Transitioning from the previous section, which discussed the crucial role of keel design in ensuring stability and balance, we now delve into how different aspects of keel design can significantly affect a yacht’s maneuverability. To illustrate this impact, let us consider a hypothetical scenario where two yachts with distinct keel designs are subjected to challenging sailing conditions.

Imagine Yacht A equipped with a deep fin keel designed for improved performance in open water racing. This type of keel offers greater stability due to its lower center of gravity but may result in reduced maneuverability at slower speeds or when navigating narrow channels. On the other hand, envision Yacht B fitted with a shoal draft bulb keel specifically designed for coastal cruising. Although it sacrifices some initial stability compared to Yacht A, this design allows Yacht B to venture into shallower waters while maintaining better control during sharp turns.

The effect of various factors related to keel design on a yacht’s maneuverability is multifaceted and deserves attention. Consider the following bullet points that highlight these key considerations:

- Shape: Different types of keels such as full-length fins, winged bulbs, or bilge boards present varying degrees of lift and drag characteristics.

- Aspect Ratio: The ratio between the width (chord) and length (span) of a keel affects both lift generation capabilities and resistance experienced by the yacht.

- Leading Edge Configuration: Rounded or elliptical leading edges offer smoother flow around the keel, minimizing turbulence and enhancing directional stability.

- Appendages: Additional appendages like skegs or spade rudders play an integral role in improving overall control and responsiveness in conjunction with the main keel.

To further explore these aspects, refer to Table 1 below summarizing their impacts on maneuverability:

Table 1: Factors influencing yacht maneuverability.

Understanding how keel design affects a yacht’s maneuverability is critical for designers and sailors alike. By carefully considering these factors during the design process, optimal balance between stability, speed, and ease of handling can be achieved. In our subsequent section on “Innovations in Keel Design for Performance Enhancement,” we will explore advancements that aim to further improve maneuverability without compromising other essential aspects of yachting performance.

Innovations in Keel Design for Performance Enhancement

Understanding the impact of keel design on maneuverability is crucial for yacht designers seeking to optimize performance. Now, let’s delve into some innovative approaches that have been employed by designers to enhance the overall performance of sailing yachts.

To illustrate the potential benefits of these innovations, consider a case study involving a racing yacht competing in an oceanic regatta. This hypothetical scenario will highlight how certain advancements in keel design can significantly influence speed and stability, ultimately leading to improved performance outcomes.

One example of an innovation in keel design is the use of canting keels. These adjustable keels are capable of changing their orientation relative to the hull, allowing sailors to optimize their position based on varying wind conditions. By altering the angle or cant of the keel, sailors can counteract heeling forces and reduce drag, resulting in enhanced boat speed and maneuverability.

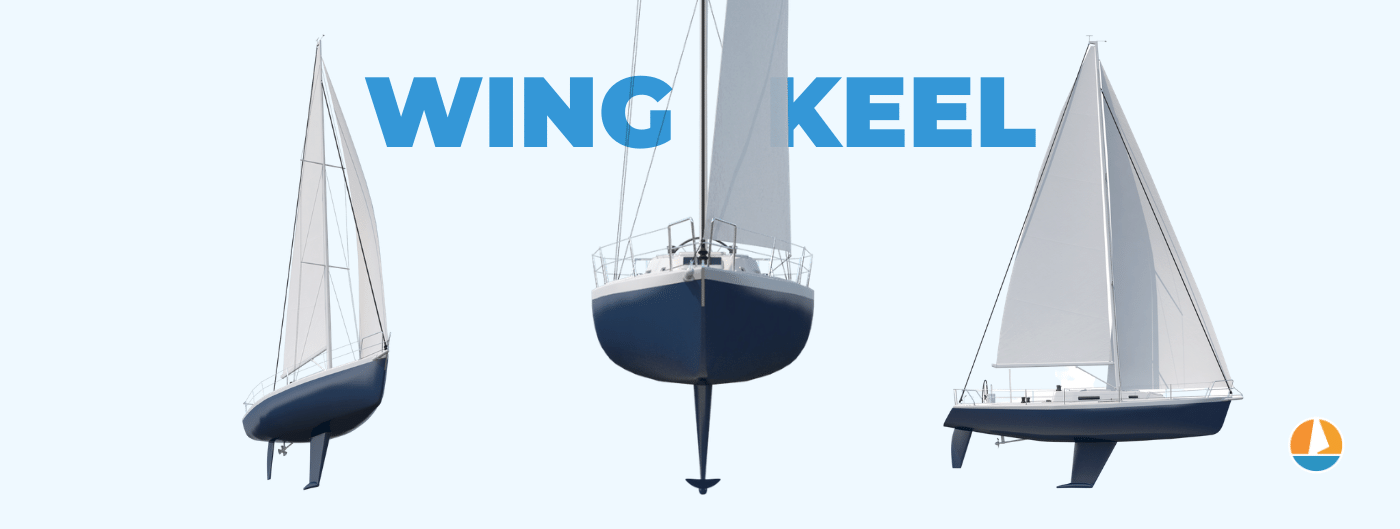

Another development worth mentioning is the advent of winged keels. With this innovative design approach, additional surface area is incorporated into the structure through specialized extensions attached at specific angles. The increased lift generated by these wings helps improve stability during maneuvers such as tacking and gybing, enabling more efficient changes in direction while minimizing energy loss.

In addition to these advancements, recent research has focused on optimizing bulb shape and weight distribution within modern yacht designs. Through computational fluid dynamics (CFD) analysis and extensive tank testing, naval architects have developed new bulb profiles that further minimize hydrodynamic resistance. Additionally, careful consideration is given to distributing weight effectively within the bulb itself, ensuring optimal balance between ballast and draft depth.

These developments reflect ongoing efforts within the field of yacht design to push the boundaries of performance optimization. By embracing innovative keel designs, designers can unlock new possibilities for speed, maneuverability, and stability on the water.

- Increased boat speed leading to a competitive advantage

- Enhanced maneuverability enabling precise navigation in challenging conditions

- Improved stability reducing the risk of capsizing

- Optimized balance between ballast and draft depth ensuring safety and efficiency

Table: Comparative Analysis of Keel Innovations

By continuously exploring these innovations in keel design, yacht designers are actively shaping the future of high-performance sailing yachts. This ongoing pursuit of enhanced performance demonstrates their commitment to pushing boundaries and achieving excellence on the water.

Related posts:

Performance optimization: yacht designers and beyond, sail design in yacht designers: performance optimization, previous marine engineering in yacht designers: materials and construction, next exterior design in yacht designers: a comprehensive exploration, victoria j. manzo, related posts.

Weight Optimization: Yacht Designers Performance Optimization

Suggested Posts

Performance: The Intricacies of Yacht Designers Hull Design

Nautical Financing for Yacht Designers: A Comprehensive Guide

Weight Distribution and Hull Design: Insights for Yacht Designers

More stories.

Loans for Yacht Building: Yacht Designers Guide to Nautical Financing

What are the pros and cons of different keels?

We all sail for different reasons, in different cruising grounds and use our yachts differently, so it makes sense that there is no one-size-fits-all keel design. At Sirius, however, we like to make the perfect yacht for each individual owner. One of the ways we serve our customers is our choice of keels – at least six different options for each model. It’s one of the ways we stand out – or should that be stand up?

We offer three styles of keel: fin, twin and lifting swing keel. All of our keels excel in many ways, but every design does have drawbacks – this is not unique to Sirius, but the keel affects the way you use the boat, so it’s important to choose the right one for you.

These are the keels we currently offer:

Standard Fin (310DS, 35DS, 40DS) Performance Fin (310DS, 35DS, 40DS) Medium Fin (310DS, 35DS, 40DS) Shallow Fin (310DS) Shallow Twin (310DS, 35DS, 40DS) Performance Twin (35DS, 40DS) Lifting Swing Keel (310DS, 35DS, 40DS)

Does the choice of keel compromise ocean capability?

For Sirius yachts, absolutely not. It’s important to realise that choosing one keel style over the other does not affect the yacht’s righting moment or compromise its ocean-going capabilities at all!

Whichever keel you choose, deep or shallow, twin or fin, they all have the same stability. This is achieved by putting more weight in the bulbs of the shallower keels as the shorter lever can be balanced with higher weight. Most of the blue water cruising and circumnavigations in Sirius Yachts have been made with twin-keel or reduced/shallow fin keel yachts.

Does keel choice affect performance?

As our shallow keels are heavier the weight dampens the yachts’ motion at sea, but as a downside, you have more weight to move with sails or engine. Once you’re moving there isn’t a difference but when tacking or gybing, or when not steered well, you will lose a bit in sailing performance. The shallower draught yachts also lose a few degrees to windward compared to their deeper keeled sisters, but they are still good all-round performers. Our customers with racing backgrounds always try to go for a keel as deep and light as their sailing area permits, either with a single or twin keel.

Pros and cons of fin keels

The standard keel on our yachts is a fin keel. Most sailing boats today use a fin keel because it gives a good all-round performance on all points of sail. By keeping the ballast lower it gives the most comfortable motion. The main downsides are that the draught (the depth of water required to stay afloat) is the greatest, and it’s very important to avoid running aground on a falling tide. Fin keel boats cannot dry out without additional support, either from a harbour wall or by fitting a pair of beaching legs. Some fin keel yachts are not built strongly enough to stand on their keels when out of the water, so they can’t dry out alongside a harbour wall and they need to be kept in a special cradle when stored ashore to avoid the risk of the hull deforming under its own weight. By contrast, all Sirius yachts can stand on their keels for any length of time with no problem at all.

We offer four types of fin keel. The standard fin is available on the 310DS, 35DS and 40DS and is fully cast-iron. It offers the best value, good performance, and excellent responsiveness. It is the deepest of our fixed-keel options, so if you want less draught you may want to look at our other fin keels.

We also offer a performance fin keel for all our models. This uses a cast iron fin with a lead bulb at the tip (bottom). The structural strength of cast iron means the fin is the slimmest profile, but lead is denser than iron so the same volume of lead will weigh around 1.4 times more than cast iron, giving more righting moment. The heavier, softer lead down low has less volume in the bulb so achieves a slimmer profile with less drag and therefore better performance.

A lead bulb is also safer if it hits something. Lead can absorb 60% of the energy in flexing and deformation so that only 40% of the force will be transferred to the laminated structure of the keel reinforcement. A lead bulb is very forgiving and easy to reshape and will not start to rust where the coating is damaged. We can use less volume of lead than iron, and achieve better stability than a wholly cast-iron keel. We can also reduce the depth of the keel and retain excellent stability. However, lead is more expensive than cast iron and the bulb must be attached very securely to the iron fin, so this option does cost more.

If you want less draught, we also offer a medium fin. This reduces the draught of the 310DS and 35DS by around 40cm/1ft 4in and 55cm/1ft 9in on the 40DS. Like the performance fin, it uses a cast iron fin with a lead bulb. To retain the keel’s grip in the water it has to have a longer chord (the distance from fore to aft). While this gives the boat better directional stability, it does make her a little less responsive and a little slower to manoeuvre.

On our 310DS, we offer a shallow fin option – a special version for very shallow cruising grounds. This fin keel offers the least draught of any of our fixed keel options at 1.15m/3ft 9in and draws 10cm/4in less than the twin keel version. The keel has a significantly longer chord (2.24m/7ft 4in compared to 0.7m/2ft 3in of the standard keel) so she has the reassuring directional stability of a long-keeled yacht but with better manoeuvrability.

Pros and cons of twin keels

Our twin keels are the most popular option. About 70-80% of all Sirius Yachts are delivered with them – and on the 40 DS it’s 90%. Some folk still believe there is a big performance penalty with twin keels. In the past this used to be true but it’s no longer the case with modern twin keel designs, from Sirius at least. We have conducted many two-boat comparison tests, often battling for hours, by ourselves, with owners, and for sailing magazines and we have found that there may only be one or two boat lengths of difference at the end of a long windward leg, if at all. At the end of many of these comparison tests, the crews could not point out which of the boats had the twin keel.

If you cruise tidal areas, twin keels will reward you time and time again. Not only do they give you a shallower draught than the typical fin keel, they also give you the ability to dry the yacht out, whether that’s for a motion-free night’s sleep, to explore cruising grounds others cannot reach, or just for cheaper mooring and maintenance costs.

We offer two styles of twin keels; performance and shallow draught. Both options have a cast iron fin with a lead bulb. The performance keels have a deeper draught and a thinner chord so they act and feel a bit livelier when sailing and manoeuvring. The shorter keels have a longer chord, but give you the ability to navigate shallower areas. Like all keel designs, twin keels do have some downsides. They are more expensive than fin keels, and when you’re sailing fast in choppy seas at a steep angle of heel, you can occasionally get a slapping sound when an air pocket is caught and pressed out under the windward fin. Lastly, we’ve yet to meet an owner who enjoys antifouling between the keels. Thankfully it only has to be done once a year and with twin keels you might get away with doing it less frequently. A twin keel yacht can be kept on a drying mooring, where fouling is reduced because the hull spends more time out of the water. And when you’re off cruising it’s easy to give the bottom a quick scrub while the yacht is dried out.

Our yachts will happily sit on their keels on a hard surface, like a drying grid, or for winter storage but on softer surfaces we use the rudder for additional support. The rudders on our twin keel yachts are specially reinforced for this: we use a Delrin sheave to take the weight of the hull and the tip of the rudder has a wide, foil-like foot to spread the weight.

A lifting swing keel

We are one of a few manufacturers to offer a lifting swing keel. There’s a lot of confusion with the term ‘lifting keel’, it seems to encompass all yachts that have centreboards, variable draught, lift-keels or swing keels. To us, a lifting keel boat should have all the ballasted weight of the boat in the keel, and that keel needs to be retracted into the hull.

Technically, a lifting keel is a keel that can be lifted or lowered and gives the boat the ability to dry out when the tide goes out. A lift-keel is a ballasted keel that raises and lowers vertically. A swing keel has a ballasted fin that has a single pivot point and the keel swings up into the boat. There are other variants of design, for example some have a lifting keel to reduce the draught of the vessel but they cannot dry out on it, others have a ballasted keel and ballasted grounding plate. All these examples have a keel that does two things: keep the boat upright and stop her sliding sideways. Our swing keel is designed with a NACA profile to give the most efficient performance.

Centreboard yachts have a centreplate to provide grip in the water and reduce leeway. The plate may carry only 15-20% of the ballast but the rest of the yacht’s ballast is within the hull and/or in the grounding plate. This is called an “integral keel” and is more common as it’s less complicated to build. The lower a yacht’s ballast is located, the better her stability, the more comfortable her motion and the better she stands up to her sail area. The most efficient place for the ballast is as low down on the deepest keel possible – this is why race boats have deep skinny keels with large torpedo-shaped bulbs on the bottom, but they don’t make practical cruising sailboats.

Our keel designs have more weight in the tip (bottom) – using a bulb on the fin and twin keel design and flaring the lower sections on our lifting swing keel yachts. You don’t have this with centreboard and integral keel yachts.

It might be surprising, but a lot of owners come to us thinking that a lifting swing keel is the best option for them. Sometimes it is, but about 98% of customers who approach us because we offer swing keels end up sailing away on a twin-keel Sirius.

The downsides of a lifting keel

A lifting swing keel does give you more cruising options. It will lift should you run into something and, of course, it gives you the shallowest draught. But that difference is only 40-50cm (1ft 4in to 1ft 8in) less draught than our shallow twin keel option. The lifting keel increases the complexity of the build and the final cost of the yacht; it also sometimes limits the internal layout and engine drive options, and you need to have twin rudders too. Twin rudders make the boat less manoeuvrable in a marina – you can opt for a third central rudder which does improve the handling, but again comes at an extra cost.

On the lifting swing keel, 40 and 310 owners are restricted to the use of a shaft drive, which is less efficient and you have to accept a bit more noise and vibration. When drying out, the drive is more vulnerable to damage, whereas it’s totally clear when taking the ground on twin keels. With twin keels, you also do not have to worry about something sticking out of the beach or stones lying around because the hull is high above the ground. With the hull up high, you do not have to dig a hole in the sand and slide down on your stomach to check or change your anodes as you would on a swing keel.

Sailors who are attracted to the idea of a lifting swing keel should carefully consider the pros and cons to compromise the least. When owners understand the repercussions of choosing a lifting keel yacht, many of them feel it restricts their options too much. They could have a lifting keel or they can sail with twin keels, dry out, have better close-quarters handling and save money in the process. Unless you need the shallowest possible draught – 0.75m (2ft 5in) on the 310DS, 0.9m (2ft 11in) on the 35DS or 0.95m (3ft 1in) on the 40DS – a twin keel might well be a better option.

How are the keels attached?

The design of the keel is important but the way they are attached is just as important, if not more so. All of our fixed keels are through-bolted. Every keel has a wide flange at the root (top) of the keel and the flange sits into a reinforced recess in the hull. The flange and the recess work together to spread the loads of the keel/s into the yacht’s hull. The keels are bonded and bolted to the hull. We use up to twelve 20mm and 24mm bolts (per keel) and these go through rolled stainless steel backing plates inside the hull to spread the bolt loads evenly into the fully laminated keel grid which goes all the way up to the chainplates and also carries the mast support.

For our lifting swing keel, we laminate a substantial keel box as part of the hull to accept the keel and the hydraulic mechanism needed to retract the keel into the hull. Unlike most other boatbuilders we don’t use a grounding plate to take the weight of the yacht, our yachts sit on the length of the leading edge of the keel. Integral keels with the majority of the ballast in the grounding plates move the ballast (weight) from low down in the keel to inside the hull. This negatively affects the stability as the more weight you have lower down, the better.

We also don’t like grounding plates because they bring the hull in contact with the ground. By leaving 10-15 cm (4-6in) of the keel out of the hull when it’s retracted, most of the time the hull is kept clear of the beach and anything that could damage it.

The problem with too much form stability

With only 15-12% of their ballast in the centreboard, most lifting-keel yachts cannot rely on keel weight for stability so their hulls need to be designed with extra form stability instead. This means the hull sections have to be much wider and flatter. A flat-bottomed hull is not what you want for a comfortable ocean cruising yacht; it isn’t sea-kindly or easy to steer in waves and gusty winds conditions. We don’t make that compromise at Sirius. With all the ballast in the swinging part of our swing keel design, we can use the same seaworthy, ocean-capable hull shape designed for our yachts with fixed keels.

If you don’t know which keel would be best for your Sirius, contact us to discuss the type of sailing you intend to do, where you want to sail and what your cruising aspirations are.

General Manager – Torsten Schmidt SIRIUS-WERFT GmbH Ascheberger Straße 68 24306 Plön/Holstein

Fax: 0049 – 4522 – 744 61-29

Receive regular updates from Sirius Yachts

Subscribe to our email newsletter

Privacy Overview

- Sails & Canvas

- Hull & Structure

- Maintenance

- Sailing Stories

- Sailing Tips

- Boat Reviews

- Book Reviews

- Boats for Sale

- Post a Boat for Sale

- The Dogwatch

- Subscriptions

- Back Issues

- Article Collections

- Free for Sailors

Select Page

Keel design: What’s best?

Posted by Ted Brewer | Boat Reviews

Ted Brewer reviews the ins and outs and ups and downs of keel design

The purpose of a keel, fin, or centerboard is to provide resistance to making leeway; in effect, to keep the yacht from sliding sideways through the water due to wind pressure on the sails. Various shapes of underwater plane have been in and out of style over the past 150 years.

The highly stylized shark fin has extreme rake and a sloping tip chord.

The basic full-keel shape had the longest run, as it was the standard for bluewater sailing craft from pre-Roman times to the earliest days of yachting. The deep, full keel was supplemented in the mid-1800s, for the shoalwater areas of Britain and North America, by centerboard craft. These cover such working types as the sharpies, Cape Cod catboats , and Chesapeake Bay oyster skiffs, to mention a few.

The first truly modern keel yacht, with a cutaway forefoot and highly raked rudder post, was designed by Capt. Nathanael Herreshoff with his Gloriana design of 1891. But it did not catch on for bluewater sailing. Until the late 1920s, the typical offshore yacht, whether cruiser or ocean racer, resembled a sailing fishing craft in the shape of its lateral plane: a long, full keel with deep forefoot and fairly vertical sternpost. Such a shape has the benefits of good directional stability, ease of steering, and the ability to heave to in heavy weather, all desirable traits for a boat. However, its faults may include slowness in stays, excess wetted surface making it slower in all types of air and an inefficient lateral plane shape that has excess leeway, considering its relatively large area. Typical small yachts of this type are seen today in the Colin Archer types and the Tahiti ketch and its copies, while replicas of traditional sailing craft such as Bristol Channel Cutters, Friendship sloops, fishing and pilot schooners, and similar lovely vessels still appear in our waters. Fortunately, many of these workboat types have been developed to the point where the ills of the true full keel have been greatly reduced. Then the result is a handsome cruiser that sails quite well and attracts a great deal of attention wherever she drops her hook.

Successful Sailboat Keel Types

The cutaway keel was revived for ocean racing by Olin Stephens in the late 1920s, with his lovely yawl, Dorade, still sailing and winning classic yacht races more than 70 years after her launching. Her offshore racing successes finally proved that the full keel was not essential to seaworthiness, and it definitely detracted from speed and weatherliness. As a result of its improved performance and handiness, the “modified full keel” form caught on quickly once Dorade showed the way and became the standard for the next 35 years. This type of lateral plane is still sailing in many popular older designs such as the Albergs, the Folkboat, the Luders 33, the Whitby 42, and even some newer yachts.

The modified full-keel form features generally good handling and directional stability plus reduced wetted surface, compared to her true full-keel sister. The yachts can perform well in all conditions and, as they are generally of heavier displacement than contemporary ballasted-fin boats, they do not give away much in light air, despite the added wetted area. A yacht with a modified full keel can sail right up with the best of them if she is given sail area commensurate with her typically heavier displacement.

In my own work, I developed a modified full keel, with the rudder set aft and vertically in the contemporary fashion, in order to improve directional stability and handiness. Then, to reduce wetted area, the lateral plane is substantially cut away ahead of the rudder in what some have termed “the Brewer bite.” The Cabot 36 and Quickstep 24 of my design were early examples of this form. The size of the cutout depends to a large degree on how insistent my client is on having a “full keel,” and I try to make the cutout as large as I can decently get away with. I don’t claim to have originated the shape, though, as the late L. Francis Herreshoff used a not dissimilar profile many years earlier in the design of the lovely 57-foot ketch, Bounty.

Taken to Extremes

Like all good things, the modified full keel was cut away more and more for bluewater and inshore racers in an attempt to reduce wetted area until, finally, some designers took it to extremes. This reduced directional stability and produced craft that were almost impossible to steer in breezy conditions, broaching with monotonous regularity. I can recall working on the design of many short-keel 5.5-Meter yachts in the 1960s, and we always said they were three-man boats with six-man spinnakers! It’s hard to believe none of them were knocked down and sunk, as they were extremely difficult to control on a reach or run, and the hulls were pure leadmines, with 3,500 pounds of ballast in their very short keel and only 1,000 pounds of wood and rig above it!

Olin Stephen’s genius began another fad in the mid 1950s, the keel-centerboard design. After Finisterre showed the way, keel-centerboard yawls were built in sizes from 24-foot midget ocean racers, to the largest offshore yachts, in order to take advantage of favorable ratings under the CCA rule and emulate Finisterre’s record of wins. The keel-centerboard hull has gone out of fashion now, but the type still has merit where a stable, beamy, shoal-draft yacht is desired with little sacrifice of weatherliness or seaworthiness. Indeed, the Bill Tripp-designed Block Island 40 and Bermuda 40 are keel-centerboard ocean racers from the old school and have been in production for more than 30 years now. These classic yachts have made many long ocean voyages, including several world circumnavigations and are first-class bluewater cruisers in every respect.

Keel Types Here to Stay

A rather squared-off fin, not unlike the Cal 40 keel.

The fin shape is not new either, as ballasted fin yachts were pioneered by Herreshoff at the turn of the century for inshore racing. Then, due to excesses and bad design, the shape died out, except for a few one-design classes, until Bill Lapworth dropped a bomb on the ocean-racing scene in the mid-1960s with his Cal 40 design. The Cal 40s made believers out of many yachtsmen who could not believe that a ballasted-fin/spade-rudder yacht was a serious bluewater ocean racer. After wins in the Trans-Pac, many East Coast races, and the 1966 Bermuda Race, it became evident that the fin was here to stay for ocean-going and coastal cruising yachts. Please note that I do not use the term “fin keel” anymore, as I feel it is a misnomer. The keel is the structural backbone of the vessel, and the fin hangs from it. Fish have both backbones and fins; so do yachts.

A less extreme fin keel, with a more parallel tip.

A well-designed fin, in conjunction with a skeg-hung rudder, can provide excellent directional stability, handiness, reduced wetted area and improved weatherliness. The fin/spade rudder combination reduces wetted surface even more. It may have a little (or a lot) more sensitive helm than a fin/skeg rudder yacht, but it has one big advantage over it and all other forms of lateral plane: it can be steered in reverse under power. This can make life a great deal easier in today’s crowded marinas, as many have discovered.

These are some of the reasons that we see fins on the great majority of our new yachts today; they are not simply a fad. There are good fins and bad fins, of course, and it is not always easy to tell them apart. The shape of fins over the years has been limited only by the designer’s imagination. Fins have been set at every angle from the vertical to highly raked aft. They have been deep and narrow, shoal and long, resembling a shark’s fin or whale’s tail, or boxy fins similar to the original Cal 40 design.

A contemporary bulb fin with winglets.

Major Problem

A very deep, narrow fin can be a problem to haul on a marine railway, so the cruising skipper should consider haulout ease when boat shopping. A crane or travel lift is the best method for hauling yachts with extreme fins, but may not always be available in out-of-the-way areas. There is also the danger of damage to the shaft or strut if slings are improperly positioned. Still, the major problem of the high-aspect-ratio fin is structural strength, as it can impose extreme loads at the point of attachment to the keel. Indeed, some years ago I was an “expert witness” in a court case concerning three men who drowned when their yacht sank as a result of its fin tearing off when the vessel ran aground.

The cruising skipper would do well to avoid yachts with extreme fins, both for considerations of haulout ease and structural strength. Fortunately, the heavier, deeper hull and generally shoaler draft of the typical cruising yacht mean there is less height available between the bottom of the hull and the point of maximum draft. So, a longer, lower-aspect-ratio fin is the only solution. On the other hand, the racing sailor will want a fin with an aspect ratio as high as the draft rule will allow. Such a fin is more efficient per square foot, so the area can be smaller and the wetted surface reduced. In Aero-Hydrodynamics of Sailing, C.A. Marchaj recommends about 4 percent of the sail area as a good guide for fin area, and I feel the cruiser should err on the high side, as a small increase in resistance is preferable to increased leeway. On the other hand, I have used as low as 1.75 percent area with good results on an extreme racer with a fin of 2.75 aspect ratio.

Sailboat Keel Aspect Ratios

This “aspect ratio” is the ratio of the span (depth) squared to the fin area; that is, my extreme fin had an 11-foot span and 44 square feet of area, so its aspect ratio was 121/44, or 2.75. If it had a 4-foot span with 44 square feet of area, not uncommon proportions for a cruising yacht, its aspect ratio would be 16/44, or a low 0.3636.

The aspect ratio can also be described as the span divided by the mean chord, the average fore-and-aft length of the fin, and this gives the same result.

A large part of the resistance of a keel is created by the vortices, similar to miniature whirlpools that form when the water flows across the bottom of the keel from the high-pressure (leeward) side to the low-pressure (windward) side. It requires energy to form those vortices and that energy is then not available to propel the boat forward. Obviously, the shorter the keel or fin tip, the smaller and weaker those vortices will be, and that translates to reduced resistance. This is one reason that racing yachts usually feature high-aspect-ratio fins with short tip chords.

However, the formation of vortices can be greatly reduced by using end plates, or wings, to change the flow direction and eliminate crossflow. My own preference, for a fin of average span, is for an end plate that is but a few inches wider than the maximum width of the fin bottom. We tested an actual yacht with such an end plate on one side only and noted a substantial improvement in performance when she was heeled so that the end plate was on the leeward side. Where the draft is shoal and the fin span is on the small side, then a wider end plate, or even a wing, might prove beneficial. However, a wide wing can be a structural weakness, particularly if the boat goes hard aground and has to be towed off, or pounds on the rocks for any length of time.

Sweepback Angles

In the 1970s, I saw more than one very-high-aspect-ratio fin with tremendous sweepback angle. This certainly gives an impression of speed but, as Marchaj pointed out, tank tests have shown that the sweepback angle can be related to the aspect ratio: the higher the aspect ratio, the more vertical the fin should be. Indeed, the very-high-aspect-ratio fin on my BOC racer was set absolutely plumb until a hard grounding set the tip back a quarter inch or so, the result of taking a yacht with a 13-foot draft through a channel dredged to 11 feet! Most cruising-yacht fins are of low aspect ratio, of course, so should have substantial sweepback, up to 57 degrees, with an aspect ratio of 0.5, according to Marchaj. Although most designers try, it is unfortunate that obtaining the perfect sweepback angle is secondary to locating the fin to balance the sailplan, as well as fitting the ballast at the correct spot for proper fore and aft trim. The taper ratio (tip chord length/root chord length) also deserves consideration. Tests on one series of fins showed that a fin with 0.32 taper ratio was 1 percent more efficient than an untapered fin and had very slightly less resistance. This is a small difference but cannot be ignored by the racing skipper. Again, the reduction in drag may be due to reduced vortices from the shorter tip chord. Marchaj also states that the taper ratio should be reduced as the sweepback angle increases. However, the very-low-taper-ratio fins may not be the best solution for a cruising yacht. The tip chord should be long enough so the vessel can be hauled on a marine railway with no major problems. Too, on a moderate-draft cruising yacht, a short tip chord forces the ballast higher, so stability can suffer.

Lower Ballast

Another consideration in the fin profile is whether the tip chord is sloped down aft or parallel to the waterline. The parallel tip chord makes good sense. It allows the ballast to be lower for added stability, it eases blocking up the boat when hauling and, fortunately, tests have shown that it is also superior to the sloped tip chord in other ways. Having the aft edge of the tip chord deeper than the leading edge has no practical effect on aspect ratio, and such a fin develops less lift and more drag than one with a parallel tip.

The National Advisory Committee for Aeronautics (NACA) tested a large variety of streamlined shapes for lift and resistance and the information on these is available in a book, Theory of Wing Sections, by Abbot and Von Doenhoff. These are the shapes that designers refer to when they say their new magic fin has an NACA section. Generally, the shape selected will be similar to NACA 0010-34 or 0010-64 series. The leading edge will be elliptical, as a blunted nose increases resistance while a pointed leading edge promotes stalling. The maximum width will be about 40 to 50 percent aft, and the shape will be streamlined to a fairly sharp (but not razor-sharp) trailing edge. The thickness ratio will be 0.8 to 0.12 of the chord length, although this may be increased to 0.15 to 0.16 at the tip chord. There are advantages to having an increase in thickness ratio at the tip chord, including being able to fit the ballast lower. This need not mean that the fin is bulbed, though. For example, a fin that is 8 feet long at the root and 5 feet long at the tip may have a 0.10 thickness (0.8 feet) at the root and 0.15 thickness (0.75 feet) at the tip. The fin is still slightly thinner at the bottom than at the top, but the thickness ratio has increased.

Increased Resistance

It is not uncommon to see fins wider than 10 to 12 percent of their length, as the designer may need to fatten the fin in order to locate the ballast in the correct spot for proper trim. Very shoal-draft boats may require fatter keels or fins in order to get the ballast as low as possible for stability. Still, extra width does increase resistance so there is a tradeoff; added stability increases performance while a thicker fin reduces performance. Thirty-five years ago, when I worked for Bill Luders, we tank-tested dozens of 5.5-Meter models. These very short-keeled 30-foot sloops had a minimum keel width of 4 inches under the rule, and whenever we tried a model with a wider keel in order to get the ballast lower, we found that overall performance suffered.

We also tested a number of bulb keels on the 5.5 models but they never proved out in the tank, either, although several different shapes were tried. Then, in the late 1970s, I tank-tested the model of the new Morgan 38 at Stevens Institute, first with a fairly fat NACA fin in order to maintain the desired 5-foot draft, and then with a patented bulb fin that we let its designer draw up, with no stipulation on draft. The bulb saved only 2 inches of draft but showed so poorly against the NACA fin that the 38 was put into production with the more conventional shape.

The tip shape, viewed from ahead, may be flat, round, elliptical, or bulbed. Tests show that the flat, squared-off tip develops a bit more lift to windward and that the round or elliptical tip has less drag on a run. The differences are slight but, today, I favor the squared-off tip with an end plate for yachts of average draft. A vee tip was tried in the 1960s on a few yachts, but never became popular. Bulbs and wings, often in combination, are fairly common on contemporary production boats. Usually, they are an attempt to produce a very shoal-draft yacht for use in waters where the bottom is close to the top and, in those cases, they may make sense.

There is a never-ending variety of fin shapes and, to be honest, I’m not sure which is best. Generally, I prefer a fin similar to the old Cal 40, a little shorter perhaps, and fitted with an end plate. Such a fin provides a desirable combination of good performance, ease of haulout, and structural strength, all very important factors for the cruising skipper.

Article first appeared Good Old Boat magazine: Volume 3, Number 4, July/August 2000 .

About The Author

Ted Brewer is one of North America's best-known yacht designers, having worked on the America's Cup boats, American Eagle and Weatherly, as well as boats that won the Olympics, the Gold Cup, and dozens of celebrated ocean races. He also is the man who designed scores of good old boats, the ones still sailing after all these years.

Related Posts

Southerly 115 Boat Comparison

March 1, 2019

Crealock 37/Pacific Seacraft 37 Boat Comparison

June 10, 2020

A Thing of Beauty is a Joy Forever

July 25, 2019

Allied Boat Company

January 1, 1999

Now on Newsstands

Join Our Mailing List

Get the best sailing news, boat project how-tos and more delivered to your inbox.

You have Successfully Subscribed!

Practical Boat Owner

- Digital edition

Keel types and how they affect performance

- Peter Poland

- June 19, 2023

Peter Poland looks at the history of keel design and how the different types affect performance

The Twister is a well-proven example of a generation of production yachts with ‘cutaway’ full keels and keel-hung rudders. Credit: Graham Snook/Yachting Monthly

Having been a boatbuilder for around 30 years until the very early ‘noughties’, I’ve already witnessed – and even taken part in – a lot of changes in the world of yacht design and building.

Yacht design originally evolved as traditional workboats developed into leisure craft.

In his History of Yachting , Douglas Phillips-Birt writes that the Dutch, who gave the name ‘yacht’ to the world, were probably the first to use commercial craft for pleasure in the 16th century.

They created the first yacht harbour in Amsterdam in the 17th century.

When the schooner America visited the UK in 1851 and raced around the Isle of Wight, this led to the America’s Cup and the resulting merry-go-round of race-yacht design that continues to this day.

The Jeanneau Sun Odyssey 35 offers three different fin keel configurations with different draughts plus a lifting keel version with a centreplate housed in a shallow winged keel stub. Credit: David Harding

The creation of what is now the Royal Yachting Association ( RYA ) in 1875 led to the introduction of handicap rules, establishing the sport in Britain.

These rating rules – and their numerous successors down the ages – have helped determine the evolution of yacht design and keel shapes.

Many early yachts were closely based on workboats, commercial cargo carriers or even privateers and naval vessels.

Initially, the ballast was carried in a long keel and the bilges .

New racing rules of the day taught designers to seek and tweak performance-enhancing features.

Maybe racing did not always improve the breed, but it certainly kept it moving ahead.

Artwork inspired by Ted Brewer’s illustration of keel types (excluding centreplate or lifting keels)

The late, great designer David Thomas believed that fishing boats, pilot cutters and oyster smacks had a large influence on the sport of sailing.

Each type of workboat was built to fulfil a specific purpose. And many had to be sailed short-handed while carrying heavy cargoes.

So they needed to combine form and function, sail well and be able to cope with heavy weather.

Proof of the versatility of working boat designs was provided by Peter Pye and his wife, Anne.

They bought a 30ft Polperro gaff-rigged fishing boat (built by Ferris of Looe in 1896) for £25 in the 1930s.

Having converted her to a sea-going cutter, and renamed her Moonraker of Fowey , they sailed the world for 20 years.

It proves how the simplest working boat design can cross oceans and fulfil dreams.

Racing influence on keel types and design

Most early yacht designs were schooners, but during the latter half of the 19th century the gaff cutter rig started to dominate the scene.

Many notable yachts were built at that time and the most important racing design was probably the yawl Jullanar (1875).

Designed and built by the agricultural engineer EH Bentall, she had, in his own words, “the longest waterline, the smallest frictional surface, and the shortest keel”.

She proved to be extremely fast and in her first season won every race she entered. Jullanar became the forerunner of such famous designs as GL Watson’s Thistle (1887), Britannia (1893), and Valkyrie II and Valkyrie III , both of which challenged for the America’s Cup during the 1890s.

Compare the She 36’s graceful overhangs with the vertical stems and sterns of most modern cruiser/racers

In the USA, Nat Herreshoff experimented with hull forms for racing yachts and produced the ground-breaking Gloriana in 1890.

She was a small boat for the times, with a waterline length of 46ft. Her hull form was very different to anything yet seen in the USA.

With long overhangs at bow and stern, her forefoot was so cut away that the entry at the bow produced a near-straight line from the stem to the keel.

It was a revolutionary design, and nothing at the time could touch her on the racecourse.

Many French models, such as this Beneteau, have opted for substantial pivoting keels. Credit: Peter Poland

Herreshoff wrote: “Above the waterline everything on Gloriana was pared down in size and weight… and every ounce of this saving in weight was put into the outside lead.”

Early English rating rules produced the ‘plank-on-edge’ yacht, where the beam became narrower and the draught got deeper.

New rating rules were then adopted to discourage this extreme type and eventually the Universal Rule was introduced in the USA and the International Rule – which produced the International Metre Classes – took over in Europe.

Yet again, racing rules proved to be a major influence on design development.

By the start of the 20th century the big, long-keeled racing yachts like the J Class attracted a lot of public attention, but after World War II everything changed. Yachts built to the Universal Rule fell from favour.

The age of the racing dinghy arrived and the ocean racer became the performance yacht of the future.

To new extremes

A 300-mile race from New York to Marblehead saw the start of offshore racing and the first Bermuda race was run in 1906.

The British were slower to compete offshore, but in 1925 seven yachts took up the challenge to race round the Fastnet Rock, starting from the Isle of Wight and finishing at Plymouth.

EG Martin’s French gaff-rigged pilot cutter Jolie Brise won the race and the Ocean Racing Club was formed.

In 1931 this became the Royal Ocean Racing Club (RORC), which remains the governing body of offshore racing in Britain.

The ‘cutaway’ modified full keel was famously used by Olin Stevens on his mighty Dorade. Credit: Christopher Ison/Alamy

The early competitors in RORC races were long-keeled cruising boats, many of them gaff rigged and designed for comfort and speed.

But everything changed in 1931 when the young American Olin Stephens designed and then sailed his family’s 52ft yawl Dorade across the Atlantic to compete in that year’s Fastnet race.

She won with ease. Then she did it again in 1933, having first won the Transatlantic ‘feeder’ race.

At 52ft LOA, with sharp ends and 10ft 3in beam, some said Dorade looked like an overgrown yawl rigged 6-metre. But her triple-spreader main mast was revolutionary. As were her cutaway forefoot, lightweight construction, deep ballast and 7ft 7in draught.

Dorade took the long keel format to new extremes.

In the USA, the Cruising Club of America (CCA), founded in 1922, played much the same role as the RORC did in Britain.

It introduced its own rating rule which influenced the evolution of yacht design in the USA.

The Elan 333. Both the deep (1.9m) and shallow (1.5m) draught models feature an elegantly faired bulb keel and spade rudder. Credit: Peter Poland

Beam was treated more leniently under the CCA rule, so wider American designs later offered more space for accommodation and a bit more inherent form stability than RORC-rule inspired yachts.

Many famous designers of long-keel racing yachts at this time developed their skills at the yachtbuilding firms they ran, such as William Fife II (1821–1902), his son William III (1857–1944), Charles E Nicholson (1868–1954) of Camper & Nicholsons and Nat Herreshoff of Bristol, Rhode Island.

Around the same time several British yacht designers made their names, including George L Watson (1851–1904) who set up one of the earliest Design Offices and Alfred Mylne (1872–1951), who designed several successful International Metre Class yachts.

Norwegian designers Colin Archer (1832–1921) and Johan Anker (1871–1940) also joined the party.

Continues below…

Boat hull design: how it impacts performance

Peter Poland explains how boat hull design has evolved over the years and how it affects boat handling and accommodation

Sail boat rigs: the pros and cons of each popular design

Peter Poland looks at the history of popular rig designs and how the different types affect boat performance

Improve performance by understanding boat design

Understanding boat design can be tricky. We’re all familiar with the questions that arise when looking for a new boat.…

Coming of age: the 1970s yacht designs that have stood the test of time

Sailing in the 1970s was characterised by innovation, enthusiasm, mass participation and home boatbuilding. Rupert Holmes reports

In 1873 Archer designed the first long keel Norwegian yacht, but his real interest was work boats – pilot boats, fishing craft, and sailing lifeboats – some of which were later converted into cruising yachts.

Erling Tambs’s Teddy was a classic Colin Archer long keel canoe-stern design in which he wandered the globe with his young wife and family.

He proved the seaworthiness of Archer’s yachts, as well as their speed, by winning the 1932 Trans-Tasman yacht race.

Fellow Norwegian Johan Anker – a one-time pupil of Nat Herreshoff – became equally famous, thanks to his Dragon-class design that still races today.

As a new generation of designers arrived on the scene in the 1930s, hull tank testing became more sophisticated.

Long keel designs became as much a science as an art.

The leader of this new wave of designers, Olin J Stephens, had been a junior assistant to Starling Burgess who designed race-winning J Class yachts, including the iconic Ranger .

Tank testing was then in its infancy but the USA was ahead of the game and Stephens stored away everything that he learned. He enjoyed a head start over his contemporaries.

Keel types: Fin keels

Between the 1930s and the 1980s more fin keel designs began to arrive on the scene and his firm Sparkman & Stephens produced many of the world’s top ocean racers.

He also designed America’s Cup 12-Metres that defended the cup up to 1983 until Ben Lexcen’s winged keel shook the sailing world.

Many S&S fin keel and skeg production boats – such as the Swan 36 (1967), 37, 40, 43, 48, 53 and 65, She 31 (1969) and 36 and S&S 34 (1968) – still win yacht races and are much sought after as classics.

The S&S 34 has several circumnavigations to its name. Stephens, of course, had his rivals.

Among these was the Englishman Jack Laurent Giles, whose light displacement race-winner Myth of Malham had one of the shortest ‘long keels’ of all time.

(L-R) A Sigma 38 designed by David Thomas and Gulvain (1949) by Jack Giles as a development of his Fastnet-winning Myth of Malham have very different keel types. Credit: Peter Poland

The Dutchman EG Van de Stadt designed the Pioneer 9 (1959) which was one of the first GRP fin keel and spade rudder racers.

Towards the end of his career, Olin Stephens also came up against Dick Carter, Doug Peterson, German Frers and the Kiwis Ron Holland and Bruce Farr.

The development of new shaped keels went hand in hand with this rapid evolution in yacht design.

The full keel, as still found on motor-sailers such as the Fisher range, gave way to the ‘cutaway’ modified full keel as famously used by Olin Stephens on his mighty Dorade , designed back in the late 1920s.

She still wins ‘classic’ yacht races in the USA. American designer Ted Brewer wrote in ‘ GoodOldBoat ’ that Dorade’s offshore racing successes proved that the full keel is not essential for seaworthiness.

The Nicholson 32’s modified ‘cutaway’ long keel results in excellent performance and handling. Credit: Genevieve Leaper

As a result of its improved performance and handling, the modified ‘cutaway’ long keel caught on quickly and became the standard for around 35 years.

This keel type is found on numerous popular designs such as the Nicholson 32 , 26 and 36, Twister 28 and many Nordic Folkboat derivations.

The modified full keel format had a cutaway profile, giving good handling and directional stability while having less wetted surface than the full keel designs.

These yachts can perform well in all conditions and have a comfortable motion.

Even though they are generally of heavier displacement than fin keelers, they are not much slower in light airs , despite their added wetted surface area.

Their main drawback is a wide turning circle ahead and reluctance to steer astern when under motor.

Keel types: Increased stability

The modified full keel was subsequently cut away more and more for bluewater and inshore racers in an attempt to reduce wetted area until, finally, some designers took it to extremes.

As a result, much-reduced directional stability produced craft that were difficult to steer in breezy conditions, broaching regularly.

Whereupon the fin keel and skeg-hung rudder took over, reinstating increased directional stability, improving windward ability, reducing drag and restoring – when under power – control astern and on slow turns.

This fin and skeg format was later followed by the NACA sectioned fin keel with a separate spade rudder .

Soon, many performance cruisers followed this race-boat trend.

The Hanse 430 has a spade rudder and bulbed keel (draught 2.16m or 1.79m shoal draught. Credit: Peter Poland

Many builders now also offer shoal draught fin keel options and shallower twin rudders.

Some, such as Hanse, incorporate L- or even T-shaped bulbs on some Hanses and Dehlers at the base of finely shaped cast iron fins.

A new international competition had encouraged the initial development of modern fin keel yacht designs.

The revamped One Ton Cup was launched in 1965 for yachts on fixed handicap ratings (typically around 37ft long).

This spawned later fixed-rating championships for Quarter Tonners (around 24ft), Half Tonners (around 30 ft), Three-Quarter Tonners (around 33ft), and finally Mini-Tonners (around 21ft).

All these yachts were eventually handicapped under the International Offshore Rule (IOR) that replaced the old RORC and CCA rules.

The revamped One Ton Cup helped encourage the developed of modern fin keel designs. Credit: Getty

Countless production fin keel cruisers designed and built in the 1970’s to 1990’s boom years were loosely based on successful IOR racers that shone in the ‘Ton Cup’ classes.

The IOR handicap system’s major drawback was its Centre of Gravity Factor (CGF) that discouraged stiff yachts.

Once the international IRC rule replaced the IOR, more thought was given to increasing stability by putting extra weight in a bulb at the base of the keel.

GRP production boats followed suit. The keel foil’s chord needed to be wide enough to give good lateral resistance (to stop leeway), yet not be so wide as to add unnecessary drag.

Exaggeratedly thin foils are not suited to cruising yachts because they can be tricky upwind.

Tracking is not their forte and they can stall out. A bonus was an easier ride downwind thanks to wider sterns.

Keel Types: Lead or iron?

And then there is lead. Almost every production cruiser has a cast iron keel for one simple reason; it is much cheaper than lead. But it’s not as good.

Not only does it rust; it is ‘bigger’ for the same given weight. A cubic metre of iron weighs around 7,000kg, while the same cubic metre of lead weighs around 11,300kg.

An iron keel displaces far more water (so has more drag) than the same lead weight. We had always put iron keels under our Hunters – as did our competitors.

But when we came to build the Van de Stadt HB31 cruiser-racer, designer Cees van Tongeren said “No. We use lead.” “Why?” I asked. Cees replied: “If we use iron, the keel displaces more, so the boat sails worse.”

Rustler 36 long keel’s cutaway forefoot delivers responsiveness and manoeuvrability – a reason the design is so popular in the Golden Globe Race. Credit: Beniot Stichelbaut/GGR/PPL

Which explains why top-flight race boats have lead keels – or at the very least composite keels with a lead bulb or base bolted to an iron upper foil, thus lowering the centre of gravity (CG).

Some modern production cruiser-racers offer high-performance lead or lead/iron composite keels – but at a price.

Many Danish X-Yacht and Elan race-boat models, for example, have a lead bulb on the base of an iron NACA section fin.

Rob Humphreys, current designer of the popular Elan and Oyster ranges, said: “The T-keel is good if you have sufficient draught available. If not, the fin element has too short a span to do its job. This is because the T-bulb doesn’t contribute as usefully to side force as a ‘filleted L-bulb.’

“I developed and tested this shape (a blended-in projection off the back of the main fin) for the maxi race boat Rothmans in 1988/9, and have since used it on the Oysters and Elan Impressions. The ‘filleted’ keel we tested for Rothmans had slightly more drag dead downwind (more wetted area) but was significantly better when any side-force occurred; and side-force goes hand-in-hand with heel angle – which is most of the time! When the model spec allows for reasonable draught, the keel option with the lowest centre of gravity will invariably be a T-keel, with a longer bulb giving the greatest scope for a slender ballast package. An L-keel is a compromise and doesn’t suffer from the risk of snagging lines, mooring warps, and nets. [many modern production cruisers have 100% cast iron L- or T-shaped keels]. A lead bulb is preferable to a cast iron keel in terms of volume and density, but it costs more. However, a lead T-keel in a production environment will almost certainly use a cast iron or SG Iron fin, which may rust.”

The Mystery 35, designed by Stephen Jones and built by Cornish Crabbers, has a lead fin keel. Photo: Michael Austen/Alamy

Rustler Yachts also uses lead instead of iron for their keels.

The Rustler 36 long keel (designed by Holman and Pye and winner of the 2018 Golden Globe Race) has a cutaway forefoot to improve responsiveness and manoeuvrability.

The long keel creates more drag but, as with the Rustler 24, the cutaway forefoot makes the 36 more nimble than a full long keel boat, which are more difficult to manoeuvre in reverse under power.

The rest of Rustler’s offshore range – the Rustler 37, 42, 44 and 57 – designed by Stephen Jones – have lead fin keels.

As does his Mystery 35 built by Cornish Crabbers.

These offer an excellent combination of directional stability, performance and lateral stability. The yachts track well, are comfortable in choppy seas, and have good manoeuvrability, all without the flightiness of shorter chord fin keels found on many production family cruisers.

A digital future

Influential designer David Thomas said: “When I started designing, I integrated sharp leading edges to the keel; until someone told me a radius was better. Then we were all taught that an elliptical shape was better still. With the advent of computers, designers could better visualise the end-product; and clever ‘faring programs’ speeded this up.”

So where next? A combination of lighter and stronger materials, rapidly developing computer programs, a desire for maximum interior volume and low costs has led us to today’s production yacht.

Twin rudders improve the handling of broad-sterned yachts when heeled.

The IRC rating rule permits low CG keels, wider beam and near-vertical bows and sterns.

And designers now have an array of new computer tools at their disposal. But maybe there’s still that element of black magic?

As David Thomas so succinctly said: “You can design a yacht 95% right, but the last 5% can be down to luck.”

Keel types : the pros and cons

Full length keel

The Fisher 31 and many motor-sailers have long keels. Credit: Peter Poland

Pros: Directional stability. Heavy displacement leading to comfort at sea.

Cons: Poor windward performance. Large wetted surface leads to drag. When under power at low speeds, the turning circle is wide unless fitted with thrusters. The same applies to manoeuvring astern.

Cutaway modified long keel form with keel-hung rudder

Pros: Reduced wetted surface area leading to increased boat speed. Better windward performance and handling than full length keel. Rudder on the aft end of the keel improves self-steering ability on some designs.

Cons: Under engine, this keel form has a large turning circle ahead and poor control astern. Since the rudder is not ‘balanced’, the helm on some designs can feel quite heavy.

Fin keel with skeg-hung rudder

The skeg gives protection to the rudder. Credit: Graham Snook/Yachting Monthly

Pros: The further reduction in wetted surface area leads to more boat speed. Directional stability and close-windedness are also improved. If full depth, the skeg can protect the rudder against collision damage.

Cons: When combined with a narrow stern, this keel format can induce rolling when sailing dead downwind in heavy winds.

Fin keel with separate spade rudder

Fin keel with spade: Low wetted surface and aerofoil shapes enhance performance. Credit: Graham Snook/Yachting Monthly

Pros: The fin and spade rudder mix reduces wetted surface and gives a more sensitive helm – especially if the blade has ‘balance’ incorporated in its leading edge. Handling under power in astern is precise and the turning circle is small.

Cons: The rudder is fully exposed to collisions. There are no fittings connecting the rudder to a keel or skeg, so the rudder stock and bearings need to be very robust.

Shallow stub keel with internal centreplate.

Pros: When lowered, the plate gives good windward performance. The plate can act as an echo sounder in protected shallow water. There is normally no internal centreplate box to disrupt accommodation. With the plate raised, off-wind performance is good.

Cons: The plate lifting wire needs regular inspection and occasional replacement. Windward performance with the plate raised is poor.

Lifting or swing keel

Boats with lifting keels tend to surf earlier downwind. Credit: Graham Snook/Yachting Monthly

Pros: Shallowest draught so more cruising options; can also be moored on cheaper moorings. Surfs early downwind. Small wetted surface so can be fast.

Cons: Reduced living space due to internal keel box. With a raised keel, poor directional control. Susceptible to hull damage if grounding on hard material.

Twin or bilge keel

Bilge- or twin-keelers can take the ground on the level. Credit: Graham Snook/Yachting Monthly

Pros: Can take the ground in a level position. Modern twin-keel designs with around 15º splay, around 2º toe-in and bulbed bases perform well upwind. Good directional stability due to the fins. Modern twin keels with bulbed bases lower the centre of gravity.

Cons: Older designs do not point upwind well. Slapping sound under windward keel when at a steep angle of heel on older designs. Antifouling between the keels can be tricky. Can be more expensive than fin keels.

Wing keel: A low centre of gravity gives a good righting moment. Credit: Graham Snook/Yachting Monthly

Pros: Low centre of gravity means good righting moment. Shallow draught. Sharper windward performance.

Cons: Larger surface area means it is more likely to pick up fishing gear, like lobster pots. Difficult to move once it is grounded. And difficult to scrub keel base when dried out alongside a wall.

Enjoyed reading Keel types and how they affect performance?

A subscription to Practical Boat Owner magazine costs around 40% less than the cover price .

Print and digital editions are available through Magazines Direct – where you can also find the latest deals .

PBO is packed with information to help you get the most from boat ownership – whether sail or power.

- Take your DIY skills to the next level with trusted advice on boat maintenance and repairs

- Impartial in-depth gear reviews

- Practical cruising tips for making the most of your time afloat

Follow us on Facebook , Instagram and Twitter

- Boat Keel: Enhancing Stability and Performance on the Water

The keel of a boat plays a vital role in ensuring stability, maneuverability, and overall performance on the water. Whether you're an experienced sailor or a novice enthusiast, understanding the significance of the boat keel and its various aspects can greatly enhance your sailing experience. In this article, we will delve into the different types of boat keels, their functions, and the impact they have on sailboats. So, let's set sail and explore the intriguing world of boat keels.

1. Introduction