Sailboat Keel Types: Illustrated Guide (Bilge, Fin, Full)

The keel type is one of the most important features of your boat. But the different designs can be confusing, so I've set out to create a very clear guide that will help you understand sailboat keels once and for all.

What are the most common sailboat keel types? The most common sailboat keel types are full-length keels, fin keels, bulb keels, wing keels, bilge keels, and lifting keels. Full keels are popular among cruisers, while fin keels are generally used for racing. Bilge keels and lifting keels are typically used in tidal waters, on small fishing boats for example.

In this article, we'll explore the most common keel types together. I'll use diagrams to really hit home the differences of all these keel types, and we'll discuss what keel types are best for liveaboard, ocean cruising, and lake weekend trips. After reading this article, you'll know what to choose - and why.

Sailboat Keels Explained

On this page:, overview of sailboat keel types, keel types: fundamentals, modified full keel, centerboard.

If you just want a quick overview, here's a list with the most common keel types and a short description. More detail will follow below.

The most common keel types

- Full keels run from front to aft and are the most stable keel type, making them the most popular cruising keel.

- Fin keels offer the best performance but are less comfortable. This makes them popular for racing. Fin keels are bolted on to the hull and generally run deep and thin.

- Bulb and wing keels are both variants on the fin keel.

- Bulb keels carry additional ballast in the tip, making them more stable.

- Wing keels have two tips at the end of the keel, which reduces crossflow, improving directional stability.

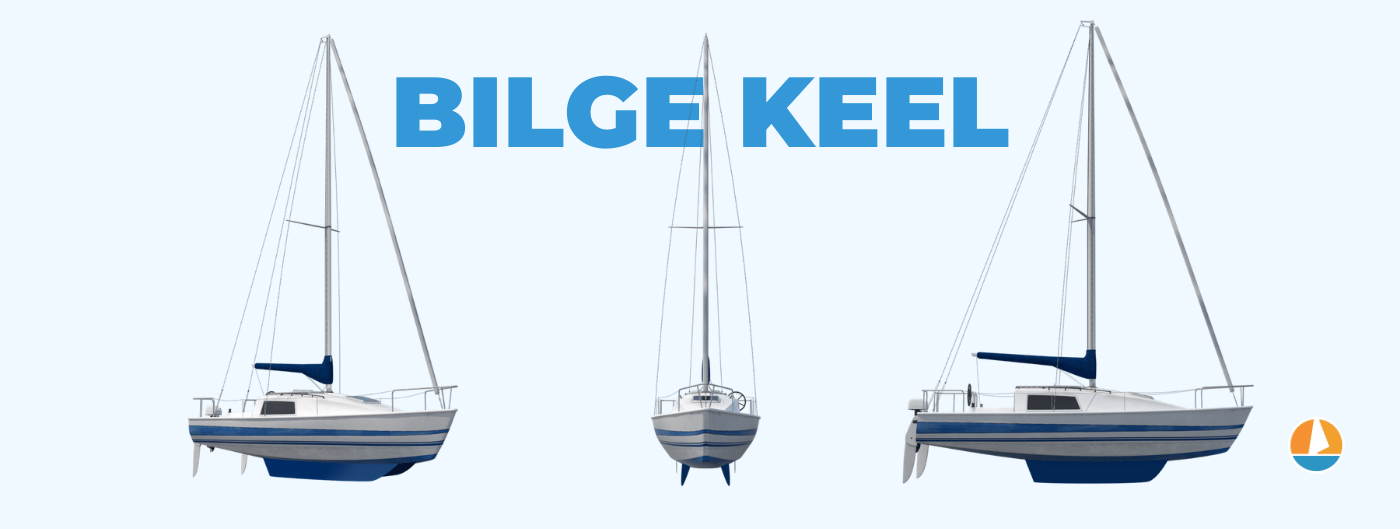

- Bilge keels are double fin or double full kees, which allows the boat to be beached, making them the most popular keel for tidal waters.

- Lifting keels are moveable keels that can be lowered and raised, allowing the boat to enter shallow waters as well.

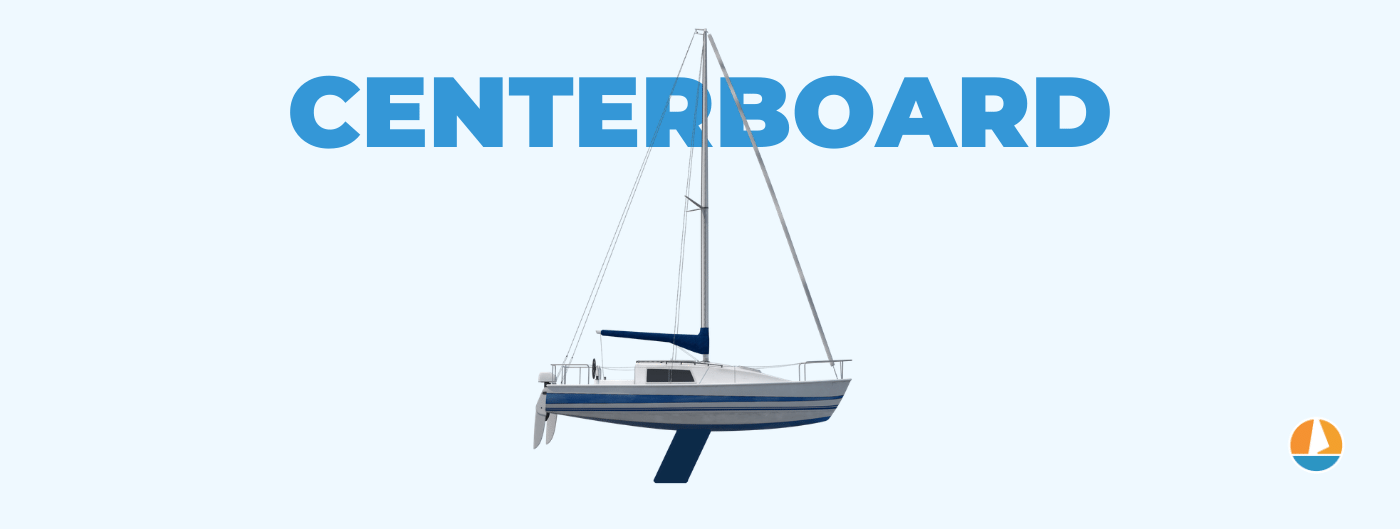

- Centerboard keels are a pivoting lifting keel, allowing to sail both coastal and inland waters.

- Leeboards are fins on the sides of flat-bottomed hulls boats, making a keel unnecessary.

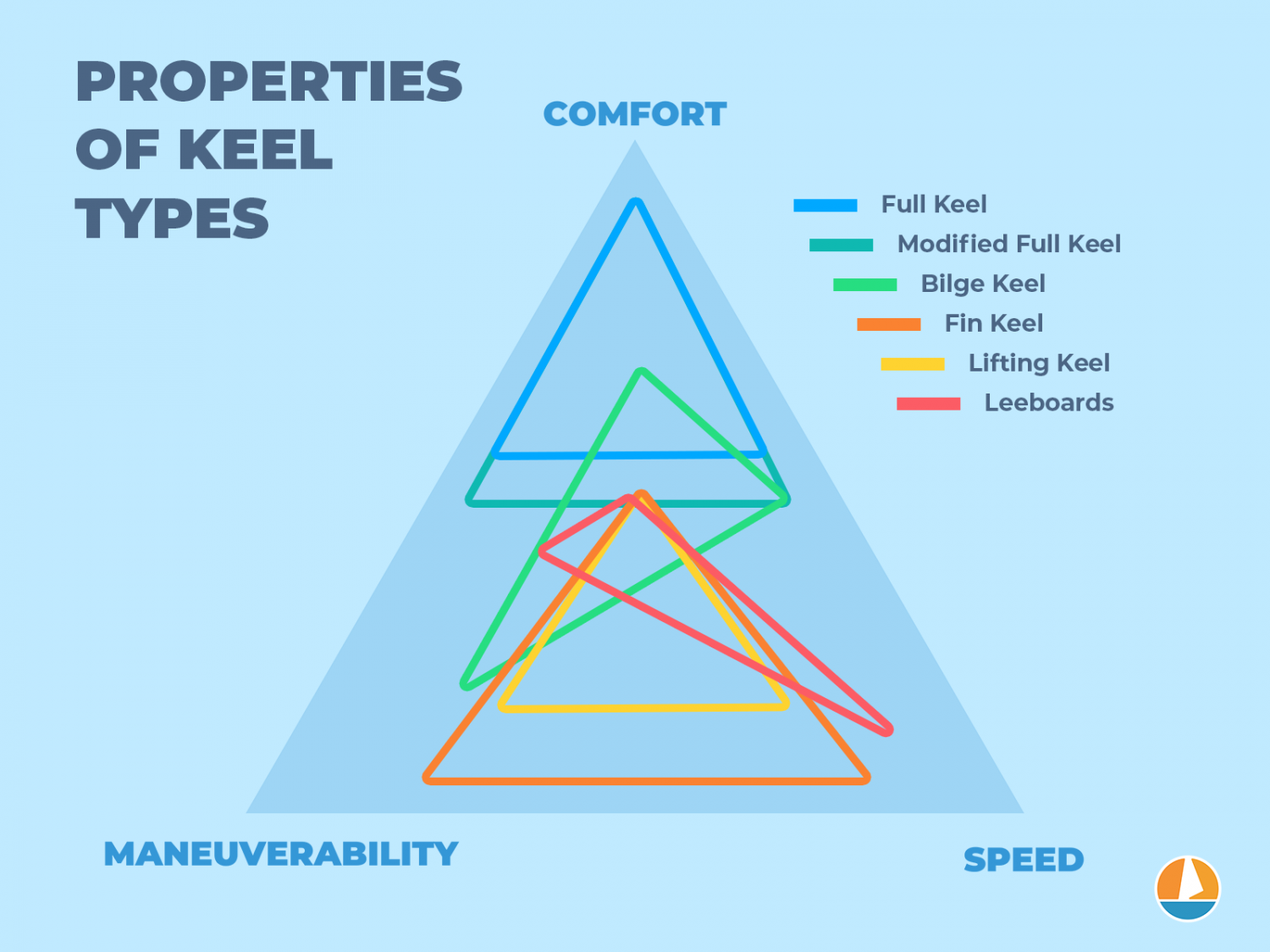

Properties of each keel type

What does a keel do?

What does the keel do? A keel is a vertical blade running down from the hull. It is weighted and acts as a ballast, countering the boat's tendency to heel and preventing it from tipping over. The wetted surface under the waterline reduces slippage to leeward by creating a track, which counters the sideway force of the wind on the sails.

The reason sailboats don't tip over is that the weight of the keel counters the buoyancy of the hull, which means it will pull the boat downward. This downward force reduces heel and prevents the boat from rolling.

A canoe doesn't have a keel. Try stepping into that: it will want to roll.

It counters the horizontal force the wind puts on the sails. Whenever the force on the sails increases, the resistance of the water on the keel increases proportionally.

The heavier the keel, the less heel you'll get.

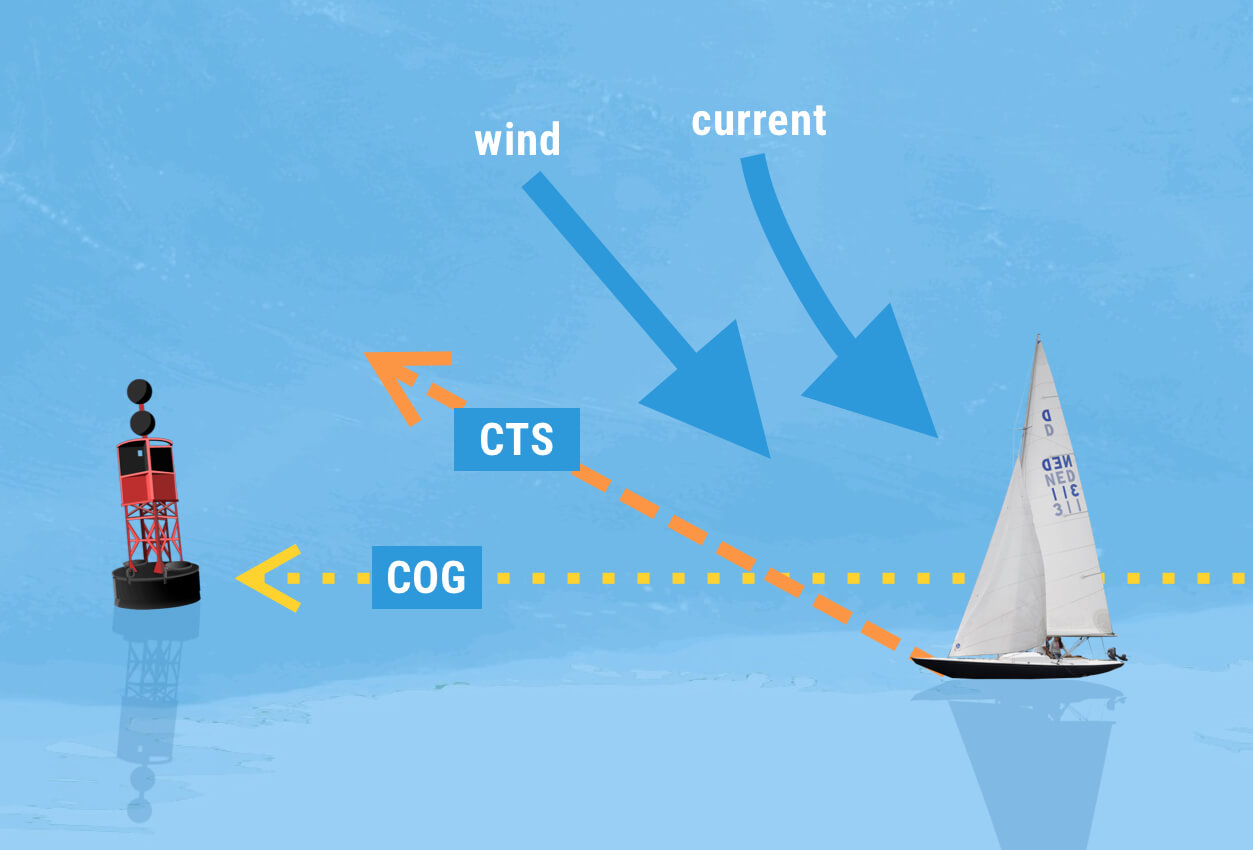

A keel reduces slippage to leeward. Slippage is simply the amount you fall off course because of the direction of the wind and current. Leeward is the side of the boat behind the wind.

So if you don't have a keel, you will fall off course quite a lot because the wind will push you over the water surface.

You will also heel quite a lot since there is nothing beneath the water surface to counter the force of the wind high up in your sails.

A keel fixes both of these issues and makes sailboats one of the most reliable boats in heavy winds and storms.

You can read on about how keels work here.

Keels can be classified by multiple dimensions. You can look at them from the side or the front. You can also classify them based on properties.

Before I dive into each keel type in-depth and show examples, let's make sure we have the same starting point.

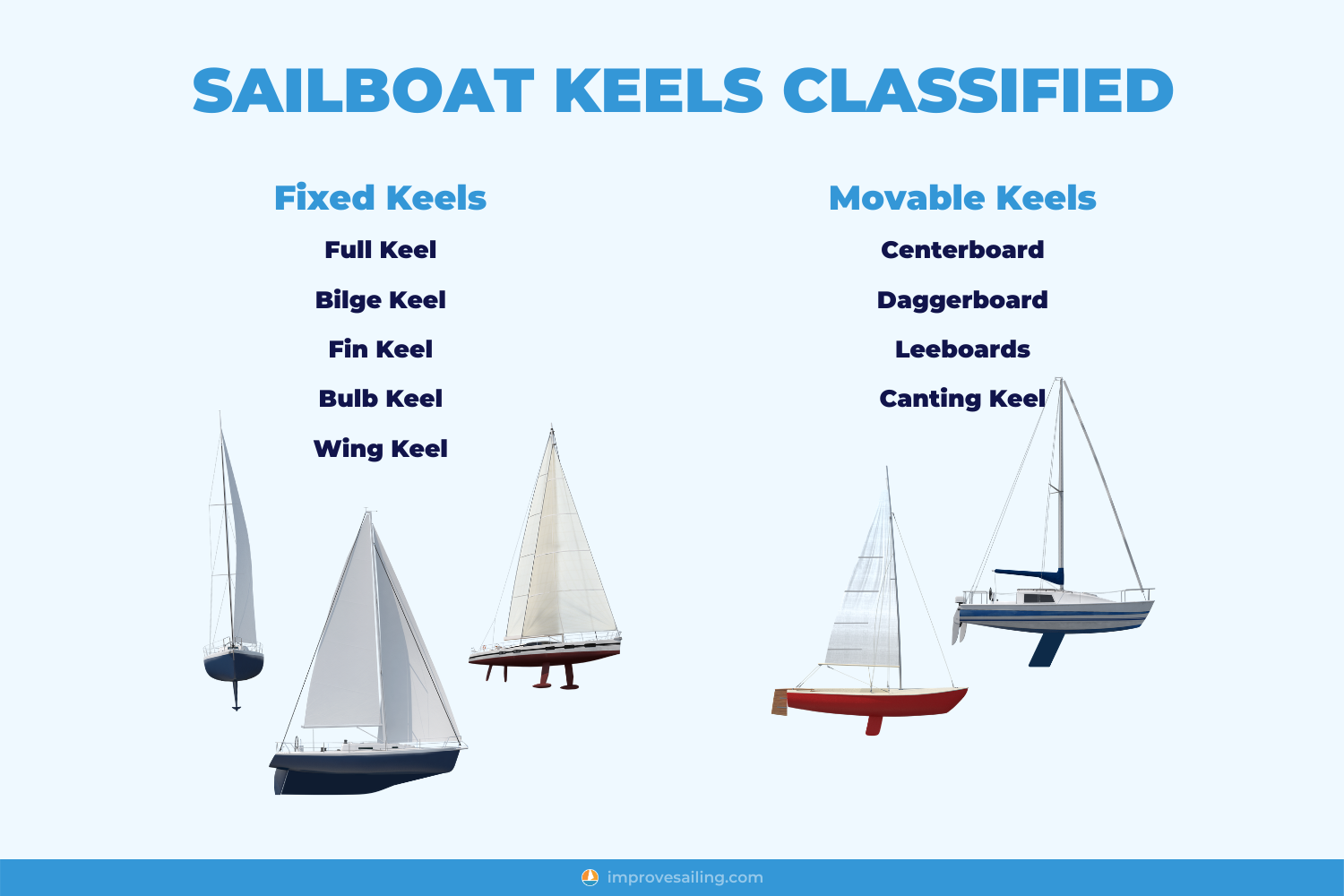

There are essentially two sorts of keels:

Fixed keels

Movable keels.

Fixed keels are keels that are integrated into the hull or bolted on. They can't be moved or lifted.

When looking at fixed keels, you can divide them up further based on the side view. There are three main categories:

Bilge keels

Full keels are more comfortable, provide better stability and protection, but are also slower than fin keels.

Fin keels are less comfortable, provide less stability, are more vulnerable, but they're also a lot faster than full keels.

Bilge keels are double keels: one on each side of the hull. This allows them to be beached, which comes in handy in tidal waters. They are generally a lot slower and less maneuverable compared to fin keels.

Movable keels can be lifted from the water, creating a shoal (shallow) draft, allowing the boat to enter both shallow waters and coastal waters. This makes it a very versatile keel type. There are two main designs:

Lifting keels

Lifting keels can be lowered and raised through a slit in the hull. Examples of lifting keels are the daggerboard and centerboard.

Leeboards are wooden swords attached to the side of the hull and prevent slippage to leeward, but they don't stabilize the boat, nor counter heel by adding ballast.

With fin keels, there are different tip designs available. The most common two tip designs are:

These are both variants of the fin keel. Generally, these keel designs are mentioned in one breath with full keels and fin keels, creating confusion on what kind of keel they are. But it's important to understand that they are a sub-category of fin keels.

Rudder design

As with the tip of the fin, there are different rudder designs that may apply to both fin and full keels. The two most common rudder designs are:

Skeg rudder

Spade rudder.

A skeg is a structural part of the keel in front of the rudder that protects the rudder. The keel encompasses the rudder, preventing any rogue ropes, weeds, or rocks from damaging the rudder.

A spade rudder is an unprotected rudder: it doesn't have any structural protection from the keel design. It is simply attached to the hull. This design is very common.

Alright, we understand the big picture. Let's dive into more detail for each keel type and discuss the pros and cons.

Fixed keel Good for cruising and liveaboards Comfortable

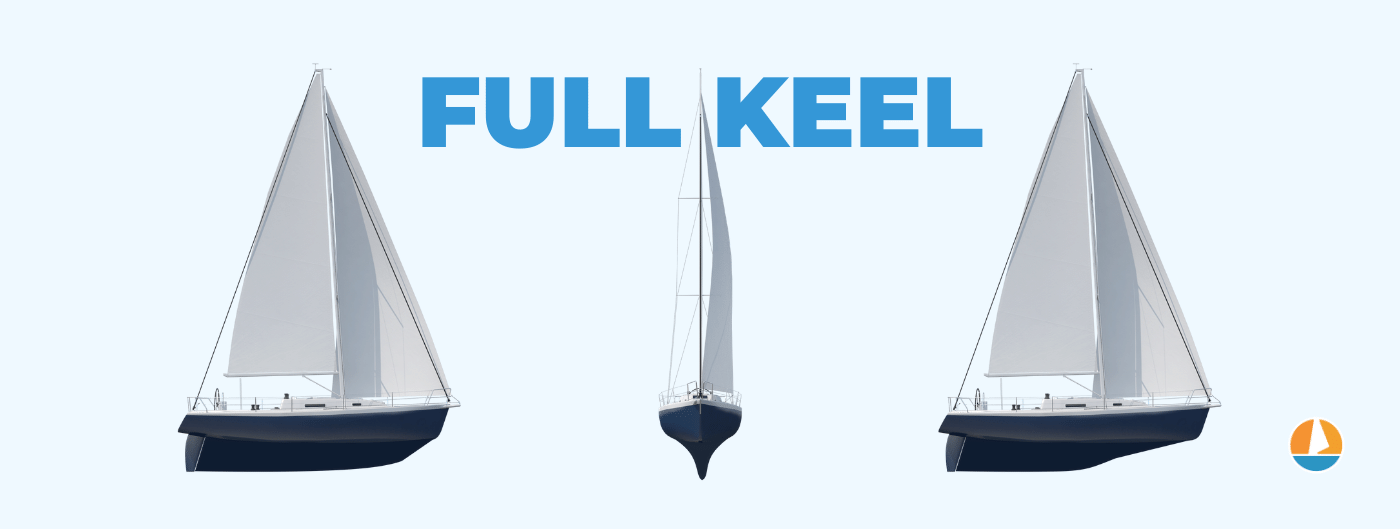

What is a full keel? A full keel runs from front to aft for at least 50% of the hull and is fully integrated into the hull. It has the largest wetted surface of any keel type, and it is also the heaviest. This results in directional stability and reduced heeling, providing the most comfortable ride, but also the slowest.

The wetted surface simply means the amount of water contact area. With such a large wetted surface, it decreases slippage to leeward the most of all keel types, while it counters heeling the most as well.

The full keel is the most comfortable and stable keel type available. However, comfort comes at a price. It delivers the worst performance due to this large wetted area. It is the slowest of the keel types, and it has the worst windward performance.

This makes full keels particularly great for longtime cruisers or liveaboards who prefer comfort over speed, but less ideal for daysailers who need to navigate in and out of slips regularly.

Since it runs for at least 50% of the hull, it doesn't need to run as deep as a fin keel, resulting in a more shoal draft.

Heavier keels result in increased displacement, so a full keel boat will need a larger sail area to compensate for its weight.

For a more detailed discussion on full keel advantages, I recommend reading William's excellent article 5 Surprising Advantages of a Full Keel Sailboat here.

Example sailboats with a full keel:

- Nicholson 22

- Island Packet 380

- Beneteau Oceanis 411 Clipper

- Beneteau First 50

- Jeanneau Sun Shine 38

- Dufour 455 Grand Large

There are a lot of great cruising boats with full keel designs , some of them considered classics.

Full Keel with skeg rudder

Full keels with a skeg rudder design have a protected rudder, thanks to putting a structural part of the keel directly in front of the rudder. This helps with fending off any hazards to the rudder, like floating pieces of rope, rocks, or garbage, and protects it in case of running aground. The skeg design ensures the rudder is nearly impossible to break off.

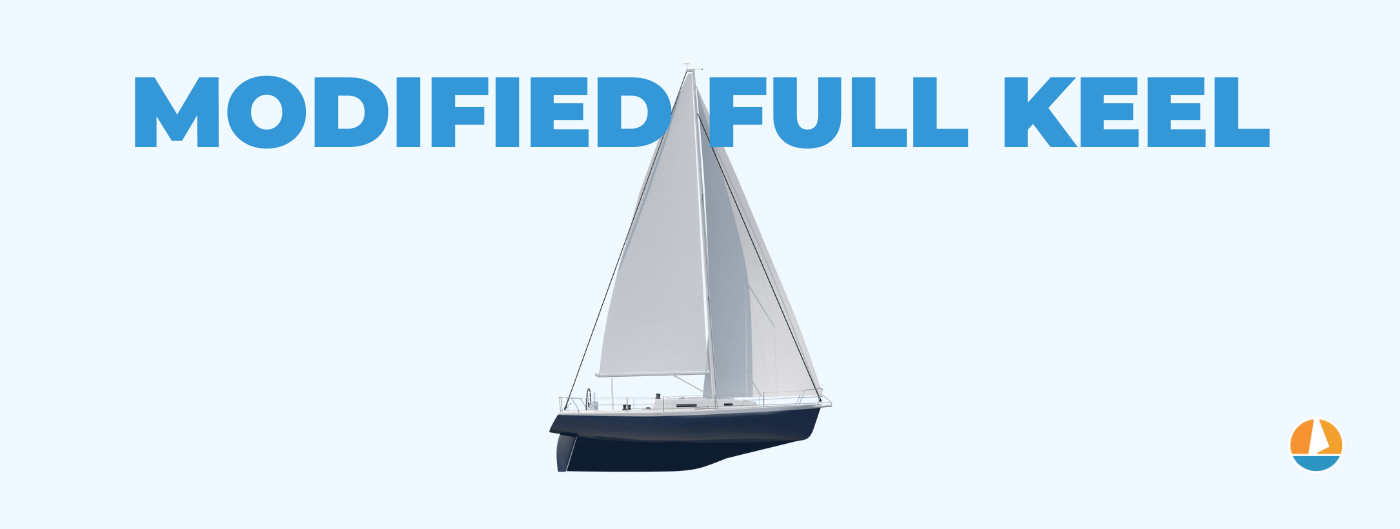

Fixed keel Good for cruising and liveaboards Faster than a regular full keel

What is a modified full keel? A modified full keel is a full keel with a cutout at the front, reducing the wetted surface slightly, which increases performance without sacrificing too much comfort and stability. After the full keel, it has the best directional stability and the least amount of heel.

The modified full keel is popular among (bluewater) cruisers, thanks to its increased handling and performance. Most modified full keels have a skeg rudder, ensuring it is well-protected.

The slightly reduced weight and wetted surface improve windward performance quite a lot, but it is still one of the most stable keel designs out there.

Example sailboats with a modified full keel:

- Hallberg-Rassy HR 40

- Dufour Arpege 30

- Beneteau Oceanis Clipper 281

- Jeanneau Sun Odyssey 37.2

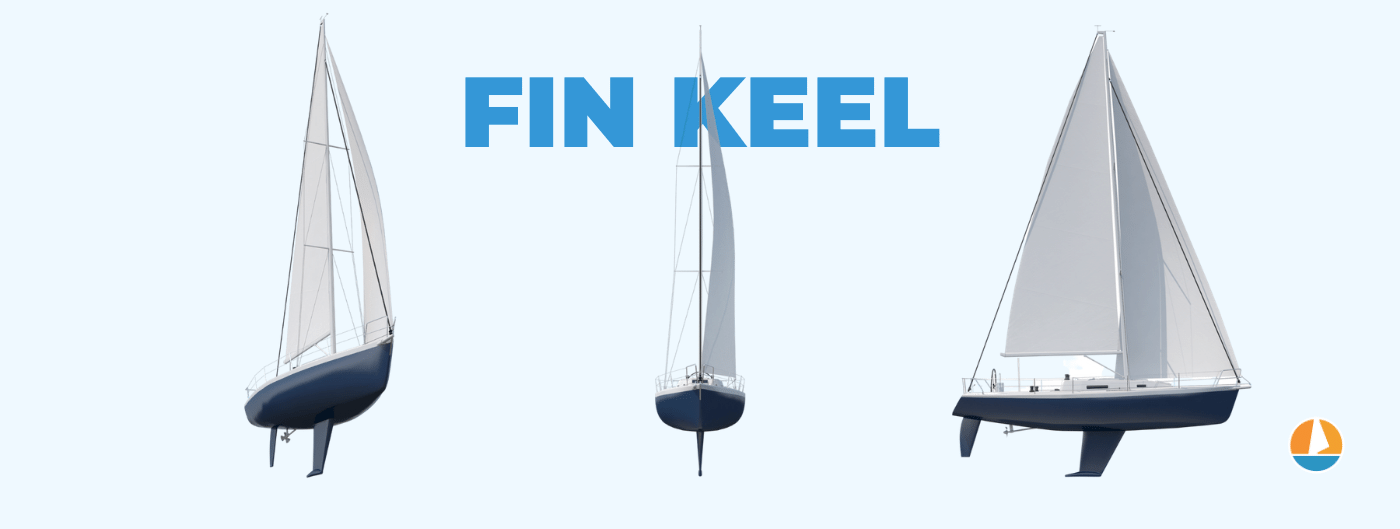

Fixed keel Good for racing Fast

What is a fin keel? A fin keel is a long, weighted blade attached to the bottom of the hull. It is lighter, faster, and more maneuverable than a full keel, but also more vulnerable. The increased distance between ballast and sails provides a lever, reducing the need for a large wetted surface or additional ballast.

Fin keels are generally bolted onto the hull and run deeper and thinner than a full keel. They are also lighter. This helps increasing performance (a lot), making fin keels a lot faster in all situations.

There are some major disadvantages to fin keels, however. Fin keels are a lot less comfortable than full keels and allow for more heel and a less solid track, so less directional stability. Fin keels are also a lot more vulnerable than full keels. They can break off when running aground, or get damaged.

They are very popular among racers and perform better when maneuvering in tight spots, like getting in and out of slips.

Example sailboats with a fin keel:

- Catalina 30

- Jeanneau Sun Odyssey 36.2

Fin keel with skeg rudder

Fin keels with a skeg rudder use a small structural part in front of the rudder to protect it. This design is mostly integrated into the hull, making it less vulnerable, and a great compromise between speed and safety.

Fin keel with spade rudder

Fin keels with a spade rudder have a completely exposed rudder, and typically a fin that is simply bolted on. The keel isn't integrated into the hull, making it more vulnerable and less comfortable.

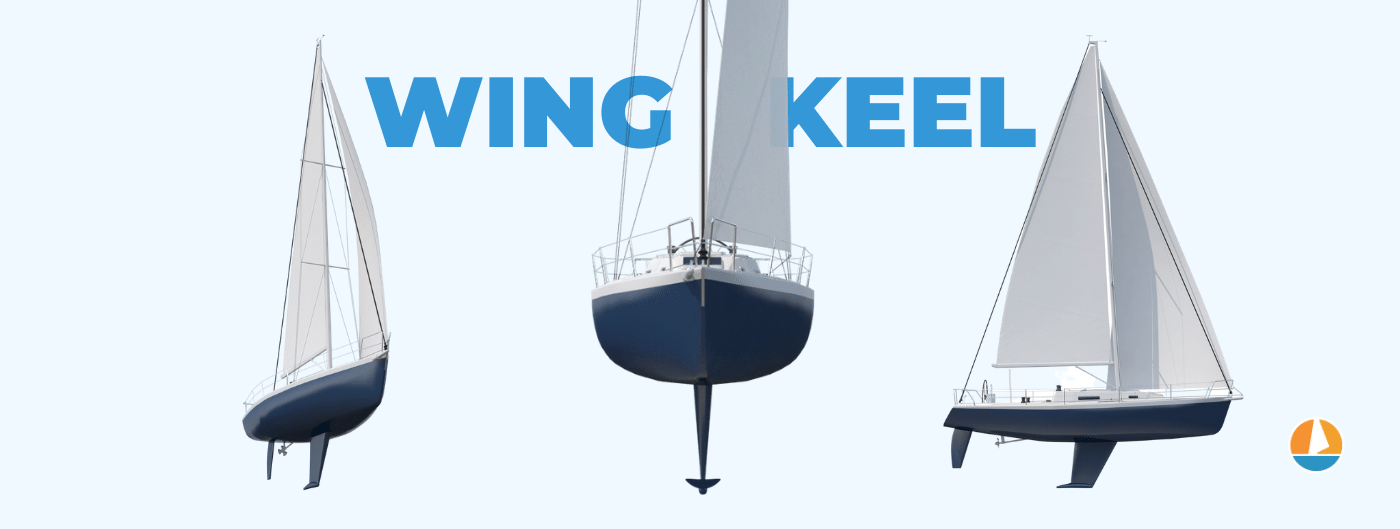

Fin keel variant Good for cruising Less crossflow

What is a wing keel? A wing keel is a fin keel with a horizontal foil at the tip, which is wing-shaped and generally weighted. Its shape reduces crossflow, improving directional stability, and its ballast decreases heel, resulting in a more comfortable ride. The addition of a wingtip allows for a shorter fin, reducing draft.

Wing keels are good for cruising since this design improves directional stability compared to a regular fin keel or a bulb keel.

We'll discuss the wing keel's advantages and disadvantages in more detail in this article.

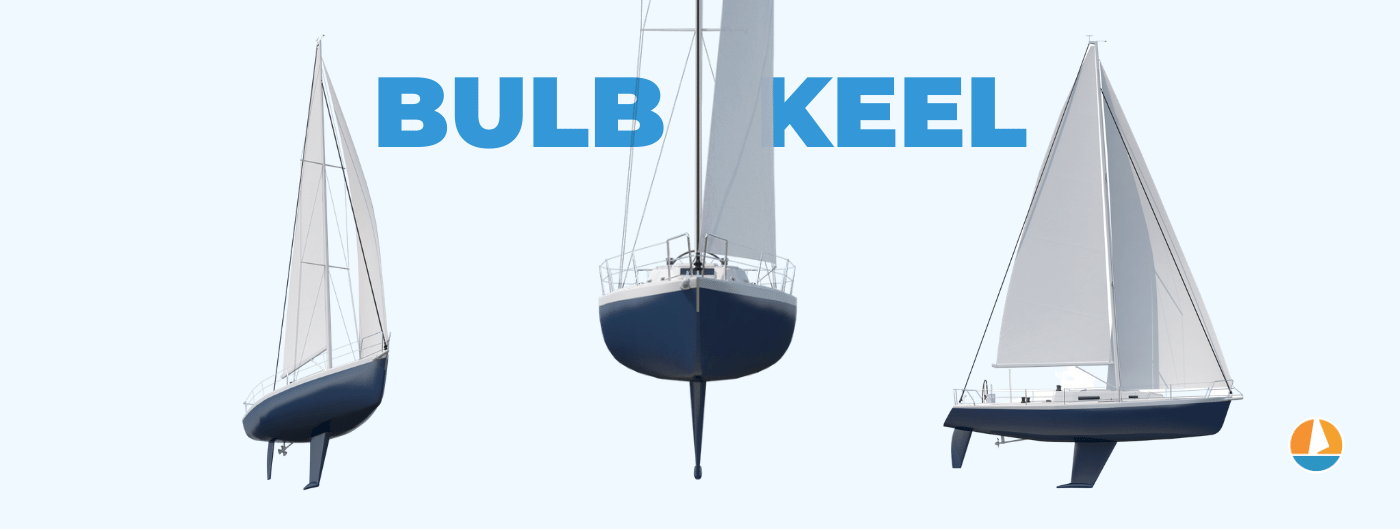

Fin keel variant Good for cruising Stability

What is a bulb keel? A bulb keel is a high-aspect-ratio fin keel with additional ballast at the end, which generally has a bulb or teardrop shape. This ballast improves stability and utilizes the distance between force and counterforce as a lever. This design reduces the need for a deep fin, resulting in a shoal draft.

By placing the weight at the largest possible distance from the force on the sails, you need relatively little extra weight for the same reduction in heel, making bulb keels very effective for cruising.

This design reduces the wetted area while increasing the weight of the keel just slightly, which increases sailing comfort big time.

Example sailboats with a bulb keel:

- Bavaria B/One

- Beneteau First 24

Fixed keel Good for racing Can be beached

What is a bilge keel? A bilge keel is a twin keel which uses double fins, allowing the boat to be beached and rest on its keel upright. Bilge keels have double the wetted surface, which increases comfort and directional stability while decreasing heel. Modern bilge keels often provide decent windward performance, thanks to better design.

The bilge keel does sacrifice speed compared to the fin keel but doesn't necessarily offer worse performance overall. Older designs performed considerably worse than other keels and were especially slow.

Bilge keels have some major advantages over full keels and fin keels. The most important is that the boat can be beached, making it a popular design in tidal waters. Bilge keels are especially common along the British coastline, where fishermen keep their boats in tidal harbors.

Another major advantage is that the boat can be stored resting on its keels, making dry storage and maintenance a lot easier.

Of course, there are many more pros and cons to the bilge keel , which we go into here.

Example sailboats with a bilge keel:

- Dufour Dynamique 62

- Hunter Duette

- Patagonia Patago 39

- Macwester 27

Lifting keel Good for daysailers Versatile

What is a centerboard? A centerboard is a type of retractable keel that rests on a hinge and can be lowered through a slot in the hull. It folds out like a pocket knife and allows you to increase or reduce the draft of the boat. Centerboards are mostly used on small fishing boats.

The centerboard is a very versatile keel type, allowing you to have both a very shoal draft for inland waters, as well as steadying the boat and reducing heel for larger bodies of water, or even oceans.

I've sailed a Cornish Crabber with a centerboard for a week, and while we stayed inland, having the option to increase the keel depth really came in handy when crossing the IJsselmeer (a former sea in The Netherlands).

There's more to the center

Olaf Roethele

https://www.theyachtmarket.com/en/new-boats/cornish-crabbers/adventure-17/218/

My name is Olaf and I am the owner of a Cornish Crabber 17 Adventure boat.

I would like to ask you if you can imagine to install on this boat a Torqeedo 2.0 Pod motor? Therefore i guess a modification of the keel/skeg is necessary ?!

Best regards from Uruguay,

You completely missed the hybrid planing/water-ballast keel of the Macgregor range

Thanks a lot for this explanation

Roger Bannon

Very well written article which provides an excellent guide for us small wooden boat builders. Thanks.

Leave a comment

Own your first boat within a year on any budget.

A sailboat doesn't have to be expensive if you know what you're doing. If you want to learn how to make your sailing dream reality within a year, leave your email and I'll send you free updates . I don't like spam - I will only send helpful content.

Ready to Own Your First Boat?

Just tell us the best email address to send your tips to:

Keel maintenance and repair – Part 1

by Simon Jollands | Boat Maintenance , Preparation , Yacht ownership

The job of a sailing boat’s keel is to control sideways movement through the water and to provide a counterweight to the sideways force of the wind on the sails, which causes a boat to heel over.

Keels are designed to act as underwater foils that generate lift as the boat moves through the water, counteracting the leeward force of the wind and enabling the boat to sail closer to the wind.

The most common type of keel used for sailing yachts is the bolted-on fin keel. Fin keels are usually made of cast iron, bolted through the undersides of GRP hulls with substantial stainless steel bolts. Other types of keel include bilge keels, shoal keels, encapsulated keels, lifting keels and canting keels, as used on racing yachts.

While iron is the most common type of ballast, lead is also widely used. Cement or concrete is sometimes used in combination with scrap iron as ballast for wooden and steel boats, but this can lead to steel rusting from the inside and is not considered good practice. Some modern racing yachts have water ballast which can be pumped into tanks to help counterbalance heeling.

Clearly, motor boats do not require deep keels to counterbalance the heeling effect and sideways force of a boat under sail, but nonetheless they do have keels designed to keep them stable and provide structural integrity. Displacement hulls are often ballasted to increase stability. As a result they have a low centre of gravity making them less susceptible to the wind and waves than planing hulls, which are designed for speed and performance.

Keel problems

It is very rare for a keel to fall off a boat. When this happens the incident often receives a lot of press attention as the subject is understandably of concern to boat owners, builders and designers. Marine accident investigators are usually called in and reports are published explaining the probable causes of these accidents.

There are more common incidents involving keels that require inspections and repairs to be carried out.

Keel bolts inspection

Keel bolts should be inspected once a year for signs of corrosion. Most keel bolts of modern boats with cast iron keels are studs, threaded into a tapped hole in the keel. Keel bolts can be made from either stainless steel or galvanised steel.

Lead keels often have J shaped bronze bolts cast into the lead. Bronze is only used with lead keels as bronze and cast iron create a galvanic reaction.

An inspection entails looking from the inside and outside of the boat:

Outside check

- If there is rust appearing along the hull to keel joint then this is a clear warning sign that the studs may be corroding.

- Look for any signs of movement between the hull and keel, such as splits in the seal or cracks in the hull area around the joint.

Inside check

- Do a visual check of the fastenings in the bilges, making sure you take a look at all of them even if they are hard to access.

- Dry and clean the bilge – the bilges should be kept dry at all times to help prevent corrosion of the fastenings, even if they are stainless steel.

- Some staining and minor rust is quite common but heavier corrosion needs to be checked over carefully.

- Surveyors tap the studs with a hammer and know what sounds to listen for. A ringing sound is good, a dull sound is not good.

- Check for any stress cracks in the bilge area around the keel bolts, which indicate there has been movement. If you see damage like this then it would be wise to have the keel removed for further inspection.

Keel bolt corrosion

Keel bolts can sometimes be withdrawn for inspection to check their condition and for any signs of corrosion. This entails first removing the nuts one by one and inspecting the threads for signs of crevice corrosion.

Quite often, it is the middle part (the waist) of a bolt where the corrosion is taking place, which is where the hull joins the keel. This is caused by the failure of the seal at the hull-to-keel joint, which allows sea water to reach the bolts and corrode them. Under these circumstances, the seal will need to be replaced as well as any corroded keel bolts.

If you have any cause for concern it is wise to ask an expert to take a look and advise whether the keel needs to be removed for further investigation and repair.

Keel bolt and hull-to-keel seal replacement

A typical repair involving keel bolt replacement and new hull-to-keel joint proceeds as follows:

- A frame is prepared to support the keel when it is separated from the hull.

- The boat is supported in the boatyard hoist or crane.

- The keel bolt nuts and washers are removed from inside.

- The boat is hoisted a little off the cradle.

- As separation begins steel blades are inserted into the hull-to-keel joint crack to cut through the seal. Steel wedges may be hammered into the joint to encourage separation. This can take several minutes as seals are sometimes reluctant to give way.

- Once the hull and keel are separated the boat is lifted clear from the keel. The keel now rests in the wooden frame.

- The keel bolt studs are inspected. If any are badly corroded or distorted then they are removed and replaced.

- The old sealant is ground away from the flat surfaces of the hull join and keel top.

- The fibreglass hull around the join area is checked for stress cracks. If these are found then the hull will need to be strengthened with new layers of woven fibreglass mat and epoxy.

- The hull and keel top are prepared thoroughly for priming in order that the new sealant can be applied.

- The boat is slowly lowered back down onto the keel, then the backing plates, washers and nuts are fastened. Excess squeezed out sealant is wiped off.

- The nuts will need to be torque tightened according to the recommended keel bolt diameter torque settings as the seal beds down and checked again after the boat is relaunched for any signs of leakage.

[fts_facebook type=page id=820902544629856 access_token=EAAP9hArvboQBAMMusRb1XctIwYq9fUcSZCVNDQAMjkZCiqAIMiZBkawPJZB3VkeSsH6gCIDfIZAslzZBRAEXYdesg0fu11YIst1FXtABBwdULjOsYFGUYqNujLSxRIWxKAcqm7bb9dmAgzJDZCVhkRj6r9useCQqJr4wJnxkBv909ySYxqj7hYl posts=4 height=650px description=no posts_displayed=page_only]

Recent Posts

- Navigating narrow channels

- DIY boat upgrades: Budget-friendly projects to enhance your (older!) boat

- Learning about diesel engine maintenance

- 2023 Rolex Fastnet Race – Part 3

Sailboat Keel Types: A Complete Guide

Last Updated by

Daniel Wade

June 15, 2022

A keel is a very important part of a sailboat, crucial to its stability and ability to sail upwind. This article will discuss the fundamentals of all keels down to the details of the best keel for your boat. We will answer questions including what it does, what it's made of, and even some problems that a keel can cause. By the end of this article, you will be an expert on all things keels!

Table of contents

What Is a Keel?

A keel is the robust underwater centerline of a boat, and often extends into a long, hydrodynamically shaped blade.. It can vary in size and shape depending on the make and model of the boat. But, generally, it will look very much like a fin. If you imagine the fin on the underside of a surfboard you will have a pretty good idea of what it looks like under the boat.

It is crucial to helping with steering and control. The word keel itself comes from Norse and Dutch roots. The word simply means a structural component of the boat. You may have heard the term keel-haul, where pirates would drag someone underneath the boat across its keel. This is pretty barbaric, but it shows just how long a keel has been an important part of the boat. From Vikings to pirates to modern sailboats it has always remained an important part of a sailboat.

What is a keel made of?

A keel will typically be made of whatever the rest of the hull is made of. If the boat is wooden, it will most likely have a wooden keel. If the boat is metal, the keel will be metal, and so on. Sometimes, particularly on fiberglass boats, the core of a keel will be reinforced with lead or a similar ballast while the outside is covered with fiberglass.

The keel needs to be strong enough to withstand a lot of pressure and strain. Traditionally Viking sailing boats would have a wooden keel with some metal plating on it. Casting metal was tedious so putting it on your boat was seen as a waste. Traditional wooden sailing boats, like you would imagine pirates sailing, would also have a wooden keel. It would be made from thick hardwood like oak and could also be metal plated.

Since it is used to control the direction it must brunt the force of the change of direction. If you imagine a boat turning sharply, there will be a lot of pressure on the side that is on the outside of the turn. The hull of your boat will stand up to this pressure easily, as it is very large and very strong. The keel must be strong enough to withstand this too. The keel also can drag on the ocean floor or the boat ramp as the boat is lowered into the water. For this reason, it needs to be strong enough to hold up to the weight and pressure of the boat too. If it were made of plastic it would break every time you brought the boat in and out of the water.

What does a keel do?

The keel is there primarily for stability and guidance. The keel provides all sorts of benefits to the boat. It improves the righting moment and controls the boat’s sideways movement. The keel will also typically hold the boat’s ballast. The ballast keeps the boat weighed down and helps prevent capsizing. The ballast is typically made of lead, sand, or water.

Keels can be fixed or moveable. Some keels can be removed completely or may just retract slightly so they aren’t damaged when the boat enters or exits the water. When a boat leans to one side, because it is turning or there is strong wind/waves, the keel provides the righting moment that keeps the boat from flipping. On larger boats, it is designed to be so heavy that ig will be able to recover a boat from almost any angle of heel. Without a keel, your boat may tip too far or roll completely. On bigger ships, this can be disastrous. In its ability to prevent this alone, the keel is one of the most important parts of the ship.

Does my sailboat need a keel?

Yes, you do need a keel. Pretty much all sailboats have a keel, with exceptions for multi-hulled and/or smaller boats.

In the case of catamarans, the very design principles that lead to the dual-hull design render the keel obsolete. The stability introduced by the outrigged, dual-hulls replaces the necessary righting moment from the keel. Because almost all the structure of a catamaran is between the two hulls, unlike a monohull which builds out from and around its centerline, there is not a lot of weight pressing out to flip the boat. Related to this, since most catamarans have the length of their hulls pressing into the water, the steering force normally placed on a keel is distributed across the length of the two hulls, which additionally will carry their own ballast.

On smaller dinghies, a small swinging centerboard or daggerboard will suffice to play the role of a keel. The centerboards can be big enough to keep the boat flowing nicely through the water without the need for a large keel. Additionally, it is not a disaster for a small sailing or racing dinghy to capsize, as they are designed to do so and recover rather easily, so the ballast from the keel is also not terribly necessary.

If you have a motorboat you wouldn’t need a keel, unless it is a very large container ship or military vessel. The reason being that they are outboard propelled. The leg provides enough stability on its own. This is only the case with full plane powerboats. Displacement (even semi-displacement) craft will still need a keel of sorts for stability purposes.

What are some downsides to having a longer keel?

If you have a long keel that doesn’t retract or detach, you may have some problems coming in or out of the water. The keel extends far below the bottom of the boat, so if you are bringing your boat up or down a boat ramp you may find that it scrapes on the bottom. If you are not careful, you may damage the keel rather badly.

Since the keel is made of metal, wood, or fiberglass it can bear the brunt of the weight quite well. If you are putting your boat in the water and cannot retract the keel, it is a good idea to go as far into the water as possible before taking your boat off its trailer. The deeper you are in the water when the boat is released the better.

Are there any nautical traditions about the keel of the boat?

The keel is interestingly very important when it comes to boat or shipbuilding.

Traditionally, the keel is one of the first parts of the ship to be made, as the rest of the ship must sometimes be built around it. This tradition is called “laying the keel,” and is a momentous occasion. It is essentially the boat’s birthday. The boat’s age is dated from this moment, and there is also typically a celebration of sorts. This goes back to the days of seafaring exploration. The only day more important in a boat’s life is the day it is finally launched.

Can other types of boats have keels?

Yes! Many other types of boats have keels, not just sailboats. A good example would be a big shipping trawler. These trawlers are very large and need all the help they can get to stay balanced. Because of this, they often have what’s called a bar keel. This is a large rectangular piece of metal that runs along the bottom of the boat’s hull. It is very thick and heavy. The idea is that it gives the boat some more directional control when steering.

Furthermore, it helps keep the trawler balanced when out at sea in rough conditions. The extra weight keeps the boat’s center of gravity as low as possible. This makes tipping the boat almost impossible. It does slow it down a bit, but that is a small price to pay for increased safety.

Huge cargo ships also have a keel, though it is different from a bar. Their keel is known as a plate keel. It is essentially another layer of the boat under the hull. Its only purpose is added weight and protection. A plate keel runs along the centreline of the bottom plate of the ship so the weight is all concentrated in the lowest place possible. This kind of keel works similarly to how the spine of a person does. It keeps your back strong and as straight as possible.

How important is it to keep my keel clean?

It is very important to keep your keel clean, just as it is important to keep the rest of your hull clean.

For any boat kept on the water rather than hauled out every day, there is always the need to clean the hulls and keels of any barnacles and other sea growth. Barnacles not only affect your performance, but can, in the long run, greatly increase your maintenance costs if not regularly addressed.

To do so, you have to do what is known as scraping. Scraping is the process of physically scraping off all the barnacles and other sea life that has attached itself to the underside of your boat. Many marinas offer this service, but you can do it on your own with a basic plastic paint scraper and a wetsuit. When you do this, it is key to get all the way down to the bottom of the keel and all across the hull. If you don’t scrape it off, it can start to erode your boat away over time. It can also slow you down.The barnacles and other marine life create a very rough bottom. This creates more friction and will reduce your speed more and more the worse it gets.

It is important to check with your port authority before you start scraping. Scraping is not allowed in some places as you may introduce invasive species to the area. It depends where you have been more than where you are. If you sailed from New York to Chicago, you will be fine. If you sailed from Cuba to New York, probably not so much.

How to maintain a sailboat keel

As mentioned above, it is important to scrape your keel from time to time. While racing boats will actually do this before every day at an event, it is at least a good idea for you to do this a couple of times a season. A great time to do this is when you plan on applying that season’s bottom paint, though anytime you plan to go on your boat is a good excuse to maintain!

You may want to cut off any of the kelp and seaweed that wraps itself around the keel. This is more likely to happen if you have a fin keel. If you do find that there is a lot of kelp and seaweed wrapped around it, you will want to buy yourself a kelp cutter. Unfortunately, the only way to cut the kelp off without taking the boat out of the water is to dive in and do it yourself. It is a good idea to do this in shallow-ish water with the proper flags displayed to inform other boaters that there is someone in the water. Swimming around under your boat, even when it isn’t moving, can be dangerous.

What do I do if my keel breaks at sea?

It is very rare for keels to just break off. It is even rarer at sea. After all, what is going to break it off? The only way a keel will break off ordinarily is if you run aground.

If you should accidentally make your way into shallow waters and break your keel off it is a good idea to set sail for home. You will manage well enough in the short term but will struggle over time. You are far more likely to capsize without the keel keeping you balanced.

If you have a detachable keel it is a good idea to keep a replacement. If one breaks off, you can just install the spare one. This isn’t the easiest thing to do at sea in rough conditions, but it is possible. Make a judgment call using your common sense whether it is worth the risk or not.

Another reason your keel might break or come loose is if the keel bolts come out. These bolts are what holds the keel in place. If you happen to have a keel held on by bolts, then doing proper maintenance is even more important. If the bolts come loose, the keel can come loose.

Since the keel is typically welded on to the boat’s hull the chances of it coming off completely are slim to none. Most often, running aground on a sandbar or anything short of an incredibly rocky bottom in heavy weather will crack off a piece or severely bend the keel, which requires a major repair. If you do notice that the keel is loose, you are better off taking it back to the marina. The bolts may not come off without using some machinery, meaning you might have to take your boat out of the water. If your keel starts to rust, you may need to speak to a professional.

What are the different keel types?

Now you know what a keel is, what it does, why it is important, and how to care for one it is time to learn about the specific types of keels. Big trawlers and cargo ships have bar or plate keels, but sailboats do not. Here are the 6 different types of keels typically found on sailboats and their purposes:

The full keel is one of the most common types of the keel that you are likely to see on a sailboat. A full keel runs from end to end of the boat lengthways. A full keel, as the name implies, runs almost the entire length of the boat. At a minimum, it must run 50% of the length of the boat. A full keel is one of the most stable keel types, which is why it is so common. Full keels are also safer should you run aground. If a boat with a full keel should come ashore, it will cut its way through the sand and eventually land on its side. Whether you are grounding your boat intentionally or not, your boat will have far better odds of surviving the ordeal with a full keel.

A fin keel is similar to a full keel, just shorter. There may be one or two fin keels along the length of the boat hull. A fin keel is defined by being less than 50% the length of the boat. The fin keel works almost entirely the same way that a shark's fin does. When you wish to turn, the keel provides the resistive force that keeps you turning. This means that it essentially acts as your tires going into a turn. Whereas a full keel is essentially just a long fin, a fin keel has very different benefits. A full keel is more stable and safer overall. A fin keel is sleeker, smaller, and most importantly makes you faster. Most racing sailboats have fin keels.

A bulbed keel is very similar to a fin keel. In fact, it is possible to make a bulb keel by shaving off part of a fin keel and attaching a bulb. Once the keel has been made substantially shorter, the bulb is fitted. The bulb is shaped similarly to how a torpedo would be on a submarine. This keel works the same as a fin keel does, offering a slightly more stability without sacrificing speed. The biggest difference between a bulb and a fin keel (besides shape and length) is where they are used. Bulb keels are most commonly used in places with very shallow waters and lots of rock/shale/coral outcrops. Somewhere like the Caribbean would be the perfect place for a bulb keel. The rounded bulb bounces off the rocks and is less likely to break off. It just isn’t going to be as quick as if you used a fin keel.

The wing keel is another alternative to your standard fin keel. Just like the bulb keel, a wing keel is an extension to the standard fin keel with an extra fitting at the bottom. A wing keel is far more streamlined than a bulbed one, at the expense of being more susceptible to breaking. A wing keel looks very similar to the tail of an airplane. It works the same way, too. The water can pass by either side of the wings, allowing you to adjust your course easily. But, a wing keel does have one major problem. If you do run aground, digging out a wing keel can be very difficult. Whereas digging out a standard fin is as simple as scraping sand away from the sides of it, a wing keel must be dug out completely. The wings act like little shovels and wedge themselves into the sand. These are generally limited to higher performance racing classes.

Centerboard Keel

A centerboard keel works similarly to a fin keel but it can retract slightly. It works by having a dagger that folds out downwards. When you are sailing, the dagger protrudes outwards and offers you all the stability and balance of a fin keel. When you are in shallow water, the dagger can be retracted upwards, essentially shortening the keel temporarily. This should be done when you are sailing in shallow waters or removing the boat from the water entirely using a boat ramp. Some centerboards work on a loose hinge. When the boat is sailing along, the dagger is out and the fin works as normal. If you should bump into something though, like some shallow rocks, the hinge would push the daggerboard back inside. This stops the keel from breaking, instead, it just moves out the way. This only works if you are only just deep enough. If you are in very shallow water you would just break the centerboard off.

Canting Keel

A canting keel also works on a hinge. Instead of working end to end, it works port to starboard. When the boat turns a corner, the canting keel swings from side to side. This allows the boat to maximize its balance and speed. Eventually, this will become the norm in racing. But at the moment it is still quite experimental. The biggest downside is that the hinge works on hydraulics, and hydraulics can fail. If they should fail at sea there is very little you can do to repair them. Once they have perfected these canting keels, they will move first into the racing classes and high performance boats, then to all new cruising boats as boatbuilders improve the technology. .

Hopefully, you now have a good idea about what a sailboat keel is,how it works, why it is so important, and, of course, all the different types. Chances are, when you buy a sailboat , the keel it has is going to be at the bottom of your list of priorities. That being said, if you are planning on sailing somewhere in particular, it is a good idea to think about what keel type you are using. Replacing them doesn’t have to be expensive, but you can go a long way to saving yourself that money either way by being prepared for your home waters!

Related Articles

I've personally had thousands of questions about sailing and sailboats over the years. As I learn and experience sailing, and the community, I share the answers that work and make sense to me, here on Life of Sailing.

by this author

Learn About Sailboats

Most Recent

What Does "Sailing By The Lee" Mean?

October 3, 2023

The Best Sailing Schools And Programs: Reviews & Ratings

September 26, 2023

Important Legal Info

Lifeofsailing.com is a participant in the Amazon Services LLC Associates Program, an affiliate advertising program designed to provide a means for sites to earn advertising fees by advertising and linking to Amazon. This site also participates in other affiliate programs and is compensated for referring traffic and business to these companies.

Similar Posts

Affordable Sailboats You Can Build at Home

September 13, 2023

Best Small Sailboat Ornaments

September 12, 2023

Discover the Magic of Hydrofoil Sailboats

December 11, 2023

Popular Posts

Best Liveaboard Catamaran Sailboats

December 28, 2023

Can a Novice Sail Around the World?

Elizabeth O'Malley

4 Best Electric Outboard Motors

How Long Did It Take The Vikings To Sail To England?

10 Best Sailboat Brands (And Why)

December 20, 2023

7 Best Places To Liveaboard A Sailboat

Get the best sailing content.

Top Rated Posts

Lifeofsailing.com is a participant in the Amazon Services LLC Associates Program, an affiliate advertising program designed to provide a means for sites to earn advertising fees by advertising and linking to Amazon. This site also participates in other affiliate programs and is compensated for referring traffic and business to these companies. (866) 342-SAIL

© 2024 Life of Sailing Email: [email protected] Address: 11816 Inwood Rd #3024 Dallas, TX 75244 Disclaimer Privacy Policy

- Forums New posts Unanswered threads Register Top Posts Email

- What's new New posts New Posts (legacy) Latest activity New media

- Media New media New comments

- Boat Info Downloads Weekly Quiz Topic FAQ 10000boatnames.com

- Classifieds Sell Your Boat Used Gear for Sale

- Parts General Marine Parts Hunter Beneteau Catalina MacGregor Oday

- Help Terms of Use Monday Mail Subscribe Monday Mail Unsubscribe

Replacement keels

- Thread starter Redemption

- Start date Feb 12, 2011

- Forums for All Owners

- Trailer Sailors

Just a guess on my part, (cos our drop-keel is lead-filled fiberglass)... but if you can still extend the keel and it's not jammed in the trunk, then the chances are good that it can be removed , all rust blasted off then recoated or epoxied. The hard part may be the space and hoisting gear required to get the keep out of the boat and support it for refinishing.

Going to be tough to find a bolt-in replacement.. I agree with Ken.. it looks like some water has penetrated the fairing compound or glass around the keel and has caused the cast iron to corrode. The corrosiion product, rust, takes up a LOT more space than the metal it used to be .. so it swells up under the covering and breaks it apart. The iron is probably still in OK shape and as Ken says, can be removed, cleaned up and re-faired if desired.. If it freezes in your part of the world, it could have been freeze damage in addition to rust swelling..but probably all from a place where water got in and sat there for a long time before making its own drain place. Remove the keel, repair/replace the lifting cable and attachments.. clean the fairing material off the keel.. sandblast, repair as necessary, and coat with a good primer then re-fiberglass as desired.. Not too bad of a job.. Good Luck!

watercolors II

Can the keel be removed? The chances are that the metal keel is OK but the keel surface and finish needs to be redone. The first question you’ll have to ask your self and then tell us, can the keel be removed? The problem with many of the trailerable sailboats manufactured in the late 60’s and early 70’s was that the keel could not be removed or replaced, this was the downfall of many early production boats. The manufactures who realized their mistakes early on survived into the 80’s before production ceased for financial reasons. These early models, the keel pivot bolt was glassed into the hull so that the inside of the cabin had to be cut out to remove the bolt to drop the keel, which added to the cost and created interior cosmetic damage that could not be covered up.

I heard that mcgregger is still arround and does respond to this type thing. I think hes in california

Thank you for your responses I am pretty certain that the keel is not jammed as the PO had the keel resting on the trailer support so its not been retracted all the way since long before I came into the picture. Early on I started taking out interior parts for repainting or reupholster and long ago found the keel bolt and lock area. those are luckily not hidden by fiberglass and the keel can be removed. I had heard that such boats existed and was relieved to know that the bolts on mine are exposed. :dance: a replacement bolt kit was ordered fro BWYachts about 4 days ago and will be here soon. I have a lead on stands for the front of the boat for 150 ea from a boat disposal yard I know of but depending on what they look like I might have to knock around with the price some. luckily I have ALL the equipment to do this job, including the sandblaster. but I do have a question regarding epoxy. I have read somewhere that is is better to use epoxy resin as opposed to the the current type because epoxy resin does not take on small amounts of water like the current does. Does anyone know anything about this? yeah I am in California but Mac is closed until the end of spring break so tomorrow after classes I will be calling them. little chance of freeze damage but unlike most swing keels this boat has been all over. NY for one

My Venture 25 has a cast iron swing keel not covered in fiberglass. I had a V-222 which had the glass keel and over time the water got in and it split. Your V-24 hull is very similar to the V-25. Try contacting someone at the San Fernando Valley Yacht Club. I still have acquaintenances there, Dave Osborn or Steve Schiff in particular who are probably the resident experts on Ventures. All the swing keel Venture/Mac keels are removable by jacking up the boat, pulling out the trailer removing the pivot bolt and dropping the keel onto a cradle. Not as easy as I describe but I have done it twice to two different Ventures. Fair Winds and Full Sails...

read your other post. I have no idea what the cost of cast iron is per pound. I have also been told they came both with and without fiberglass. would you say there is any benifit one way or another?

Redemption said: read your other post. I have no idea what the cost of cast iron is per pound. I have also been told they came both with and without fiberglass. would you say there is any benifit one way or another? Click to expand

Ill do that, might be cool to cast my own keel, supposing the iron one is shot

Your keel may look like this under all that stuff-- http://sailingsmall.com/photopages-ext/photo8.html follow the pictures

Merlin Clark

timebandit said: Your keel may look like this under all that stuff-- http://sailingsmall.com/photopages-ext/photo8.html follow the pictures Click to expand

merlinuxo said: ==== Is that yours? What a great job on that boat! I'm restoring an old Morgan and hope she looks half that good when I get done. Click to expand

- This site uses cookies to help personalise content, tailor your experience and to keep you logged in if you register. By continuing to use this site, you are consenting to our use of cookies. Accept Learn more…

- New Sailboats

- Sailboats 21-30ft

- Sailboats 31-35ft

- Sailboats 36-40ft

- Sailboats Over 40ft

- Sailboats Under 21feet

- used_sailboats

- Apps and Computer Programs

- Communications

- Fishfinders

- Handheld Electronics

- Plotters MFDS Rradar

- Wind, Speed & Depth Instruments

- Anchoring Mooring

- Running Rigging

- Sails Canvas

- Standing Rigging

- Diesel Engines

- Off Grid Energy

- Cleaning Waxing

- DIY Projects

- Repair, Tools & Materials

- Spare Parts

- Tools & Gadgets

- Cabin Comfort

- Ventilation

- Footwear Apparel

- Foul Weather Gear

- Mailport & PS Advisor

- Inside Practical Sailor Blog

- Activate My Web Access

- Reset Password

- Customer Service

- Free Newsletter

What You Can Learn on a Quick Test Sail

Cabo Rico’s Classic Cutter

Bob Perrys Salty Tayana 37-Footer Boat Review

Tartan 30: An Affordable Classic

Preparing Yourself for Solo Sailing

Your New Feature-Packed VHF Radio

Preparing A Boat to Sail Solo

Solar Panels: Go Rigid If You have the Space…

When Should We Retire Dyneema Stays and Running Rigging?

Rethinking MOB Prevention

Top-notch Wind Indicators

The Everlasting Multihull Trampoline

Taking Care of Your 12-Volt Lead-Acid Battery Bank

Hassle-free Pumpouts

What Your Boat and the Baltimore Super Container Ship May Have…

Check Your Shorepower System for Hidden Dangers

Waste Not is the Rule. But How Do We Get There?

How to Handle the Head

The Day Sailor’s First-Aid Kit

Choosing and Securing Seat Cushions

How to Select Crew for a Passage or Delivery

Re-sealing the Seams on Waterproof Fabrics

Waxing and Polishing Your Boat

Reducing Engine Room Noise

Tricks and Tips to Forming Do-it-yourself Rigging Terminals

Marine Toilet Maintenance Tips

Learning to Live with Plastic Boat Bits

- Inside Practical Sailor

Keel Bolt Repair Options

In a few of our past reports on boat financing , Practical Sailor discussed how to pre-inspect your potential dreamboat before committing to the next step and how to bring in a surveyor. Although the articles are geared to the prospective buyer, it is just as relevant to the owner of an older boat. If the boat in question has more than 20 years behind her, one item that will likely come up on a survey is keel bolts – the heavy duty fasteners that keep your keel from going on a bottom tour while you reach for handholds on your suddenly tippy craft.

Despite advances in imaging technology, keel bolts are still very difficult to fully inspect without a bit of surgery. Fortunately, some hints of trouble are obvious, like large gaps in the keel- stub joint, weeping rust stains near the keel-stub joint or crumbling bolt-ends in the bilge.

A recent question on keel bolts from subscriber Ed Giles prompted me to plumb the archives of our files on keel bolts, and I came up with several articles going back to some of our earliest issues. (This is one of those fundamental repair jobs that hasn’t change much over the centuries.) Most of the articles were responses to inquiries to PS Advisor , like the one that Ive included below from George Alihof, written to us back in 1990.

For some of our more recent articles associated with keel bolts check out: Sistering Keel Bolts ; When Keel and Stub Part Ways ; and most recently, this months Bilge Oil and Keel Worries . There is also an interesting article from our archives in keel bolt inspection . (Im still looking for Part II to this article which first appeared sometime before 1998.)

Mr. Alihof described a typical problem that many owners face, an ever-widening gap between the keel and stub, often referred to as a smile, since it usually appears at the bow of the boat and assumes the sardonic curve of a slack tightrope. The course of action we recommended back then for Mr. Alihof is simpler than the more complete repair we recommended in When Keel and Stub Part Ways . Either approach is viable. Keel bolt repair is one of those mentally stimulating jobs, because no repair is ever the same, and a proper fix often require a bit of creative engineering. Mars Metal, the maker of most lead keels in North America offers a complete description of their comprehensive keel bolt repair process on its website.

Keel bolt replacement is also an interesting project because you find yourself wielding some unlikely tools, like the pickaxe I used to dig a trench under Toscas iron keel, so we could punch out the keel bolts from above. Amazingly, all but two of the pre-World War II keel bolts were in serviceable shape. They don’t make them like they used to I suppose.

Here is Mr. Alihofs query, followed by our response:

Our 37-foot boat has a bolted-on keel, and the joint between the keel and the hull keeps breaking open. Should I drop the keel and put bedding compound between the two, or should I try to fiberglass over the joint? The keelbolts are tight.

George Alih

This is a fairly common problem with fin keel, flat bottom boats, and there are several possible causes, including cast-in bolts that are slowly pulling out of the keel, or inadequate structural support for the keel in the bottom of the hull. If you tighten the bolts every year, and more thread shows above the nuts inside the hull, the bolts are almost certainly pulling out of the keel, and you have a big job ahead of you, which would include cutting holes through the ballast near the top, drilling through vertically from the inside of the hull into the openings in the keel, and installing new bolts with nuts and big washers at both the top and the bottom.

We’d also look for signs of compression of the hull laminate in the bilge under the keelbolt nuts. If it’s a cored hull without solid glass up the middle of the hull, the core could be crushing under the nuts, allowing the keel to drop slightly more every year. We’d be tempted to back off the nuts in the bilge, and jack the boat up slightly off the keel. If the joint has indeed opened all the way through, you may be able to lift the hull using a series of screw jack hull poppets, but you must use a minimum of six, and place them only under strongly reinforced sections of the hull, such as under bulkheads.

The boat should be totally emptied of gear, and the tanks should be pumped out to reduce the weight as much as possible. This is potentially a very dangerous job. You must stop immediately if the keel starts to lift off the ground, if the hull begins to dimple under the poppets, or if the chain between the poppets becomes heavily loaded. Sometimes, you can separate the keel by driving a series of hardwood wedges into the joint as you jack up the hull. It ‘ s far safer to do this job with a Travelift or crane, and if you do it in the off-season, the cost should not be excessive.

With the keel free of the hull-but dropped no more than an inch or so, with the bolts still in their holes-thoroughly clean out the joint with a scraper or putty knife, finishing off by flushing thoroughly with fresh water. Allow both the top of the keel and the bottom of the hull to dry. Don’t stick your hand in the joint, ever! We’d put a thick washer of polysulfide compound around each bolt where it enters the hull. but we’d fill the rest of the joint with a stiff, reinforced epoxy putty mixed from resin and Gougeon Brothers 404 high-strength high-density filler.

The boat should immediately be lowered back down on the keel, the keelbolt nuts set up firmly, and the excess squeezed-out putty cleaned away. While you’re at it, replace the existing washers under the nuts in the bilge with large plate washers cut from stainless steel stock at least -inch thick. For a 1-inch diameter bolt, make these plate washers about 4-inch square, and bed them in polysulfide, too. Give the compound a couple of days to cure fully, then re-torque the nuts using a 3/4-inch drive socket and a breaker bar, with a 2-foot length of steel pipe slipped over the breaker bar to increase your leverage.

RELATED ARTICLES MORE FROM AUTHOR

Leave a reply cancel reply.

Log in to leave a comment

Latest Videos

The Great Loop – The Basics

Bottom Paint Showdown – Six Paints, One Winner!

Tartan 30 | Boat Review

Fuel Contamination? The Baltimore Francis Key Bridge Collapse

- Privacy Policy

- Do Not Sell My Personal Information

- Online Account Activation

- Privacy Manager

Boat Genesis is reader-supported. When you buy through our links, we may earn an affiliate commission at no cost to you. Learn more .

Fiberglass Boat Keel Repair

Has your sailboat or powerboat sustained damage to its vulnerable keel? Impact with underwater objects can crack, chip or puncture a fiberglass boat’s keel, compromising structural integrity.

When keel damage occurs, proper repairs are essential for restoring seaworthiness.

This article provides a DIY overview of assessing damage and performing a fiberglass boat keel repair.

5. Fairing & Refinishing Repairs

Fiberglass boat keel repair guide, 1. inspecting keel damage.

After a grounding or collision, thoroughly inspect the keel for cracks , fractures, holes and delamination. Look for stress cracks radiating from the point of impact. Check inside the boat along the keel joint for signs of damage. Determine how extensive the repairs need to be.

Minor chip repairs may only require some basic grinding, filling and refinishing.

Major cracks, holes and delaminated bottom skin necessitate more extensive fiberglass work.

If damage compromises over 30% of the keel depth, professional repairs may be needed to meet safety standards.

2. Grinding Out Damaged Areas

Start by sanding and grinding down all cracked, chipped and punctured areas with 36-80 grit disks to open up the damage.

Remove loose fibers and degrade the gel coat surface to improve adhesion. Create a rough surface profile for the repair compounds to mechanically bond with.

For cracks, the saw cut a V-groove along the length with a circular saw at least 1/8″ deep to increase the surface area. Grind damaged fibers at the root.

Vacuum and solvent wipe repair areas to remove debris and grease before applying materials.

3. Filling Holes, Cracks and Chips

Fill scratches, gouges , cracks and drill holes with thickened epoxy adhesive filler thickened with colloidal silica or micro balloons. Apply filler in layers until flush with the surface, allowing cure time between applications.

For cracks, wet out the inside surfaces with neat epoxy before applying thickened epoxy. Overfill the repair and allow the adhesive to cure before final sanding.

Finish filling holes and cracks by applying structured repair materials.

4. Applying Fiberglass Repair Laminates

Cut several plies of woven fiberglass cloth to overlap damaged areas by at least 2″ on all sides. Pre-fill any cloth texture with epoxy filler.

Wet out each layer of cloth with epoxy resin before applying it to the repair. Use a plastic spreader to smooth the cloth, removing air pockets and excess resin. Apply 4-6 layers of cloth based on existing laminate thickness.

For cracked keels with bottom skin delamination, the detached skin may need re-bonding and supplementary layers of glass cloth overlap for added structural strength.

Allow resin fill coats to fully cure between layers based on product guidelines.

Once the repair plies fully cured, use 80-120 grit sandpaper to fair in the repair and blend with surrounding fiberglass. Fill any remaining pinholes or surface irregularities with polyester or epoxy filler/fairing compound, then sand flush.

Solvent clean and apply three coats of two-part polyurethane topside paint to match your boat’s color.

Lightly sand between paint coats. Touch up registration numbers, draft marks and antifouling bottom paint as needed.

Final Thoughts

Performing quality fiberglass repairs takes some work, but restored integrity and seamless refinishing is achievable with the right techniques.

Follow safety precautions when grinding glass materials and mixing/applying resins. Use protective equipment and ensure adequate ventilation.

With time, patience and the proper methods and materials, you can repair damage to your boat’s vulnerable keel without breaking the bank.

Take things slow, allow adequate cure times and the result will pay off with a keel that’s shipshape. Your fiberglass sailboat or powerboat will be back cutting smoothly through the seas in no time!

Share this post:

Related posts, best gelcoat repair kit for boats in 2024.

How To Fix Small Holes In A Fiberglass Boat? 6 Easy Steps

Repairing a large hole in a fiberglass boat: definitive guide, leave a comment cancel reply.

Your email address will not be published. Required fields are marked *

Save my name, email, and website in this browser for the next time I comment.

Boat Genesis is reader-supported. We try all the products we recommend - No freebies from manufacturers. If you click on our links, we may earn an affiliate commission, which helps support our website. Learn more .

Subscribe To Boat Genesis

Get updates on the latest posts and more from Boat Genesis straight to your inbox!

- CREATE AN ACCOUNT

- Boat Cover Finder

- Bimini Top Finder

- Boat Propeller Finder

- Engine Parts Finder

- Anchor & Dock

- Watersports

- Clothing and Footwear

- Engine Parts

- Cabin and Galley

- Covers and Biminis

- Electronics

- Paint and Maintenance

- Pumps and Plumbing

- Anchor Chains & Ropes

- Boat Fenders

- Boat Mooring

- Boat Protection

- Dock Storage & Protection

- Ladders, Steps, & Platforms

- Top Sellers

- Fishing Rods

- Fishing Reels

- Fishing Rod & Reel Combos

- Fishing Tools & Tackle Boxes

- Fishing Line

- Fly Fishing

- Fishing Bait & Fishing Lures

- Fishing Rod Holders & Storage Racks

- Fish Finders, Sounders & Sonar

- Trolling Motors

- Fishing Nets

- Fishing Downriggers & Acessories

- Fishing Outriggers & Acessories

- Fishing Kayaks

- Fish Cleaning Tables

- Inflatable Rafts

- Paddle Boarding

- Paddles & Oars

- Wakeboard, Wakesurf & Ski

- Wakeboard Towers

- Tow Ropes & Handles

- Life Jackets & PFDs

- Snow Sports

- Roof Racks, Carriers, Dollies

Men's Clothing

- Accessories

Men's Footwear

- Atheltic Shoes

- Water Shoes

Women's Clothing

- Dresses & Skirts

Women's Footwear

- Fuel Systems

- Sacrificial Anodes & Zincs

- Generator Parts

- Inflatable Boats

- Propeller Parts & Accessories

- Boat Manuals

- PWC Parts & Accessories

- Fishing Boat Seats

- Offshore Boat Seats

- Ski Boat Seats

- Pontoon Boat Seats & Furniture

- Boat Seat Pedestals & Hardware

- Boat Seats by Manufacturer

- Boat Tables & Hardware

- Boat Seat Covers

- Boat Seat Vinyl

- Floating Boat Cushions

- Barbeque Grills

- Boat Drink Holders

- Cabin Accessories & Hardware

- Boat Ventilation

- Interior & Cabin Lighting

- Marine Teak Products

- Carbon Monoxide & Smoke Detectors

- Binoculars & Telescopes

Boat Bimini Tops

- Bimini Top Accessories

- Pontoon Bimini Tops

- Other Biminis

- RV & Trailer Covers

- Boat Shrink Wrap & Accessories

- Boat Shelters

Boat Covers

- Boat Cover Accessories

- Boat Lift Canopy Covers

- Other Covers

- Boat Wiring & Cable

- Marine Batteries & Accessories

- Marine DC Power Plugs & Sockets

- Marine Electrical Meters

- Boat Lights

- Marine Electrical Panels & Circuit Breakers

- Power Packs & Jump Starters

- Marine Solar Power Accessories

- Marine Electrical Terminals

- Marine Fuse Blocks & Terminal Blocks

- Marine Switches

- Shore Power & AC Distribution

- Marine Audio & Video

- GPS Chartplotters & Accessories

- Electronic Navigation Charts & Software

- Digital Instruments

- Display Mounts

- VHF Radios & Communication

- Marine Radar

- Auto Pilot Systems

- Action Cameras

- Fiberglass & Epoxy Boat Repair

- Boat Paint & Varnish

- Marine Adhesives, Sealant, & Caulking

- Marine Engine Maintenance

- Boat Cleaners & Waxes

- Boat Cleaning Supplies

- Fresh Water Boat Systems

- Bilge Pumps

- Marine Plumbing Parts

- Wash Down Pumps

- Livewell Aerator Pumps & Live Bait Wells

- Toilet & Waste Pumps

- Marine Pump Replacement Parts

- Tires, Rims, & Hub Kits

- Boat Trailer Winches

- Boat Motor Supports & Transom Savers

- Boat Trailer Guides & Rollers

- Boat Trailer Fenders

- Boat Trailer Lights

- Boat Trailer Hardware

- Boat Trailer Jacks

- Boat Trailer Brakes & Axles

- Boat Trailer Tie Downs

- Couplers, Mounts, Hitches, & Locks

- Boat Deck Harware

- Marine Nuts, Bolts, & Screws

- Boat Handles, Pulls, & Rings

- Prop Nut Kits & Hardware

- Boat Cabin Hardware

- Marine Fasteners

- Boat Windshield Parts

- Boat Tubing & Rails

- Boat Mirrors

- Marine Tools & Tool Kits

- Boat Lettering

- Women's Clothing Deals

- Men's Clothing Deals

- Fishing Deals

- Anchor & Dock Deals

- Electrical Deals

- Electronics Deals

- Paint & Maintenance Deals

- Pumps & Plumbing Deals

- Boat Seats Deals

- Trailering Deals

- Camping & RV Deals

- Dealer Login

- Forums Login

- Search forums

- Boat Repair and Restoration

- Boat Restoration, Building, and Hull Repair

How to fix or repair a keel that has exposed or pitted fiberglass

- Thread starter Sailor98277

- Start date Aug 28, 2013

Sailor98277

- Aug 28, 2013

How would I go about fixing a keel that has its gel coat missing from being grounded on a beach? Would you first fill in the divits with small pieces of fiberglass and resin, then rough sand and put on gel coat or would you just fill in the divits with gel coat? I will take pics tomorrow and post them here to give you a better idea of what I am refering to. Thanks all for your help. Vr, Michael

- Aug 29, 2013

Re: How to fix or repair a keel that has exposed or pitted fiberglass Quite honestly, if it is still watertight and you intend to continue to beach, I would "repair" by installing a keelshield or keelguard strip. I abused the heck out of a previous boat for one season by beaching it multiple times. by the end of the season the gelcoat had worn completely down to where you could see the cloth. I just sanded everything smooth and installed the keelguard over the worn gelcoat. When I installed the keelguard I sealed it all around the edge with 5200, and for two more seasons of boating/beaching I never had an issue. Keelguard looked practically brand new when I sold the boat at the end of last season. When I purchased my new boat, the first thing I did was install a keelguard. Good luck Eric

Woodonglass

Supreme mariner.

Re: How to fix or repair a keel that has exposed or pitted fiberglass Yup ^^^ sound advice. If no more beaching will occur then mix up some thickened resin using resin, cabosil, and some copped up CSM to fill the divots then sand and shape. Use some 3M premium filler for final fairing, then us a Preval Sprayer to spray on 3-4 coats of Gelcoat. Sand and Polish. DONE

Re: How to fix or repair a keel that has exposed or pitted fiberglass Thank you eavega for the information. I had asked this very question to some guys over at West Marine about using a keel guard to fix this and was told that it would not stop the water from leaking through the keel into the bottom of the boat. This was because when water is in contact for an extended period of time, water will seep through the fiberglass and into the inside of the boat. I do not know if that is true or not, hence my reason for asking you experts here. Thank you again for your help. I will be doing what you recommended. Vr, Michael

Re: How to fix or repair a keel that has exposed or pitted fiberglass Thank you woodonglass for your help as well. I will be sure to do as you said and put the keel guard over the patch. It will take me a bit of time as I still have to figure out a way to get the boat raised up so that I can work on the bottom of it and the trailer out from under it. Thanks again. Vr, Michael

Re: How to fix or repair a keel that has exposed or pitted fiberglass If the keel is damaged bad enuf to expose the glass and water can penetrate then it for sure needs to be repaired prior to the installation of a keel guard.

- Aug 30, 2013

Re: How to fix or repair a keel that has exposed or pitted fiberglass Yup, I'd be grinding that down, filling all major gouges and laying 2-3 layers of 1.5oz CSM over all of it and then 3-4 coats of gelcoat with a Preval Sprayer. If you are going to continue beaching her then by all means a Keel guard is in your future!!! What kind of boat is this?

Re: How to fix or repair a keel that has exposed or pitted fiberglass Thank you Woodonglass, I have never had this boat in the water. My brother-in-law convinced my wife it was a great boat for us to use on Puget Sound to go fishing and crabbing in. The floor was soft so that when you stepped into it you felt like you were gonna fall through, the motor wont start even though it has good compression, and the keel is all torn up from beaching. I won't be beaching the boat when completed, but I will be installing a keel guard to protect it none the less. If I remember right, it is an 18' 1967 Las Vegas Sierra Tri-Hull. I have done so many searches for information on this particular boat it is not funny, but have come up snake eyes. I planned on picking up some CSM tomorrow so that I can use it to put down the initial layer of glass and resin on the floor joints then cover that over with woven mat. I am using West Marine Polyester Boaters Resin that I bought in (2) 1 gallon cans. I believe that should be enough to do the joints in the floor and sides where the floor meets the gunnals. I hope that it will also be enough to do one layer on the floor of just resin but we will see as I also have to buy the pour in foam yet this coming Sept. I would love to have the floor all done before the rains hit here in a few weeks. Vr, Michael

Petty Officer 1st Class

- Aug 31, 2013

Re: How to fix or repair a keel that has exposed or pitted fiberglass Did you pay much for the boat? The reason that I ask is that soft floors are quite often indicative of other structural issues, namely wet or rotted stringers and bulkheads. Once you get the floor up, you are likely find that you've opened up a major can of worms. If that happens then you have to decide whether to do a half assed repair, go all the way on a restoration, or scrap it and try to recoup your money. I'm not trying to sound negative, just being realistic as I stumbled into the same situation and now have 36 days straight on my renovation.

Vice Admiral

Re: How to fix or repair a keel that has exposed or pitted fiberglass Hello Bakerjw and grub1grub2, I paid $500 for the boat which included a 80 hp merc outboard that would not run, though the guy said it did. My brother-in-law convinced my wife like I had said and there was nothing I could really do about it as she had her head set on getting it. I pulled up the soft floor, took out close to 800 lbs of water logged foam, and found that one cross member was rotted out. The long stringers seemed solid at the back end of the boat but I had no way of taking the cap off the boat so I could pull out all the stringers and start from scratch. I intend to put 2 lb flotation foam back in which will give it some structural support as well as the obvious floatation requirements. I'm not sure if I will keep the boat or not but I will fix it up all the same as is. It is at best just a temp boat that when I have more money, I will buy a decent boat (like this will ever happen). However, it is only for doing some basic salmon fishing in pretty much calm waters, and wont be taken out into the heavy chop. I still need to fix the motor and find a way to lift the boat up so I can fix the keel with the recommendations from above. It's not the boat I wanted to get but the wife would not let me spend more even though this one will cost me about $1000 just to get it back to seaworthy status and that does not include a functioning motor. Oh well, what is a guy to do? I like being on and around the water so I will make do. When I have the floor done or further along with its first coat of glass, I will take a pic of it. Vr, Michael

Re: How to fix or repair a keel that has exposed or pitted fiberglass Thanks Woodonglass, I have checked part of the stringers where the foam was the wettest and the stringers were ok there, however that does not mean the whole of them are fine. As for the transom, it is solid. The motor on it will not be the one staying on it. the control arm that turns the motor left and right comes into contact with the left side of the troff in the top. I will most likely down grade the motor if I keep the boat to about a 50 hp. I have a neighbor who wants to buy the boat for $500 or so to include the trailer. I have been giving that serious thought. I do not have the funds to pull the whole bottom apart and redo as necessary being I am on such a limited income. However others might and this guy would most definately have the cash. Then again, who knows. Thanks for the tips and information as it is greatly appreciated... it is also a very good learning experience. Vr, Michael

Re: How to fix or repair a keel that has exposed or pitted fiberglass Did you actually drill into the stringers and the transom to inspect the shavings or just do an outward visual inspection and some tapping around with a hammer and such??

- Sep 2, 2013

Re: How to fix or repair a keel that has exposed or pitted fiberglass It was a drill as I made a pilot hole when I put the new cross member in toward the rear of the stringers. When I screwed the floor down, the screws again had pilot holes to follow, and the ones at the back were or seemed fine, but the others might have been a bit to easy going in now that I think of it.

Petty Officer 3rd Class

Re: How to fix or repair a keel that has exposed or pitted fiberglass repair with a kevlar reinforced epoxy paste - you can use glass with it , but sounds like you don't need to google wet dry 700 epoxy Paul Oman - MS. MBA A.K.A. “Professor E. Poxy” Internet Epoxy Confederation (IEC) Homepage epoxies since 1994 Member: NACE (National Assoc. of Corrosion Engineers) -- SSPC (Soc. of Protective Coatings)

IMAGES

VIDEO

COMMENTS

Ship Wright Chris Carl shares his step by step process for fiberglass keel repair.

At the end of the 2020 season Plastskador took Aurora carefully into the yard to await the repair. Now it's finally time to take her in and start fixing her ...

Treatment of superficial gouges in gelcoat or the first layers of the laminate is straightforward. First, wash the damaged area thoroughly with high pressure fresh water. Dry the gouged area with a handheld hair dryer. Roughen the edges of the gouge with very course sandpaper - 50 grit or 36 grit.

Keel bolt replacement is also an interesting project because you find yourself wielding some unlikely tools, like the pickaxe I used to dig a trench under the iron keel of my former boat a 1937 Atkin ketch. The holes were required to punch out the keel bolts from above. Amazingly, all but two of the pre-World War II keel bolts were in ...

Encapsulated keel repair of a Aloha 27 sailboat suffering from water infiltration.Thanks to Cory for his hard work and dedication to this project and Denis f...

The most common sailboat keel types are full-length keels, fin keels, bulb keels, wing keels, bilge keels, and lifting keels. Full keels are popular among cruisers, while fin keels are generally used for racing. Bilge keels and lifting keels are typically used in tidal waters, on small fishing boats for example.

Don Coxe, the buyer, completed the replacement project himself last winter using a document available from Beneteau USA. New galvanized bolts purchased from Beneteau were threaded into the iron keel from the top. (Lead keels use stainless steel studs cast into the lead.) The challenge is to wind the old bolts out, but for the truly confident ...

For safety reasons, the act of removing the keel bolts makes the boat unable to balance the keel in the vertical position. Environmental precautions, we have all the required procedures in place to deal with the use of lead, most yards do not. Access to the bolts, the repair procedure, removal and replacement, requires that the keel be sitting ...

Keel bolt and hull-to-keel seal replacement. A typical repair involving keel bolt replacement and new hull-to-keel joint proceeds as follows: A frame is prepared to support the keel when it is separated from the hull. The boat is supported in the boatyard hoist or crane. The keel bolt nuts and washers are removed from inside.

A full keel runs from end to end of the boat lengthways. A full keel, as the name implies, runs almost the entire length of the boat. At a minimum, it must run 50% of the length of the boat. A full keel is one of the most stable keel types, which is why it is so common. Full keels are also safer should you run aground.

Let's define the keel as follows: Offered in USD. It is 5,000 lbs. with 8 bolts. Is within approx. 1,000 hundred miles of our facility. The re and re of the keel that is up to your local yard. (Additional cost not covered by MarsKeel Technology) The bolt replacement is $475.00 per bolt plus freight. 8 bolts ...

It should be pretty obvious that the boat can not be resting on its keel on the ground to this job. The keel must be blocked up, and the supports must be clear of the part of the keel through which the bolts pass. With a deep keel, it may also be necessary to dig a hole under the keel to get enough depth to drive the bolt free.

Remove the keel, repair/replace the lifting cable and attachments.. clean the fairing material off the keel.. sandblast, repair as necessary, and coat with a good primer then re-fiberglass as desired.. ... Easiest way to drop the keel is to jack the boat up to get it off the trailer.. then winch the keel down until the bottom is resting on the ...