- No products in the cart.

Catamarans and Trimarans

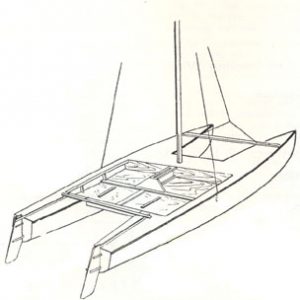

Catamaran and Trimaran Boat Plans make it a reality to build your own catamaran or trimaran. Multi-hulled sailing vessels are a special class of boat. A very different mind set is required when thinking about sailing a multi hull, let alone getting your head around building one.

There are some unique challenges building a multi-hull sail boat, the extra beam added by each hull for instance can create storage issues while under construction. Hartley boat plans make the build process straight forward for even amateur builders. However with all things considered, building a multi can be an amazing journey.

Fast Twin Catermaran

Lively 28 Cruising Trimaran

Lively 35 Cruising Trimaran

Your sailing multihull DESIGN-INFO site for…

Small trimaran information, small multihull design, design issues, construction methods, comparisons of designs, speed, stability, and much more….

W17 Main Page

—Chris, Queensland

—Andrew, Philippines

—Jonathan, Michigan

—JR, first W17 kit owner

—Alan, St-Jean-de-Luz, France

—Louis & Luigi, Philippines

—David, Philippines

…I'm very impressed with the seaworthiness of this little boat. I have been in places I clearly should not have been, and in some very bad weather too…

—Andrew, Philippines

Read more sailors' comments…

…was immediately struck that Mike's design goals closely matched my own. Really liked the look of the curved akas and plans for a wing mast are a big plus.

—Gary, Virginia

Read more builders' comments…

This boat…has such style and lines that she'd look totally in place as a sporty tender or toy on the deck of a fine Italian mega yacht. Very nice indeed!

—Marshall, Florida

—Don, Alberta

" ... the W17 feels like it's flying through the water and air, unlike any other sailboat I've ever been on .... as it slips over the water with such agility and efficiency

—Bill, W.Virginia

‘The Waters Edge’

W22 main page.

Fram's Building and Sailing Pages

Introduction.

Hello and thank you for showing interest in the building story of Fram, my F-39 trimaran.

Using the “Next” button at the bottom of this page will guide you trough the whole construction process. But be warned, there is a lot of information and thousands of pictures, so it can take some time for the interested reader.

Initially, the choice for my new to build boat fell on the high-tech F-36 trimaran, a design by the famous New Zealander Ian Farrier ( † RIP Dec.8, 2017).

In those days the F-39 did not exist yet. Although the F-36 missed my preferred folding option, the design nevertheless meets most of my wishes. According to Farrier, there was simply not enough demand for a folding option for such a large trimaran. And is it not true that a boat is always a compromise ?

Actually, the determining factor to go on with this Farrier (F-boat) design was the superbly detailed building plans and the building method. The more I studied the plans, the more I realized that this boat is an engineering marvel and accompanied by an building method that I could manage. So all necessary attributes for an high quality yacht!

However, somewhere in my head I still felt the obligation to find out whether it was not better to outsource the construction to a suitable yard. Though, I had already realized that this would be far above my budget, which was indeed proven by offers from various yacht builders at home and abroad.

“The desire to build a boat ... begins as a little cloud on a serene horizon. It ends by covering the whole sky so that you can think of nothing else.“ quote Arthur Ransome

I can not deny that this state of mind led to the purchase of the building plans. A stack of paper from which a boat has to be built. This is the beginning of an almost incalculable adventure.

I bought the original F-36 plans in the spring of 2000 and planned the start of the construction process by the end of that year. But it worked out differently.

And I want some new furnishings too ................

And the kids want a bigger rabbit hutch..............

By finishing this and carry out your promises I will be ready for the project.

Of course she was right !

Update to the F-39

Autumn 2001 everything was done. In the meantime I have been searching for materials and suppliers, and have negotiated for prices and specifications. As still being a greenhorn in composites, I tried to get familiar with all these composite materials and worked on another F-36 (thanks Gary Mulder) to go through the laminating process of the main hull.

And just before I ordered the materials for the first float there was a very welcome note from Ian Farrier that he decided to upgrade the F-36 to an F-39. The new design is not only larger but also includes a number of improvements, the latest design insights, rotating mast and last but not least the folding option.

So this delay wasn't too bad at all and now I could update without any trouble and not having done the wrong things. Spring 2002 I ordered the updated plans. Not all drawings were ready yet but there was enough to make a start.

In the spring of 2003 the form frames for the first float are upright.

Vacuum Resin Infusion.

In the year 2000 when I started to study the possibilities for a DIY boat building project, I was a total composite greenhorn, but I already had learned that a vacuum treatment was desirable to get the lightweight multihull quality I was looking for. However, it was hard to find any information about how to get a vacuum densified laminate within my range of possibilities.

I learned to understand the vacuum bagging technique but the implementation looks to be very challenging. At least to me. The fact that this technique should start with old-fashioned hand lay-up and then to be completed within the time constraints of the resin clock currently looks very discouraging to me. And for laminating and subsequent vacuum bagging the hulls are many helpers needed for which I do not have enough space in my humble workshop.

An article in our local ″ Zeilen ″ magazine put me on the trail of the vacuum infusion technique. This has given me a whole new perspective on the matter. Although, there was almost no information available, except that it was some kind of black magic, operated behind closed doors by some very professional boat building plants.

A breakthrough was made possible through the purchase of knowledge at Polyworx in the person of Mr. Arjen Korevaar.

With almost no previous composite experience, I suddenly saw the possibilities to make my boat building project possible and still be assured of the best possible quality. After all, vacuum infusion is a defined process that not depends of my initially lack on knowledge and experience and skills for laminating big boat hulls. It gave a boost to the preparations.

Earlier in the eighties I have built an epoxy/wooden boat, somewhere in a remote barn. From that I learned that I will never build a boat again in a different location than at home.

In the past I did a rebuilding of the garage of our modest house with the intention to enlarge the living room with the aft part of the (former) garage. But I had also a hidden motive to built a new boat, so the actual joining with the living room had still to wait some time ....

Building at home is essential for me. Despite the small room for this project, it is much more efficient than a workshop somewhere else. It's save, I can leave the things behind me and every single moment of the day, or when I feel like to do something, the project is just a few steps away. But the most important advantage is the fact I can stay at home and near my family, a great benefit to family- and social live.

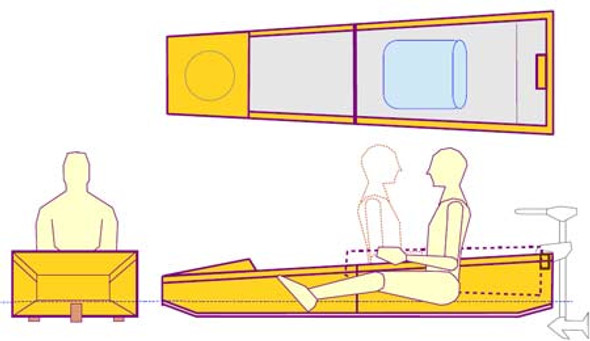

With extension the working area is about 13 x 3,7 m², but the height is not enough to join the two main hull halves together. So I have to do this somewhere else.

Since there is only just enough room for the main hull (or halves), I made an attic floor for workbench and vacuum table. In fact, the whole floor is a 3,5 x 3,7 m² bench and a standing room is 0,9m. lower in front of this (removable). With the main hull in place, I don't need this lower floor anymore as working at the bench is possible while standing on the F-39 cabin roof.

However, I still need to learn to have the discipline to be very organized and clear, to be able to manage this job in this limited space. Anyway, I don't have a choice. I would never attempt such a project in another location than at home.

As I am going to build with epoxy, there is no inconvenience with bad smell because epoxy is almost odorless. Which is not the case with the two part painting products. These have an awful smell and for this reason I installed a big ventilation unit capable to maintain a low pressure in the workshop. With this the painting fumes flow outside instead of causing troubles with the family.

Workshop extension

There was still one difficulty to overcome: the garage is 2m. too short so I had to enlarge the garage a bit. This turned out to be a big problem in our highly civilized and urbanized small country! July 2001 the plans for a temporary extension were sent to the officials of the my hometown.

By the end of August they decided to turn my request down...............

As I've said before, home building is essential. No permit is no project, but this is something the Jacks-in-office didn't want to know and certainly would never understand. (and here they are right, it's nuts probably ;-)

Wow, I never expected this. The extension is simply, small and temporal while I knew (almost) for sure the Dutch building laws must allow this! So next step was to raise an objection to this decision and for this we have a special committee of independent wise men. They decided that the refusal was taken on wrong arguments and advised the officials to think about other arguments for a refusal (no sailors neither)!

Now it became a bad joke. Better arguments were hard to find, but they found them, legal ones against a temporary extension, but, as I found out, nothing against a permanent extension...........

All parties were agreed that this enlargement is not an embellishment for the house, so the legal permanent option is the worst solution. This strange situation came to an climax by a special permission by the Lord Mayor himself, which allowed me to build the temporary (and inexpensive) option. I received this long awaited document in the summer of 2002.

After one year of struggle, the actual building of the workshop extension was finished in just 3 weekends. Even the neighbors like the result and are getting curious about my activities (which are quite abstract for non-yachties).

I started the building of the F-39 in the Spring of 2003 at home. By the end of 2009 I have build and finished both floats as well as the starboard half of the main hull together with some interior parts as settee and galley. Roughly a little less than half of the entire construction job, although it has taken much too long.

But then that once-in-a-lifetime opportunity came along ....

2010 Changes, another workshop

While sitting in the sunny garden in summer 2009 and looking at the successful work we did with once more an alteration of the house (expanding the attic into a fully-fledged living floor), we thought we had made a good descision to cross out the idea of once moving to our ″Dreamhouse″ and instead making our house more comfortable. That dream was living near the water with the boat along the garden jetty. This kind of villa's are always far above our budget.

However, it is a buyers market nowadays and while having peace with the decision to give up this apparently not realistic dream, a once in a lifetime opportunity came along. A radical turnover lead to buying a house with a private harbor on the South side of the IJsselmeer, without any bridges or locks to pass and with plenty of room (33'x40') for the unfolded F-39, very rare in our little country.

When I had known this just a few months earlier, we would not have start the extension of the roof. Now it is not finished yet and we are moving to another house. Challenging times so to speak !

So, the Fram project had to move to a new workshop, which I found quite nearby and not coincidentally being our company workshop.

Much more room, but also not at home, which was a major condition to undertake this huge building project. Much less privacy too. This of course is a temporal solution with the necessity of getting in a hurry. This means from now on I will focus on finishing the F-39 on the outside and get her in the water to tie her up along the jetty of our new home. Further work on interior, hardware and rigging will be delayed till she is at home again.

What is my schedule ? This seems to be the most important question, not anymore for me but apparently for others who have asked me that already 1000 times. My answer has always been simple, next year! And that is the most accurate answer I can give as that planning turns out to be correct every year.

It is a part-time project, besides a day-job that requires a lot of time and attention, and I work in spurts and bursts, not steadily. And always on my own without any outsourcing. One needs an optimistic mindset because everything takes three times longer than previously thought. I now know why many of these kinds of projects are stranded halfway.

I once met a German catamaran builder and asked him how many years it has taken him to finish his beautifull catamaran .... 14 Years ! was his answer. I complimented him with the great result and shake hands, meanwhile thinking ″that man must be bloody crazy, not my piece of cake ...″

There are only a few F-39's sailing in the world nowadays. Almost all have been built commercially. A sign on the wall? I know of some half build project, resting in parts in a remote barn somewhere, waiting for that enthusiastic builder who will take up the challenge again. But I also know of some almost completed projects that are not far from launching.

It's time for more F-39's in the water.

My schedule:

Please be warned! If anything on this web site appears to be a recommendation on how to build a boat it is an error of writing or editing. This site is my builder's documentation to chronicle the adventure I had in building Fram.

The Internet is such a lovely open source. Remember this when you see something in this website what you think is yours. If I didn’t ask you before then there was no copyright and I borrowed it. If you think I made a mistake in this, I will give it back to you. If you think I forgot to mention my sources, please let me know. However, everything on this site is mine and no part of this may be reproduced in any form without permission in writing by me. As you may have noticed, this site is a labor of love with lots of free information that has been assembled for your entertainment. Please respect the spirit of this site and don't engage in behavior that I consider hostile.

All information is composed with care and consideration using my background and personal experiences. You may disagree with my opinions or, better, let them support you in your own dreams. You are free to do the same things or to use the procedures, practices or methods as described in this site, but you should always use your own common sense when applying this information to your personal projects and you do this on your own risk for which I am not responsible. I do not warrant or make any representations regarding the use or the results of the materials, practices or methods on this site or linked sites in terms of their correctness, accuracy, reliability, or otherwise. The only thing I can promise you is that I have or will have enough confidence in the info supplied that I already have or will use it in my own project.

While you and I might consider some of the images on this site quite pretty, please respect copyright and do not enhance your site by hotlinking to images on mine. Hotlinking does not only violate my copyright, it also makes me pay for the delivery.

If anything I do or say happens to offend you, that is unfortunate, you are free to go elsewhere.

I explicitly disclaim any responsibility for the accuracy, content, or availability of information found on this site and sites that link to or from this site or that this site or sites that link to or from this site are free of viruses or other harmful components.

I am not affiliated with the manufacturers or resellers of products featured on this site in any other way than perhaps being a customer. Furthermore, since I'm not charging you anything for the use of this site, you're going to be the one assuming the risk of anything and everything you do as a result of reading content here.

Believe it or not, I do get a lot of mail. It may take a few days or longer to answer, as time allows. However, I do attempt to answer all e-mails.

- BUILDING RAKU FROM A KIT

- Duflex Kit Construction in 9 Steps

BUILD YOUR RAKU CAT WITH A DuFLEX KIT BY FOLLOWING THESE NINE BASIC STEPS

Step 1. Kit Design

Work with us to finalise the details of the design you have chosen including any design options or additional modules to be included in the kit.

We will determine the laminates, the number of panels required for each laminate, create the cutting files and prepare a quote for the kit if it is not already priced.

Once the design details and pricing are confirmed you are ready to place your order.

Step 2. Unpacking

2. The kit arrives at your workshop door, usually by container, as a stack of 1.2m x 2.4m routed composite panels ready to be joined. The shipment will normally include additional reinforcements, resins, and ancilary products as specified.

Unpack the shipment and stack the panels out of the way of the space where the panels will be joined.

If you have purchased a joined kit many of the panels will already be joined up to the length that can be shipped in a container (12m).

Step 3 Joining the Panels

Set up the work space where the panels are to be joined.

The panels have a scarf join called a Z join that facilitate the join without needing tapes.

The joining can be done with a heated Z press that cures the epoxy join quickly. Alternatively they can be joined with clamping pressure.

If the panel are are being joined with the Z press you will need an elevated work bench the full length of the longest panels you are using. (image below).

If you are joining them with a clamping technique the space can be on the factory floor.

A nesting booklet is provided with the kit to show how the panels are joined (right)

Joining the panels with clamping pressure

Panels are being joined into a single long panel by painting the surfaces of the scarf join with epoxy screwing through plywood battens that have a release film applied to one side.

Joining the panels with the Z Press

Step 4 Stacking Joined Panels

Once the joins are cured the panels are stacked to one side until they are needed for the job. The inividual parts should not be cut free of the panels until they are required.

Bulkhead and floor panels will be needed before the hull sides and cabin top so they should be left to the front of the stack wherever possible.

Step 5. Separating the Parts

When assembly is ready to begin the individual parts are separated from the panels by cutting the joining tabs. It is likely you will be building onto moulded hull bottoms that have been built from strip planking or another method of building moulded components. The process for building moulded components is described in another article.

Step 6. ASSEMBLY

As the joined panels are assembled onto the job you will need to apply glass tapes to the joins as specified in your plans.

Panels can be surfaced and coated inside and out with high build while they are on the workshop floor to minimise fairing time once they are assembled to the boat. The paint on the panels shown here has been kept back from the edges to provide a good bond for the tapes.

Smaller items such as steps, seats and dagger cases are nested into the kit and for the more complex parts diagrams are provided to assist with the assembly process.

Step 7. Interior

Interior kits can be ordered with the primary kit, or they can be ordered later when final decisions have been made about the interior arrangement.

A compromise solution is to order the interior as a set of plain planels that can be cut to shape on site after finalising the layout.

Step 8 Fairing, Painting, Hardware Installation

8. The DuFLEX construction process goes a long way to minising the amount of fairing that has to be done, but inevitably any boat that has not come out of a female mould will require some level of fairing and surface preparation prior to painting.

The fillers and resin systems required for the fairing work are normally supplied as part of the kit.

Hardware installation is the same as for any other form of construction using high density core inserts or consolidated laminate in way of fittings.

Step 9. Sailing

Go Sailing. This Barefoot 40 Catamaran was built entirely with a Duflex kit in Foam/Glass and Epoxy resin systems from ATL Composites

DuFLEX Kits are manufactured and supplied world wide by ATL Composites

atlcomposites.com.au

And in Europe by VDL Composites

www.vonderlinden.de/her/28/vdL-Composites-GmbH

For more information on DuFLEX and associated Products

atlcomposites.com.au/category/27/DuFLEX

Join the Newsletter

- Scroll to top

Yachting Monthly

- Digital edition

Wow, that was fast! Why trimarans are SO much fun to sail – and how to do it

- Theo Stocker

- February 13, 2024

For their size, trimarans can punch well above their weight in speed, cruising potential and fun. Monohull sailor Theo Stocker gets to grips with how to handle one

Humans tend to gravitate into tribes of like-minded enthusiasts, enjoying the encouragement, support and sense of identity, while often looking askance at others; sailors at motorboaters, cruising sailors at racers, monohull sailors at raft, I mean, multihull sailors, and everyone looks askance at jet-skiers.

Large cruising catamarans (40ft now counts as a small one) are a world apart from monohull sailing, but there’s a sub-tribe of sailors dedicated to life on three hulls and builders such as Dragonfly, Corsair, Farrier, and Astus give them plenty of choice.

I’ve been sailing a 22ft (7m) Astus 22.5 this season, with just enough space for a family of four and a minimum of creature comforts. Thanks to her VPLP-designed hulls and 650kg all-up weight, we can sail upwind at 7-plus knots and downwind at over 10 knots with ease, all on a roughly even keel, while the kids play Duplo down below. It can also be beached and is towable behind a car.

Having, it seems, caught the trimaran bug, I wanted to get better at sailing and handling the boat, but my monohull sailing experience and habits were proving something of a hindrance, so we sought advice from some existing trimaran owners, and well as the UK’s top multihull sailors.

Much of the advice will apply to all multihulls , whether two or three-hulled, while other parts are just for small trimarans. I also found that brushing-up some of my rusty dinghy sailing skills helped get my head around what we were trying to do.

To try out our expert tips we went out sailing to see what difference they made. On the day, we got a solid Force 4-5 southwesterly, averaging 16 knots, but fluctuating between 12 and 20 knots true.

Blasting about on a sporty trimaran is a whole world of fun, but is much calmer than it looks

Trimaran sail trim

One of the biggest differences between a cruising monohull and a multihull is how the mainsail is trimmed. Leech tension on a yacht is often largely controlled by the kicker and the backstay, while the mainsheet sheets the mainsail in and out, predominantly controlling the angle of the boom to the centreline, and there may be a short traveller.

On a mulithull, however, there’s more than enough space for a good, wide traveller. Those who sail on performance monohulls will also be used to this. The sail shape is mainly controlled by the mainsheet, and the traveller then moves the boom towards or away from the centreline.

This is exaggerated on a multihull which has wide shrouds, swept well aft with no backstay, making space for a powerful square-top mainsail with full-length battens. There’s no backstay to bend the mast and flatten what is anyway a pretty rigid mainsail.

The mainsheet purchase creates enough power to control the leech of the square-top mainsail

Depowering a trimaran

Sailing on a monohull, heel and weatherhelm and eventually a broach give loads of warning that you’re pushing too hard. With straight hulls and little heel, those warning signs don’t really apply to multihulls.

In reality, however, there are a host of warning signals that it’s time to back-off; they’re just a bit different. Even then, there’s still a large safety margin before you get close to danger.

By way of reassurance, with the boat powered up on a beat, Hein, from Boats on Wheels, the boat’s owner, stood on the leeward hull and lent on the shrouds. Even as his feet got wet and the wind gusted at the top of Force 4, the boat didn’t bat an eyelid, thanks to the huge buoyancy of the floats.

Even with a person on the leeward float the boat was extremely stable

On the water – sail trim

My first inclination was to point the boat as high upwind as possible, pin the sails in and go for height. Doing that resulted in a not-terrible boat speed of 5-6 knots and a good pointing angle.

Free off by a handful of degrees however, and ease the sails just a smidge, and the speed leapt up to 8-9 knots – over 50% more; a huge increase. So, don’t pinch. If you had a decent chartplotter on board, you could find your optimum speed to angle using velocity made good (VMG).

I was also tempted to pinch in the gusts, but it’s better to hold your course and let the speed increase until the main needs easing.

On the wind, it’s time to get the boat fully powered up

If that’s the case, drop the main down the traveller an inch or two or ease some twist into the mainsail and it makes all the difference in the world, but not so far that the top battens fall away and invert – that really isn’t fast. Push too hard and the boat will slow down, largely from the drag of submerging the leeward float and crossbeams. If you’re still overpowered and the main is luffing, it’s time to reef. Downwind is different, but we’ll get onto that later.

After we put a reef in the main, our boat speeds upwind remained largely the same, and the boat was much happier. I came away feeling reassured that even a little trimaran like this would be pretty difficult to capsize, and there were always plenty of warning signs telling me to take my foot off the pedal a little.

Article continues below…

Catamaran sailing skills: Mooring and anchoring a multihull

How do you make an average passage speed of 7 knots, fit in three double cabins and a huge saloon…

Monohull or multihull: which is best for blue water?

As former editor of Yachting World, David Glenn has plenty of experience of both monohull and multihull cruising. Here he…

Tacking and gybing a trimaran

Everyone knows that multihulls don’t tack as well as monohulls. Straight hulls and wide beam don’t lend themselves to turning, especially when coupled with the displacement and fixed keels of big cats. Trimarans are a little easier, with a single central daggerboard to act as a pivot, and one or other of the floats will generally be clear of the water. On the downside, light displacement means that there isn’t much momentum to keep you going through the turn and plenty of windage to stop you.

On a trimaran the central daggerboard helps the boat to turn by providing a central pivot point that catamarans lack

Speed is your friend. Build speed up before the tack to give you as much momentum as possible. The helm needs to steer positively into and through the turn, and if necessary, keep the jib backed on the new windward side to help the bow through the wind. Don’t worry about scrubbing speed off, but you don’t want to get stuck in irons.

When it comes to gybing, speed is again key. The turning bit isn’t going to be an issue as you’ll be scooting along, but the faster you’re going, the less load there will be on the sails. The more you slow down, the more the true wind will pile up.

Trimaran sailing skills

Tacks took a bit of practice. It felt plain wrong to jab the tiller across the boat, slamming a big break on in the water but I ended up putting us through the tacks far too slowly, losing a lot of speed. A more aggressive approach worked better. On the Astus, the traveller was between me and the tiller, so the tiller extension needed to be swung around the stern behind the mainsheet onto the new side.

Similarly, old habits of controlling a gybe needed to be modified. With the asymmetric set, we were planing at well over 10 knots, and the ideal is to stay on the plane. Heading dead downwind and centring the main lead to a more violent manoeuvre than flying into the gybe as fast as possible and, as the boom was never that far out thanks to the apparent wind angle, it didn’t need much extra controlling.

Coming up onto the wind after the gybe helped the asymmetric around the front of the jib and to fill on the new side. Stay too deep and it’ll get blanketed by the main. Once we had built up some apparent wind, we could bear away again.

You’ll be on a course deep downwind before you know it, hitting speeds in the double digits

Downwind in a trimaran

Upwind cruising may be fun in a multihull, but bearing away and going with the wind is what it’s all about. Easily-driven hulls, a generous sailplan and light weight mean you can be up and planing, leaving displacement boats wallowing in your wake.

The big difference comes from apparent wind. If you’re in a boat that can do 15 knots downwind in 20 knots of true wind, the resulting wind angles can really mess with your head.

To get going then, says Brian Thompson, ‘Use those leech tell-tales again when sailing downwind and reaching to set the correct twist through the mainsheet, and use the traveller to set the correct angle of the whole sail to the wind.’

As the wind and your speed builds, bear away and trim the main accordingly.

In theory, you shouldn’t need to ease the traveller at all, but you may need to if you want to sail deep downwind. As the gust fades, you’ll find the boat slows down, so you can come back up towards the wind a little to pick up some more breeze, and then bear away as you accelerate again.

Bear away as the boat accelerates. Your course will be something of a slalom as you look to keep a consistent wind angle

This results in something of a ‘slalom’ course, and will also be accentuated if you’re sailing down waves, but that’s all quite normal for apparent wind sailing. Ultimately, you’re looking for a consistent apparent wind angle, even if the resulting wake isn’t straight.

It’s worth remembering that apparent wind reduces the felt effect of the wind, so you need a sailplan to suit the true, not apparent wind speed.

I found that the boat was more sensitive to having a balanced sailplan and trim downwind than upwind, largely because you’ve got almost double the canvas up, with the bowsprit as an extra lever. When weather helm built, I needed to ease the mainsheet to increase twist to depower so that I could bear away. I must admit, getting the boat balanced, sailing fast and light on the helm at 15 knots was something I came away feeling I needed more practice at.

Reviewing the images, I suspect the asymmetric was sheeted in too hard, with too much twist in the main.

Getting a float fully submerged is when it’s time to back off

On the water

Unfurling the gennaker worked best on a beam reach, giving plenty of airflow over the sail to help it fully unfurl. This was also roughly the fastest point of sail, ideal for getting up some speed for apparent wind sailing. We mostly had the sails set for a close reach, even when we were beyond 120º off the true wind on a broad reach.

It was possible to soak deeper downwind, but lose the apparent wind benefit downwind and our speed dropped off dramatically, prompting us to point a bit higher to find some more speed.

As the boat powered up, it paid to hold a slightly higher angle than I would have done in a monohull for the boat to properly take off and get up into double digit speeds – topping out at 15 knots. Lymington to Cowes would have taken us just half an hour at that speed. It’s easy to give yourself a heck of a beat back!

We were sailing on a pretty flat day, so didn’t have to contend with any waves to speak of. On the recent RTI this is what caused the capsizes of at least two multis, a sobering reminder that you need to sail much more conservatively in lumpier conditions.

The bows want to point downwind, so a stern-first approach works with rather than against the boat

Coming alongside

A 650kg boat with no draught and plenty of windage feels dreadfully skittish when manoeuvring in confined spaces. Straight hulls with no forgiving curves and fragile-looking sharp bows make berthing tricky. You’ve got a couple of advantages on your side, however. In the Astus, the floats are at pontoon height making stepping off easy.

Whether you have an engine in each hull of a cat, or one in the central hull of a tri, there’s also a lot more leverage to play with to turn the boat and drive her on or off the pontoon. A steerable outboard gives you even more options.

If the boat has a lifting keel or daggerboards, put them down if there’s enough depth to give you a pivot and to resist drifting. Think about getting corners onto the pontoon, rather than putting the boat alongside. On tris, you won’t be able to get to the bow to fend off as it’s too narrow. You can rig a fender up forwards on a line, and two fenders are enough on the flat sides.

Steering with the outboard towards the pontoon will drive the stern in more; steer away to drive the bow in more

Offshore wind

Coming onto the pontoon with wind blowing off, it worked well coming in stern first. If there’s a tide running, you’ll want to be heading into the tide, so find a spot down wind and down tide to start your approach so you come in at an angle.

On our first attempt we had a bit of tide under us to start with so we came in at a much steeper angle, almost 90º, although this worked out OK in the end.

The crew could then step ashore, taking a line from the stern quarter round a cleat.

Drive forwards against the line and the bow will obediently drive up towards the pontoon, bringing you flat alongside. Getting off was simple, releasing the bowline, and allowing the bow to swing out the before slipping the stern line.

Coming in astern and stopping upwind of the berth meant the bows blew towards the pontoon far to quickly

Onshore wind

Getting onto and off a pontoon with onshore wind proved rather trickier. On our first attempt we came in stern first. The issue was that once we were just upwind of our desired berth and stopped, we lost steerage and the bow immediately blew off with alarming speed towards the pontoon.

Going ahead would only increase the force of the impact, while going astern only increased the bow’s sideways drift. I managed to back out without smashing the bow, but only just, and ended up awkwardly stern to the wind with the bows pointing at the pontoon.

On our second attempt we came in bows first but having aimed at the berth, I had to motor the stern to leeward to stop the bow hitting, making for a rather forceful coming alongside.

On take three, I came in forwards and began ferry gliding towards the berth early, keeping the bows to windward of the stern. Being able to steer with the outboard meant I could go ahead to keep the bow up, and go astern with the engine pulling the stern down toward the pontoon. In this way, it was possible to come in pretty well controlled and parallel to the berth.

To get out, motoring astern against a bow line pulled the entire boat clear before slipping the line

Leaving was a different proposition all together, as I didn’t want to drag the bow along the pontoon, or to drive hard onto it to spring off. Instead, we rigged a slip-line from the forward cross beam. Going astern against this, and then turning the engine towards the wind, I could pull the stern, and the rest of the boat, out and away from the pontoon.

Keeping power on astern, once we’d reached a decent angle, we slipped the line and went astern, finding steerage way almost at once, with the bow following obediently in our wake with more control than I had anticipated.

Whether the wind is blowing onto, or off the pontoon, you want the engine to be driving or pulling the boat off the pontoon with a line on the corner you are going away from. That way you avoid point-loading fine ends where it’s hard to fender.

You’ll want a bridle to reduce swinging, but keep the pick up lines on the bow as backup

Anchoring and mooring a trimaran

While mooring a catamaran is complicated by the lack of a central bow, things should be simpler on a trimaran, and they are, mostly. Picking up a mooring buoy from the main hull bow with a low freeboard and dropping the pick-up line onto a cleat is easier even than a monohull.

The bow may be narrow, but for any lines that pass through a ring on the buoy, you still need to take it back to the same cleat to avoid chafe. That should be it, but windage from the two extra bows and the lack of keel mean the boat can dance merrily around the mooring buoy in a breeze.

Rig the bridle so the buoy sits to one side to stabilise the boat

In practice, we found that a trimaran benefits from a mooring bridle in the same way that a catamaran does. It can’t be rigged from the floats’ bows, as there are no mooring cleats, so a line passed around the outboard ends of the forward beams gave a pretty good angle, again with long lines passed through the mooring and back to the same side. The main pick-up lines stay as a safety backup.

The other trick is to rig the bridle asymmetrically so that the buoy sits to one side or the other, just enough to not be dead head to wind, making it much more stable in the wind.

On the plus side, the lack of draught or keel means that you’ll nearly always be lying head to wind, so the cockpit remains nice and sheltered whatever the tide’s doing.

We ran out of time on the day to try anchoring, but rigging a bridle, effectively a long snubber to a point on the anchor chain in a similar way wouldn’t be tricky.

If you needed not to swing, or to behave more like deeper boats nearby, hanging a bucket over the stern can help, or there’s always anchoring with a kedge, either out ahead in a V, or in line astern.

Enjoyed reading this?

A subscription to Yachting Monthly magazine costs around 40% less than the cover price .

Print and digital editions are available through Magazines Direct – where you can also find the latest deals .

YM is packed with information to help you get the most from your time on the water.

- Take your seamanship to the next level with tips, advice and skills from our experts

- Impartial in-depth reviews of the latest yachts and equipment

- Cruising guides to help you reach those dream destinations

Follow us on Facebook , Twitter and Instagram.

Folding System

Legendary ability, unbeatable reliability.

Folding and unfolding a Corsair trimaran takes only a minute. With just 4 bolts to remove, it is easily managed by one person, and is normally done while afloat. Simply raise (to fold) or press down (to unfold) the inboard end of one cross beam. It can be done from the safety of the cockpit and only a little force is needed due to the folding system’s carefully balanced geometry, and the movement of the floats being mostly horizontal.

The solid aluminium folding struts have absolute control over the folding motion and prevent flexing or racking. A stainless steel bolt on the inboard end of each beam secures the floats for sailing. Crucially, wingnets remain attached during the folding process – their frictionless fixing allows them to tension themselves appropriately through the folding process. The system is so simple and balanced that Corsair trimarans can even be folded while motoring.

TRAILERING ACROSS CONTINENTS

Corsair Marine trimarans are especially weight-conscious, and sit low on their trailers meaning they have excellent trailering characteristics. They are equally easy to launch, giving you more time on the water, and the ability to expore many more remote cruising grounds or participate in regattas far from home. Some Corsair trimaran models go from trailer to water in 25 minutes, and with practice even the largest boat models can be done in 40 minutes.

Corsair 880 Trimaran | 2022 Boat Review by Multihulls World

Corsair 880 – Drive Out, Fold Out, Thrill Out, Chill Out

Australian Debut of the Corsair 880 at the Sydney International Boat Show

- Folding Corsair Trimarans: Legendary Ability, Unbeatable Reliability

- 5 Reasons Why The Corsair 760 Trimaran Won Multihull Of The Year

- Corsair Range Brochure

- Corsair Community

- Find A Dealer

Tel +84 28 3873 3630

Sales Enquiry:

Customer Service Enquiry:

© 2024 Corsair Marine International. Alls rights reserved.

Privacy Policy

- Plans & Kits

- Qty in Cart

West Mersea Duck Punt PDF Free Plans

Making Hand Screw Clamps Free Instructions

Tape & Glue Process Free Instructions

Lisa b good - free plans.

Folding Mast & Boom Free Plans PDF

Slipper PDF

Drifter 12L Free Plans

Wanigan (free plans).

1 Sheet Wedge Plans PDF

Drifter 12 Free Plans

Mouse Free Plans

Little bretton free plans.

- Total: items /

- Add all to cart

Adding your products to cart

6 Best Trailerable Trimarans For Bluewater and Coastal Sailing

As an Amazon Associate, we earn from qualifying purchases. We may also earn commissions if you purchase products from other retailers after clicking on a link from our site.

Having a boat costs a lot of money, even when you are not using it, marina fees, etc. And once it is in the water most sailors never go very far from their “home marina” and sailing will be somewhat restricted. However, what if you could fold your trimaran and put it on a trailer, store it at your house, and go to a new sailing spot the next time?

Here are 6 of the best trailerable trimaran:

- The Dragonfly series

- Corsair Series

- Windrider 17

Choosing the best trailerable trimaran (a multi-hull with three “hulls”) will depend on crucial factors like speed, durability, design, and ease of transportation. This article is here to help you get started with your research and hopefully help you on the way towards your dream boat!

Table of Contents

Cruising Trimarans That Can Be Transported

Cruising boats are made for multiday sailing either on the coast of your favorite sailing area or full-out blue-water ocean crossings. Extended living should be a priority in these designs.

1. The Dragonfly 25 and 28 (Dragon Fly Series)

Dragonfly is in the business of making the “best foldable trimarans on the planet” many would agree with this statement. Dragonfly is known for its commitment to easy trailering and ease of use, shown in designs for the Dragonfly 25 and Dragonfly 28.

The “Swing Wing” system on the linchpins is one of the key features of the dragonfly series. The system’s application makes it possible for the trimaran to narrow its beam as much as 50%.

Attesting to its Scandinavian manufacturing, most parts of the trimaran are made in-house. This guarantees quality and ensures that all used parts are above standard.

You don’t need to look further than the Dragonfly 25. Its centerboard slightly offset to port. Extra space is created in the main hull’s interior with a trunk buried under a settee. Performance-wise, the low drag and narrow hull shape allow the boat to reach blistering speeds.

Dragonfly 28 In Numbers

- Length: 8.75m

- Beam folded: 2.54m

- Max crew: 5-7 people

- Max Speed: 22+knots

Dragonfly 25 In Numbers

- Length: 7.65m

- Beam folded: 2.30m

- Max crew: 4-6 people

- Max Speed: 21+knots

2. Farrier F-22

New Zealand enters the trimaran manufacturing race with this premium sea goer. The vessel comes in two different versions: a performance variation with more horsepower and a full cabin cruising version.

Compared to the dragon series the F-22 has the biggest allowance for space.

The F-22 is known for being one of the easiest trimarans to fold and load.

The sports version of the F-22 has some really good performance to offer. It has an aggressive spirit: you can mount a sail while leaving plenty of space for the boat’s fine entry and flared forward sections. The build quality is also topnotch—a lasting memorial to a principle that Ian Farrier always worked by: excellence.

Farrier F-22 In Numbers

- Length: 7.0m

- Beam folded: 2.5m

- Max crew: 3-5 people

- Max Speed: 20+knots

3. Corsair Series

This boat series has an exciting history. Farrier created it to promote his trailerable tri concept. However, the series is now independent with a top-class vehicle to its name.

The Corsair 760 is listed as providing some of the best performance and safety benefits to sailors.

Building off the spirit of excellence of the founder, the Corsair 760 has created a boat with comfort and racing potential. The boat can be tricky to handle at first, but it will be a breeze once you get the hang of it.

It is also worth noting that the corsair 37 is the largest trailerable trimaran on the market today.

Daysail Trimarans That Can Be Transported

Boats that are made for dayssailing are usually smaller, cheaper and more easily handled. They are perfect for those looking to enjoy a full day on the water in calm weather, but are usually less suitable for multiday events or rough sea sailing.

4. The Astus Models (20ft, 22.5ft, and 24ft)

If you’re looking for something small but still capable of doing day sailing, this 22.5-foot trimaran is for you. Built for speed and maneuverability, the Astus 22.5 has optional foils to optimize speed.

The modern design, coupled with the spacious interior, can fit up to four beds. Accordingly, this trimaran is suited for family outings.

The Astus brand specializes in transportable trimarans, worth noting is that some models need a specific trailer whilst the smaller boats use a standard trailer.

5. Weta 14.5

The 2019 Weta trimaran is a 14.5-foot (4.4-meter) trimaran featuring a carbon frame, centerboard, rudder foil, and rudder shock. The hull is made from fiberglass and foam. The Weta is built for strength and speed based on these lightweight materials.

The 2019 Weta trimaran is easy to sail and is worth considering whether you want to take a quiet sail, race with your friends, or take kids to a sailing lesson. It has a simple design and is easy to set up independently.

The small size makes it more suitable for daysailing in good weather rather than multiday cruising, although more experienced sailors will of course push the limits of this boat.

6. WindRider 17

The 17.4-foot (5.3-meter) WindRider 17 is one of the more versatile trimarans in the market. It packs high performance for a low cost. This trimaran has a light rotating mast to boost performance, and a full-battened mainsail optimizes visibility.

This sailboat is made from rotomolded polyethylene, which is more durable than fiberglass and demands less maintenance.

The WindRider 17 has a comfortable interior and can fit six adults. This is an ideal choice for social sailing for a couple or a family and friends. It’s easy to ride, and a shallow draft allows easy maneuverability.

What’s the Largest Trailerable Trimaran?

The largest trailerable trimaran is the Corsair 37 , this multihull is built for single-handed cruising while still maintaining the ability to comfortably seat 6 people.

The Corsair 37 provides comfort, speed, and safety. It also contains just enough space to accommodate amenities like a propane stove, a sink, and other equipment.

The vessel is designed to be a performance cruiser. It features an aluminum rotating wing mast, carbon fiber bowsprit, and premium deck hardware. The corsair can still cut through the water with ease despite its size, putting the wind in your sails.

What Is a Catamaran?

A catamaran is a boat with two hulls (a trimaran has three) connected by a bridge deck. Catamarans usually offer more space than both monohulls and trimarans of the same length. The catamaran is usually somewhat slower than a trimaran but faster than a monohull. They are usually made of fiberglass or carbon fiber.

Catamarans come in all shapes and sizes. You can find straightforward sailing catamarans, perfect for those who are only starting their sailing journey. Larger sailing catamarans have become extremely popular for long-distance sailing.

There are also power catamarans, they have huge diesel-powered engines (sometimes electric) and no sails. Also called “power cats”, these boats can reach 30+kts.

Can a Trimaran Be Trailerable?

As discussed above, some trimarans are possible to put on a trailer and move to another sailing area or to be stored at home. This is usually not possible with catamarans but is sometimes possible with the trimarans that are fitted with foldable amas (the two outer “floats” or “hulls”).

Some trimarans can be trailerable, this is mainly due to the ability to drastically decrease the vessels beam, sometimes as much as 50%. This allows the trailer plus trimaran to be below the legal requirements of the road.

Final Thoughts

It has proven difficult to beat the trimaran in terms of speed. Through the ages, this type of vessel has proven to be immensely enjoyable in all kinds of sailing activities. These can range from sea adventures to waterborne relaxation in your free time.

Trimarans come in various types, foldable, for cruising or racing, etc. However, there is a common factor: many of the small ones are trailerable. This makes them easier to move than most other types of boats.

Owner of CatamaranFreedom.com. A minimalist that has lived in a caravan in Sweden, 35ft Monohull in the Bahamas, and right now in his self-built Van. He just started the next adventure, to circumnavigate the world on a Catamaran!

Leave a Reply Cancel reply

Your email address will not be published. Required fields are marked *

Save my name and email in this browser for the next time I comment.

Recent Posts

Must-Have Boat Gear for Catamaran Sailors!

Sailing is probably the most gear-intensive activity I've ever done; there are so many decisions to be made about what gear to buy now, for tomorrow, and what to definitely never buy. The gear on...

What Kind of Boat Is The Best Liveaboard? Trawler, Monohull, or ...?

Living in a boat can be a thrilling, once-in-a-lifetime experience; however, knowing how to choose the right vessel to sustain the lifestyle you want to achieve can be crucial in making the most out...

24 Foot Sailing Trimaran

Introduction: 24 Foot Sailing Trimaran

Indonesian style, built out of recycled stuff. Here we are busting out through the surf in 30mph winds at Stinson Beach California on the maiden voyage. The boat works great! There are no swimmers or surfers out because of the rough conditions. The kids are on the beach making forts out of their boogieboards instead of surfing. Specifications: Hull Length 24 ft at deck Hull 22" wide amidships at deck, 18" wide inside hull (there's a wide lip at deck) Hull 24" deep amidsnips. The hull round bottom is a semicircular arc of 8.25" radius. Hull rocker is about 4" measured from points 16' apart. Outrigger crossbeams are 14' 7" long 3.5"x2.5" fir beams tapering to 3x2.25" at ends The outrigger floats are 4.5" diameter, 19 feet long with foam plugs in ends. ~134lbs buoyant. The plugs in the front of the floats are shaped into a nose that protrudes 6.5" more. 1.5" diameter stainless steel tubing connects the crossbeams and floats. The Sail is an 8 sq. meter crabclaw / leg-o-mutton sail on 14ft. windsurfer masts. The mast is supported by three stainless steel cable stays. Total cost of materials was $200 or less. The outrigger floats are fiberglass chemical pipes full of empty plastic soda bottles. The main hull is made from a pair of old 16' catamaran hulls cutoff and glassed end-to-end. Junked catamaran hulls are easy to get. If you can't find a free hull, build a hull like the Kenya Canoe but bigger. Use scavenged plywood from crates if you want it free. The wood for the crossbeams came from a big pallet, with the nails and crossboards pulled off. Then I scarfed them together for extra length. The sail is blue tarp on windsurfer mast spars. Great action photos by kenny

Step 1: Beaching After the Maiden Voyage

Star , Damon and myself rode the boat in on the back of a big wave, just like the Malibu Outrigger manual recommends. Then we carry the boat up the beach. The sail helps us and we scamper up the beach and get clear of the break zone before the next wave hits. What a great boat. Unlike trials of previous boats in Mexico and Kenya which got badly damaged by surf landings, this boat is fine. It helps that there's a lot of wind and the boat is faster than the waves.

Step 2: Cartopping

Here it is on top of the ugly truckling. It assembles quickly without tools. The main hull is the heaviest part, about 90 lbs. It takes two people to lift it onto the roof rack because it's so big. The other parts are a lot lighter and one person can handle them. 4 or 5 people can ride in the cab of my truck. The boat could carry that many also, so it's a good match. We could only get three people to volunteer for the maiden voyage because the conditions were so rough, but there was room for more.

Step 3: Or on a Trailer

To launch it from a trailer, you drive to the boat ramp, assemble the boat while still on the trailer, then launch and land it in the usual way.

Step 4: Inspiration

I once tried to sail to Cuba in an outrigger canoe. There were some problems. When I was almost to Havana my rudder broke so I couldn't sail, the current carried me away, I was caught in a storm, etc. etc. I spent a lot of time trying to not to die and hallucinating from exhaustion. I also spent a lot of time thinking about the perfect hull shape for a sailing canoe. In the following year I traveled to Indonesia and Papua. I learned a lot by gaping at and measuring sailing canoes there. Here are some Makassarese (Sulawesi) canoes I saw in Jayapura Harbor, Papua. In severely technical terms, here's what I was looking for in a hull: 1) High prismatic coefficient (fat ends) 2) Round bottom 3) Straight sides in the middle 4) Just the right amount of rocker. Curved like a banana. 5) A beam to length ratio of around 12:1

Step 5: Cut and Paste Catamaran Hulls Together End-to-end

I found a pair of 16' catamaran hulls for sale on craigslist that were exactly what I was looking for. By no coincidence, they were designed and built by Karl Westbroek, an engineer from Malang, Java, Indonesia. They were a nice bright yellow that emphasized their banana-like shape. Hence Karl's original name for his catamaran, "Bananas". I wanted my hull to be pointy at both ends. These hulls had square transoms at the stern. So I had to cut off the sterns and butt up the pointy ends to make my hull. To figure out the right place to cut them I slid a piece of paper over the hulls to find a special transverse curve called the "Geodesic". That's the shortest path between two points on opposite sides of the hull. I cut the hulls, butted them up, and checked to make sure the keel and sides met at a reasonably fair curve.

Step 6: Thinning the Edge

Before we can start glassing, we need to grind down the existing fiberglass so it's a smooth transition. Michael Kearney helps me out by grinding the edge thin on the inside of the joint.

Step 7: Jigging It Up

Next we clamped and screwed a bunch of sticks to the outside of the hulls to hold them in alignment. Jrlee checks that the decks are parallel.

Step 8: Glassing

Jrlee mixes some epoxy. We cut and lay out strips of fiberglass cloth on a piece of plastic on the deck. We soak the cloth with epoxy. We layup the glass into the hull, squeegeeing and painting the epoxy so the cloth is fully saturated. The wider strips of cloth go over the narrow strips, so the rough edges of the cloth aren't exposed.

Step 9: Rough Fairing

I mix some glass microballoons with epoxy and slather that all over the outside of the hull. When it sets up I grind it flat with a sanding disk. While I'm doing that Danny comes and suggests a better way.

Step 10: Rapid Fairing

He's glued a board to a sanding pad and glued a full sheet of 80 grit sandpaper to that. He creates an artificial snowstorm while sanding the hull, and in a few seconds it's smooth and faired. Wow.

Step 11: Glazing and Finish Sanding

Next I squeegee some body putty over the nicks and imperfections. When that's dry I wet-sand it with a sanding block.

Step 12: High Build Sanding Primer

Next come a couple of coats of fast-dry high build sanding primer, then some wet-sanding with a sanding block, and finally a coat of yellow paint. The hull is all one hull now.

Step 13: Outrigger Floats

A friend gave me some fiberglass chemical pipes. They are 19 feet long and 4.5" in diameter. I would have been worried about the chemicals but the pipes were brand new. Actually they might be intended as covers for glass pipes. I tied strings to the necks of some 2 liter soda bottles and shoved them into the pipes. The string is to keep the bottles from floating away in case of a disaster. I carved some minicel closed cell foam to make plugs for the pipes. I shaped the front plugs into the noses seen here. The flat front feature is like the "manu" on the front of a Hawaiian canoe. As it plows into a wave, it sprays the water away forming a giant air bubble around the float. The bubble rises through the wave, pulling the float up with it. It works really well.

Step 14: Float Blocks

The outrigger floats are 4.5" diameter fiberglass chemical pipes. I made some wooden blocks to rest on them. They will be the "feet" of some short legs made of stainless steel tubing. Those in turn get connected to the crossbeams. Just like Ezekiel, the foot bone's connected to the leg bone, the leg bone's connected to the thigh bone. Here I am testing the first block I made to see if it fits the pipe right.

Step 15: Cutting Curved Grooves With a Tablesaw

I setup my ghetto tablesaw, which is a circlesaw screwed to a board. Yes, it's very dangerous. Don't do it. I set up the fence at an angle to the blade. I made a lot of cuts of increasing depth in a block of wood until I had a nice round trough cut in the bottom of the block.

Step 16: Wooden Shoes

Then I repeated the process on some narrower blocks, cut holes the right size all the way through with a hole saw.

Step 17: More Wooden Shoe Cobbling

I glued a wooden disk in the bottom of the hole so the tubing leg wouldn't touch the float directly. I heated up the block to cure the epoxy quicker. Don't breathe those buttery fumes! When the epoxy was set up I shaved the protruding plugs off with the tablesaw. I drilled some lashing holes in the sides of the blocks and cut the corners off the ends so they would enter the water better. Jumping ahead, let's go sailing and I'll show you how this stuff turned out.

Step 18: Hot Spring Break

Star organized a trip to a hotspring on the coast that's only exposed at the lowest tide of the month. We camped nearby on friday night, woke up at 5 am to hike down. It's pretty amazing. There's a main pool and also a cave full of hot water that goes back into the cliff face. We relaxed in the hot spring until the tide rose and waves of cold water started washing into the spring. Then we hiked back up to the truck and it was time to put the yellow canoe in the water. So we drove to Stinson Beach and parked as close to the beach as we could. We unloaded the canoe parts onto the grass in the park there.

Step 19: Lashing It All Together

We swarmed over the canoe, lashing all the arms and legs to it with bicycle innertubes. The front beam takes most of the load, so it has a double tube 'H' shaped stainless tubing leg that connects the beam to the float. The foot of the 'H' rests in sockets in a wooden block. The bottom of the wooden block is carved to fit the top of the float tube. The float is lashed to the block with spectra string and innertube. That part stays lashed permanently.

Step 20: Carry It to the Beach

We had plenty of help from relaxed sleep-deprived pals from the hotspring trip. When it was all tied together we picked it up and carried it to the water.

Step 21: Please Return!

In case something went wrong and we lost the paddles we wrote plaintive messages on them in hopes that someone would return them. These are instant paddles made in a few minutes from a hockeystick, a board and some string, but they're so nice it would be a shame to lose them.

Step 22: Farewell Hugs

The wind had increased to a gale. The sea was rough. Time for farewell hugs!

Step 23: Raising the Sail

We hoisted the sail and watched the waves. The surfers were all on shore so we couldn't use them to judge the size of the waves. But at least we didn't have to worry about hitting them.

Step 24: Launching!

Star , Damon, and I carried the boat to the water just as a big wave washed ashore. We jumped on, sheeted in the sail, and started paddling at the breakers.

Step 25: So Far So Good

The boat took off like a racehorse. It's easy to steer with a paddle. It goes to windward just fine. We sped toward the outer break. Wait a minute. That's a big wave coming!

Step 26: What's Going to Happen?

We hit the wave and there was whitewater everywhere. We kept going through it, and when we could see again we were still moving fast and there was hardly any water in the hull. The boat works in surf!

Step 27: Sailing and Landing

We sailed around until one of the lashing buttons broke, then decided to head back in. We surfed in on a wave, outran it, and executed a perfect landing on the back of a wave. Jubilation! The boat could have handled more passengers and rougher conditions.

Participated in the Earthjustice United States of Efficiency Contest

Recommendations

Pets and Animals Contest

Paper and Cardboard Contest

Making Time Contest

- BOAT OF THE YEAR

- Newsletters

- Sailboat Reviews

- Boating Safety

- Sailing Totem

- Charter Resources

- Destinations

- Galley Recipes

- Living Aboard

- Sails and Rigging

- Maintenance

Sailboat Review: Rapido 40

- By Mark Pillsbury

- May 6, 2024

In the great debate among sailors about what’s better—a monohull or a catamaran—both sides make compelling arguments. Monohulls are more efficient at going upwind. Their sufficient ballast ensures stability in a seaway. Some would say that a keelboat is just plain more exciting to sail. But cat lovers counter that they don’t care to “sail on their ear.” They’re willing to motor to windward if necessary, they enjoy the ability to pull up next to a beach, and they rave about the outdoor living space that two hulls afford.

And then there’s the trimaran crowd, which, on a boat like the Rapido 40, gets the best of both worlds. Fast, flat sailing upwind and down? Check. Shallow draft for cruising in skinny water? Check. Lots of room to spread out on deck, and generous accommodations below for a cruising couple with kids or occasional friends? You bet.

The Rapido 40 is designed by the high-performance team at Morrelli & Melvin, and is built in Vietnam by Triac Composites. Rapido was co-founded in 2014 by Paul Koch and Richard Eyre. Koch is an old hand at trimarans—he was formerly president of Corsair—and he says that there is a market out there, albeit a niche one, for performance-oriented, oceangoing cruising trimarans.

Rapido’s 40 is the smallest in a line that ranges upwards of 60 feet—its original model. Just sitting at the dock, the all-carbon-fiber build is one sleek-looking boat. It has a rotating, spreaderless, double-tapered wing mast; a V-shaped boom; and a square-top main that’s paired with a versatile two-headsail sail plan. That sail plan includes a self-tacking jib for upwind sailing or days when it’s blowing, and a screecher set on a sprit. There’s also a continuous-line furler for off-the-wind or light-air conditions.

Underway, that package provides plenty of horsepower, as my Boat of the Year judging colleagues and I would discover on Chesapeake Bay this past fall. It was a ride where we all vied for the dubious honor of top tiller hog.

In 10 to 12 knots with the small jib rolled out, we skipped along at close to 8 knots, according to the GPS. Things got really lively when we rolled up that sail and unfurled the big dog. Twelve knots and change was about top end for us in those relatively light conditions.

And boy, was the Rapido fun to sail! The boat has bench-style seats outboard to either side of the cockpit, so skippers can sit with the tiller extension in hand and legs stretched out, watching the world fly by. C foils in the amas are adjusted up or down depending on the point of sail; strategically placed electric Harken winches raise them, and gravity drops them down. Sheets and halyards can also be led to the winches, so, for a shorthanded crew, sailhandling—especially with the self-tending jib—is pretty simple.

A base model Rapido 40 runs just under $700,000, though the boat we sailed in Annapolis—with top-of-the-line North Sails, B&G electronics and a composting head—carried a price tag of $800,000 and change. Other options include a performance mast and electric propulsion. Lithium batteries are standard.

I’ve been on smaller tris, where the interior can feel cramped because of the relatively narrow beam of the center hull, but the 40 has more-than-adequate living space. An inline galley takes up the starboard side of the salon, with a dining table opposite. The raised cabin top and windows all around provide 360-degree visibility and 6-foot-6-inch headroom. Rear-facing ports are removable for ventilation and to provide better visibility forward from the cockpit. I liked the look of the carbon-fiber countertops and drawers, which felt light as a feather to open. And the composite work was clean as a whistle.

Beneath the cockpit, there’s a double berth that’s accessible through a cockpit hatch or from below. It would be a great place to stash the kids, and two single berths are an option. I’m told that in later models, the cockpit sole has been raised 3 inches, making the aft cabin that much roomier. The owner’s stateroom, with a double berth offset to port, is in a cabin forward of the salon, along with a head and shower.

Hulls and deck are foam-cored. The prepreg autoclave-cured components such as the bulkheads, boom, mast, C foils, structural beams and T-foil rudder are all made in-house. The main hull and amas (which fold in, reducing the beam from 28 feet, 10 inches to 19 feet, 3 inches) all have watertight bow crash compartments. The engine compartment, which houses a 30 hp Yanmar with a shaft drive, is also surrounded by watertight bulkheads, just in case.

Rapido US importer Bob Gleason—an experienced multihull guy and owner of The Multihull Source in Cape Cod, Massachusetts—had fit out the boat that we got aboard to keep the weight down. I still found it packed with all that I’d need for a comfortable getaway. Workmanship and equipment was top-notch, just as I’d expect on a boat built to go places.

Mark Pillsbury is a CW editor-at-large and was a 2024 Boat of the Year judge.

- More: Print May 2024 , Sailboat Reviews , Sailboats

- More Sailboats

Now For Sale: Leopard 45

For Sale: 2002 Hylas 46

Sailboat Review: Beneteau Oceanis 37.1

Sailboat Preview: Outremer 52

Swallow Tattoos and Sailors

Welcome Aboard, Starlink

Winning the Party: A Rally Around the Leewards

- Digital Edition

- Customer Service

- Privacy Policy

- Email Newsletters

- Cruising World

- Sailing World

- Salt Water Sportsman

- Sport Fishing

- Wakeboarding

- Yekaterinburg

- Novosibirsk

- Vladivostok

- Tours to Russia

- Practicalities

- Russia in Lists

Rusmania • Deep into Russia

Out of the Centre

Savvino-storozhevsky monastery and museum.

Zvenigorod's most famous sight is the Savvino-Storozhevsky Monastery, which was founded in 1398 by the monk Savva from the Troitse-Sergieva Lavra, at the invitation and with the support of Prince Yury Dmitrievich of Zvenigorod. Savva was later canonised as St Sabbas (Savva) of Storozhev. The monastery late flourished under the reign of Tsar Alexis, who chose the monastery as his family church and often went on pilgrimage there and made lots of donations to it. Most of the monastery’s buildings date from this time. The monastery is heavily fortified with thick walls and six towers, the most impressive of which is the Krasny Tower which also serves as the eastern entrance. The monastery was closed in 1918 and only reopened in 1995. In 1998 Patriarch Alexius II took part in a service to return the relics of St Sabbas to the monastery. Today the monastery has the status of a stauropegic monastery, which is second in status to a lavra. In addition to being a working monastery, it also holds the Zvenigorod Historical, Architectural and Art Museum.

Belfry and Neighbouring Churches

Located near the main entrance is the monastery's belfry which is perhaps the calling card of the monastery due to its uniqueness. It was built in the 1650s and the St Sergius of Radonezh’s Church was opened on the middle tier in the mid-17th century, although it was originally dedicated to the Trinity. The belfry's 35-tonne Great Bladgovestny Bell fell in 1941 and was only restored and returned in 2003. Attached to the belfry is a large refectory and the Transfiguration Church, both of which were built on the orders of Tsar Alexis in the 1650s.

To the left of the belfry is another, smaller, refectory which is attached to the Trinity Gate-Church, which was also constructed in the 1650s on the orders of Tsar Alexis who made it his own family church. The church is elaborately decorated with colourful trims and underneath the archway is a beautiful 19th century fresco.

Nativity of Virgin Mary Cathedral

The Nativity of Virgin Mary Cathedral is the oldest building in the monastery and among the oldest buildings in the Moscow Region. It was built between 1404 and 1405 during the lifetime of St Sabbas and using the funds of Prince Yury of Zvenigorod. The white-stone cathedral is a standard four-pillar design with a single golden dome. After the death of St Sabbas he was interred in the cathedral and a new altar dedicated to him was added.

Under the reign of Tsar Alexis the cathedral was decorated with frescoes by Stepan Ryazanets, some of which remain today. Tsar Alexis also presented the cathedral with a five-tier iconostasis, the top row of icons have been preserved.

Tsaritsa's Chambers

The Nativity of Virgin Mary Cathedral is located between the Tsaritsa's Chambers of the left and the Palace of Tsar Alexis on the right. The Tsaritsa's Chambers were built in the mid-17th century for the wife of Tsar Alexey - Tsaritsa Maria Ilinichna Miloskavskaya. The design of the building is influenced by the ancient Russian architectural style. Is prettier than the Tsar's chambers opposite, being red in colour with elaborately decorated window frames and entrance.

At present the Tsaritsa's Chambers houses the Zvenigorod Historical, Architectural and Art Museum. Among its displays is an accurate recreation of the interior of a noble lady's chambers including furniture, decorations and a decorated tiled oven, and an exhibition on the history of Zvenigorod and the monastery.

Palace of Tsar Alexis

The Palace of Tsar Alexis was built in the 1650s and is now one of the best surviving examples of non-religious architecture of that era. It was built especially for Tsar Alexis who often visited the monastery on religious pilgrimages. Its most striking feature is its pretty row of nine chimney spouts which resemble towers.

Plan your next trip to Russia

Ready-to-book tours.

Your holiday in Russia starts here. Choose and book your tour to Russia.

REQUEST A CUSTOMISED TRIP

Looking for something unique? Create the trip of your dreams with the help of our experts.

Follow Puck Worlds online:

- Follow Puck Worlds on Twitter

Site search

Filed under:

- Kontinental Hockey League

Gagarin Cup Preview: Atlant vs. Salavat Yulaev

Share this story.

- Share this on Facebook

- Share this on Twitter

- Share this on Reddit

- Share All sharing options

Share All sharing options for: Gagarin Cup Preview: Atlant vs. Salavat Yulaev

Gagarin cup (khl) finals: atlant moscow oblast vs. salavat yulaev ufa.

Much like the Elitserien Finals, we have a bit of an offense vs. defense match-up in this league Final. While Ufa let their star top line of Alexander Radulov, Patrick Thoresen and Igor Grigorenko loose on the KHL's Western Conference, Mytischi played a more conservative style, relying on veterans such as former NHLers Jan Bulis, Oleg Petrov, and Jaroslav Obsut. Just reaching the Finals is a testament to Atlant's disciplined style of play, as they had to knock off much more high profile teams from Yaroslavl and St. Petersburg to do so. But while they did finish 8th in the league in points, they haven't seen the likes of Ufa, who finished 2nd.

This series will be a challenge for the underdog, because unlike some of the other KHL teams, Ufa's top players are generally younger and in their prime. Only Proshkin amongst regular blueliners is over 30, with the work being shared by Kirill Koltsov (28), Andrei Kuteikin (26), Miroslav Blatak (28), Maxim Kondratiev (28) and Dmitri Kalinin (30). Oleg Tverdovsky hasn't played a lot in the playoffs to date. Up front, while led by a fairly young top line (24-27), Ufa does have a lot of veterans in support roles: Vyacheslav Kozlov , Viktor Kozlov , Vladimir Antipov, Sergei Zinovyev and Petr Schastlivy are all over 30. In fact, the names of all their forwards are familiar to international and NHL fans: Robert Nilsson , Alexander Svitov, Oleg Saprykin and Jakub Klepis round out the group, all former NHL players.

For Atlant, their veteran roster, with only one of their top six D under the age of 30 (and no top forwards under 30, either), this might be their one shot at a championship. The team has never won either a Russian Superleague title or the Gagarin Cup, and for players like former NHLer Oleg Petrov, this is probably the last shot at the KHL's top prize. The team got three extra days rest by winning their Conference Final in six games, and they probably needed to use it. Atlant does have younger regulars on their roster, but they generally only play a few shifts per game, if that.

The low event style of game for Atlant probably suits them well, but I don't know how they can manage to keep up against Ufa's speed, skill, and depth. There is no advantage to be seen in goal, with Erik Ersberg and Konstantin Barulin posting almost identical numbers, and even in terms of recent playoff experience Ufa has them beat. Luckily for Atlant, Ufa isn't that far away from the Moscow region, so travel shouldn't play a major role.

I'm predicting that Ufa, winners of the last Superleague title back in 2008, will become the second team to win the Gagarin Cup, and will prevail in five games. They have a seriously well built team that would honestly compete in the NHL. They represent the potential of the league, while Atlant represents closer to the reality, as a team full of players who played themselves out of the NHL.

- Atlant @ Ufa, Friday Apr 8 (3:00 PM CET/10:00 PM EST)

- Atlant @ Ufa, Sunday Apr 10 (1:00 PM CET/8:00 AM EST)

- Ufa @ Atlant, Tuesday Apr 12 (5:30 PM CET/12:30 PM EST)

- Ufa @ Atlant, Thursday Apr 14 (5:30 PM CET/12:30 PM EST)

Games 5-7 are as yet unscheduled, but every second day is the KHL standard, so expect Game 5 to be on Saturday, like an early start.

Loading comments...

IMAGES

VIDEO

COMMENTS

Genuine Hartley Boatplans and Samson Boatplans are only supplied by hartley-boats.com, New Zealand. Catamaran & Trimaran Boat Plans from Hartley Boats make it a reality to build your own multihull at home. Build with Plywood or Fibre Glass. 12-35 ft plans.

The DESIGNER'S book TRIMARAN and CATAMARAN CONSTRUCTION is part of the plans (over 21') and covers all phases of construction. Plans are leased to build ONE boat, NO time limit. Tri-Star designs are proven designs, sailing the seven seas since 1964. Free consultation is provided to the original non-professional builder till he or she is sailing ...

The ultimate multihull design and building resource - catamarans and trimarans to 150 feet. New Design Books Are Here, with 2016 Updates! Home New Designs ... Kurt Hughes Design boats for sale. KHSD boat Videos. Tel: 206.719.4893 Email: Kurt Hughes. [email protected] ...