- New Sailboats

- Sailboats 21-30ft

- Sailboats 31-35ft

- Sailboats 36-40ft

- Sailboats Over 40ft

- Sailboats Under 21feet

- used_sailboats

- Apps and Computer Programs

- Communications

- Fishfinders

- Handheld Electronics

- Plotters MFDS Rradar

- Wind, Speed & Depth Instruments

- Anchoring Mooring

- Running Rigging

- Sails Canvas

- Standing Rigging

- Diesel Engines

- Off Grid Energy

- Cleaning Waxing

- DIY Projects

- Repair, Tools & Materials

- Spare Parts

- Tools & Gadgets

- Cabin Comfort

- Ventilation

- Footwear Apparel

- Foul Weather Gear

- Mailport & PS Advisor

- Inside Practical Sailor Blog

- Activate My Web Access

- Reset Password

- Customer Service

- Free Newsletter

Affordable Cruising Sailboats, Continued

Maine Cat 41 Used Boat Review

CS 30 Used Boat Review

Hinckley 49 Used Boat Review

Best Crimpers and Strippers for Fixing Marine Electrical Connectors

Thinking Through a Solar Power Installation

How Does the Gulf Stream Influence our Weather?

Can You Run a Marine Air-Conditioner on Battery Power?

Need a New Headsail Furler? Here’s What’s Involved

Master the Sailing Basics: Never Stop Learning the Little Things

How to Mount Your Camera on Deck: Record Your Adventures with…

Un-Stepping the Mast for America’s Great Loop

Sinking? Check Your Stuffing Box

The Rain Catcher’s Guide

How to Change Your Engine Mounts

Keeping Water Clean and Fresh

Vinyl Boat Lettering DIY Application and Repair

Those Extras you Don’t Need But Love to Have

Three-Model BBQ Test

Alcohol Stoves— Swan Song or Rebirth?

UV Clothing: Is It Worth the Hype?

Preparing Yourself for Solo Sailing

How to Select Crew for a Passage or Delivery

Preparing A Boat to Sail Solo

Chafe Protection for Dock Lines

Waxing and Polishing Your Boat

Reducing Engine Room Noise

Tricks and Tips to Forming Do-it-yourself Rigging Terminals

Marine Toilet Maintenance Tips

- Boat Maintenance

Topside Paint Test Kicks Off with a Look at Application and Gloss, Tips and Techniques

Practical sailor rates dozens of enamel, one-part urethane, and two-part urethane paints..

All that glitters isn’t gold, and as the price of professional topside makeovers continues to climb, many do-it-yourselfers are looking to other alternatives.

A gleaming paint job remains an icon of yacht-quality maintenance, and paint makers spin the transformative ability of what comes in their cans. The good news is that there’s still some truth in advertising. After a close look at the latest paint systems, Practical Sailor testers offer a report on just how user-friendly topside paints have become.

A few decades ago, an aircraft paint company executive decided to paint his boat with the same stuff used to coat aircraft that flew at 450 knots—the stuff that seemed immune to UV degradation and shed hydraulic fluid like water off a duck’s back. The results were more than impressive, and his experiment with a paint called Alumagrip led to a marine-coatings revolution and the birth of Awlgrip.

With the new brand came a new coating process that featured an epoxy primer and a sprayed linear-polyurethane topcoat. Today, Awlgrip has expanded its line to both polyester and acrylic-modified polyurethane top coats. The paint has become the gold standard among pros, but it’s occasionally used by amateurs.

Paint companies have responded to the demand for do-it-yourself (DIY) glossy finishes, and a plethora of single-part modified alkyd enamels, mono-urethanes, and two-part products line chandlery shelves.

In the same vein as our bottom paint and wood coatings tests, this topside paint evaluation begins with a report on application, handling, coverage, and initial gloss. After some field testing, we’ll rate each paint’s hardness, gloss retention, and long-term durability. Our last long-term look at these products was launched in the Feb. 15, 2002 issue and closed with a final report in the May 2006 issue.

What We Tested

We applied 29 topside paints from nine manufacturers to fiberglass panels. With such a large test field, we opted to divide the products by paint type. Of the test paints, seven are alkyd enamels; 12 are one-part urethanes; and eight are two-part linear polyurethane. We’ve classified two as “other” as they fit into none of the categories.

• Enamels: We found that choosing the right topside paint for the job at hand is based both on paint characteristics and applicator skill. At the easiest-to-apply end of the spectrum are traditional alkyd enamels, paints that are relatively soft, easy to sand, and almost creamy in brushability.

In the days of carvel-planked and clinker-built wooden boats, an annual coat of topside paint was part of the spring commissioning routine. The softer enamels delivered a season of shine, oxidizing a little over winter, and by spring, they were ready for a light-scuff sanding and a rejuvenating coat of alkyd enamel. Products like Pettit’s Z-Spar 100 and semi-gloss 101 and Interlux Premium Yacht Enamel were hard to keep on the shelf.

Today, there’s still an “enamel” demand, and products like Sherwin-Williams 1000, Kirby’s Hull and Deck enamel, and Z-Spar 1195 have been added to the fray. These paints excel in their ability to be easily applied. They are reduced with mineral spirit-based solvents and are soft enough for easy sanding between coats. However, the long-term gloss retention and adhesion of enamel is not as good as that of the higher-tech paints that have cornered the market.

• One-parts: In the middle range of topside paint technology are one-part urethane modified enamels. These are harder, glossier, and tougher coatings than alkyd enamels. They exhibit traits more akin to two-part systems, yet handle with almost as much ease as a traditional enamel. They are faster-drying, quicker-to-skin paints, and must be carefully thinned with specific reducers to retain good flow characteristics. A major benefit of these paints is their forgiveness on vertical surfaces where “hangs and sags” are just waiting to happen. Single-part urethane enamels offer multi-year shine, and on a couple of applications we have been field testing, the paint has weathered four years as a nonskid surface in a cockpit sole (Interlux Brightside).

• Two-parts: At the high end of the topside paint spectrum—in cost, durability, and gloss—are the two-part linear polyurethane (LPU) products that use an isocyanate catalyst to cure the paint. More a plastic resin than an old-fashion enamel, these “wonder coatings” typically afford a wet look that packs automotive showroom brilliance. The downside of this reflective quality is the need for smooth, even, dust-free application, and the extra effort associated with surface preparation.

All of the two-part products we tested produced superior results but also proved to be more difficult to handle than one-part products. One factor common to all of the two-part paints is the detailed prep work required, but testers found that it does pay off in the long run.

What We Found

• Enamels: Don’t sideline traditional alkyd enamels. They are easy to handle, require less exacting preparation, and are a pure pleasure to brush on. When used in low-abrasion situations where modest gloss is an asset, they can prove to be just the right paint.

Pettit’s Z-Spar No. 1195 Grand Banks Beige stole the show with its smooth, even flow and Excellent coverage. Other oil-based alkyds in the Z-Spar line (Nos. 99 and 100) featured the same remarkable handling quality that makes it a favorite among carvel and clinker-built wooden boat owners.

Both Kirby’s Hull and Deck Enamel gloss white and semi-gloss proved easy to handle and developed a smooth, even skin. The only disappointment was the streaky nature of its medium-gray enamel. Even after re-stirring, it required three coats to develop a smooth hue. The difference highlights the fact that even though one manufacturer makes multiple colors of paint, one color may not have the same gloss or application qualities as another color.

Sherwin-Williams’ Seaguard 1000 was another smooth-flowing, user-friendly, oil-based alkyd enamel. It spread evenly on vertical surfaces and was reluctant to hang or sag.

Bottom Line: Most of the enamels we tested performed well, comparatively. Our top picks so far for application and initial gloss are the Z-Spar Solid Coat No. 99 and Marine Enamel No. 1195.

• Single-part urethane enamels: By far, DIY topside paint technology has grown the most in the one-part urethane modified enamels sector, a best-of-both-worlds formulation that boasts of shine and longevity. Almost as user-friendly as an alkyd enamel and with almost as much gloss as the two-part paints, these hybrids certainly live up to expectations.

In a near photo finish in our application testing, Interlux’s Toplac and Epifanes’ Mono-urethane crossed the line in a dead heat with Insignia’s Resilience rounding out the winners’ circle. (Resilience is branded as a “for pro application-only paint.”) Snapping at their heels were Interlux Brightside, Pettit Easypoxy, and West Marine’s SeaGloss Pro. Two of the most popular colors on the nautical pallet have been Interlux’s Kingston Gray and Hatteras Off White.

Bottom Line: This was a close race, but the very slight edge for application goes to Interlux’s Toplac.

• Two-part paints: When it comes to surface toughness, bright gloss, and maximum longevity, two-part paints stand alone. Paint in name only, these acrylic and polyester modified-urethane resins have the ability to suspend pigment in a flat, highly reflective skin. The trick lies in applying the coating evenly and just thick enough for it to flow, making brush strokes or orange peel disappear.

As with all forms of juggling, a minor slip can spell major problems. Consequently for DIY interest, we looked carefully for paints that behaved well when rolled and brushed. Once again, Interlux and Epifanes crossed the line in a dead heat: Interlux’s Perfection and Epifanes’ Polyurethane products flowed smoothly over horizontal and vertical surfaces and resisted the tendency to hang or sag.

Fabula Inc.’s Signature Finish, which comes with brushes, rollers, tape, mixing graduates, stirrers, and detailed instructions also hit the mark. Sherwin-Williams’s vivid red two-part was the smoothest flowing red of the three we tested. Insignia’s Brilliance, like Awlgrip is a “pro only” recommended product, and once the right amount of brushing reducer was added to cope with the warm weather, these products also ranked as standouts.

The volatility of the solvents in all these two-part system leaves the user with less time to muck around, and maintaining a wet edge is essential to the “cutting in” process. Each manufacturer provides a “slow” brushing reducer that has to be carefully used. Too much causes excess flow—and the drama mentioned earlier of hangs and sags. In short, two-part paints typically provide the best gloss and toughest, longest-lasting finish, but they are the hardest to handle.

Bottom Line: The Awlgrip, Epifanes, and Interlux two-parts were the only products to earn across-the-board Excellent ratings.

• Other: As soon as we popped the lid on the first can of CrystaLac Crab Coat, we noticed change in the air. Absent was the aroma of oil or the volatile solvent jolt of urethane-based chemistry. In fact, the smell was imperceptible, and that made this paint especially appealing for those working inside a shop or below deck.

Crab Coat is not a water-based paint, but it is hydrophilic enough to allow water-only cleanup. It handles more like a blend between thick, creamy enamel and a water-based Latex. However, this paint is meant for exterior marine use. Time and our test panels will spell out how it weathers the environmental onslaught. It brushed on smoothly, but its Mystic Green color presented a somewhat streaky appearance.

Bottom Line: Though not as glossy as the current crop of urethanes, the Crab Coat produces a very appealing semi-gloss finish.

Topside and deck painting are labor-intensive undertakings that can rejuvenate an aging vessel as well as protect the substrate that lies beneath. Those enamored by the finish of the dark-blue Hinckley and Morris fleets have a tall order to meet.

Those willing to stay with white or a light color who are ready to invest equal amounts of time, patience, and skill, can parlay the cost of materials into a durable and attractive finish.

To say that the average roll-and-tip finish is just as good as a pro-sprayed finish would evoke too much of the Pinocchio factor. The results attainable by the average applicator can be quite good, but to hit the bull’s eye takes a steady hand, or the willingness to follow an autobody shop approach one of the paint manufacturers recommends.

One paint maker, Signature Finish, offers three sets of instructions, allowing DIYers to choose the level that suits them. Level 1 is straightforward: Apply three coats of their two-part paint (no primer), scuff sand between coats, and accept the last coat as the done deal. A Level 2 finish involves buffing with 3M Super Duty rubbing compound, and for those with more vigor and higher standards, there’s an exacting Level 3: Apply three or more coats, and once it’s dry (three to five days), wetsand it down to 1,200 or 2,000 grit followed up with the machine-buffing process. The workable acrylic LPU paint is highly buffable, and the result is a smooth, glossy surface, but care must be taken not to remove too much material.

Before committing to a big project, do a bit of testing of your own. A good test is to paint a pair of dinghy oars with good-quality enamel, then paint the inside of the dinghy with a one-part urethane, and finally flip it over, and go through a full prep-and-prime process that leads up to a roll-and-tip application of a two-part LPU paint. From this experience, you’ll have developed important painting skills and better understand the task that lays ahead.

All of the products we tested ranked at least acceptable in handlability, and many excelled. Only time will answer questions about durability and gloss retention.

Regardless of the paint you choose, be sure to review all of the manufacturer’s printed and online technical information, follow all safety procedures, and keep in mind that when it comes to painting, success is in the eye of the paint-brush holder.

- How We Tested

- Practical Sailor Value Guide: Topside Paints Application

- DIY Notebook

RELATED ARTICLES MORE FROM AUTHOR

Spring Season Engine Start-Up for Winterized Engines

Leave a reply cancel reply.

Log in to leave a comment

Latest Videos

Pearson 37 & 37-2 – Behind the Curtain

How To Test a Boat Engine

Hunter Legend 35.5 – Behind the Curtain

Whipping Line On Your Sailboat

- Privacy Policy

- Do Not Sell My Personal Information

- Online Account Activation

- Privacy Manager

- International Marine Coatings

- International Protective Coatings

How do I paint my anodized aluminum mast?

It is difficult to paint over anodizing. If it is in very poor shape remove it before painting. To paint anodized first degrease using Fiberglass Solvent Wash 202. Then give it a heavy sanding using 60 or 80-grit sandpaper. Apply one coat of InterProtect 2000E (Thinned 15-20% with 2316N Reducing Solvent). Allow to dry overnight and apply a second coat of either Epoxy Primekote (thinned 25%) or Pre-Kote primer. Sand and apply Perfection (if using Epoxy Primekote) or Brightside (if using Pre-Kote).

Paint your boat like a pro

Find the best products to keep your boat in great condition

Get all the support you need to paint with confidence

Benefit from our continuous innovation and scientific expertise

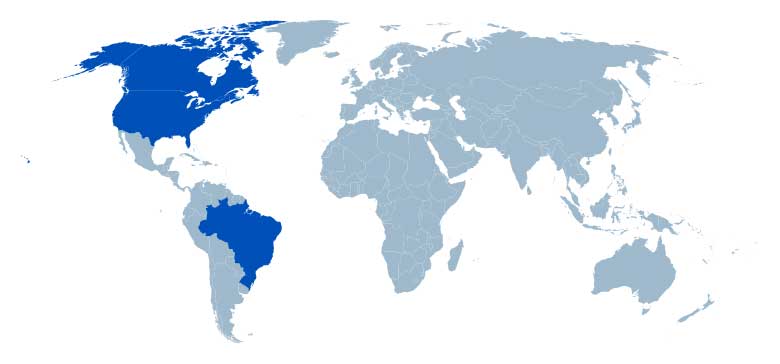

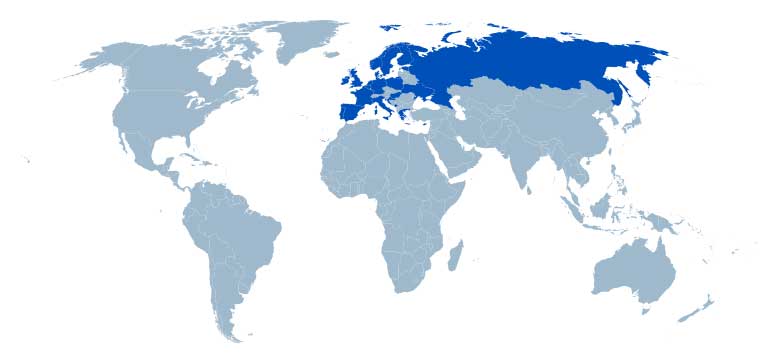

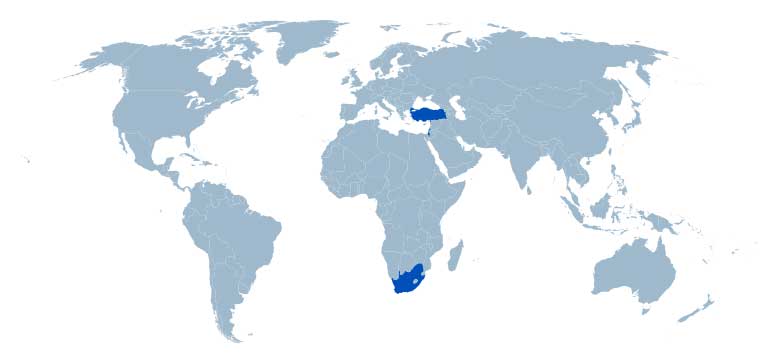

Select your country

Our products and guidelines are customised for each country. Please select yours below.

- Canada Canada

- United States United States

Asia Pacific

- Australia Australia

- New Zealand New Zealand

- Singapore Singapore

- België Belgium

- Hrvatska Croatia

- Danmark Denmark

- Suomi Finland

- France France

- Deutschland Germany

- Ελλάδα Greece

- Ireland Ireland

- Italia Italy

- Nederland Netherlands

- Norge Norway

- Portugal Portugal

- España Spain

- Sverige Sweden

- United Kingdom United Kingdom

Middle East & Africa

- South Africa South Africa

- Türkiye Turkey

Who's painting?

Choose one of the following to tailor the site to your needs.

- Search forums

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

- Maintenance and Systems

- General Maintenance

Painting my mast

- Thread starter CEC

- Start date Oct 8, 2018

- Oct 8, 2018

Senior Member

I'm about to take my mast off and refinish/rewire it. I'm wondering what's the best paint to use over the wood? I have Brightside polyurethane and the primer so I can roll and tip it with that? Wondering if I would be better off with epoxy paint or something else for the wood? Thanks for any suggestions.

Nomad Willy

I’d say heavy Tung oil thinned w turpentine at various ratios as a primer. I’ve done 12-14 coats. Just keep applying short of any significant build. For the first 3-4 coats I use kerosene as it’s best to drive the oil (or paint) into the wood. Then topcoat w the best quality oil based marine finish. High oil and high UV resistance. The best color is “mast buff” as very traditional. If you’re anti-oil based finishes many many here have had good experiences w Interlux Brightside Poly primed w Interlux Primer (grey). Almost all my cabin ect have been fininshed w Brightside and I think highly of it. Only downside is on decks. Brightside dosn’t stand up to deck “wear and tear”. But on cabin sides it’s great. We haven’t painted our cabinsides for close to 10years and it still looks good. A finish that can be easily touched up is important on things like masts.

Greetings, Mr. CEC. I repainted our wooden mast 3 years ago with Alexseal epoxy paint. This was the same paint used to re-coat the rest of the boat. The previous coating (type of paint unknown but PROBABLY some sort of one part enamel) was degraded. Good sanding, NOT down to bare wood, epoxy primer on the bare/worn spots and 2 coats of Alexseal. That being said, I think almost ANY good quality paint should work and since you already have the Brightside, I'd say, use it.

TF Site Team

I would use the Brightside primer and paint . Just make sure clean and tack off all sanding dust before primer and paint . I think good sanding and clean before coats is the key when using Brightside paint . Brightside paint likes it’s own primer . They already know each other . Any paint will probably separate along a joint . Wood is alive always and always trying to equalize to its surroundings. . It’s gonna move no matter what , shrink and swell . That’s how raised panel doors came to life . You can’t trap wood movement ever When it comes to painting anything to me preparation and using like materials including thinners gives me peace of mind .Its just to much work to do otherwise.

- Oct 9, 2018

I used Home depot paint last time and that was 3 years ago. Needs touch up again, and I'll hit it with the same stuff in the spring.

Brightside it is then. I have the primer and paint already so Ill go with that. RT as for bare wood there's already some showing, and I have a feeling any sanding will expose more. Ill do a few light coats of primer then sand primer and paint a few topcoats. On my mast anyway it appears to be one solid piece of wood but I cant tell 100%. No splits or seams I can see. Kinda wondering how heavy it will be when I take it down.. My guess is 75-100lbs? Boats a 38' C&L aft cabin. Mast is around 12' if I'm way off and I should expect it to weigh a lot more let me know. I'm taking it down for the first time this afternoon... Thanks everyone

Greetings, Mr. CEC. "I have a feeling any sanding will expose more." Isn't that sorta what you want? Your primer will most probably stick to bare wood a bit better than existing paint. Plus, your primer should stick to sanded paint better than non sanded paint (more tooth). Be careful dropping your mast. It may be heavier than you think. I would suggest help. A couple of extra bodies might prevent injury or damage.

I have about 12' of mast above the flybridge deck, with another couple of feet down to the aft cabin deck. Mine has spreaders, lights, radar, radar reflector and halyards, but the mast itself is Aluminum (3" pipe) so is quite light per foot. I lower it myself, using a line attached to the underside of the radar mount. The weight of what I have is the limit for me to lower or raise it without more mechanical advantage or additional help. I can't imagine your 12' of wood would be any lighter. I guess the weight of your woodie at about twice the weight of my setup, so before you lower it, make sure you have more mechanical advantage or at least one strong helper.

The big fishing poles on trollers in SE Alaska are seldom if ever painted at all. But they seldom if ever see the sun. And the fishermen walk through the woods extensively to find the best poles. But fishermen use tar on decks, housepaint on hulls, concrete in plank seams and Claw anchors. Wouldn’t pass muster in our yacht club. Just oil would be a good “finish” but applying oil frequently would be a downer.

Thanks guys I had a feeling it might be heavier then it looks. Its got wire running down the center so I know there's at least a 1" hollow hole down the middle. I grab some buddies and have them lend a hand. There's two through bolts that extend through the thick ss bracket at the bottom. The mast is square at the bottom flush to the deck, so no pivoting on one bolt. Both bolts will have to come out before it can be tilted, so Ill rig something up to try and help. So much for my idea to bring it home to work on it. If its a couple hundred pounds its getting fixed up on the dock! Id sand and paint it in place if it did not need new lights and wiring. Old radar is off, new is ready to go, so its time to fix the mast up a bit while I'm at it. Nomad If the mast were fresh wood and didn't have a bunch of old screw holes that need filling, and I could get all the old paint off I might go with a varnish or oil. In this case, its gonna remain white...

CEC, OK good I’d do Brightside if it wasn’t wooded down. The oil would just get under the old finish that was there and lift it. And what’s better than white for a pleasure boat?

- Oct 10, 2018

Yesterday I got the mast off the boat. It was not heavy maybe 50lbs. Once off the first thing I noticed is how much more I like the boat without it, or maybe just without the cable tie downs. I need the mast for the radar and lights. I rather it be an arch off the FB though. First thing we did when we bought the boat is take the boom off the mast. It was just in the way and we have no need for it. I'm wondering what everyone's input is on the need for the cable stays when using just the mast without the boom. The big stainless mast mounting bracket is stout, and its through bolted to the fly bridge floor. When I removed the cables it did not seem to effect the masts stability. I don't believe a lot of boat roll ext would strain the bracket with the light weight of the mast. Are the four cables stays only needed when the boom is installed/used to lift things off the dock or deck? Is there a reason I need to use them when just the mast is up?

Greetings, Mr.CEC. I can't remember what boat you're on or how big/tall your mast is (if you ever mentioned it). Your mast is a lever with the mounting/base, the fulcrum. I would put the stays back on. Your mast may seem light but add the weight of the radar and unknown upcoming sea conditions....Just sayin'

Boat is a 38' C&L 1979 The mast is around 10' (now that I have it off and can get a good measurement) Ill take and post some photos after I'm done painting and put it back up. I hear what your saying, so Ill stay on the safe side.

Painting or varnishing a wood mast that has failed glue joints will be a pita and not successful in the long run. Y'gotta' keep the wood from changing shape with water leaking into the crack or passing through the finish. I'd take it home for the winter, remove all the finish and let it dry for several months. Then I'd coat the thing as completely as possible with epoxy, then varnish or paint. I use West System 105/ and special coating hardener. The epoxy's low permeability will prevent the wood from moving, tend to rebond the crack, and provide an excellent base for paint. I replaced our original wood mast a couple years ago due to rot. I used fiberglass components epoxied together, an epoxy-glass ferrule that I made to couple the original bronze maststep to the new aluminum (spinnaker pole) tubing. All painted with 'Heavy Duty', Home Despot's finest, white spray paint in aerosol cans. Looks fine. I also made a laminated, curved Ash kayak davit, coated in epoxy and painted with the same stuff. Those damn shrouds/guy wires were a head-catcher for me. I eliminated them and made a table/partner to hold the mast. It's fiberglass, bolted to the flybridge seatback, has a quick-remove section for lowering the mast. The one-part Brightside Polyurethane works fine on properly prepared surfaces, too. Pics are in my album on this site.

You need to know some of the physics involved in order to know whether the stays are required. Of critical importance is the strength of the mast itself under side loading or a bending moment. My own mast came to me with an aluminum base (tabernacle), Aluminum pipe mast and boom, (too short) stainless shrouds, two per side. In order to eliminate the neck height shroud that interfered with access up the flybridge steps, I moved the mast step to the lower deck (top of the aft cabin) and put a fastening on the edge of the upper deck, where the original step had been located, to hold the mast in a vertical position. The relocation gave me the opportunity to add several feet of height to the mast and length to the boom. I add temporary shrouds opposite to any load over 50 lbs if I am using the lifting boom. Otherwise, I am happy with the unstayed aluminum pipe. It carries lights, spreaders, flag halyards, radar, radar reflector, boom and all boom rigging, but no shrouds. I made the change to unstayed more than 20 years ago, so it has stood the test of time.

Veteran Member

Cetol

koliver said: You need to know some of the physics involved in order to know whether the stays are required. Of critical importance is the strength of the mast itself under side loading or a bending moment. My own mast came to me with an aluminum base (tabernacle), Aluminum pipe mast and boom, (too short) stainless shrouds, two per side. In order to eliminate the neck height shroud that interfered with access up the flybridge steps, I moved the mast step to the lower deck (top of the aft cabin) and put a fastening on the edge of the upper deck, where the original step had been located, to hold the mast in a vertical position. The relocation gave me the opportunity to add several feet of height to the mast and length to the boom. I add temporary shrouds opposite to any load over 50 lbs if I am using the lifting boom. Otherwise, I am happy with the unstayed aluminum pipe. It carries lights, spreaders, flag halyards, radar, radar reflector, boom and all boom rigging, but no shrouds. I made the change to unstayed more than 20 years ago, so it has stood the test of time. Click to expand...

CEC I think DHeckrotte was responding to my post about a separation along a bond line (the mast is laminated). I hadn't considered before a potential issue of moisture working its way in an causing wood damage. I think I will be pulling the mast this winter and refinishing it.

- Oct 19, 2018

for max life you want a wood stablizing clear epoxy primer (solvent based) - a few coats of real marine spar varnish and then roll and tip (or spray) two part LPU clear with uv blockers (most 2 part polys do not have uv blockers due to added cost). google ESP 155, India Spar Varnish, Acrylic Poly UV plus as examples of this sort of 3 layer clear coat system. No one product by itself will do 'everything' - paul

Similar threads

- Feb 26, 2024

- Feb 24, 2024

- Oct 21, 2023

- Apr 20, 2024

- Apr 9, 2024

Latest posts

- Latest: Irish Rambler

- 30 minutes ago

- Latest: FWT

- Today at 3:40 AM

- Latest: tiltrider1

- Today at 1:47 AM

- Today at 1:45 AM

- Latest: Hydraulicjump

- Today at 1:37 AM

- Latest: SteveK

- Today at 1:23 AM

- Today at 12:58 AM

- Latest: motteatoj

- Yesterday at 11:59 PM

- Latest: Pdxstriper

- Yesterday at 11:29 PM

- Latest: whistlerxc

- Yesterday at 11:19 PM

Visit our Popular Forums

- Monohull Sailboats

- Multihull Sailboats

- Powered Boats

- General Sailing

- Antares Yachts

- Fountaine Pajot

- Lagoon Catamarans

Cruising Business

- Boat Classifieds

- General Classifieds

- Crew Positions

- Commercial Posts

- Vendor Spotlight

Life Aboard a Boat

- Provisioning: Food & Drink

- Families, Kids, & Pets Afloat

- Recreation, Entertainment, & Fun

- Boat Ownership & Making a Living

- Liveaboard's Forum

Seamanship, Navigation & Boat Handling

- Seamanship & Boat Handling

- Training, Licensing, & Certification

- Health, Safety, & Related Gear

- Rules of the Road, Regulations, & Red Tape

Engineering & Systems

- Const. / Maint. / Refit

- Product / Service Reviews

- Electronics: Comms / AV

- Electrical: Batts / Gen / Solar

- Lithium Power Systems

- Engines & Propulsion

- Propellers & Drive Systems

- Plumbing / Fixtures

- Deck Hdw: Rigging / Sails

- Aux. Equipment & Dinghy

- Anchoring & Mooring

Photo Categories

- Member Galleries

- Life Onboard

- Sailing in the Wind

- Power Boats

- Cruising Destinations

- Maint. & Boat Building

- Marine Life

- Scuba Diving & Divers

- General Photos

Recent Photos

Listing Categories

- African Cats

- view more »

- Crew Wanted

- Crew Available

- Enhance Your Account

- Meet the Mods

- Meet the Advisors

- Signup for The Daily Cruiser Email

IMAGES

VIDEO

COMMENTS

Re: Recommend Me a Mast Paint. "... Bare Aluminum: Wipe the surface free of oil and grease with Pettit 120 Thinner. Remove oxidation and etch the surface with medium grit emery cloth; remove sanding residue. Apply one thin "wet" coat of 6455/044 Metal Primer; allow to dry at least two hours. Proceed with the first coat of Easypoxy.

Most painted masts are white and there are so many shades of the color that a perfect match is all but impossible. The best answer is to purchase the exact paint used the last time the spar was painted. If not, an "almost the same" color will look just fine and more importantly, corrosion will be halted dead in its tracks.

The right answer is to do everything possible to separate dissimilar metals. Putting a Delrin strip or dielectric PTFE tape between the hardware and the mast wall really helps. When installing larger stainless steel hardware on a mast, it's easy to cut out a gasket from a sheet of 30 mil thick Teflon.

Jay Tracy. Mar 17, 2004. #5. Painting an old alum. mast. We repainted our alum. mast but used a different approach as suggested by a rigger. He suggested we wet sand the mast, wash it off, treat it with alum. prepainting solution and paint it with Krylon clear enamel.

After a rough surface prep you will want to use Alumiprep (acid etch/cleaner) follow directions for dilution, let dwell for 5 minutes or so and rinse with plenty of fresh water. Then you will want to make sure the surface is dry and the temperature is over 70 degrees at min., hotter is much better, and then coat with Alodine.

I did the mast on my 26 footer thirty years ago. Used two-part epoxy paint (Awlgrip). Removed all the mast hardware, sanded it down to bare metal, used the proper etcher and primers, and applied a few coats of paint. Sold the boat a few years later, then saw it about 20 years later and the mast looked great. Anything less than properly applied ...

Un-Stepping the Mast for America's Great Loop. ... an aircraft paint company executive decided to paint his boat with the same stuff used to coat aircraft that flew at 450 knots—the stuff that seemed immune to UV degradation and shed hydraulic fluid like water off a duck's back. ... a best-of-both-worlds formulation that boasts of shine ...

Originally Posted by nfbr. 27yo white painted aluminium mast is losing paint / showing surface corrosion at most rivet / screw points. This basically means the stainless hardware wasn't installed right the first time. Unless it is all removed and installed with Ted-Gel or Duralac you can expect a repeat. Quote:

Put on a coat of over priced yellow stuff. Put on some over priced primer in less than 24 hours OR do the yellow again. Try and find some way to get all the stuff back on without dinging the paint which takes 14 days to full cure. Perfection or Awlgrip is Like Ford and Chevy. Do a bunch of sailing and enjoy it.

To paint anodized first degrease using Fiberglass Solvent Wash 202. Then give it a heavy sanding using 60 or 80-grit sandpaper. Apply one coat of InterProtect 2000E (Thinned 15-20% with 2316N Reducing Solvent). Allow to dry overnight and apply a second coat of either Epoxy Primekote (thinned 25%) or Pre-Kote primer.

bob77903. 178 posts · Joined 2008. #5 · Jul 30, 2015. Just painted my mast. Sanded the old paint with 80 grit, removing half of it to bare aluminum. Washed the sanded mast with acid bath, and primed with zinc chromate. Sanded primer with 280 grit, and finished coated with Awlcraft 2000 Jet Black....

I repainted our wooden mast 3 years ago with Alexseal epoxy paint. This was the same paint used to re-coat the rest of the boat. The previous coating (type of paint unknown but PROBABLY some sort of one part enamel) was degraded. Good sanding, NOT down to bare wood, epoxy primer on the bare/worn spots and 2 coats of Alexseal.

Jan 2, 2006. #7. Painting a mast. In 1996, I painted my Irwin 31 Citation's aluminum mast and boom Imron beige, matching the new paint for the hull and deck. Although the boat was sold two years ago, it remains in the harbor near my new boat. The mast paint is holding up extremely well although there are spots of corrosion in a few places.

If it was my 16' boat, I'd either do the mast right or not do it. I say that because it's aluminum, and painting aluminum is more difficult to paint properly as compared to wood, steel, or fiberglass. Paint doesn't like to stick to it unless the surface has been properly prepared. That means, as others have suggested, properly abrading it.

There's a lot going on in this video as we try to get the boat ready for launch. We repaint the topsides after our our last coat of paint went terribly wrong...

I have a friend who just bought a boat with an aluminum painted mast.There is some bubbling of paint around some of the fittings but overall the mast looks great and the step and bottom of the mast are fine. The quote he got to remove all the mast hardware and repaint is a good deal higher than he wants to spend. I've never liked the idea of painting aluminum because it always seems to have ...

3)Alodine, a really weird chemical that treats the metal. 4) zinc chromate primer, cheap and widely available in hardware stores. 5) topcoat like Awlgrip. Edit: don't let it sit too long between the chemicals, follow the directions but if you leave the aluminum exposed to salt air a long time it defeats the purpose.

Catalina 22 home. Jul 4, 2011. #8. Anodizing is just a controlled corrosion, somewhat along the lines of gun bluing on steel. There is no reason to avoid painting it. First, wash with detergent, rinse and dry; then wipe down with acetone, naptha, or some similar solvent to remove all traces of wax. Ideally, you should roughen the surface with a ...

The mast paint wasn't in good shape and the mast had been removed and stowed for shipping with the boat, so it was an opportune time to paint it before install. I wanted to do the job right and was diligent in seeking professional assistance before undertaking such a job for the first time.

It's good I was sitting down at the time because it's a bit more than I expected. $4,616.17 to be exact. They propose to chemically strip, etch, prime and paint the 40 foot mast, boom & spreaders with Awlgrip. The breakdown is $3,570 for 42 hours labor @$85/hour, $959.79 for supplies & materials, and $86.38 tax.

I moved a boat from San Diego to Port Townsend, in the spring of 2017. The mast was showing some corrosion and loosing paint in several spots. So on the advice of a well know PT Boat Rigger, I scraped and sanded those areas, wiped it down with Denatured Alcohol, painted the bare spots with zinc chromate, sanded that lightly and recoated any bare spots again with zinc chromate and applied a ...

Use a 2-part paint and at the end of the day, I think brush-tip method will be fine. I actually sprayed mine with a 2-part but think brush-tip would have resulted the much the same. You don't need that much of a glimmer on a mast verses doing a hull for example. Paint the mast, boom and spreaders and it will make the boat look sharp. Good luck ...

87689 posts · Joined 1999. #11 · Feb 27, 2003. I have painted several masts. remove all the stuff you can, sand, prime & paint with a brush, roller or spray. Our best paint job was done with the roll & tip method using Brightside paint. The manifacturer instructions will lead you to a beautiful job. John.