- For Sale/Wanted

- Readers Tips

- Your Yarns.

- Restoration

- Miscellaneous

- DIY Boat Yards

- Boat Building

- Cabin Cruisers

- Free Boat Plans

- Begin Boating

- Boating Terms

- Ropes and Rigs

- Just for Fun

- Celestial Navigation

- Passage Planning

- VHF Marine Radio

- Diagonal Scale

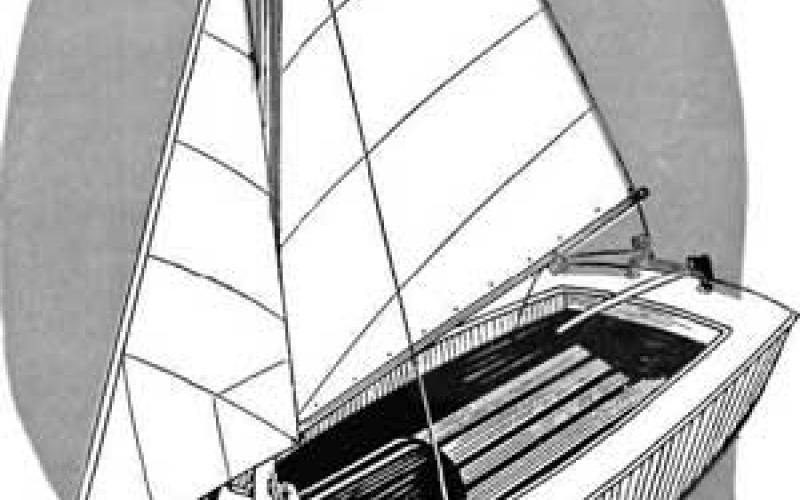

Sailboat Plans

Free Sailboat Plans

A selection of some of the Free Sailboat Plans (pdf) that were published in magazines such as “Popular Mechanics”, "Popular Science" and the "Boat Builder Handbook".

If you need help with lofting out the plans click here for an article here which should help.

- Open Dayboats/Dinghys

- Rowing Boats

Open/Dayboat, Free Sailboat Plans

Everyone who digs boating has heard of the Hobie Cat, the sleek little catamaran that burst on the scene and captured the attention of all the fast-action sailors.

Marked by asymmetrical hulls and special trampoline supports, the Hobie can reach speeds above 20 mph and perform with a rare agility.

But it has one drawback.

It costs mucho dinero.

Thus, we introduce the Hobby Kat, sailboat plans, a build-it-yourself version of the “Hobie” that should cost from half to a third of the commercial version. If you have the moola, of course, go for a Hobie and have the time of your life on the water.

If not, try our Hobby

The homebuilt is not quite the same.

But she sails sweetly and fast—qualities which have made the “Hobie” popular

Even in a light air she’ll slip through the water at a fast clip.

She has no centreboards, leeboards or keel, and needs none.

The inside of each hull has built-in lift, like an airplane wing, so that as the boat heels and one hull digs in the boat is pulled back to windward.

Click Here for the Plans

She can run in very shallow water and the rudders kick up for beaching.

You can carry her on a trailer or even disassemble her.

Many a “stink pot” addict will take a second look at Tern because she planes in modest breezes, is easy to handle, and her streamlined prow arid pod-shaped, “inland scow” type hull offer slight water resistance. Then too, there’s a charm about the tiller of a sailer that’s not matched by the wheel of a motor-powered boat. Part of it is the challenge of making the most of nature’s free-wheeling breezes. Even with her 72sq.ft of sail, this Free Sailboat Plan is remarkably stable, and packs as many as four persons aboard

For thousands of inland lakes, Tern is the answer to sailing water sport, she is rugged and easy to launch

And she’s remarkably easy to build.

Falcon is a small, speedy, sporty sailboat which handles well. Tests on the original Falcon showed that she could easily out-distance boats of comparable size such as the one design class Snipe and Comet sailers.

And she will pace neck and neck with 18 footers with considerably greater sail spread.

This strong, beamy, eight-foot pram may be sailed either cat-rigged or sloop-rigged.

The dagger-board may be adjusted forward to balance the helm when sailing with the addition of a jib sail.

Oars or a small outboard motor may also be used to power this versatile Free Sailboat Plans.

Dart” is a small two or three person sailing craft, designed for use on protected waters such as bays. lakes, rivers or wherever sheltered waters are found. Its construction will repay the builder handsomely and provide a fast sailing craft, light in weight, easily transportable and cheap to construct with all difficult joinery eliminated

It provides thrilling and economical sport.

The 'Crescent', designed by C. T. Allen, is the ideal sailboat for day sailing on a small lake, river, or protected waters of a bay.

Centreboard design (Fig. 2) reduces Crescent's draft, so Shallow is not a problem.

Its broad beam of over 5½ft. makes it an ideal family boat because there is room for a cockpit large enough to accommodate four adults or two adults and three kids, and side and forward decks big enough to stretch out on when sun bathing.

"Jewel" is a 16' Crescent Sailboat being built by Mike Allen from the free sailboat plans by C.T .Allen in the 1958 "Boat Builders Handbook". And what a superb job Mike is doing check out his photos here .

Click Here for the Free version of the Plans

Sailing enthusiasts and backyard boat builders are not likely to find free boat plans for a sailing pram that can be built faster, lighter, stronger, or less expensively than Graefin-10. Two men can begin work on a Friday evening and have a smart, lively 10-ft. 85-pound sailboat in the water by Sunday evening (it’s been done).

Zephyr Is a refinement of a type of boat developed by the English for use in the rough open waters of the English Channel. Not only is it fast under sail, but it can stand up under punishment. And it’s light enough to be easily loaded atop an auto or light trailer.

Breeze-Baby

Skimming off a brisk wind or with the wind abeam, Breeze-Baby actually planes with one person aboard. Despite her rowboat lines that make her easy to build, she handles easily under her simple sail, an ideal first boat. Simple lines are adapted to plywood construction that’s strong, light and that keeps Breeze-Baby’s bilges dry

You can take her with you atop your car or on a lightweight trailer for summer fun wherever you vacation or get in a week-end’s sailing.

Cat’s Paw is easy to build because of the straight-sided hulls. The sheer line is flat and that simplifies building the form. Bow and stern are straight, so there’s no cockeyed bevel to fit and fuss with

She Is an Ideal boat to learn or practice sailing in because she will forgive so many mistakes.

Cabin Cruiser, Free Sailboat Plans

Previous posts

See What Others Have Posted

Recent Articles

Owens Boats

Jun 05, 24 12:14 PM

- Boat Plan Books

- Boatbuilding Tips

- Glass Cloth

- Stitch and Glue

- Strip Plank

You might like these

Knotty wood, problems with boat building timber.

Knotty wood, how to avoid structural problems with knots in lumber when using softwood timber for fitting out and boat joinery

Build a Boat, tips for the DIY Wooden Boat Builder.

How to Build a Boat, Wooden Boat Building methods for the DIY, backyard, self-builders explained, carvel, lapstrake and plywood

Wood Screws for Boat Building and Repair.

Wood Screws are the most widely used and versatile fasteners used on wooden boats. Which type to use and how to use them

Wood, Environmentally Friendly Boat Building Lumber.

Make sure that the Wood that you buy and use is sustainably grown and harvested.

Timber, Lumber for Boat Building.

A brief description of the most common Timber used for building Wooden Boats how to choose wood for your project boat

Timber Properties

A brief guide to timber properties and wood, characteristics such as strength, stiffness and elasticity for choosing lumber for wooden boat building and restoration.

Rivets and Copper Rove Wood Boat Fastenings.

How to use Copper Rivets and Roves construction guide to fasteners on your wooden boat.

Ring Nails for Marine Fastening.

Ring Nails sometimes call Gripfast or ring shank, silicon bronze boat nails are renowned for their holding power. but how to get them out?

Plywood and Veneer Guide for Marine use.

A guide to plywood for boat building and why you should use the best marine grade you can afford.

Glue for Wooden Boat Building

Which Wood Glue to use when building or restoring a wooden boat, resorcinol to epoxy.

Rowing Boat Plans

Free Rowing Boat Plans for the backyard home builder, build your own rowing boat, dory, folding dinghy or pram using these simple plywood designs.

Free Motorboat Plans

Free Motorboat Plans for the backyard home builder, build your own speed boat, cabin cruiser, runabout or utility boat using these simple plywood designs.

Wooden Boat Kits.

Wooden boat building is easy and inexpensive with wooden boat kits. From row boats and kayaks to sailing cruisers, boat to be proud of

Supplies for Wooden Boat building and Maintenance

Supplies for Wooden Boat Building and restoration, how to choose the materials and marine chandlery for your project.

Small Boats, Made of Wood

What Everybody ought to know about building Small Boats, guidance and tips for self-building or restoring.

Penn Yan Boats

May 28, 24 07:51 AM

Chris Craft Boats

May 21, 24 06:16 AM

Wooden Boat Restoration, Repair and Maintainence.

Wooden boat restoration, how to fix up an old wooden boat, one of the cheapest ways to get afloat and have a boat to be proud of.

Epoxy Resin for DIY Wooden Boat Building.

A guide to the epoxy resins and sustainable enrtopy resins to use when building wooden boats with marine plywood.

Wood Rot Repair and Treatment

Wood rot in wooden boats, how to treat, repair and replace rotten timbers in a wooden boat

Privacy Policy

Advertising Policy

Cookie Policy

I am perfectly aware that the majority of Wooden Boat aficionados are sensible folk. However, I need to point out that I am an amateur wooden boat enthusiast simply writing in order to try to help other amateur wooden boat enthusiasts. And while I take every care to ensure that the information in DIY Wood Boat.com is correct, anyone acting on the information on this website does so at their own risk.

Learn How to Make a Miniature Sailboat | Step-by-Step Guide

Alex Morgan

Making a miniature sailboat can be a rewarding and enjoyable hobby. Building your own miniature sailboat allows you to unleash your creativity, learn about boat construction, and have a functional piece of art. With the right materials, tools, and techniques, you can create a beautiful miniature sailboat that is both aesthetically pleasing and capable of sailing. In this article, we will guide you through the process of making a miniature sailboat, from gathering materials and tools to painting and finishing touches, testing and setting sail, as well as troubleshooting and maintenance. Let’s embark on this exciting journey of constructing your very own miniature sailboat.

Key takeaway:

- Making a miniature sailboat maximizes creativity: Building a miniature sailboat allows individuals to express their creativity and craftsmanship while creating a functional toy or decorative piece.

- Gathering the right materials and tools is crucial: The quality of the miniature sailboat depends on using the right materials and tools for each component, such as the hull, mast, sails, rigging, and accessories.

- Attention to detail enhances the finished product: Painting and adding finishing touches to the miniature sailboat, including sanding, priming, applying paint and varnish, and adding details and decorations, bring the sailboat to life and make it visually appealing.

Gather Materials and Tools

Get ready to set sail on a fantastic DIY adventure! In this section, we’ll dive into the essential steps of gathering materials and tools for creating your very own miniature sailboat. From crafting the sturdy hull to designing the mast and sails, we’ll cover all the bases. We’ll even explore the intricate details of rigging and accessories that will give your sailboat that extra touch of authenticity. So, hoist your imagination and get ready to embark on this nautical journey with us.

To create the table for the sub-topic “ 1. Hull “, the following information is provided:

| The material used for constructing the hull: wood, fiberglass, or plastic. | |

| The shape of the hull, which can vary from flat-bottomed to v-shaped or round-bottomed. | |

| The length of the hull in inches or centimeters. It determines the overall size of the miniature sailboat. | |

| The width of the hull, also known as the beam. It affects the sailboat’s stability. | |

| The keel is a fin-like structure attached to the hull’s bottom to improve stability and prevent capsizing. | |

| The lowest interior part of the hull where water collects. It is important for draining any water that enters the sailboat. |

The table above provides vital information about the hull of a miniature sailboat. It includes details about the construction material , shape , length , width , keel , and bilge . These factors greatly impact the sailboat’s performance and stability on the water.

2. Mast and Sails

When building a miniature sailboat, the mast and sails are the most crucial components. It is essential to select a strong and lightweight material such as aluminum or carbon fiber for the mast. Cutting the mast to the desired length is also important, ensuring that it is tall enough to catch sufficient wind. To guarantee stability, securely attaching the mast to the boat’s deck using screws or bolts is necessary. Attaching the sails to the mast with sail ties or rigging clips is essential, ensuring proper alignment and tightness. Setting up the necessary rigging lines to control the positioning and tension of the sails is also important. Prior to setting sail, it is crucial to test the mast and sails to ensure that they are securely fastened and functioning properly.

I once had the exciting experience of building a miniature sailboat, and attaching the mast and sails filled me with anticipation. As the wind caught the sails and propelled the boat forward, a sense of pride engulfed me for my creation. Witnessing my sailboat smoothly glide across the water, responding to the wind, was an exhilarating sight. Building and sailing a miniature sailboat truly showcases the ingenuity and craftsmanship of humans.

3. Rigging and Accessories

Below is a table outlining the steps of rigging and accessorizing a miniature sailboat:

| Step | Task |

|---|---|

| Attach mast to hull using adhesive or screws. | |

| Attach sails to mast using sail rings or suitable fasteners. | |

| Add rigging lines to connect mast and sails for support and angle adjustment. | |

| Install additional accessories like pulleys, cleats, and winches for sail handling and control. |

Rigging and accessories are vital for the performance and functionality of a miniature sailboat. Securely attaching the mast and sails ensures stability and proper maneuvering. Rigging lines adjust the sails to catch wind effectively. Accessories such as pulleys, cleats, and winches enhance overall control and ease of operation. Paying attention to proper rigging and accessories leads to a well-functioning and enjoyable miniature sailboat experience.

Throughout history, sailing has fascinated and allowed people to explore open waters. Sailboats have been used for transportation, discovery, and leisure from ancient civilizations to modern times. Miniature sailboats now provide enthusiasts with the thrill of sailing on a smaller scale. With the right rigging and accessories, these vessels navigate waters gracefully and precisely, bringing joy to builders and sailors. The art of rigging a sailboat has been passed down through generations and holds tremendous importance in sailing. By understanding the rigging process and selecting suitable accessories, sailors can create miniature sailboats that embody the spirit of adventure and love for the sea.

Building the Miniature Sailboat

To set sail on the journey of building a miniature sailboat , we’ll dive into the practical steps that bring it to life. Get ready to embark on a captivating adventure as we tackle the art of constructing the hull, attaching the mast and sails, and adding the intricate rigging and accessories. From the sturdy foundation of the hull to the intricate details of the rigging, each sub-section will unveil essential elements to create a captivating miniature sailboat . So, grab your tools and let’s set sail into the world of boat building !

1. Constructing the Hull

To begin constructing the hull, gather all of the necessary materials including plywood, a saw, and sandpaper. Measure and cut the plywood to the desired dimensions for the hull .

It is important to sand the edges of the plywood in order to achieve a smooth finish . Next, apply wood glue along the edges and join the pieces together to form the hull . While the glue is drying, use clamps to hold the pieces in place.

To reinforce the hull , add epoxy resin to the joints. Once the entire hull is dry, sand it down for a polished look. For added protection, apply a primer . Paint the hull with the desired color using marine-grade paint for water resistance.

It is important to note that the hull plays a vital role in the stability and performance of a sailboat on the water.

2. Attaching the Mast and Sails

To successfully attach the mast and sails to your miniature sailboat, simply follow these steps:

1. Begin by preparing the mast, ensuring it is clean and free from any debris or imperfections.

2. Carefully position the mast in the designated area on the hull, making sure it is properly aligned.

3. Secure the mast to the hull using either adhesive or small screws, ensuring a stable attachment.

4. Attach the sails by positioning them on the mast and securing them with small strings or ropes.

5. To improve the catchability of the wind, adjust the tension of the strings or ropes to properly tighten the sails.

6. Test the attachment by gently moving the sailboat to ensure the mast and sails are securely attached. Make any necessary adjustments for stability.

7. Check that the sails can move freely and are not obstructed by the mast or any other parts of the sailboat.

By following these steps, you will achieve a secure attachment of the mast and sails to your miniature sailboat . This is crucial for optimal performance and the enjoyment of your sailing experience.

3. Adding Rigging and Accessories

Adding Rigging and Accessories

When adding rigging and accessorizing your miniature sailboat , you should follow these steps:

1. Begin by attaching the mast to the hull using either glue or screws.

2. Next, secure the sails to the mast using small clips or ties.

3. Then, add the rigging lines by tying them to specific locations on both the mast and hull. These lines play a vital role in controlling the movement and positioning of the sails.

4. Attach smaller accessories, such as life rings or flags , to the boat using either adhesive or small hooks.

To ensure optimal results, make sure that the rigging lines are tight and the accessories are securely fastened. This will help prevent any accidental detachment while in use.

If you want to enhance the overall appearance of your mini sailboat, you can consider using colorful and eye-catching accessories. You can also experiment with various types of rigging materials, such as thread or thin wire , to achieve different visual effects.

Painting and Finishing Touches

Give your miniature sailboat the perfect finishing touches with the section on painting and finishing . From sanding and priming to applying paint and varnish, we’ll cover all the steps you need to know. Plus, we’ll show you how to add those final details and decorations that will truly make your sailboat shine. Get ready to transform your creation into a masterpiece that will impress all who see it.

1. Sanding and Priming

When sanding and priming a miniature sailboat, it is important to follow these steps:

1. Prepare the surface: Start by cleaning the hull with a damp cloth to effectively remove dust and debris.

2. Sand the hull: Take a gentle approach and sand the entire hull using fine-grit sandpaper in a circular motion.

3. Remove any sanding residue: After sanding, it’s crucial to wipe away any residue or dust with a clean, dry cloth.

4. Apply the primer: To ensure a smooth surface, use either a small paintbrush or foam brush to apply a thin, even coat of primer to the hull. Make sure to cover the entire surface area and allow the primer to dry completely.

5. Sand the primer: Once the primer is dry, lightly sand it using fine-grit sandpaper. This step will help smooth out any imperfections.

6. Remove any sanding residue: Eliminate any remaining residue or dust by using a clean, dry cloth.

By following these steps, you will ensure that the hull of your miniature sailboat is properly sanded and primed, creating a smooth surface for painting.

2. Applying Paint and Varnish

To apply paint and varnish to a miniature sailboat , follow these steps:

1. Sand the surface to remove imperfections and create a smooth, even surface.

2. Apply primer to the hull and other parts of the sailboat. This helps the paint adhere better and provides a good base for the colors.

3. Choose the colors you want and apply them using a small brush or airbrush. Start with the base color and let it dry before adding additional colors or details.

4. Once the paint is dry , apply varnish to protect the paint and give it a glossy finish. Use a brush or spray varnish, following the product instructions for application.

5. Allow the varnish to dry completely before handling the miniature sailboat or adding any additional details.

Pro-tip: When painting a miniature sailboat, use thin coats of paint and varnish for smooth, even coverage. Work in a well-ventilated area to prevent fumes. Remember to clean brushes thoroughly after each use to maintain their quality for future projects.

3. Adding Details and Decorations

– First , gather all the necessary materials for adding details and decorations to your miniature sailboat. This can include flags, stickers, miniature figures, or decorative ropes.

– Next , consider where you want to place these decorations on your sailboat. Popular areas include the hull, mast, and sails.

– Carefully attach each decoration using an appropriate adhesive, ensuring that they are securely in place.

– Use small paintbrushes to add intricate details or accents , such as patterns or designs, to the flags, figures, or other decorative elements.

– To protect the decorations and give them a glossy finish, apply a coat of varnish or sealant. This will also keep them from getting damaged over time.

– Take a moment to inspect the added details and decorations , making any necessary adjustments to improve their overall appearance.

– Be patient and allow ample time for the glue, paint, and varnish to dry completely before moving or handling the miniature sailboat.

Testing and Setting Sail

As we delve into the thrilling section of “ Testing and Setting Sail ” in our article on “ How To Make A Miniature Sailboat ,” get ready to embark on an exciting adventure. We’ll explore the essential steps in this process, including preparing for launch , selecting the right conditions , and monitoring and adjusting the sailboat. So, hold onto your hats and let’s navigate the waters of sailboat testing together!

1. Preparing for Launch

To effectively prepare for the launch of a miniature sailboat, it is important to follow these steps:

1. Assess the weather conditions: Before launching, it is crucial to check the weather forecast. Look out for calm winds and clear skies, as this will ensure smooth sailing and minimize any accidents.

2. Position the boat properly: Ensure that the sailboat is placed in a clear area, away from rocks or other boats. This will provide enough space for maneuverability.

3. Secure the mast and sails: Double-check that the mast and sails are securely attached. This is essential for effective wind-catching and to ensure a smooth sailing experience.

4. Inspect the rigging and accessories: Take the time to examine the rigging and accessories, such as ropes, pulleys, and hooks. Make sure they are in good condition and properly connected to prevent any mishaps or malfunctions.

5. Conduct a final safety check: Before launching, perform a thorough safety check. Confirm that all necessary safety equipment, including life jackets and flotation devices, are on board and easily accessible.

6. Position the sailboat in the water: Carefully place the sailboat in the water, ensuring that it floats steadily. Avoid any sudden movements or excessive force during this process.

7. Adjust the sails: Based on the wind conditions, adjust the sails accordingly. Raise and trim them for optimal performance and speed.

8. Launch the sailboat: Release the sailboat into the water gently, either by pushing it or releasing it from a docking position. Observe its movement and make any necessary adjustments for a successful launch.

By following these steps, you can effectively prepare your miniature sailboat for a successful launch and enjoy a pleasant sailing experience.

2. Selecting the Right Conditions

Selecting the Right Conditions

When setting sail with your miniature sailboat , it is crucial to select the right conditions. Here are a few key steps to follow:

1. Analyze wind patterns and carefully choose a location that offers consistent and steady wind direction. By doing so, you can ensure smoother sailing and a more enjoyable experience.

2. Before embarking on your sailboat adventure, make sure to check the weather forecast. Avoid sailing on days when strong winds, storms, or unfavorable conditions are expected. This will help you steer clear of potential risks and hazards.

3. Look for calm waters with gentle waves for optimal stability and maneuverability. Avoid areas known for strong currents, rapids, or turbulent waters as they can greatly affect your sailboat’s performance.

4. It is important to select a location that provides ample space for your sailboat to navigate freely. Avoid crowded areas to minimize the risk of collisions and enhance your overall safety.

5. Opt for a location with good visibility to easily keep an eye on your sailboat. Avoid areas with dense fog, limited visibility, or high traffic, as they can hinder your ability to navigate effectively.

By diligently following these steps and carefully selecting the right conditions, you can have a safe and enjoyable sailing experience with your miniature sailboat .

3. Monitoring and Adjusting the Sailboat

Monitoring and adjusting the sailboat is crucial for optimal performance on the water. By following these steps, you can ensure that your miniature sailboat is in top condition:

Regularly check the balance of your sailboat to make sure it is evenly weighted and not leaning to one side. This will help maximize its performance.

Observe the wind direction and any changes in speed. Adjust the sails accordingly to harness the power of the wind effectively.

Monitor the position of the rudder to control the sailboat’s direction. Make small adjustments as needed to stay on course.

Pay close attention to the water conditions. If the waters are rough or choppy, you may need to make adjustments to the rigging or sails. It is important to ensure that everything is secure and properly adjusted for safe navigation.

Continuously monitor the sailboat’s speed and be ready to make changes to the sails or rigging to either increase or decrease speed as desired.

It is essential to take note of any issues or malfunctions that may arise. Address problems such as loose lines or a broken mast before continuing your sailing adventure.

By following these steps , you can effectively monitor and adjust your miniature sailboat , providing you with a successful and enjoyable sailing experience.

Troubleshooting and Maintenance

Looking to keep your miniature sailboat seaworthy? In this section, we’ll tackle troubleshooting and maintenance to ensure smooth sailing. From addressing balance and stability issues to repairing damages and wear, we’ve got you covered. Plus, we’ll reveal tips for keeping your sailboat shipshape through proper cleaning and storage practices. Get ready to take charge of your miniature vessel’s longevity and performance!

1. Handling Balance and Stability Issues

Handling Balance and Stability Issues

To effectively handle balance and stability issues in a miniature sailboat, it is important to follow these steps:

1. Check the alignment of the keel and rudder to ensure that the keel is securely in place and that the rudder is properly aligned with the centerline of the boat.

2. Adjust the position of the mast by moving it either forward or backward in order to determine the ideal balance point. Moving the mast forward will increase weather helm , while moving it backward will increase lee helm .

3. Modify the shape of the sail by adjusting the tension on the halyard and cunningham lines in order to control the sail draft. A flatter sail shape can help reduce heeling and improve stability.

4. Trim the sails by making small adjustments to the main and jib sheets in order to achieve proper sail trim. Over-trimming the sails can lead to excessive heeling, while under-trimming can result in poor performance.

5. If the boat continues to be unstable even after making adjustments, consider adding small weights to the keel or hull. This can help lower the boat’s center of gravity and enhance stability.

Pro-tip: Achieving the perfect balance and stability in a miniature sailboat may require some trial and error. Experiment with different adjustments and take note of their effects on the boat’s performance.

2. Repairing Damages and Wear

When repairing damages and wear on a miniature sailboat , follow these steps for proper maintenance and longevity:

1. Identify the damage: Inspect the sailboat for cracks, scratches, or broken parts.

2. Gather necessary tools and materials: Prepare epoxy resin, sandpaper, paint, and replacement parts if needed.

3. Prepare the damaged area: Clean and remove debris, using sandpaper to create a suitable surface.

4. Repair the damage: Apply epoxy resin according to the manufacturer’s instructions, ensuring a secure bond.

5. Sand and paint: After the repair has cured, sand the area for a smooth finish. Use matching paint for a seamless appearance.

6. Inspect and test: Carefully check for any remaining damages and test the sailboat’s functionality.

7. Maintain regularly: Clean and maintain the sailboat regularly to prevent further wear and damage.

By following these steps, you can effectively repair damages and wear on your miniature sailboat , ensuring its continued functionality and enjoyment. Proper maintenance is key to prolonging the life of your sailboat and ensuring many happy sailing adventures.

3. Cleaning and Proper Storage

To ensure the longevity and enjoyment of your miniature sailboat, it is essential to follow these steps for cleaning and proper storage:

1. Begin by rinsing the sailboat with freshwater immediately after sailing. This will effectively remove saltwater and debris.

2. Allow the sailboat to thoroughly air dry before storing it. This step is crucial in preventing the growth of mold or mildew.

3. When cleaning the hull, gently scrub away any dirt or stains using mild soap and water. Rinse with freshwater to ensure a thorough clean.

4. Carefully remove the sails and inspect them for any dirt or damage. Clean the sails using mild soap and water, making sure to rinse them thoroughly. It is important to allow the sails to completely dry before storing them.

5. Take the time to check the rigging for any signs of wear or damage. Use a damp cloth to remove any dirt or grime that may have accumulated.

6. Find a secure, temperature-controlled storage area that is dry. This will protect the sailboat from potential damage. Ideally, store the sailboat on a rack or shelf to avoid placing unnecessary pressure on the hull.

By following these cleaning and proper storage practices, you can extend the lifespan of your miniature sailboat and enjoy it for years to come.

Some Facts About How To Make A Miniature Sailboat:

- ✅ Making a miniature sailboat requires basic woodworking skills. (Source: SailChecker)

- ✅ There are many online tutorials and videos available that provide step-by-step instructions on making a miniature sailboat. (Source: The Spruce Crafts)

- ✅ The materials needed to make a miniature sailboat include wood, glue, paint, and fabric for the sail. (Source: Model Boat Builder)

- ✅ Miniature sailboats can be made in various sizes, from small tabletop models to larger display pieces. (Source: Model Yachting)

- ✅ Building a miniature sailboat is a fun and creative project that can be enjoyed by people of all ages. (Source: The Artful Parent)

Frequently Asked Questions

How do i cancel my contracts or subscriptions on youtube.

To cancel your contracts or subscriptions on YouTube, follow these steps:

- Go to the ‘Verträge hier kündigen’ section on the YouTube website.

- Read the instructions carefully and fill out any required forms.

- Submit the cancellation request and wait for confirmation.

- Your contracts or subscriptions will be terminated as per the provided instructions.

How can I test new features on YouTube?

To test new features on YouTube, you can follow these steps:

- Keep an eye on the YouTube website for announcements or notifications regarding beta testing.

- If a beta testing opportunity is available, visit the ‘neue funktionen testen’ section on the YouTube website.

- Follow the instructions provided to join the beta testing program.

- You may be given access to test new features and provide feedback to help improve YouTube.

What guidelines and safety measures should I be aware of when using YouTube?

When using YouTube, it is important to follow the guidelines and safety measures outlined by the platform:

- Visit the ‘Richtlinien & Sicherheit’ section on the YouTube website to familiarize yourself with the community guidelines.

- Respect copyright laws and avoid uploading or using copyrighted content without proper permission.

- Report any inappropriate or harmful content using the reporting tools provided by YouTube.

- Protect your personal information and avoid sharing sensitive data with unknown individuals or websites.

What information does the NetzDG Transparenzbericht provide?

The NetzDG Transparenzbericht on YouTube provides information on how the platform handles illegal content and user complaints in compliance with the German Network Enforcement Act (NetzDG). It includes details on the number of complaints received, actions taken, and the overall transparency of YouTube’s content moderation policies.

Will the copyright for YouTube content expire in 2023?

No, the copyright ownership for YouTube content is not set to expire in 2023. The statement refers to the copyright ownership by Google LLC, which remains valid. The specific copyright duration for content on YouTube may vary depending on the applicable laws and the rights of the content creators.

How does YouTube work?

YouTube is a video sharing platform where users can upload, watch, and interact with a wide variety of videos. Users can create their own channels, subscribe to other creators, and engage with content through likes, comments, and shares. YouTube operates through a website and mobile applications, allowing users to access videos and features from various devices.

About the author

Leave a Reply Cancel reply

Your email address will not be published. Required fields are marked *

Save my name, email, and website in this browser for the next time I comment.

Latest posts

The history of sailing – from ancient times to modern adventures

History of Sailing Sailing is a time-honored tradition that has evolved over millennia, from its humble beginnings as a means of transportation to a beloved modern-day recreational activity. The history of sailing is a fascinating journey that spans cultures and centuries, rich in innovation and adventure. In this article, we’ll explore the remarkable evolution of…

Sailing Solo: Adventures and Challenges of Single-Handed Sailing

Solo Sailing Sailing has always been a pursuit of freedom, adventure, and self-discovery. While sailing with a crew is a fantastic experience, there’s a unique allure to sailing solo – just you, the wind, and the open sea. Single-handed sailing, as it’s often called, is a journey of self-reliance, resilience, and the ultimate test of…

Sustainable Sailing: Eco-Friendly Practices on the boat

Eco Friendly Sailing Sailing is an exhilarating and timeless way to explore the beauty of the open water, but it’s important to remember that our oceans and environment need our protection. Sustainable sailing, which involves eco-friendly practices and mindful decision-making, allows sailors to enjoy their adventures while minimizing their impact on the environment. In this…

WOODEN BOW TIES

How to build a wooden sailboat: a beginner's guide.

Are you interested in building your own sailboat? If so, building a wooden sailboat can be a rewarding and fulfilling experience. Not only will you have a unique vessel to call your own, but you’ll also learn valuable woodworking skills along the way.

To get started, you’ll need to gather the necessary materials and tools. This may include oak plywood, epoxy resin and hardener, thickener, brad nails, masking tape, a pull-saw, and a table saw. Once you have everything you need, you can begin the process of building your sailboat. From creating a jig and frame assembly to making the mast, there are many steps involved in building a wooden sailboat. But with patience and attention to detail, you can create a beautiful and functional vessel that will bring you joy for years to come.

Understanding the Basics of a Wooden Sailboat

If you are interested in building a wooden sailboat, it’s important to understand the basics of how a sailboat is constructed. In this section, we’ll cover the parts of a wooden sailboat and the different types of wooden sailboats.

Parts of a Wooden Sailboat

A wooden sailboat is made up of several parts, each with its own unique function. Here are some of the most important parts:

- Hull : The hull is the main body of the boat. It is the part of the boat that sits in the water and provides buoyancy.

- Keel : The keel is a long, narrow fin that extends down from the bottom of the hull. It helps to keep the boat from capsizing by providing stability.

- Rudder : The rudder is a flat piece of wood or metal that is attached to the back of the boat. It helps to steer the boat.

- Mast : The mast is a tall, vertical pole that supports the sails.

- Sails : The sails are large pieces of fabric that are attached to the mast and other parts of the boat. They catch the wind and propel the boat forward.

- Boom : The boom is a horizontal pole that is attached to the bottom of the mast. It helps to control the shape of the sail.

Types of Wooden Sailboats

There are many different types of wooden sailboats, each with its own unique characteristics. Here are some of the most common types:

- Dinghy : A dinghy is a small sailboat that is typically used for recreational sailing or racing.

- Sloop : A sloop is a sailboat with a single mast and a fore-and-aft rig.

- Ketch : A ketch is a sailboat with two masts, with the main mast taller than the mizzen mast.

- Yawl : A yawl is a sailboat with two masts, with the mizzen mast located aft of the rudder post.

When choosing a type of wooden sailboat to build, it’s important to consider your needs and experience level. A dinghy is a good choice for beginners, while a ketch or yawl may be more suitable for experienced sailors.

By understanding the basics of a wooden sailboat and the different types available, you can make an informed decision about which type of boat to build.

Choosing the Right Materials

When building a wooden sailboat, choosing the right materials is crucial to ensure the boat’s durability and performance. In this section, we will discuss the two most important materials you’ll need to choose: wood and sails/rigging materials.

Selecting the Right Wood

Choosing the right type of wood for your sailboat is critical. You want a wood that is strong, lightweight, and resistant to rot and decay. Some of the most popular types of wood used in sailboat building include:

- Cedar: Lightweight and easy to work with, cedar is an excellent choice for planking and decking.

- Mahogany: Strong and durable, mahogany is often used for building frames and keels.

- Oak: A dense and hard wood, oak is commonly used for building frames and planking.

When selecting your wood, make sure it is free of knots, cracks, and other defects that could weaken the boat’s structure. You should also consider the wood’s grain pattern, as this can affect the boat’s strength and appearance.

Choosing Sails and Rigging Materials

The type of sails and rigging materials you choose will depend on the type of sailboat you’re building and your sailing needs. Some of the most common materials used in sail and rigging construction include:

- Dacron: A strong and durable synthetic material, dacron is commonly used for sailcloth.

- Nylon: Lightweight and flexible, nylon is often used for spinnaker sails.

- Stainless Steel: Strong and corrosion-resistant, stainless steel is commonly used for rigging hardware.

When selecting your sails and rigging materials, consider the conditions you’ll be sailing in and the type of sailing you’ll be doing. For example, if you’ll be racing, you may want to choose lightweight sails and rigging materials that will help you achieve maximum speed. On the other hand, if you’ll be cruising, you may want to choose more durable materials that can withstand rougher conditions.

By choosing the right materials for your wooden sailboat, you can ensure that your boat is strong, durable, and performs well on the water.

Designing Your Sailboat

Before you start building your wooden sailboat, you need to design it. This will involve creating a blueprint and determining the size and shape of your boat.

Creating a Blueprint

Creating a blueprint is an essential step in designing your sailboat. It will help you visualize your boat and ensure that you have all the necessary components in place. You can create a blueprint using software such as AutoCAD or SketchUp, or you can draw it by hand.

When creating your blueprint, consider the following:

- The length, width, and height of your boat

- The position of the mast and sails

- The location of the rudder and keel

- The number of cabins and their layout

- The placement of any storage compartments or equipment

Determining the Size and Shape

The size and shape of your sailboat will depend on several factors, including your budget, the type of sailing you plan to do, and the number of people who will be on board.

Consider the following when determining the size and shape of your sailboat:

- The type of sailing you plan to do (coastal cruising, racing, etc.)

- The number of people who will be on board

- The amount of storage space you will need

- The amount of deck space you will need

- Your budget

Once you have determined the size and shape of your sailboat, you can start gathering materials and building your boat.

Building the Hull

When building a wooden sailboat, the hull is the most important part of the boat. It is the main structure that holds everything together and keeps the boat afloat. Building the hull requires cutting and assembling the wooden frame.

Cutting the Wood

To begin building the hull, you will need to cut the wood into the appropriate sizes and shapes. The wood should be cut according to the plans or blueprints that you have created. You can use a saw or a jigsaw to make the cuts.

It is important to use high-quality wood that is free of knots or other defects. The wood should be strong enough to withstand the pressure and weight of the water. Common types of wood used for building a wooden sailboat include cedar, oak, and mahogany.

Assembling the Frame

Once you have cut the wood, you can begin assembling the frame of the hull. The frame is made up of vertical pieces of wood called frames, which hold the shape of the boat. The frames are attached to the keel, which is the main structure that runs down the center of the boat.

To assemble the frame, you will need to use a sawhorse or other support to hold the lumber in place. You can then use screws or bolts to attach the frames to the keel. It is important to ensure that the frames are level and straight.

After the frames are attached to the keel, you can add the planks to the hull. The planks are attached to the frames and keel using screws or nails. It is important to ensure that the planks are properly aligned and spaced.

Once the planks are attached, you can sand and finish the hull to give it a smooth and polished look. This will also help to protect the wood from the elements.

Building the hull of a wooden sailboat requires patience and attention to detail. With the right tools and materials, you can create a strong and beautiful hull that will last for years to come.

Installing the Deck and Cabin

Installing the deck and cabin of your wooden sailboat is a crucial step in the construction process. It not only adds to the aesthetics of your boat but also provides structural support. Here are some tips to help you through the process.

Deck Installation

The deck of your wooden sailboat should be installed after the hull has been completed and before the cabin is built. It is important to ensure that the deck is watertight to prevent any leaks. Here are the steps to follow when installing the deck:

- Cut the deck to fit the hull and sand the edges to ensure a tight fit.

- Apply a layer of epoxy to the hull and deck joint to seal it.

- Secure the deck to the hull using screws or bolts.

- Apply a layer of fiberglass cloth and epoxy to the deck to make it watertight.

- Sand the surface of the deck to prepare it for painting or varnishing.

Cabin Installation

The cabin of your wooden sailboat provides shelter and storage space. It is important to ensure that it is properly installed to prevent any leaks. Here are the steps to follow when installing the cabin:

- Build the cabin on a flat surface using marine-grade plywood.

- Cut the cabin to fit the deck and hull and sand the edges to ensure a tight fit.

- Apply a layer of epoxy to the cabin and deck joint to seal it.

- Secure the cabin to the deck using screws or bolts.

- Apply a layer of fiberglass cloth and epoxy to the cabin to make it watertight.

- Install any windows, hatches, or doors in the cabin.

- Sand the surface of the cabin to prepare it for painting or varnishing.

By following these steps, you can ensure that your wooden sailboat’s deck and cabin are properly installed and watertight. This will not only make your boat look great but also ensure that you have a safe and enjoyable sailing experience.

Setting Up the Mast and Sails

Now that you have built your wooden sailboat, it is time to set up the mast and sails. This process may seem daunting, but with a little patience and attention to detail, you can have your boat ready to sail in no time.

Step 1: Install the Mast

The first step is to install the mast. Depending on the design of your boat, the mast may be a single piece or assembled from multiple sections. Make sure the mast is secured properly and is straight. Use a level to ensure the mast is vertical in both directions.

Step 2: Prepare the Sails

Next, prepare the sails. Make sure the sails are clean and free of any debris or damage. Attach the sail to the mast using the halyard, which is a rope used to raise and lower the sail. Make sure the sail is hoisted all the way to the top of the mast.

Step 3: Attach the Boom

Attach the boom to the mast and secure it with a boom vang, which is a rope used to control the angle of the boom. The boom is the horizontal spar that holds the bottom edge of the sail.

Step 4: Set the Sail

Once the boom is attached, set the sail. Adjust the angle of the boom and the sail to catch the wind and start moving. You can use the main sheet to control the angle of the sail and the boat’s speed.

Step 5: Trim the Sail

Finally, trim the sail to optimize its performance. This involves adjusting the sail’s shape and position to maximize its power and minimize drag. Use the sail controls, such as the cunningham and outhaul, to adjust the sail’s shape. Use the main sheet to control the sail’s position relative to the wind.

Congratulations! You have successfully set up the mast and sails of your wooden sailboat. Now it’s time to hit the water and enjoy the thrill of sailing.

Applying Finishing Touches

When it comes to building a wooden sailboat, applying the finishing touches is a crucial step that can make all the difference in the final product. Here are some tips and tricks to help you get the perfect finish.

Sanding and Finishing

Before you can apply any finish, you need to make sure the surface is smooth and free of imperfections. This means sanding the wood with progressively finer grits of sandpaper until you achieve the desired smoothness. Once you’ve finished sanding, you can apply a wood conditioner to help the wood absorb the finish more evenly.

When it comes to choosing a finish, you have several options. Some popular choices include varnish, paint, and oil. Varnish is a popular choice for wooden boats because it provides a durable, glossy finish that can withstand the harsh marine environment. Paint is another option, but it requires more maintenance than varnish and may not provide as much protection against the elements. Oil is a good choice if you want a more natural look, but it may not provide as much protection as varnish or paint.

Painting and Varnishing

If you decide to go with paint or varnish, there are a few things to keep in mind. First, make sure you apply the finish in a well-ventilated area to avoid inhaling fumes. Second, make sure you apply thin, even coats and allow each coat to dry completely before applying the next. This will help prevent drips and ensure a smooth finish.

When it comes to varnishing, it’s important to use a high-quality brush and work quickly to avoid brush marks. You may also want to consider using a foam brush for hard-to-reach areas. Once you’ve applied the final coat of varnish, you can buff the surface with a soft cloth to achieve a high-gloss finish.

Painting requires a different approach. You’ll need to choose the right type of paint for your boat and make sure you apply it evenly. If you’re painting a large area, you may want to consider using a paint sprayer to achieve a smooth, even finish. Once the paint has dried, you can apply a clear coat to protect the paint and give it a glossy finish.

In conclusion, applying the finishing touches to your wooden sailboat is an important step that requires careful attention to detail. By following these tips and using the right tools and materials, you can achieve a beautiful, long-lasting finish that will protect your boat and make it stand out on the water.

Safety Measures

When building a wooden sailboat, safety should always be your top priority. Here are some safety measures you should take to ensure a safe and successful build.

Installing Safety Equipment

Before you start building, make sure you have all the necessary safety equipment installed in your workshop. This includes fire extinguishers, smoke detectors, and first aid kits. You should also have a clear and unobstructed path to the exit in case of an emergency.

When working with power tools, always wear eye and ear protection, as well as a dust mask to protect your lungs. If you are using chemicals, make sure you are working in a well-ventilated area and wear gloves and a respirator if necessary.

Conducting a Safety Check

Before you start working on your sailboat, conduct a safety check to make sure everything is in order. Check that all tools and equipment are in good working order and that there are no loose or damaged parts. Make sure your work area is clean and free of clutter, and that all cords and cables are properly secured.

When working with wood, be aware of any knots or cracks in the wood that could weaken the structure of your sailboat. Use only high-quality marine-grade wood and be sure to follow the plans carefully to ensure a strong and safe boat.

By following these safety measures, you can ensure that your wooden sailboat build is a safe and enjoyable experience.

Maintaining Your Wooden Sailboat

Congratulations on building your own wooden sailboat! Now that you have a beautiful vessel, it’s important to keep it well-maintained to ensure its longevity and safety on the water.

Regular Maintenance

Regular maintenance is essential to keep your wooden sailboat in top condition. Here are some tips to keep in mind:

- Clean your boat regularly with a mild soap and water to prevent dirt and grime buildup.

- Check for any signs of damage, such as cracks, rot, or loose fittings, and address them promptly.

- Apply a fresh coat of varnish or paint every few years to protect the wood from the elements.

- Keep your boat covered when not in use to protect it from the sun and rain.

Seasonal Maintenance

In addition to regular maintenance, there are also some seasonal tasks that you should perform to keep your wooden sailboat in top condition:

- At the beginning of the season, inspect the hull for any damage or wear and make any necessary repairs.

- Check the rigging and sails to make sure they are in good condition and make any necessary repairs or replacements.

- Before storing your boat for the winter, make sure to properly winterize it to protect it from the cold and moisture.

Additional Tips

Here are some additional tips to keep in mind when maintaining your wooden sailboat:

- Use high-quality marine-grade products when cleaning and maintaining your boat.

- Avoid using harsh chemicals or abrasive materials that can damage the wood.

- Regularly check the bilge for any water buildup and pump it out as needed.

- Keep your boat well-ventilated to prevent moisture buildup and mold growth.

By following these tips, you can keep your wooden sailboat in top condition and enjoy many years of safe and fun sailing.

Leave a Reply Cancel reply

You must be logged in to post a comment.

Become the Confident Skipper of Your Own Sailboat

How to make a small sailboat.

- Post author: Anns

- Post published: October 11, 2022

- Post category: Uncategorized

- Post comments: 0 Comments

Introduction

Are you looking for a fun and rewarding hobby? Making your own sailboat is a great way to spend your free time, and it can also be a very rewarding experience. A small sailboat takes about six months to complete, but if you have the right materials and tools on hand, it’s not too difficult.

Getting Started

In this series, we’ll be going through the entire process of making a small sailboat. This will cover everything from ideas and plans to building and launching.

By the end of the series, you should have all the knowledge required to build your own boat.

Buying the Materials You Need

When you are building a small sailboat, it’s best to buy the materials you need from an online store. That way, you can be sure that the parts will fit together correctly and that everything is of high quality. The following list includes all of the materials needed for this boat:

- Wood for framing (plywood)

- Planking (plywood)

- Balsa wood sheets or blocks for covering the hull with fiberglass resin and cloth tape

Constructing the Hull

When constructing your boat, it is important to consider all aspects of the hull. You want it to be strong enough for rough seas, able to withstand collisions with rocks and other boats, and watertight so that you don’t sink into the ocean. The hull will also have a significant effect on how long it takes you to build your boat—if it’s too heavy or difficult to transport, you’ll need more time than if you built one out of lightweight materials like carbon fiber or aluminum.

In addition to shaping its overall form, keep in mind that there are many different ways to construct a hull: some boats use wooden planks while others use composite materials such as carbon fiber or Kevlar; some have flat bottoms while others have rounded bottoms (rounded bottoms make fast sailing possible); some are made from metal sheets riveted together while others are molded together using plastic resin such as epoxy resin glue. The construction method that works best for you depends on what type of material(s) you’re using—and even then it may be necessary to experiment before finding optimal results!

Constructing the Sailboat’s Keel

Once you have the hull and deck formed, it’s time to attach the keel. The keel is one of the most important parts of your sailboat because it:

- Is heavy. The keel is usually made from fiberglass or wood, so it will be very heavy and add a lot of stability to your boat.

- Keeps the hull straight while sailing downwind at high speeds (called point-to-point sailing). It prevents wobbling around in circles when you’re using all that power!

The Deckhouse

The deckhouse is the cabin of your sailboat. It should be large enough for you to comfortably stand up in, and it needs to keep out water when it’s raining or when you’re going through waves. Also, if you want your sailboat to have a nice aesthetic, then you’ll want your deckhouse to look good!

The shape of your hull will determine the shape of your deckhouse. For example, if you have a round-hulled sailboat with no keel (a flat bottom), then there’s no reason why you shouldn’t make your deckhouse rectangular or square-shaped instead of attempting something more complex like an L-shaped design with rounded edges along each side because this would just waste materials without providing any functional benefit whatsoever compared against just using straight lines instead which are easier both financially as well as physically speaking since they don’t require any additional tools than what’s already available whereas curved lines do require special tools such those used by carpenters who work with wood frames such as saws designed specifically for cutting curves into wood pieces rather than straight lines which can be done easily without fancy equipment at all).

If however you were building this same boat using plywood sheeting rather than solid lumber boards though then different considerations might apply depending on whether or not there was sufficient space within those sheets’ thicknesses (they could only handle so much weight before breaking apart) versus their widths (how wide each sheet would need be before splitting along its lengthwise edge). In either case though I’d recommend sticking with simple geometric shapes unless absolutely necessary due to space limitations; otherwise stick with simple rectangles/squares since these tend

Fitting the Sailboat Together

Now that the hull, keel and mast are in place and secured, it’s time to make sure your boat is ready for water. First things first: check that your boat is watertight by testing it with a bucket of water. If any leaks appear, tighten the screws or add more glue before continuing on.

Next, turn your attention to the rigging and rudder. The rigging should be secure at all times; however if you feel like something is loose or if there are sharp edges poking out somewhere then feel free to trim them down as needed with scissors or sandpaper while they’re still attached to their respective parts (you can always cut off extra threads later).

If you haven’t already done so earlier this week, now would also be an ideal time for me for me test out my rudder on land before attaching it permanently into place on our sailboat!

Finishing and Painting Your Small Sailboat

Now that you have your boat, you can paint it. You’ll want to make sure that the paint is dry before using it. Make sure you are happy with the color before applying a second coat! If the paintbrush feels good on your hand and has a good point, then it will be easy to apply the paint evenly. If not, replace it with one that does so (be sure not to use an old one because then you might get some unwanted colors). Good luck!

Learn how to make your own sailboat

Learning how to make your own sailboat is one of those activities that can be a real eye-opener. It’s not for everyone, but for those who are interested in taking on such an endeavor, it can be a rewarding and enjoyable experience. There are many advantages to building your own sailboat; for example, you can choose the type of boat you want and customize it as much as possible based on your personal preferences.

The first step in learning how to make your own sailboat involves choosing a design that suits both your needs and abilities as well as finding the right materials needed for construction. You might find yourself working with wood or fiberglass if the project calls for either one of these materials (or both). If so, there are several ways this may be done including using traditional woodworking tools like saws while others prefer using power tools instead which speeds up production time greatly compared with hand tools but requires more investment upfront since these types require expensive equipment purchases before starting any projects needing them such as sanding machines used when finishing off surfaces after applying paint coats or varnishes coatings onto finished pieces made from different materials such as metal sections which may need buffing out after being painted over twice during initial stages before final touches were added later down line depending on type work being done which could range anywhere from weeks months depending size job being tackled at time being completed

In this article, we’ve covered everything you need to know about building your own small sailboat. We hope that by following these steps and examples, you will be able to design and construct your own boat!

You Might Also Like

The most affordable yacht charter destinations in the world, which catamaran type is right for you the monohull or catamaran, leave a reply cancel reply.

Save my name, email, and website in this browser for the next time I comment.

- About Modern Wooden Boats

- Tips & tricks

- What’s inside a boat plan ?

Idea 21 sportboat

The development of the family of small offshore capable sailboat plans : chined hull for the highest stability, vertical lifting keel, trailerable, suitable for club racing or cruising (two interior versions) , plywood and epoxy hull with the radius chine system, sparkling performances while sailing and reasonable interiors for coastal cruising.

| DOWNLOADS | ||

| 6,30 m | 27,5 m2 | |

| 2,50 m (trailerable) | 45-26 m2 | |

| 1,75 m – 0,50 m | outboard 2.3-5 HP on transom bracket | |

| 900 kg | ||

| 1200 kg | ||

| 1700 kg | ||

| 300 kg | ||

First boat launched : read the first impressions here

Idea 21 small sailboat plan is the latest development of my family of small plywood & epoxy sailboats plans for homebuilders : it was quite a time since i was thinking of an evolution of her smaller 19 footer sister, so i finally take the decision to publish this new plan. the goals of this plan is simple: add interior volume, simplify the work for homebuilders switching to a complete plywood & epoxy radius chine hull, enhance slightly the sparkling performances of idea 19, keeping the sailboat very balanced and suited for sailors ranging from enthusiast beginners to experienced seamen., first boat launched and several other boats in building stage make idea21 the most sparkling project on our catalogue, hull: chined hull on a small light sailboat has a simple reason to exist: it gives more stability to the sailboat when heeled, much more than a round hull similar sailboat. i managed to keep a very low wetted area of the unheeled hull, in order to achieve a good pace in light air and avoid excessive drag. stern sections are quite flat to gain speed downwind (idea 19 has been clocked with speed steadily in excess of 15 knots)., bow sections: experiences on racers showed that “knife-blade” bows may give you less resistance, but the price to pay is high in terms of buried bow sailing downwind, so i decide to provide this plan a large u-shaped section on the bow ; sails provide the sailboat plenty of power to defeat the small amount of added drag., sailplan: i have a very good starting point with idea 19, so we’re doing small adjustments and no revolutions: square top mainsail, 7/8 fractional rig , very wide single swept spreaders, no backstay, deck stepped mast with sturdy section, 110 % j jib, code zero, jennaker hoisted on swinging retractable bowsprit, and a good amount of sail area., keel and ballast: idea21 have a solid hard wood cored & unidirectional glass epoxy laminated lifting keel, with a naca optimised profile and a low resistance hydrodynamical shaped 280 kg lead bulb bolted on the keel tip; it can be made by a homebuilder, no need for professional welder; the fin area is on the low side, speed will help generating the required lift without adding too much drag. keel case is in 20 mm thickness plywood and epoxy laminated glass reinforcements, and it’s perfectly waterproof while sailing., full lifting keel version : after a request from a builder, idea 21 cruise is available in a version featuring an integral watertight keel case running form hull bottom to cabin top panels, this feature called flk (full lifting keel) will allow the boat to sail with keel partially raised or to motor with keel totally up, a good option if you sail in shallow waters frequently., cockpit: was one of the strongest point in idea19, we simply keep the same arrangement and dimensions, so we have a really huge area for the crew and a simple and sturdy building in plywood panels epoxy glued on a structure of bulkheads and stringers., interiors: here i focussed on several upgrades; i decided to split the project in two versions (so two different sets of plans, you have to specify on order), “sport cruise” or “racing” ; both versions have 4 berths, a classic v berth on bow and two quarter berth after; in the cruising version cabin is 55 cm longer, giving wider interiors, enough room for a separate toilette and more comfortable after berths ; in the racing version we have a marine toilet (there’s room for a jabsco compact one) under the bow v-berth; cabin height is 1.65 m in both versions. interiors plywood panels are detailed on plans., taking advantage form the first season of sailing, i can now say that i strongly advice the cruise version as long as you are not going to run a sailing school, thus needing extra space in the cockpit., wooden rig: starting form summer 2019 we deliver two extra drawings with the plans, both for race and cruise version, describing how to build a wooden rig suited for this boat. keep your budget low at the price of a small extra weight , how to build the boat: we chose the plywood & epoxy resin “radius chine” system, as for petrel 28 and hirundo 750, so the hull planking is in okume marine grade plywood ; planking the hull is quite fast , and the internal structure of the boat is made by plywood bulkheads, floors and solid wood longitudinal stringers, all glued with epoxy and strengthened with epoxy laminated glass tape, assembled on a cheap wood scaffold, keeping the hull light, sturdy and quite easy to build for homebuilders ; the goal is to keep the total weight of the 19 footer, raising the ballast fraction of the sailboat at the same time. here are a couple of pictures of the first planked hull perfectly showing the radius chine planking system.

a HUGE Thanks to Nils Theurer ([email protected]) for the awesome pictures taken during the first sea trials

Plans availability: Plans are available in italian and english. Plans are available in imperial units upon request (send me a mail before purchase).

Great Projects

Build a small sailboat free plans.

These plans are for a small 15 foot knockabout sailboat.

I like these plans for their ease. Building a smaller boat is a lot more attainable than a cabin cruiser! And these plans get right to the specifics of building. From the plans:

ANY SAILBOAT fancier will like "Tramp," the trim, 15-ft. knockabout that's so easy to build in plywood. The first operation is to cut the stem, transom and side planks and assemble the forms.

Use casein or waterproof glue under the butt strap joining the side planks together. Forms can be made of almost any scrap material on hand. If you are a good enough mechanic, they can be dispensed with and correctly beveled frames made to their exact shape can be placed permanently in the boat. Screw-fasten the oak frame at sides and bottom on the inside of the transom. Then notch out the bottom of the frame to receive the keel batten...

The transom is placed last and must be beveled so that the side planks fit tightly against the cleats and the transom edge. Be sure to place white lead and a thin thread of cotton between planks and stem and transom prior to joining them together...

Related Plans

All Our Vintage Projects Categories

Vintage projects.

All rights reserved, 2020 [email protected] Copyright, Safety and Legal Information Terms of Use - Privacy Policy Site Map

Discussion Forum

Ask questions, get answers, share stories in our discussion forum!

How to Make a Small Sail/Row Boat

Introduction: How to Make a Small Sail/Row Boat

Step 1: Tools

Step 2: supplies, step 3: beginning.

Step 4: Cutting the Ribs or the Structure of the Boat

Step 5: Attaching Sides

Step 6: Bending the Wood

Step 7: Center Board Hole

Step 8: The Floor

Step 9: Attaching Rear Piece

Step 10: caulking, step 11: attaching the "deck".

Step 12: Rudder

Step 13: Mast Time

Step 14: Painting

Recommendations

Make it Resilient

Water Contest

Text Contest

- Basic Kayaking Knowledge , Learn

15 Free Boat Plans You Can Build This Week (with PDFs)

Boatbuilding is one of the most ancient forms of craftsmanship still alive today. As long as our ancestors have had a curiosity about exploring open waters, they have been practicing and honing their boatbuilding skills.

To be honest, however, building a boat is no small task. It will require a lot of work and patience to ultimately create a finished product that you are happy with and that is actually seaworthy.

Of course, we have also included a few free boat plans. You can keep in your back pocket for the next time you are asked to build a cardboard boat as part of a contest or lakefront teambuilding adventure.

We hope that these resources help you in your journey to build your own boat!

Photo by SeventyFour via Shutterstock

Free Boat Plans

- The Wanigan

- The Slipper

The Handy Andy

- The Jolly Roger

- The Hobby Kat

The White Duck

- The Sea Midge

The Crazy Cardboard Boat

Why Build Your Own Boat?

Photo by Halsey via Shutterstock

There are a lot of reasons why you should explore building your own boat versus buying a pre-made model. Here is a quick breakdown of the most obvious benefits:

- You will know the ins and outs of your finished boat better than anyone

- It can be a great project to work on with your teenage or even adult children

- You will gain valuable skills molding and shaping wood and other materials

- You can design your boat for your specific needs

- You don’t have to trust the sometimes-questionable manufacturing of mass-produced boats

- You can create a boat that functions as your second home on the water

- You can save money if you source materials mindfully

Of course, most first-time boatbuilders still experience some level of trial-and-error. With patience and perseverance, however, you can craft a one-of-a-kind vessel that has no equal anywhere in the world.

Free Boat Plans You Can Build This Week (with PDFs)

1. the wanigan.

PC Duckworks Boat Builders Supply

The Wanigan boat began as a garvey design, which is one of the older boat plans known to the Americas. Traditionally, these boats were built as work scows and were very popular among American summer camps.

The design itself is very simple, but these boats can carry heavy loads. It can also handle a trolling motor being mounted to the stern so you can cover more ground if you want to use it as a fishing boat.

The creator of this boat plan became aware of some of the downsides of the garvey design, such as the heavier weight that made it less efficient than some other designs. So he combined elements of dory and wanigan designs to create a hybrid.

The main changes include an enlarged beam, tilted lathes to provide a stiffer hull, and knocking off the top strakes to reduce the boat’s overall weight.

The Wanigan text

These additional The Wanigan drawings  may also prove useful for your build process!

2. The Mouse

The Mouse is one of the most compact and nimble boat plans we have found for this list. It is an easy build and also a great boat for two kids or a single teenage paddler.

The original builder began with a one-sheet boat design in an effort to create the lightest and most affordable boat possible. This means it is only suited for calm waters and should not be used in high winds or wavy conditions.

That said, it was built in roughly 12 to 24 hours of work time and doesn’t require a full workshop to construct. The main material that is required for building this boat is quarter-inch plywood. But the builder recommends using one-inch by half-inch pine or something a little sturdier.

The plywood and pine components are held together using a method called ”˜stitch and glue’. This method requires choosing one of the best glues for kayak outfitting , which are typically made of epoxy and glass tape rather than something cheaper like polyurethane.

The Mouse Instructions

Also, here are a few extra useful The Mouse Notes for builders

3. The Slipper

The Slipper is the first of many sailboat plans on our list and it is faster, easier, and cheaper to build than most. It also features a deeper cockpit than many other sailboat designs, which makes it safer for intermediate sailors.

This sailboat plan features dual steering stations so that you can sail from inside or outside of the helm. It also includes a centerboard trunk that hardly intrudes into the cabin at all. So that, it is easier to work around while you are in the cockpit.

The exterior hull and cabin of this sailboat feature a modified dory design using two sheets of plywood ripped to three feet wide before being joined together. The resulting hull is a modified V-shape that reduces drag.

The centerboard of this boat can also be winched up to the level of the top of the cabin or lowered down to alter the draft. This allows you to customize the boat design for a stiffer and more weather-worthy vessel if you need it.

The Slipper was also intentionally designed with an aft cabin that naturally helps to keep the bow pointed into the wind whether you are underway or the boat is anchored in the port.

The Building Slipper

4. The Handy Andy

PC DIY Wood Boat

The Handy Andy is a great little 10-foot portable rowboat for hunting, camping, fishing, and other recreational uses. It is actually the only folding boat design on our list, which makes it best for folks that need the most portable boat plan possible.

This boat features a 42-inch beam and a depth of about 15 inches at the mid-section. It also weighs roughly 80 pounds when assembled and can handle up to three average-sized human passengers.

The design boasts a flat bottom with canvas-bound edges and the primary material used for construction is ⅜-inch marine-grade plywood. Despite its lightweight nature, this rowboat can handle trolling motors or even outboard motors with a maximum of five horsepower.

Once finished, the hull can be folded or unfolded in less than a minute’s time.

This design makes it one of the only boats on this list that can be stored in a truck bed or easily carried by two people to be launched at more remote locations.

5. The Junior

If you are looking for an all-purpose dinghy that can handle almost any use you might imagine, look no further than The Junior free boat plan. It can carry three or four average-sized adults and is much easier to row than a traditional dinghy.

It is also durable enough to be equipped with a small outboard motor. You could even set it up with sailing equipment if you want to use it as a sailing vessel. As we said, this is truly an all-around boat design!

This boat plan requires constructing three frames that will provide the majority of the load-bearing support. The builder recommends using ¾-inch framing with ⅜-inch plywood as the exterior material for this boat build.

Resin glue and flathead screws are also required to hold this boat together. But there is a full list of materials included in the plans we have linked to below. Sticking to that plan should also give you enough leftover materials to construct two six-foot oars for rowing this boat until you install a trolling motor or outboard motor down the line!

6. The Jolly Roger

Channel your inner Captain Morgan when you are following these plans to build your very own Jolly Roger boat. This flat bottom boat design is designed for pond fishing . It can also be a useful yacht dinghy for getting from your dock to a larger vessel anchored offshore.