The global authority in superyachting

- NEWSLETTERS

- Yachts Home

- The Superyacht Directory

- Yacht Reports

- Brokerage News

- The largest yachts in the world

- The Register

- Yacht Advice

- Yacht Design

- 12m to 24m yachts

- Monaco Yacht Show

- Builder Directory

- Designer Directory

- Interior Design Directory

- Naval Architect Directory

- Yachts for sale home

- Motor yachts

- Sailing yachts

- Explorer yachts

- Classic yachts

- Sale Broker Directory

- Charter Home

- Yachts for Charter

- Charter Destinations

- Charter Broker Directory

- Destinations Home

- Mediterranean

- South Pacific

- Rest of the World

- Boat Life Home

- Owners' Experiences

- Interiors Suppliers

- Owners' Club

- Captains' Club

- BOAT Showcase

- Boat Presents

- Events Home

- World Superyacht Awards

- Superyacht Design Festival

- Design and Innovation Awards

- Young Designer of the Year Award

- Artistry and Craft Awards

- Explorer Yachts Summit

- Ocean Talks

- The Ocean Awards

- BOAT Connect

- Between the bays

- Golf Invitational

- Boat Pro Home

- Pricing Plan

- Superyacht Insight

- Product Features

- Premium Content

- Testimonials

- Global Order Book

- Tenders & Equipment

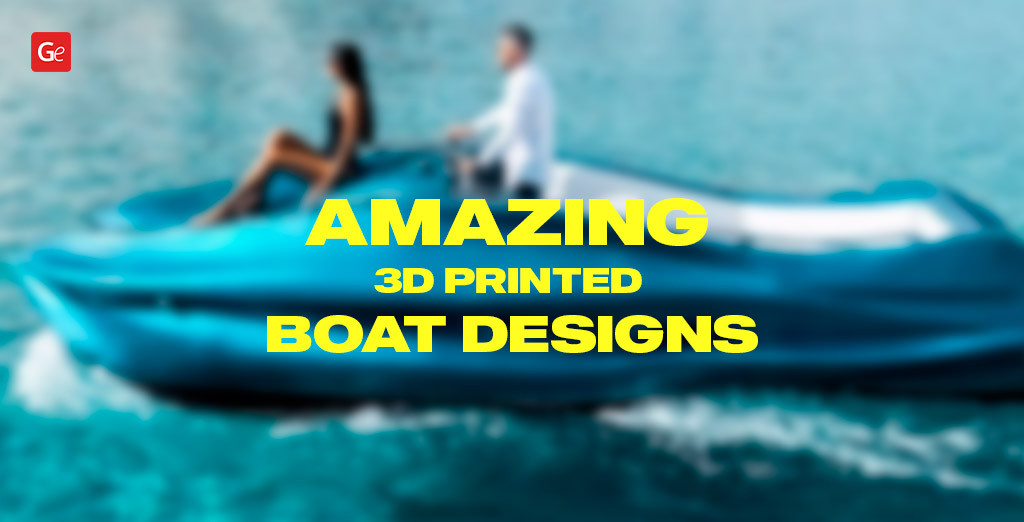

Can 3D printing transform the way boats are designed and built?

From spare parts on demand to click-and-buy tenders, 3D printing is transforming how boats are designed and built, discovers Tristan Rutherford

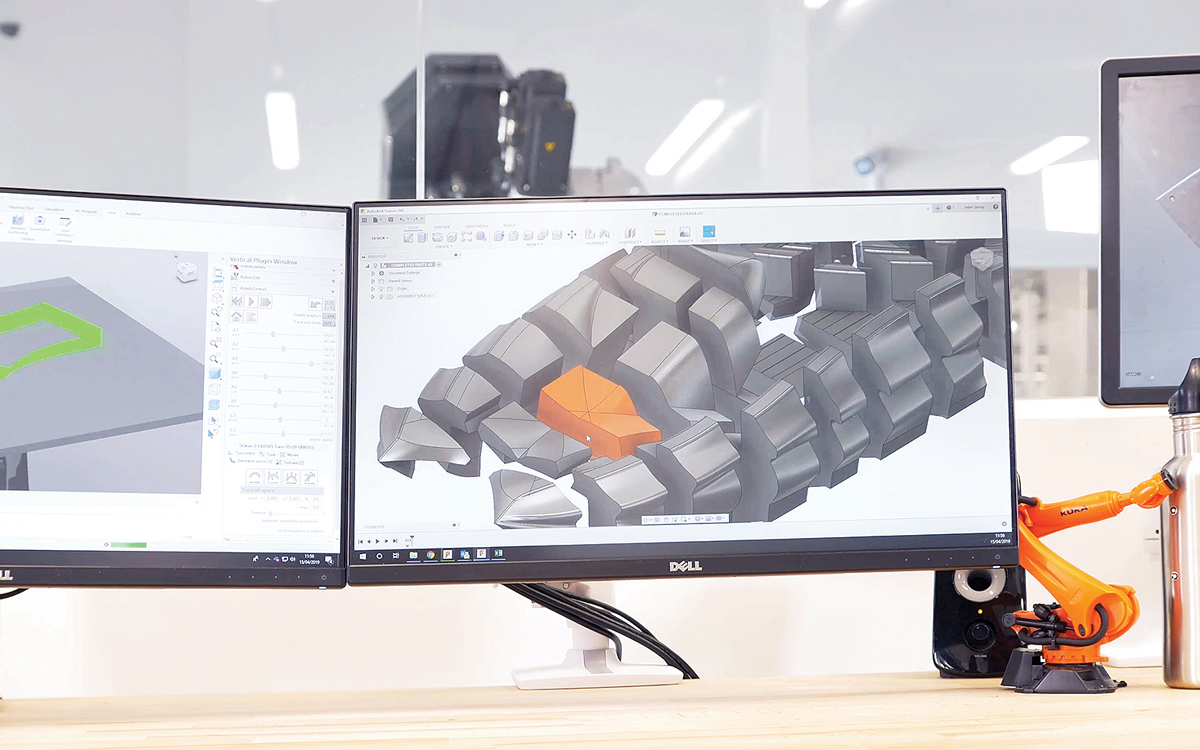

Espen Øino holds a 3D-printed model of a yacht up to his laptop camera. “We use 3D printing for quickly printing out models to evaluate,” explains the celebrated naval architect. “The more you look at a virtual model on a screen the more you feel the need to physically touch it and feel how the hull shape is.”

Øino states that 3D printing “is going to revolutionise boatbuilding”. Circuitry could be printed inside a hull without cable trays. Local geometries and structural arrangements will not be based upon accessibility for a welder or engineer to do their job. “It’s really promising because once we have different printing heads with different materials you can optimise structures.” The timescale? “Don’t get too excited,” warns Øino. Printing entire superyachts are still some way off.

Last December the excitement was palpable as one of Scandinavia’s best-selling runabout models powered along Sweden’s blustery west coast. But this version of the 4.2-metre Pioner 14 Active was different. It had been printed in just three days, entirely in one piece. No moulds, no tools and minimal labour required. The build wasted just four per cent of raw material. The boat could have been printed in sky blue or shocking pink. The style-conscious Swedes chose black.

In the three leading yacht manufacturing nations of Italy, the Netherlands and Turkey, dozens of designers, shipyards and service companies are using 3D printers to create models, parts and entire boats in very different ways. It’s a fragmented market buzzing with ideas, yet one that’s breaking convention with every passing month.

Also last December, Rotterdam startup Tanaruz clicked “print” on the tender of the future. Tanaruz’s runabouts (from €15,000, and 4.5 metres to 7.5 metres in length) look like the eco-chic offspring Nike and Apple, with swooshing lines and ice-white interiors. The range envisions a voyage without fossil fuels. Solar panels are seamlessly integrated into the boat’s design and can maintain the digital display, trip data and 48V electric engines, which are backed up with a rechargeable battery. The company’s third hull, printed in March 2022, putters down the Rotte River at its top speed of six knots.

Tanaruz imagines a Tesla-like world without brokers too: models are customised via an app (toggle to vary length, colour, cushions and power pack) then delivered by truck two weeks later across Europe.

Naval architect and Tanaruz co-founder Alexey Shifman explains the allure. “With 3D printing, I don’t need welders or specialists with different knowledge,” he asserts. “I don’t need to build a shipyard; [all that’s required is] one or two people working around a printer.” In the 3D future, bigger boats won’t blow the budget. “With a GRP boat, if you go from five to 10 metres you need four times more people. If we printed bigger it simply doesn’t matter.”

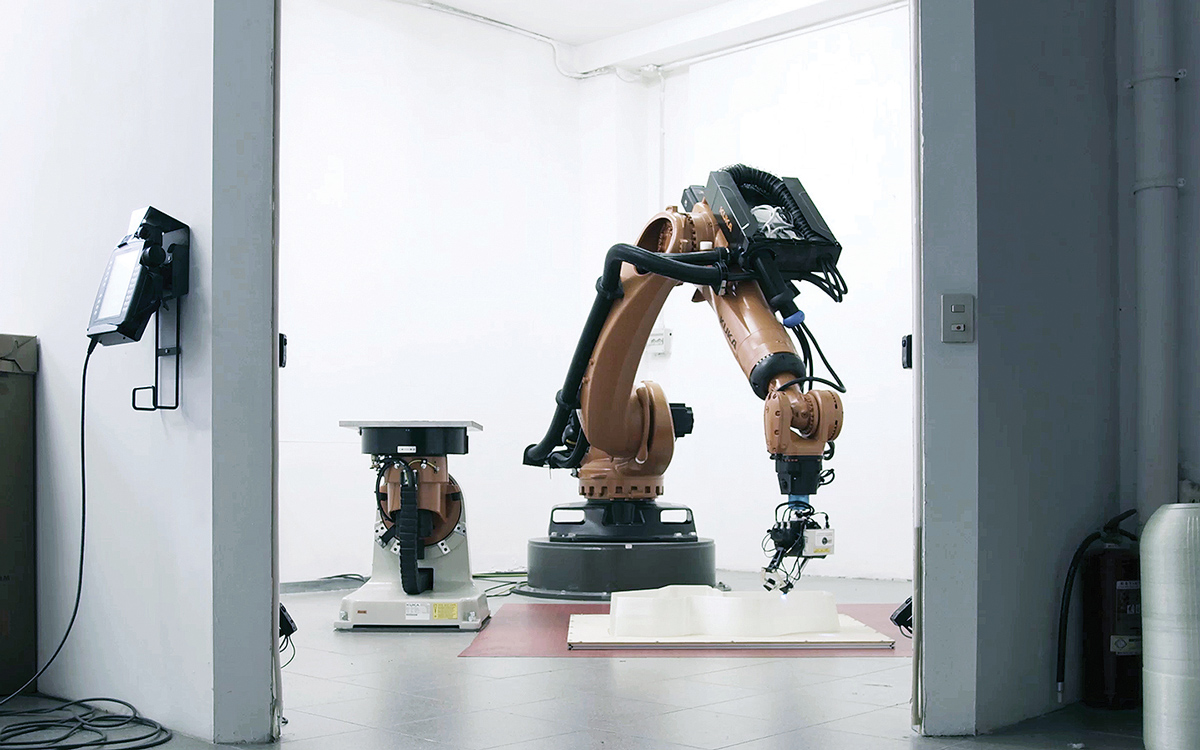

Key to costings at Tanaruz is the company’s belief in a circular economy. Around 99 per cent of the boat is made from recycled polypropylene left by factories across Belgium, mixed with discarded glass fibre. Both waste materials are incredibly cheap. Its Track Motion printer made by Swiss-Swedish robot manufacturer ABB (the pricey bit at around €350,000) eats up to 30 kilograms of plastic flakes an hour, while building the boat layer by layer. Although a 500-kilogram, five-metre-long boat takes around 60 hours to produce, as printing curves and corners takes patience – even for a robot.

Here’s the fun bit. “We can shred and reuse each Tanaruz boat five times,” explains Shifman. “A client can recycle a boat back to us to reprint into one that’s bigger, smaller, a different colour or design for a small fee. It’s a closed circle.” With Tanaruz’s tech, it would be practical to change your little electric tender every couple of years.

Across the Netherlands, Feadship uses 3D printing to speed up the production process, says lead exterior engineer Jitze van Zelst. “More than 10 years ago we started with small items.” In particular objects that took too long to produce elsewhere or were tricky to procure by other means, like bespoke stainless-steel fittings for a railing. “On one recent yacht we installed 100 of these 3D-printed brushes for cabinet door knobs,” continues van Zelst. Feadship owns its own printers and a network of 3D-printing specialists. “In the future, crew might be able to print their own spare parts on board.”

Note that most yacht spares will have to be printed in metal, which comes at a cost. While a 30-centimetre-long resin printer can be snapped up for €2,500, a similar-sized unit to print in aluminium or stainless steel can easily touch half a million euros. Yet 3D-printing converts state that the process is like printing money. Firstly as there is so little waste, and secondly as so little material is needed because handrails, drains and other deck items can have an 80 per cent hollow latticework interior, thereby paving the way for lighter boats too.

The naval architect who can best envisage a printed metal future is Greg Marshall . “When we learned that GE was printing turbines, that was our big watershed moment,” remembers the Canadian yacht designer, who started experimenting with 3D printing around 18 years ago. “We flew down to Concept Laser [a German manufacturing company with a subsidiary in Dallas] and were just blown away by what they were printing in metal.” Marshall says that metal printers, the largest of which can currently craft an object around 75 centimetres long, are best used when designers wish to combine a huge amount of complexity with minimal material outlay. “My belief is that artists are going to rule the 3D-printed world,” because any shape is possible to produce. “We’re not buying this from a manufacturer. We can have [the design] suit the boat exactly how we want.”

There’s a second factor in the metal printing stakes. As materials are used so sparingly during the printing process, “in the next 10 years” printers might be able to produce an entire boat from titanium, which has the greatest strength-to-density ratio of any metallic element. “Because titanium doesn’t corrode, all of a sudden you can make tiny little pipes to do all sorts of things,” continues Marshall. These include “drain details in the decks themselves or miles and miles of cooling lines that take seawater, blow it through the boat, and keep all the decks cool.” The technology is already there to print hinges on doors or sinks in the heads, with the possibility to physically print wiring into a boat so that a shipyard doesn’t have to draw cables. To build a full-sized boat, “what you have to do is increase the size of the machine. That’s just a scaling thing.”

Printing in metal opens up other opportunities. “We can go down to three microns (.003mm),” explains Marshall. This creates the quality of production in terms of measurement and cutting that one might expect on an iPhone and a more complex finish possible than on a GRP-moulded boat. Better still, if a designer wishes to colourise their titanium prior to printing, a paint job could become a thing of the past.

What about the holy grail of 3D printing on board a yacht? “They just loaded [a 3D printer] on one of the big aircraft carriers,” he continues. “It’s not an inexpensive way to produce parts, but if you’re in Antarctica and you don’t have a choice…”

In Milan, printing experts Moi Composites have floated yet another 3D business model: bringing the latest printing deck directly to shipyards. The backstory is that three sea-loving scientists spent years creating their own specialist printing materials. These are mainly based around fibreglass, carbon fibre or Kevlar, mixed with a resin that solidifies directly after printing – imagine the world’s most expensive printer cartridge. Other firms have struggled with generic plastics. Their conventional printers melt coils of plastic that harden slowly and frequently get doused in the dust – a nightmare in terms of finish.

“Our materials are also much stronger and more lightweight, as well as resistant to chemicals and heat,” says Moi Composites’ chief technical officer Michele Tonizzo. To prove it, they printed a one-of-a-kind boat called MAMBO for the Genoa Boat Show in 2020. The vessel is a wave-like sculpture capable of 26 knots, crafted by robots that worked through the night to push nautical engineering to the limit. “It’s not supposed to look conventional,” says Tonizzo, but more of a showpiece of what 3D-printing technology can produce. “[ MAMBO ] is elegant, crazy, and it would have been impossible to achieve with normal methods.”

Could a shipyard send Moi Composites a set of naval architect drawings to print out? “We did a project with Sanlorenzo to produce parts for its newly designed boat and shorten the time to market,” Tonizzo says. “We are also enabling manufacturers to print parts by themselves by providing them with our 3D-printing system.”

Tonizzo claims that while he has the space to print an entire small boat “it’s better to install a machine directly at a shipyard where the experts are”. Potentially Tonizzo and his colleagues could test a yacht concept in Milan, tailor the machine to a shipyard’s needs, then transport it to Livorno or Ancona and train people how to operate it. The price of this? Tonizzo remains tight-lipped, but it’s likely to be similar to the price of a snazzy apartment in Milan.

Back in the Netherlands, Marnix Hoekstra, co-creative director at Vripack , enjoys a daily dose of 3D. “Earlier this week our team designed some railings,” he says. “We couldn’t decide on the scale so we just printed them off.” A webcam was recently positioned above the 3D office printer, allowing Vripack staff to print around-the-clock from home. “Recently we used it to print an art piece to install on a yacht that was impossible to make by hand.” The complete steering console of a yacht has also been 3D printed.

Hoekstra shows me a set of superyacht models that his colleagues have printed out. “Here is a 60-metre currently in build with Alia Yachts . Next to it is a sportsfisher in build with Royal Huisman .” At Vripack, blocks of each 3D model are printed then glued together – “a bit like how you build a ship,” laughs Hoekstra. By making precise printed samples, “three or four feet in length”, the Vripack team “can judge sheers, angles, the flare of a bow. You get a good visual compared to virtual reality. It’s an actual model.”

Will 3D printers be installed inside every engine room in future? “ Gene Machine , an Amels yacht, has 3D printers on board,” continues Hoekstra, as does the Nobiskrug Artefact , but he believes the process of printing tough-as-nails spares is “still a bit more talk than practice”. In the future that might change. “What everybody will find out is that the printing itself isn’t difficult because the machine does it.” Hoekstra believes that younger crews will be trained to use the tech. “We’re already seeing scanning apps on the new high-end phones,” he continues, which could photograph a broken bolt or propeller. “From that scan, it automatically transfers to a printable model,” which could be sent to a printer on board.

So will we see entire yachts printed with no moulds, little waste and few staff in the near future? “Yes, I have no doubt,” says Hoekstra. “They can print food, so there’s no end to the materials used to print. Anybody who thinks differently will be disrupted. With quality labour being so short, robots will take over many tasks.”

First published in the November 2022 issue of BOAT International. Get this magazine sent straight to your door, or subscribe and never miss an issue.

Similar yachts for sale

More stories, most popular, from our partners, sponsored listings.

7 Best 3D Printed Boats in 2023

Written by: 3DSourced

February 20, 2024

3D printed boats have seen a lot of developments in recent years, and have yielded some impressive results, overall showing a lot of promise for exciting and environmentally friendly vessels.

In this guide I’ll be showing you some of my favorite examples of companies making huge waves in 3D printing boat technology, everything from upcoming luxury liners to customizable sloops made from recycled materials.

Solvit3D – 3D Printed Boat Parts

Top 3d printed boats projects, 3dirigo – the largest 3d printed boat from the university of maine.

- Company: University of Maine

- Price: Not For Sale

- Where to Learn more: 3Dirigo and Guinness World Records Official Site

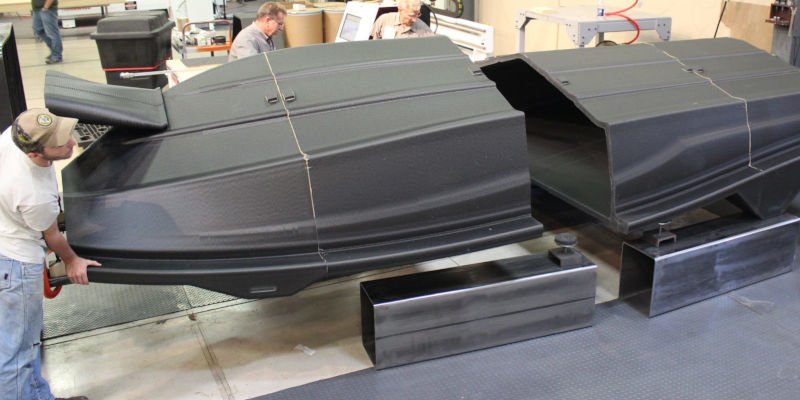

University of Maine Composites Center research team broke three Guinness World Records with 3Dirigo, the largest 3D printed boat to date , weighing 2.2 tonnes and measuring 7.62 meters.

Created in just 72 hours with a plastic-wood cellulose mix, this milestone was achieved using a 3D printer developed in partnership with Ingersoll Machine Tools. This wasn’t the only example of such a partnership, as the University of Maine’s Advanced Structures department has since worked in military equipment development in 2022 .

Capable of additive and precise subtractive manufacturing, the printer can prototype for defense, civil, and infrastructural applications. With a capacity to print objects up to 100 ft long, 22ft wide, 10ft high, and a rate of 500 pounds per hour, UMaine has found itself a real game changer.

The same 3D printer drew the attention of the US Army Combat Capabilities Development Command for deployable shelter systems production, with the UMaine presenting a 3D printed army communication shelter alongside 3Dirigo.

Tanaruz Boats – Customized 3D Printed Boats

- Company: Tanaruz

- Price: $16,000+ (Price varies depending on model and customization options)

- Where to Buy: Tanaruz Boats

One of the biggest advantages of 3D printed boats is customization. Dutch start-up company Tanaruz offers fully personalizable 3D printed boats made to order via their app.

From this app you can select the model, shape, color, and even engine type to get exactly the boat you’d like using additive manufacturing to maximize efficiency and precision.

With the cost-cutting advantage of 3D printing, the Tanaruz team makes their boats very affordable for most customers without sacrificing quality. For just a €500 (~$556) deposit, you can reserve your dream 3D printed boat.

Pegasus 88m – The Carbon-Neutral Superyacht

- Designer: Jozef Forakis

- Price: Not Yet Released

- Where to Learn More: Pegasus 88m

The Pegasus 88m is a 3D printed ‘superyacht’ that even in 2023 only really exists on paper, but is still well worth talking about. Designed as a completely carbon neutral 3D printed luxury boat, it was conceived with nature a the forefront of designer Jozef Forakis’ mind.

Solar powered panels power electrolyzers that convert seawater into hydrogen, which is then stored in long-term tanks for later fueling. This means the Pegasus 88m can harness the power of the ocean for theoretically unlimited power, removing the need for fossil fuels entirely.

The Pegasus 88m is designed to look like a cloud as it floats on the water. Using a clever mirrored design, the idea is for the frame to reflect the ocean and great the illusion of invisibility.

While still a work-in-progress, we recommend keeping an eye on this exciting, albeit likely unaffordable, 3D printed boat project.

Hydra – The World’s First 3D Printed Aquatic Drone

- Company: AI Seer Marine

- Learn More: Naval News

UAE company AI Seer Marine specializes in unmanned boats, and they unveiled the final version of their 3D printed vessel, Hydra, in 2023.

The 5 meter (~16’ 5’’) Hydra is effectively a proof-of-concept that additive manufacturing can play a key role in boat construction. AI Seer Marine uses the lightweight nature of 3D printed frames and parts to enhance speed and efficiency as well as cutting costs along the way.

The project has been underway for some time, and only recently been unveiled as close to finished. You can see the first active trials of the Hydra’s prototype below.

Those of you familiar with boats will recognize the Hydra employs a ‘stealth’ shape, intended for use in naval ISR (intelligence, surveillance, and reconnaissance) missions. This means that it likely won’t be available for sale, but it’s still a cool project to keep an eye on.

Autonomous Ferry – 3D Printed Ferry For Paris

- Companies: Roboat, Holland Shipyard, and Sequana Développement

- Learn More: Holland Shipyard

The collaborative effort of innovation partners Roboat, Holland Shipyard, and Sequana Développement has born this concept for the autonomous ferry designed to carry tourists and athletes along the Seine river in Paris in preparation for the 2024 olympics.

The model builds on previous Roboat builds of self-sailing and docking passenger vessels in Amsterdam, as you can see in the video below.

Offering visitors and locals alike a unique and futuristic experience in small-scale aquatic travel, the three companies hope this ferry will showcase enough features to be a great step in the future of 3D printed autonomous boats, possibly even replacing bridges.

The companies are being quite secretive about their 3D printed ferry so far, but Olympics-goers are looking forward to experiencing the boat for themselves. And at a planned size of 9 x 3.9m (29.5 x 12.7′), it promises to be the world’s largest 3D printed autonomous ferry ever made.

Impacd Boats – Sustainable 3D Printed Sloops

- Company: Impacd Boats

- Price: $40,000+

- Where to Buy: Impacd Boats

3D printed boats don’t have to be big and flashy, they can also be simple but effective crafts to handle small-scale sailing. Impacd Boats offers customizable 3D printed sloops as comfortable and easy-to-ride boats for any lazy river fan to buy and enjoy.

The main mission is tackling carbon emissions and making a positive impact on environmental health. Their boats are 3D printed using recycled waste material, and even the decorative items included with their models are from sustainable origins.

Impacd Boats took inspiration from data taken from TU Deflt research into sustainability in aquatic travel , and developed a greener, more environmentally friendly construction process using additive manufacturing. Each boat even features an energy-efficient motor that is as silent as they are safe.

They only have two models available at the moment, but are working on the technology to release different kinds of sloop at affordable prices for anyone who wants to discover how to sail guilt-free.

- Designers: Alexander and Roman Schmidt

- Price: $1 – $16,694.85

- Where to Buy: Solvit3D

3D printed boats are exciting, but 3D printed boat parts are making just as much of a difference. Solvit3D specializes in 3D printed objects like boat parts and decorations, offering over 60 different examples from light fixtures to compass covers and even custom switch panels.

Brothers Alexander and Roman founded Solvit3D after discovering additive manufacturing’s ability to create complex geometrical shapes with speed and ease. The parts are light and highly customizable for any taste or any boat.

While they don’t 3D print entire boats, Solvit3D should be bookmarked by any sailing enthusiast for practical replacement parts and aesthetic upgrades at very reasonable prices.

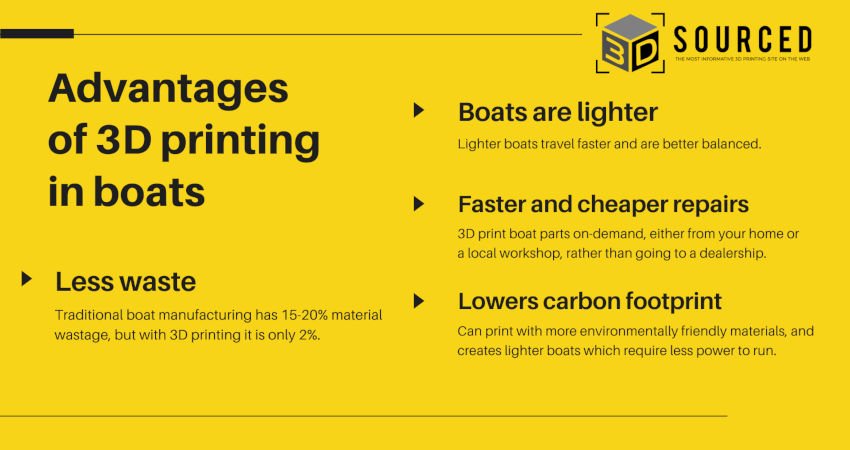

Advantages of 3D Printing in Boats

3D printed boats have several key advantages including less waste, lighter weight, quicker and cheaper repairs, and lower carbon footprint.

Reduced Waste

Traditional subtractive boat production, such as CNC milling, results in a lot more waste than 3D printing , making additive manufacturing a more cost-effective and sustainable process.

It’s also worth mentioning that some woods used in boat production are unsustainably, and sometimes even illegally, sourced , further adding to the need for alternative materials and manufacturing methods.

Research in the sustainability measures in boatbuilding carried out in 2021 shows some frankly alarming statistics . Only 55% of companies have a sustainable sourcing policy for their building materials, while 40% claim to not have the budget to research or implement more environmentally friendly construction methods.

Lighter and Better Balanced Boats

Additive manufacturing yields boats that are lighter, faster, and better balanced due to the use of 10-30% infill . Projects like Rammses predict 3D printed boat propellers weighing 40% less than conventional ones. By 2030, lighter titanium could replace steel in yacht production.

Efficient Repairs

3D printing can expedite and reduce the cost of repairs by producing spare parts on-site , a strategy already utilized in the automotive industry.

Lower Carbon Emissions

3D printed boats are more environmentally friendly due to research into lighter, more efficient materials like aluminum alloys for propellers , which can be printed anywhere to minimize transportation.

This innovation is crucial for the maritime sector striving to reduce carbon emissions and waste material through CNC machining. Searious Business, a Dutch association fighting against plastic pollution, even plans to print a 3D boat from plastic waste like Impacd Boats are.

Future of 3D Printed Boats

The boat design industry’s future includes a growing shift to 3D printing, resulting in cheaper, better-performing, and more eco-friendly vessels. The technology will revolutionize the industry by 2030, according to expert Gregory Marshall , with potential applications ranging from self-driving canal taxis to futuristic super yachts, as seen in the innovative 3Dirigo project.

Was this content helpful? Give us your feedback here.

Learn More About 3D Sourced

Exceptional Value with AnyCubic’s Latest 3D Printer Deals

11 Best 3D Printers in 2024 (All Budgets)

The 6 Main Types of FDM 3D Printer Explained

5 Best 3D Printers for Miniatures & Terrain in 2024

The 56+ Coolest Things To 3D Print in 2023

44 Common 3D Print Problems – Troubleshooting Issues 2023

13 Best Free 3D Modeling Software (For Beginners) 2024

6 Best Large 3D Printers in 2024 (All Budgets)

4 Fastest 3D Printers in 2024 (All Budgets)

5 Best 3D Printers For Beginners in 2024

40+ 3D Printing Industry Statistics (2024 Update)

22+ Coolest 3D Printed Robotics Projects (2024 Update)

8 Best DIY 3D Printer Kits in 2024 (From $150!)

3D Printing In Space – Top Projects in 2023

Best 3D Printed Shoes in 2023 (Sneakers, Heels & More)

The Best 3D Printer Buyer's Guide Resource & 3D Printer Reviews

[email protected]

3D Printers 3D Scanners 3D Software Guides Rankings Interviews News

Most Popular

Best 3D Printers Best 3D Scanners Best 3D Modeling Software Best 3D Slicers Best Resin 3D Printers Fastest 3D Printers Best Large 3D Printers

Useful Links

About us About the team How we do our reviews Careers Contact Us

Sign up to our newsletter

Privacy policy

Affiliate disclaimer

Editorial policy

Discover in this new collection of 3D models all the 3D printer files related to boats and sailing

⛵ best boat 3d models.

3D printed boats

On this page you will find a large number of free or paid 3D files for boat enthusiasts. Some boats are only decorative, but others can easily sail on water. There are sailboats, catamarans, fishing boats and even huge cargo ships.

Popularity Ranking

/https://fbi.cults3d.com/uploaders/133/illustration-file/1428782346-8151-9279/_1__3D-printed__3DBenchy_by_Creative-Tools.com.JPG)

Benchy - The jolly 3D printing torture-test

/https://fbi.cults3d.com/uploaders/13398202/illustration-file/76f865dc-f060-4656-a3f0-21a84f339d66/Capture%20d%E2%80%99e%CC%81cran%202018-02-27%20a%CC%80%2018.32.53.png)

BEN the floating BENCHMARK (Benchy)

/https://fbi.cults3d.com/uploaders/13398202/illustration-file/43ef548f-5f85-41b9-b486-0b0f27632967/Capture%20d%E2%80%99e%CC%81cran%202018-02-27%20a%CC%80%2017.31.42.png)

RMS TITANIC - scale 1/1000

/https://fbi.cults3d.com/uploaders/13653283/illustration-file/641a6d2a-4c6b-4935-b528-dda1870e3226/Image031.jpg)

Columbus caravel Nina (1492)

/https://fbi.cults3d.com/uploaders/13398202/illustration-file/da9aa50b-0239-4502-9cb1-f1e0c2b6fa25/Capture%20d%E2%80%99e%CC%81cran%202018-02-27%20a%CC%80%2017.33.46.png)

bathtub boat

/https://fbi.cults3d.com/uploaders/13398202/illustration-file/9c6e534c-1db9-469e-8229-23eb966c3bc3/Capture%20d%E2%80%99e%CC%81cran%202018-02-27%20a%CC%80%2018.35.24.png)

LEO the little fishing boat (visual benchy)

/https://fbi.cults3d.com/uploaders/13398202/illustration-file/96285fc0-481a-4b4c-96a0-2396730ff945/Capture%20d%E2%80%99e%CC%81cran%202018-03-02%20a%CC%80%2010.15.03.png)

JUN - the Jungle Queen

/https://fbi.cults3d.com/uploaders/384187/illustration-file/f60f0452-708c-4774-bbe4-c154a0c42085/Capture%20d%E2%80%99e%CC%81cran%202016-10-17%20a%CC%80%2009.51.47.png)

Smoke for #3DBenchy boat

/https://fbi.cults3d.com/uploaders/13398202/illustration-file/d187fe7a-d142-4d27-a9b1-67d3cf4c3099/Capture%20d%E2%80%99e%CC%81cran%202018-02-27%20a%CC%80%2018.01.22.png)

Little bathtub tug boat (visual benchy)

/https://fbi.cults3d.com/uploaders/13398202/illustration-file/3bf1b32c-b372-4543-9f25-064fc27a627f/Capture%20d%E2%80%99e%CC%81cran%202018-02-27%20a%CC%80%2017.49.49.png)

Small compressed Titanic and scale example of the iceberg

/https://fbi.cults3d.com/uploaders/15648110/illustration-file/29993fe8-fce6-4539-9971-db083aca3bab/Preview1.jpg)

Small fishing boat - floating toy for kids

Turbo-boat --> print in place / no supports / no assemble.

/https://fbi.cults3d.com/uploaders/13398202/illustration-file/bbc0682e-b625-4792-920c-7cea66492f0a/Capture%20d%E2%80%99e%CC%81cran%202018-04-09%20a%CC%80%2018.09.48.png)

CAS - the modular xyz-cube cargo ship

/https://fbi.cults3d.com/uploaders/14182283/illustration-file/ed2510e6-0d49-4ce9-b447-eb47aab8f9e4/boat6-square.png)

Container Ship

/https://fbi.cults3d.com/uploaders/14182283/illustration-file/53df0cdf-fd01-4aa3-ad63-2872eb3d5baf/boat4-square.png)

COS - the Container Ship

/https://fbi.cults3d.com/uploaders/14182283/illustration-file/ff6caba2-afa2-4387-b5f9-fb3fdfcc7321/boat5-square.png)

Paddle Boat

/https://fbi.cults3d.com/uploaders/13331160/illustration-file/d1f1da12-4e9f-49c2-b50f-9a79c6201c88/Capture%20d%E2%80%99e%CC%81cran%202017-09-05%20a%CC%80%2018.40.20.png)

The Endeavor

/https://fbi.cults3d.com/uploaders/13398202/illustration-file/9d0b738f-e2c1-4262-818a-5c1c1d7ae0fb/DSC_1616.jpg)

FIN the little Trawler (visual benchy)

/https://fbi.cults3d.com/uploaders/13716053/illustration-file/a25bf66d-7279-4a57-901d-8fae2e12b0e3/inCollage_20210728_223706349.jpg)

Mini RC Jet Boat 200 Mono

/https://fbi.cults3d.com/uploaders/13398202/illustration-file/21a8c4f7-f6bd-4fe9-91cd-4c436b80a4b1/8b0613b2e697db139d8841998624e059_display_large.jpg)

EMMA - a Maersk Ship

/https://fbi.cults3d.com/uploaders/1587822/illustration-file/03cd8c8b-adec-4308-a11e-a06bf81d08f6/427f8f6eb11abfa3797f69b55066b6de_display_large.jpg)

Battleship - Recreated

/https://fbi.cults3d.com/uploaders/4244034/illustration-file/1439899740-14732-5541/Capture_d__cran_2015-08-18___14.08.14.png)

Motor Boat RC small (experimental)

/https://fbi.cults3d.com/uploaders/13331160/illustration-file/9fbe8f0f-5e60-4a1f-8c12-89a2f6f42d68/Capture%20d%E2%80%99e%CC%81cran%202017-09-06%20a%CC%80%2009.39.32.png)

The Trinidad

/https://fbi.cults3d.com/uploaders/133/illustration-file/1440167019-13228-7519/Capture_d__cran_2015-08-21___16.20.37.png)

Sailboat Scale Model Esc: 1:43, based on Westerly Tiger 25

/https://fbi.cults3d.com/uploaders/13331160/illustration-file/0efa4ab7-e7e8-437a-a9dd-df94e434bbc5/Capture%20d%E2%80%99e%CC%81cran%202017-09-05%20a%CC%80%2018.38.30.png)

The Bao Chuan

/https://fbi.cults3d.com/uploaders/13331160/illustration-file/c1da1815-41fd-4723-8a9b-2eee5cbf844e/Capture%20d%E2%80%99e%CC%81cran%202017-09-05%20a%CC%80%2019.03.13.png)

The Sao Cristovao

/https://fbi.cults3d.com/uploaders/13673763/illustration-file/55b945dc-f4d0-4aad-a475-a1a4a7a8f60f/ship.jpg)

ship (battle)

/https://fbi.cults3d.com/uploaders/13398202/illustration-file/c5b327bf-830c-41ab-b7b7-399d502d6af8/3b1f9bd9ef64f10eb7fc69bd3a76fb9d_preview_featured%20copie.jpg)

FERRY - the little transport miracle

/https://fbi.cults3d.com/uploaders/13398202/illustration-file/38d60bf9-c9c3-454e-b8d4-c7ee5a03df95/5663c176557862d64ac27c8ec9fc47d7_display_large.jpg)

ICE - the icebreaker

/https://fbi.cults3d.com/uploaders/16207324/illustration-file/490f5f97-d89b-445a-9682-1bf3223f290b/IMG_9260.jpg)

RC Cruise Ship / Ferry Viking Grace (toy)

/https://fbi.cults3d.com/uploaders/3793290/illustration-file/1434717422-11144-3639/boat_3.jpg)

RS1: Cargo ship

/https://fbi.cults3d.com/uploaders/14182283/illustration-file/8622c0b0-bf3d-42fe-8f7f-196ed6167310/resize-boat7-square.jpg)

Research Vessel

/https://fbi.cults3d.com/uploaders/13398202/illustration-file/5cec7de3-a8a6-427c-b820-083edc661e01/7e2e8cdaafcb3f5299d5592191aec103_display_large.jpg)

VOS - the Supply Ship

/https://fbi.cults3d.com/uploaders/14182283/illustration-file/8bf6cea0-fb7f-4762-b828-9e33c5fdb058/resize-boat8-square.jpg)

Cruise Ship

/https://fbi.cults3d.com/uploaders/4244034/illustration-file/1439898113-14732-3549/Capture_d__cran_2015-08-18___13.40.44.png)

Impeller Boat RC - spiral vase printable

/https://fbi.cults3d.com/uploaders/14814100/illustration-file/44f4c6d5-f63d-484f-9700-3767c11f7a24/IMG_5345.JPG)

Speed Boat 2 RC

/https://fbi.cults3d.com/uploaders/13786663/illustration-file/9896378d-3537-46df-aa0c-96e49793bdb0/20150717_101005_display_large.jpg)

OLI - the little Ocean Liner

/https://fbi.cults3d.com/uploaders/4244034/illustration-file/1439898694-14732-1773/Capture_d__cran_2015-08-18___13.49.51.png)

Two Hulled Impeller Boat RC (experimental)

/https://fbi.cults3d.com/uploaders/13398202/illustration-file/05f49c2c-6c33-46a2-9298-0b763cd8b16f/Capture%20d%E2%80%99e%CC%81cran%202018-07-30%20a%CC%80%2014.56.43.png)

SAR - Search & Rescue boat

/https://fbi.cults3d.com/uploaders/13398202/illustration-file/80d7695f-1352-4ad0-9059-a79f1c5e0bff/1d77ed95b68cd34d4551e7e8c5bc8f6a_display_large.jpg)

B - a hommage of brigitte bardot

/https://fbi.cults3d.com/uploaders/14182283/illustration-file/5302f2d9-42dd-4d85-ac14-40b9909c0d4d/boat2-square.png)

Cargo Container for Cargo Ship Marauda

Latest 3d models of the collection, printed by the makers.

/https://fbi.cults3d.com/uploaders/13821679/photo-file/b6494a04-2cb6-4c52-8f8f-318a05e2e5a2/IMG_20240313_203235036~2.jpg)

Here is our selection of the best STL boat files , all these beautiful boats are from the 3D file library Cults and are perfectly printable in 3D .

This collection includes many free and paid 3D files that will allow you to 3D print at home many variations of boats. Each Cults 3D designer has his own vision of the boat, so you will find incredibly realistic boats designed like models, but also more childish boats to play in the bath. Obviously impossible to talk about 3D printing and boat without mentioning the famous Benchy , this boat that floats and is an excellent calibration test for your 3D printer .

Then of course, there are the purely decorative boats to carefully place on your shelf, then there are the 3D printed boats that float and can therefore go on an adventure, and finally there are the remoted RC 3D printed boats . Some 3D designers have even created boats with a 3D printed engine that is perfectly functional ! In terms of format there is everything you can imagine: large cargo ships, catamarans, sailboats, fishing boats...

- Become a partner

- Merchandising

- Terms & conditions

- upload tips

- Maker Toolbox

- Design on Demand

- Coupon codes

- best stl files

- Best sellers

- Best CNC Laser Cutting Designs

- Trending searches

- Best 3D designers

- Subscribe Now

- Digital Editions

3D printed boats: Why this radical custom yacht is just the tip of the iceberg

- Top stories

Could 3D printed boats become the next big trend in boatbuilding? Vasileios Sofikitis explains all…

You are at home, sitting at your desk. In front of you, on your laptop, is a bespoke 3D rendering of the boat you’ve just finished refining online. You lean back gazing admiringly at your design. The detailed online forms took you a couple of days to fill in but the result looks exactly like the boat of your dreams. OK, time to print it out.

Wait, what? It reads like a scene from a sci-fi novel but this might well be the reality of how we will all go about buying and manufacturing boats in the not too distant future. The current GRP boat building procedure is a complex, time-consuming and expensive process with limitations on the type of shape and structures that are achievable.

It usually starts by handbuilding or milling and fairing a perfect full size model from which the female moulds for the hull and deck can be created. These moulds have to be carefully aligned, reinforced and waxed before the gelcoat and multiple layers of glass matting and resin can be added.

Article continues below…

Sharrow MX-1: This toroidal boat propeller could be top of the props

Welcome to the future: 5 futuristic yachts being built today, recommended videos for you.

This then needs time to cure at a precisely controlled temperature before the hull and decks can be removed and the whole cleaning and waxing process starts again. But this won’t be the process for much longer if the latest advances in 3D printing are anything to go by.

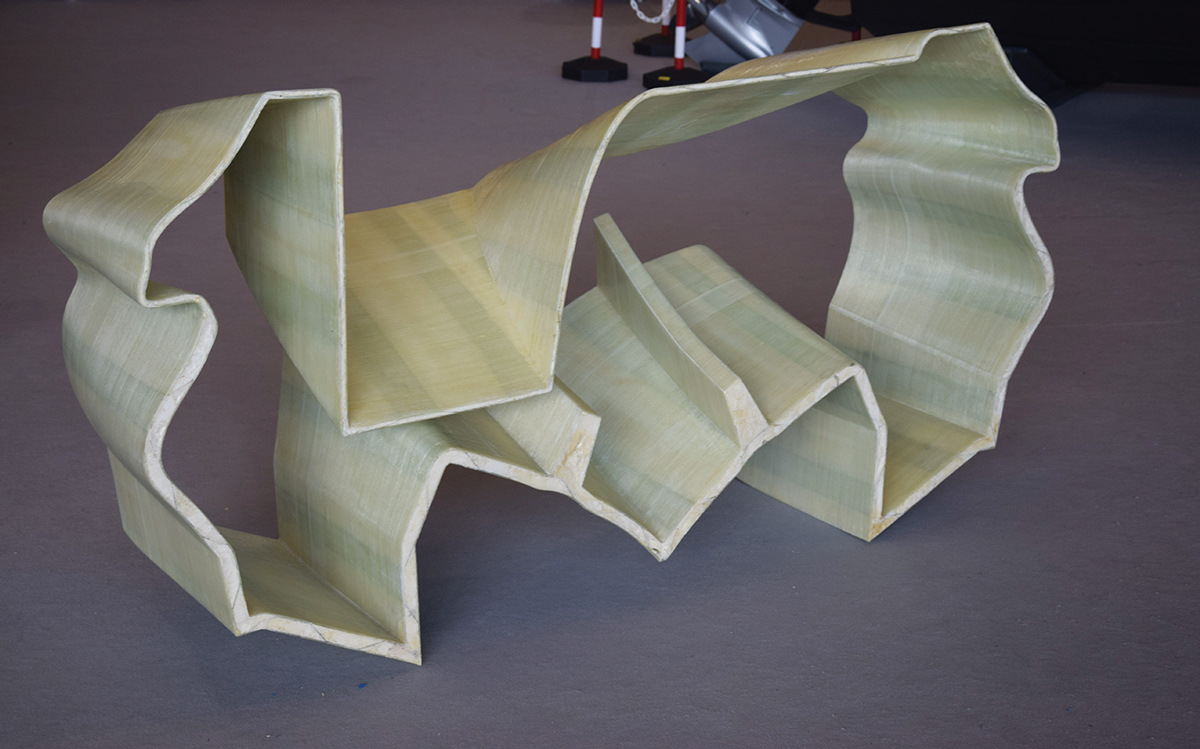

Meet MAMBO (Motor Additive Manufacturing Boat), the world’s first 3D printed fibreglass boat. It was launched by Moi Composites at the 2020 Genoa Boat Show in October. The Italian start-up drew inspiration from the Arcidiavolo design of British power boating legend Sonny Levi.

They spent almost six months running hydrodynamic simulations on Autodesk’s cutting-edge design and simulation software to refine Levi’s multihull before settling on a final design that takes full advantage of 3D-printing’s capabilities.

Software breaks the shape into printable sections

As a result, MAMBO sports some very unusual design ideas both above and below the waterline that simply wouldn’t be possible with the limitations of the moulding process (you have to be able to remove the moulding without destroying the mould).

MAMBO features a radical three-pointed hull featuring an asymmetrical deck layout and intricate organic forms that play a role in both its aesthetics and structural integrity. It measures 6.5 metres long by 2.5 metres wide and has a dry weight of just 800kg.

A relatively modest 115hp Mercury Pro XS outboard engine provides the power. The aft bench, the shape of which resembles a baby grand piano, is a reference to Mambo, the Cuban musical genre. These unorthodox design solutions not only help differentiate the boat from other craft on the water but also showcase the seemingly limitless possibilities offered by 3D-printing.

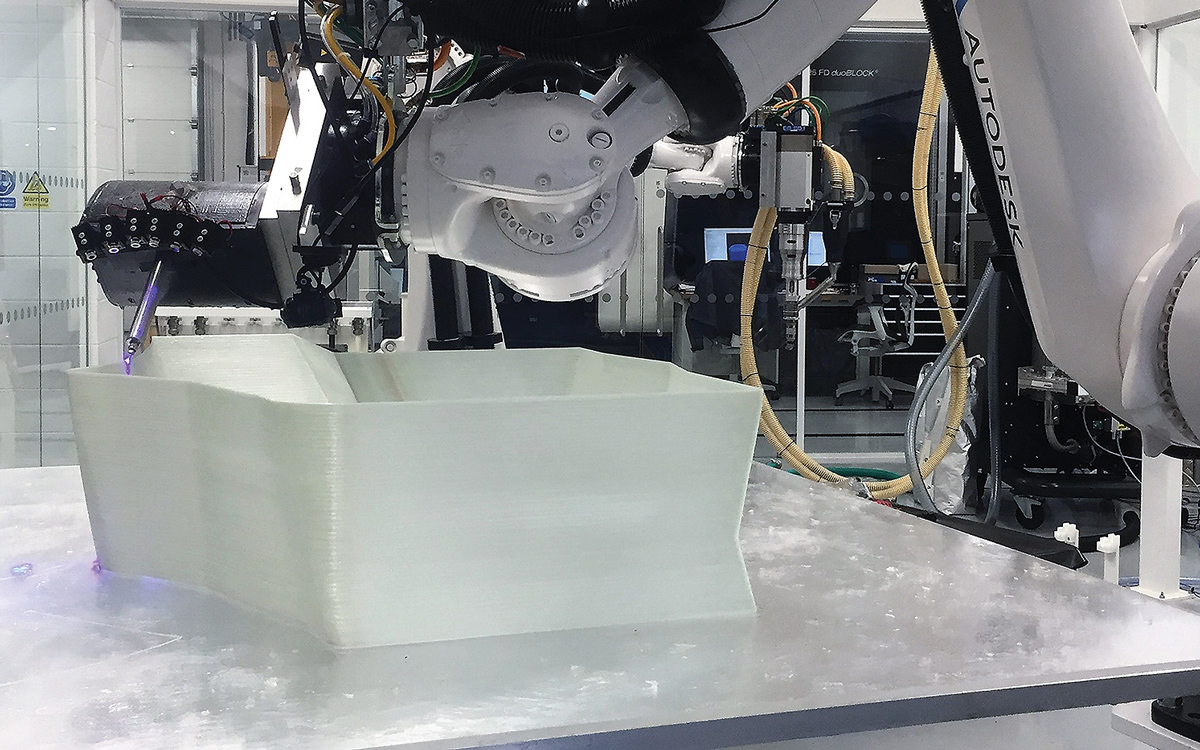

A robotic arm prints out each segment using a continuous glass fibre filament impregnated with thermo-setting resin that cures instantly

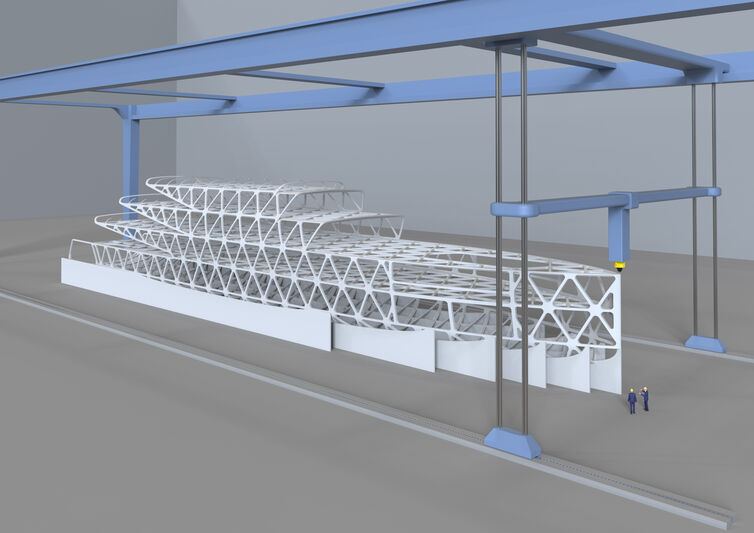

In order to print MAMBO, Moi employed an innovative, remote cloud-based workflow process that helped leverage the best talents and facilities around the world. Two separate printers, one in Moi’s headquarters in Milan and the other in Autodesk’s manufacturing facility in Birmingham, UK, jointly produced MAMBO’s components, demonstrating another advantage of 3D-printing — decentralised manufacturing.

MAMBO’s greatest innovation however, lies in its 3D printing technology. It uses a patented process known as continuous fibre manufacturing (CFM) that extrudes a continuous stream of glass fibre infused with thermosetting resin, which instantly cures under the printer’s UV lights.

This continuous glass filament creates an immensely stiff structure, resulting in a much lighter but more durable hull. The use of CFM minimises waste, enhances precision, and enables the creation of shapes that would be impossible or prohibitively expensive using traditional methods.

By repeatedly going over and over the previous layer it slowly builds up into a single finished 3D shape that is lighter, stiffer and more complex than a conventional GRP moulding

Once printed, MAMBO’s components were sent to Catmarine’s shipyard in Miggiano, Italy, for final assembly. Here the different sections were laminated together using glass fibre matting and polyester resin and painted electric blue. The deck was covered with eco-friendly cork and its seats upholstered in white leather.

MAMBO suggests that 3D printing will appear first in smaller sportsboats and day cruisers . As printers become larger and quicker though, we could start to see bigger boats manufactured in this way. 3D printing is already being adopted in other industries as an alternative to the traditional, more expensive methods of lost-wax casting or plastic moulding, especially for complex shapes and small production runs.

Many boatyards are also starting to use 3D printing for low-volume parts and rapid prototyping applications.

The individual sections were printed at two different facilities in the UK and Italy

Even boat owners wanting custom pieces or replacement parts that are no longer available are starting to look to 3D printing as a solution, with companies being set up to answer this demand. The Italian firm Superfici exhibited just such an example of their work at Genoa, an innovative steering wheel design prototyped on a 3D printer.

There are still some limitations to 3D printing when it comes to the size, cost and scalability of large items such as boats. The assembly of many small components and the need for post print processing pose a challenge. The variety of materials used in boat-making, such as wood and stainless steel, neither of which are yet printable, also present problems. However, projects like MAMBO prove that most of these problems will eventually be solved.

When projects like MAMBO start to lure boat builders into the realm of 3D printing and how that will coexist with the art of traditional boat building, remains to be seen. However, the recent addition of glass fibre to the repertoire of 3D printing materials is certainly going to be a boon for recreational boaters.

Designs that are currently restricted to a virtual world of CGI renderings due to the difficulty of making them using conventional moulding techniques will soon become viable, opening up a world of new possibilities and disrupting boat building as we know it. The big question now is whether we, as consumers, are ready to press print.

First published in the February 2021 issue of Motor Boat & Yachting.

These sections were laminated together by hand

The completed boat gets a final spray paint, the finished mambo in all its glory complete with complex curves and an unusual three pointer hull, if you’ve got $500k to spend on a motorboat, what should you get, swift trawler 54 first look: plugging a gap in the beneteau range, world’s coolest boats: aston martin am37 – the james bond boat that never was, latest videos, sacs rebel 50 tour: the world’s most luxurious rib, fairline targa tour: sensational new british sportscruiser, navan s30 & c30 tour: exceptional new axopar rival, galeon 440 fly sea trial: you won’t believe how much they’ve packed in.

3D PRINT AN IOM YACHT

And go racing for less than half the price..

ALIOTH is an International One Metre class design optimized to be manufactured using 3D printing technology.

FOR HOME 3D PRINTERS

For FFF/FDM printers with 210 x 210 x 250 mm build volume or larger.

EASY ASSEMBLY

FAST MODERN DESIGN

The design team worked exhaustively in achieving modern, functional and harmonic shapes.

WHAT IS HAPPENING IN THE ALIOTH COMMUNITY?

Facebook group.

FREQUENTLY ASKED QUESTIONS & ANSWERS

Does alioth design cumply with the iom class rules.

Yes. A lthough the design has not been on the market for a long time, there are already some that have been registered with measurement certificate.

I am interested in home build an Alioth yacht but I don´t have a 3D printer.

If you don´t have a 3D printer but would like to build an Alioth, 3D printed kits are available for that purpose. More details soon.

I´ m thinking of purchasing a printer, which one would you recommend for a nice finish?

Most popular low price printers are good to print PLA material if they are well calibrated and work in a suitable place away from drafts or vibrations.

Make sure the build volume is 210x210x250 mm or larger.

Typically, you need to spend some time understanding and calibrating a 3D printer.

What material do you recommend to print the Alioth files?

PLA+ is stiff, has low shrinkage and is easy to print. The disadvantage is a low glass transition temperature.

Darker colours warp on direct sunlight as the temperature of the surface builds up fast. To avoid this, use bright clear colours.

Is the hull designed to be printed in vase mode?

Yes. Vase mode guarantees good layer adhesion and the best surface quality, and it reduces a lot the printing time.

What sailwinch servos can I use?

Files include three different servo trays for:

- Standard size (40×20 mm) sailwinch servos, like DSNA SW22HV.

- S100 sailwinch.

- RMG and ARS808 sailwinch servos.

- Privacy Overview

- Strictly Necessary Cookies

- Cookie Policy

This website uses cookies so that we can provide you with the best user experience possible. Cookie information is stored in your browser and performs functions such as recognising you when you return to our website and helping our team to understand which sections of the website you find most interesting and useful.

Strictly Necessary Cookie should be enabled at all times so that we can save your preferences for cookie settings.

If you disable this cookie, we will not be able to save your preferences. This means that every time you visit this website you will need to enable or disable cookies again.

More information about our Cookie Policy

Our newsletter is free & you can unsubscribe any time.

3D Printed Superyacht Concept Unveiled

February 3, 2023

Designer Jozeph Forakis has recently unveiled the world’s first 3D printed superyacht, the 88-metre Pegasus concept. The yacht is designed to be sustainable and virtually invisible” thanks to mirrored facades that reflect the ocean and sky, mounted to the exterior of the yacht.

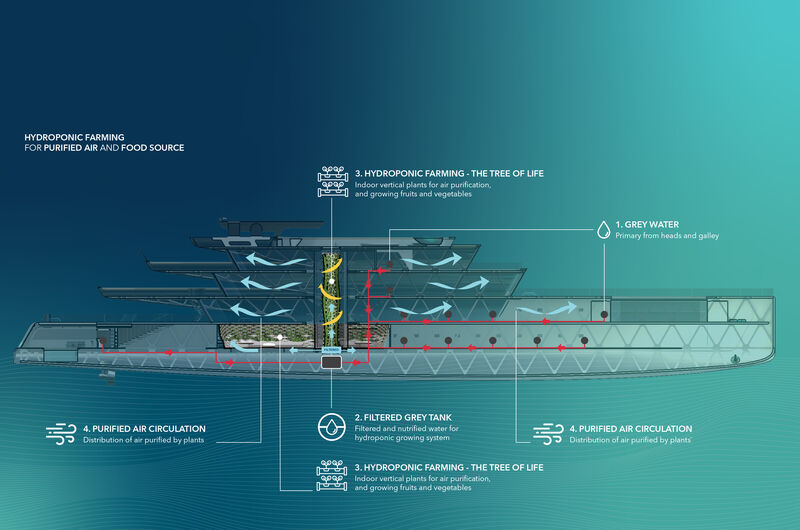

The construction of Pegasus will use robotic 3D printing to create a mesh framework, which will be more energy, waste, space and material efficient compared to conventional construction. Jozeph Forakis is known for his innovative designs and is considered a disruptive force in the superyacht industry.

The yacht runs on solar energy, converting seawater into hydrogen, producing zero emissions and offering an infinite range.

The interior spaces of Pegasus offer a minimalist design combined with living nature, including a hydroponic garden, wellness zen garden and reflective pool. The yacht will feature a hydroponic “tree of life” that will pass through multiple decks, providing food for passengers.

The top level is exclusive to the owner with a forward-facing primary suite and various luxurious amenities.

While Forakis has a background in biomedical research, his work as a designer has seen him working in marine architecture before, as he previously designed the CLX96 SAV – Sea Activity Vessel, which was first shown at the Fort Lauderdale International Boat Show.

What do you think of the 3D printed superyacht?

Is additive manufacturing the future of shipbuilding?

Come and let us know your thoughts on our Facebook , Twitter , and LinkedIn pages, and don’t forget to sign up for our weekly additive manufacturing newsletter to get all the latest stories delivered right to your inbox.

Nikon Introduces Metal Additive Manufacturing System and 3D Scanner

Nikon Corporation has unveiled its latest metal additive manufacturing system, the Lasermeister LM300A, alongside the Lasermeister SB100 3D scanner. Designed for industrial use,... read more »

Best 3D Scanners for Medium-sized Items

In this article, we will be taking a look at the best 3D scanners for scanning medium-sized items.

Materialise Expands 3D Printing Material Portfolio for HP and FDM Applications

Materialise has announced the integration of three new industrial-grade materials into its portfolio: Polyamide 12S (PA 12S), Polyamide 11 (PA 11), and Carbon... read more »

Researchers Speed Up Complex 3D Printing with Multi-Beam Lasers

In a recent breakthrough, scientists have accelerated the pace of intricate 3D printing by utilizing multi-beam laser technology. This advancement, detailed in a... read more »

Aurora Labs Successfully 3D Prints Micro Gas Turbine

Aurora Labs, an Australian manufacturing company, has achieved a significant milestone by successfully 3D printing a micro gas turbine. This turbine, designed for... read more »

Introducing the CR-Scan Otter: A Highly Versatile 3D Scanning Solution

Within the CR-Scan lineup from Creality, the CR-Scan Otter emerges as a versatile solution for 3D scanning, catering to both personal and commercial... read more »

3D Printer Automatically Determines Parameters for Unknown Materials

In the past, adopting sustainable materials in 3D printing faced hurdles due to the manual tweaking of printer settings. However, a collaborative effort... read more »

Take a Look at @properprinting’s New Experimental 3D Printer

This video demonstrates the construction of a unique 3D printer with two tools moving independently in all axes, termed as the TIME-system (True Independent Multiple Extrusion).

Researchers Develop 3D Printed Cellulose Aerogel

Empa researchers have achieved a significant milestone by 3D printing cellulose-based aerogels, unlocking a realm of possibilities for precision insulation and medical applications.... read more »

PPPL Uses 3D Printing to Develop The MUSE Stellarator

Princeton Plasma Physics Laboratory (PPPL) has utilized additive manufacturing to construct the first stellarator in decades, showcasing a fusion experiment with significant cost-saving... read more »

3D Printed Supermodels of Real Life Super Yachts

Share this Article

[All Images: SuperYacht Times]

There’s a great deal of money riding on the creation of the full sized boat; the design and development process can take years and the end models are works of art in their own right. These models can retail for around $10k and travel extensively to boat shows around the world as demonstrations of the work performed. As such, they not only provide the final vision to the client to seal the deal, they also are an investment in future clients who see the work and how it measures up to their own standards of excellence.

“When we started 30 years ago [I] carved the models using simple tools, basswood and planks to frame the hull. We then started adding foam as it was easy to shape. Everything was handmade. We used pencils to draw the decks. We cut out the windows and frames by hand. Furnishings were cut out of wood by hand. Now we have machines running and we can produce much more in a shorter time with more accuracy.”

“We use every type of material and technology at our disposal to create our products. We have sculpting machines as well as 3D printing devices. The hull, for instance, will be milled, for deck railings we use brass for our authentic finish, and our laser cutting machines accurately outline the teak decks of the yachts. The quality of the model is extremely important as this becomes a direct representation of the design. If the model is low quality, the project and time which has been dedicated to creating the design, can be lost…its purpose is to capture the emotion of the design and relay that experience for the client even before stepping on board.”

“We want to offer a very exclusive yacht model for someone who wants the best of the best. Our next adventure is to work with a jeweler to have all the deck fittings, railings and other items created using gold and platinum.”

Truly a model fit for a king…or at least a super wealthy president-elect. Discuss in the 3D Printed Yacht forum at 3DPB.com.

Subscribe to Our Email Newsletter

Stay up-to-date on all the latest news from the 3D printing industry and receive information and offers from third party vendors.

- Enter your email address *

- Phone This field is for validation purposes and should be left unchanged.

Recent News

3D Printing News Unpeeled: Recycling PLA, More Efficient Atomizing

Researchers Gain New Levels of Control over Volumetric 3D Printing

3D Printed Art

3D Printed Food

3D Printed Guns

You May Also Like

Scholars call for 3d printing to be made sustainable from the ground up.

At a time when climate change and resource scarcity loom large, the imperative for industries to adapt is more pressing than ever. We all know that additive manufacturing (AM) is...

3D Printing News Briefs, April 3, 2024: Kickstarter FDM 3D Printer, Artificial Eyes, & More

In 3D Printing News Briefs today, we’re talking about an FDM 3D printer on Kickstarter, advancements in artificial eye creation, and 3D printed solenoids for electromagnets. Then we’ll move on...

Stanford Researchers 3D Print Elusive Shapeshifting Structures

Nano 3D printing is a field that continues to make steady progress, but whose applications are still being discovered. One of the most exciting areas where additive manufacturing (AM) at...

3D Printing News Briefs, March 23, 2024: AM in the US Coast Guard, Navy, & More

In today’s 3D Printing News Briefs, we’re discussing the use of 3D printing in various branches of the military, including the U.S. Coast Guard, the U.S. Navy, and the German...

Print Services

Upload your 3D Models and get them printed quickly and efficiently.

- 3DPrinting Business Directory

Site Sponsor

Additive Manufacturing Strategies

Networking & Intelligence Summit, February 4-6, 2025

3D Printing jobs around the world.

- I would like to also register for free and access proprietary industry data from SmarTech and 3DPrint.com

3D Printing Guides

- Desktop 3D Printer Buyer’s Guide

- 3D Scanner Buyer's Guide

- Metal 3D Printer Guide

- Industrial Polymer 3D Printer Guide

- The 3D Systems Zone

- The HP Zone

- Desktop Metal Zone

- Bioprinting Zone

- The Space Zone

- 3D Printing Stocks Zone

Register to view and download proprietary industry data from SmarTech and 3DPrint.com Questions? Contact [email protected]

Already have an account?

- First name *

- Last name *

- Password * Enter Password Confirm Password

- I agree to receive the 3DPrint.com Daily newsletter and promotional email correspondence.

- THE PRINCESS PASSPORT

- Email Newsletter

- Yacht Walkthroughs

- Destinations

- Electronics

- Best Marine Electronics & Technology

- Boating Safety

3D-Printing and Boatbuilding

- By Kim Kavin

- Updated: November 9, 2020

Last fall, when the University of Maine announced that it had created the world’s largest 3D-printed boat, imaginations ran wild. The idea of pressing a touchscreen and having a boat spit out of a gigantic printer suddenly felt possible. The notion of having a boat designed in a newfangled shape became a realistic-sounding option. And because the team in Maine had printed the 25-foot boat in just 72 hours, dreams of having production boats fly off factory lines became the stuff of serious conversations.

Practically speaking, here in reality, things are moving a bit slower on the innovation timeline. Habib Joseph Dagher, who leads the project as director of the university’s Advanced Structures and Composites Center, says the most likely immediate outcome will be a new way to make boat molds in the 50-foot range. “We think some of the first products that will come out over the next year will be full-size or close-to-full-size molds for boats made of recyclable materials,” Dagher says. “We think what’s going to happen next is shipyards evaluating the molds and giving us feedback, so we can get the technology honed in and able to roll out on a commercial scale.”

It’s a baby step in what experts say will be leaps and bounds of creative uses for 3D-printing technology once it can be harnessed to its full potential. Additive manufacturing, as it’s also known, is now the stuff of tests and experiments in fields as wide-ranging as aerospace and dentistry. Researchers are figuring out all kinds of materials that can be 3D-printed, as well as all kinds of ways to build the 3D printers themselves. The US Army is testing ways to use the machines in fields of combat, to print replacement parts on demand. Carnegie Mellon University just got funding to create software that will identify components in a CAD file that can be optimized and built better, such as in a different shape to reduce weight. BMW recently opened an entire additive-manufacturing campus in Germany, looking to improve upon the 300,000 or so parts the company built this way in 2019.

“One day, we’ll all be printing boats without a mold,” Dagher says, “but we’re all going to have to wait a little bit for that.”

As far as boats go, advances are happening all around the world. At the IYRS School of Technology and Trades in Rhode Island, the Digital Modeling and Fabrication Program is heading into its fourth year. Jeff Elsbecker, who heads it up, says that to understand where 3D-printing technology is today, we have to think about printers from the 1980s.

“If you remember dot-matrix printers, I would say that 3D-printing technology is almost where dot-matrix printers were,” Elsbecker says. “We’ll follow that with lasers and jet printing and all kinds of things. I suppose the far end would be replicators like in Star Trek.”

IYRS is focusing on teaching students design fundamentals and the basics of the technology. By the time they start working in naval-architecture firms or shipyards a few years from now, everything will have changed many times over, but the fundamental skills will still be needed to use whatever form the technology takes.

“There’s so many people doing so many things, one of the issues is also getting the machines to communicate with each other,” he says. “It’s sort of like deciding whether to go with beta or VHF. It’s at that stage.”

Boatbuilders who are early adopters in the 3D-printing world are using the technology for things like components and molds, says Bill Kenyon, director of education at IYRS. One example, he says, is Brooklin Boat Yard in Maine. It’s mostly a traditional boatbuilding and repair facility.

“When I was up there in January, they showed us a bow chock that the guys had designed,” Kenyon says. “They worked it all up in CAD and sent it off to a company that 3D-printed a prototype. They got it back, tweaked their design, sent it a couple of times, and then the guy could print it for them in titanium.”

Similar experimentation is happening in Auckland, New Zealand, where Richard Booten, head of design at Yachting Developments, says the yard’s purchase of 3D printers led to all kinds of ideas.

“Once you’ve got the machines, you start thinking about what you can use them for,” Booten says. “A lot of what we use them for is printing hull components—anything that has a highly complex shape. We’ve done exhaust-tube fittings. We’ve done hull fittings. We’ve achieved all sorts of stuff. Anything we would traditionally have gone and built on a CNC at great expense, we have done that. It’s really saving us some money by doing that.”

Yachting Developments is also now using the technology to plan vessel refits, to help clients understand how a final component will look and feel.

“The boat in the shed at the moment that we’re doing a refit to, they’re putting a new screen on the helm console,” Booten says. “Before we committed to making something out of carbon or fiberglass, we are able to print that addition and melt the screen in it so the captain can see what he’s actually going to get in real life. I think we’ve printed two or three of them now, and he’s changed stuff along the way. It’s relatively inexpensive to do that. Before, you’d kind of do it on the computer screen, and everybody would peer at it. The real-life version can look a bit different, so this is a real advantage.”

What will come next for the technology in boatbuilding, he says, is anybody’s guess. Right now, 3D-printing materials don’t compare to

fiberglass or carbon in terms of strength for building hulls, but new materials are being developed all the time. Most boatbuilders can’t afford a mammoth-scale 3D printer of their own, so they’re limited by whatever additive-manufacturing company can do the printing off-site. Boatbuilders, like everyone else, are just trying to keep up with the technology and think toward the future.

“There’s people around the world playing with all sorts of stuff with regard to 3D printing,” Booten says. “There’s people printing houses. There’s people printing bridges with welders stuck on the end of robots. It’s only going to gain more traction as a process and in the industry over the coming years.”

Old and New

It’s an odd thing, hearing the name Nathanael Herreshoff mentioned in the same sentence as 3D printing.

Herreshoff, of course, is the yacht designer best known for his America’s Cup designs of the late 1800s and early 1900s. He died in 1938, a time when the V-8 engine and the metal-cutting contour band saw were bleeding-edge technology.

The 3D printer wasn’t invented until decades later, in the 1980s. But that’s not stopping the team at the IYRS School of Technology and Trades in Newport, Rhode Island, from using the modern tech to build a Herreshoff.

This past year, the team was creating a replica of a 100-year-old Herreshoff design. Some of the hardware that Herreshoff had specified on the plans was not to standard; it had to be custom-made. IYRS decided to make it with 3D printing, converting the original drawings into files the printer could read.

“They worked them up in CAD and printed a 3D pattern, and the pieces could be made out of bronze,” Bill Kenyon, director of education, says of the team that Jeff Elsbecker leads at the school.

Superfici, a company based in the superyacht-building mecca of La Spezia, Italy, is using 3D printing in myriad ways, such as to create the sailboat rigging shown above. Paolo Licinio Nazzaro, at right in the photo below, is the company’s co-founder and managing director. His team worked with the owner of an Amer 94 to create what they say is the first 3D-printed helm console. It looked just like a traditional console, made from regular design plans.

Next, Superfici worked with Sacs to design and 3D-print the helm console shown on the opposite page. This console is a shape that can’t be created with a traditional mold, and the multifunction display is integrated in a way that lets it be upgraded later.

Today, the company is thinking about ways to make entirely new boat hulls, with features such as integrated lights and fenders.

- More: 3d Printing , September 2020 , Technology , Yachts

- More Yachts

Riviera 585 SUV Reviewed

Meet the maritimo black edition, azimut’s new flagship: grande 44m, meet the italia yachts veloce 43, riva 76 bahamas for sale, for sale: ocean alexander 78 sport bridge, for sale: ferretti yachts 750.

- Digital Edition

- Customer Service

- Privacy Policy

- Email Newsletters

- Cruising World

- Sailing World

- Salt Water Sportsman

- Sport Fishing

- Wakeboarding

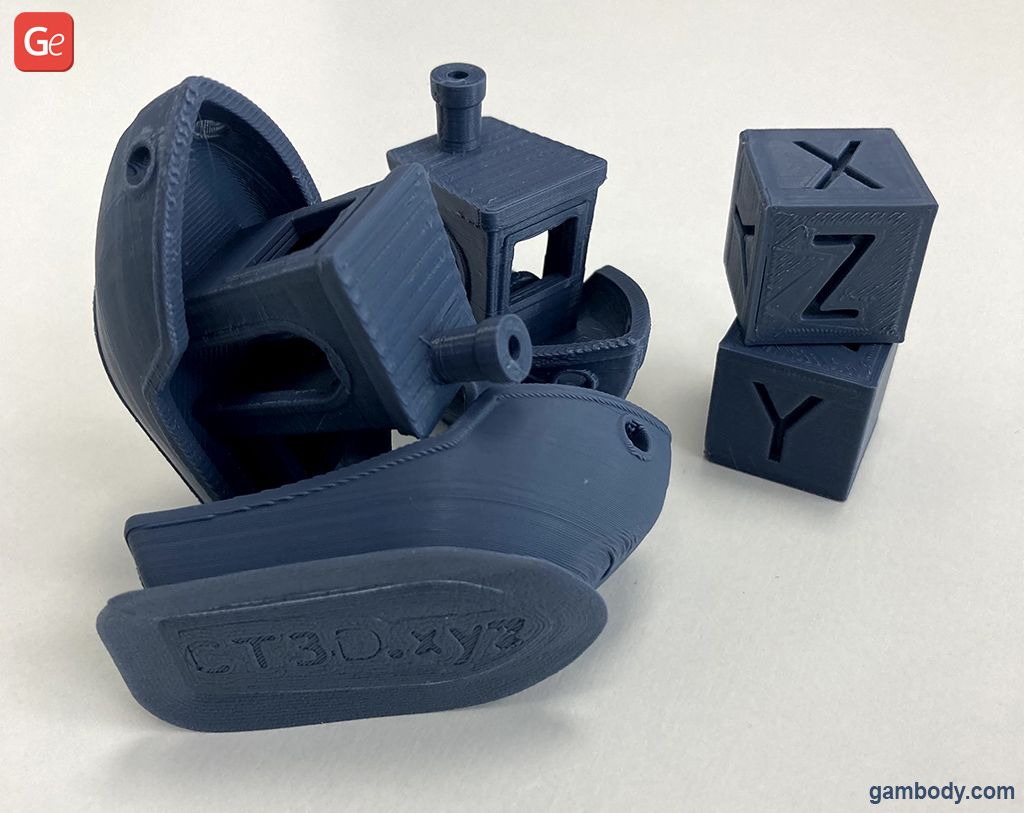

Amazing 3D Printed Boat Models and Parts

Gambody team.

- 30th Jun '22

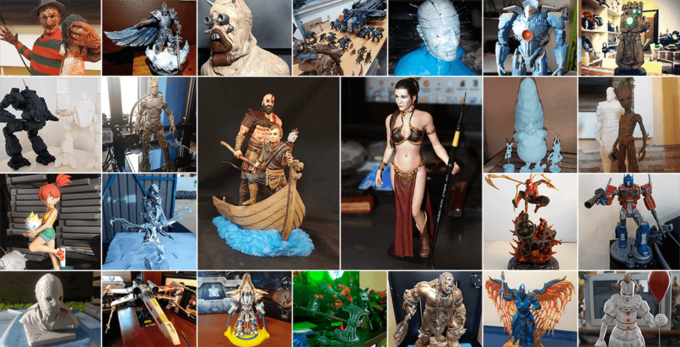

Today, when you see a boat or a yacht on a lake or a river, you don’t immediately know whether it was printed on a 3D printer or assembled at a shipyard. The term “3D printed boat” has long been in vogue. And the sizes of 3D printed yachts, kayaks, and sailboats have long outgrown the size of ordinary toys or collectible models .

Gambody has selected some of the most amazing boat 3D model designs you can look at and choose to recreate yourself. From a popular test benchy 3D printed boat to life-size boat prints, you will find something to enjoy and turn into your next dream project.

Read also: 15 Most Impressive 3D Printed Ships

3D Printed Boat

Thanks to additive manufacturing , different industries develop way quicker than they used to years ago. 3D printing is used in medicine, automotive business, space, air, everyday life, and also maritime services. Thus, it is not surprising to see more and more boat parts 3D printed.

Thanks to a significant number of 3D boat model STL files, anyone can 3D print boat accessories, sterns, bows, hull parts, and other important components using different scales. So take some time to enjoy photos of small and giant 3D printed boats (fully or partially) and you might need one of the large 3D printers to build one for yourself.

1. Boat 3D Print: Largest Ever

A 3D printing boat can be as giant as you want it to be. The University of Maine currently holds the world record for building the biggest solid 3D printed boat in the world.

To make this project real, the University used the biggest prototype polymer 3D printer in the world. It is now the biggest solid 3D print in history, and it took only three days to construct this impressive vessel.

What makes the largest 3D printed boat a miracle is that she truly floats! Her size is 25 feet (7.6 meters) long and her weight is 5,000 pounds (2,268 kg).

While this boat 3D model is not available to the public, the University tested its seaworthiness and assured the vessel boasted a multidirectional wave basin.

The boat 3D print even goes by its name of 3Dirigo. While it’s not the largest thing a 3D printer can build, it is the biggest solid vessel ever created through additive manufacturing.

Read also: Best 3D Printed Cars to Wow Everyone

2. 3D Printed Sailboat

It is now possible to 3D print sailboat projects to prevent some of the dangerous plastic waste. It can be a win-win idea for businesses and organizations that save the oceans from tons of plastic waste that gets into the waters every minute.

A firm Searious Business hopes to make a unique 3D printed boat as a part of its big fight against polluting the waters with plastic bottles. The company will 3D print a sailboat out of 44,092 pounds (20,000 kg) of PET plastic obtained from the used plastic bottles. Another firm Lay3rs will help to bring this project to life through its 3D printers.

The more 3D printed sailboat objects are created, the less ocean pollution would exist.

3. 3D Printed Kayak

The imagination lets you use your 3D printer to create all kinds of stuff , including a 3D printed kayak. Jim Smith from Grass Roots Engineering worked hard to create a real functioning 5-meter-long (16.4 feet) kayak of ABS plastics.

This model is more than just a prototype. Its weight is slightly over 66 pounds (30 kg). It is a life-size 3D print that only required some screws to assemble and extra accessories (silicone adhesive and threaded inserts).

To 3D print his dream boat, Smith even built a large custom 3D printer.

4. 3D Print Boat that Functions

Some years ago Italians saw a real 3D printing boat sailing through local waters. The size of that cutie was slightly over 21 feet (6.5 meters) x 8 feet (2.5 meters). And she weighed 1,765 pounds (800 kg).

That functioning boat print was made by several companies, including Moi Composites, Autodesk, and others. She presented herself well during the Genoa boat show back in 2019.

Known as MAMBO, this 3D printed boat became the world’s first vessel made of fiberglass with the use of 3D printers. While the company doesn’t publicly share the 3D printed boat cost, you can visit their official website and find contacts to get more information about this unique project.

5. 3D Printed Boat Hull

A 3D printer can help you build any giant vessel you wish, including a yacht. Thermwood company has proved this with its innovative project when it 3D printed boat hull sections from a 51-feet-long (6.4 meters) yacht.

The firm chose carbon fiber reinforced ABS for this project. It assures that such material is a low-cost solution if comparing it to other high-quality thermoplastics.

The 3D printed boat hulls can change the future of how vessels are made and low down the costs of producing yachts and other big ships.

Read also: Incredible Stuff You Can Make with a 3D Printer

6. 3D Printer Boat Model

Some firms begin to take full advantage of additive manufacturing when building their projects. Tanaruz, a 3D printed boat manufacturer, has big plans to increase its production of vessels to 300 a year by 2023.

The company relies on reusable polymers to make boat 3D print production more affordable to customers. When such a vessel ends its life, it is possible to shred it down and reuse it to 3D print a new boat.

Their 3D printer produced by ABB company has a length of about 46 feet (14 meters). And the production itself leads to no waste! Such an eco-friendly solution can help to make all 3D boat designs easily accessible and buildable. Besides, you can always use renewable energy to get lights on your vessel and think of friendly materials to recreate its interior. This would however add to the basic 3D printed boat cost that starts at $15,785 (€15,000).

7. Boat 3D Model (Seaworthy)

Modern companies know how to 3D print boat projects that are seaworthy. Two firms, Research Institute of Sweden and Cipax, collaborated to work on the first-ever European one-piece seaworthy 3D printed boat.

Such a unique 3D print was built from glass fiber and plastic with the help of ABB robotic arms. The model was named Pioner 14 Active Dark Line.

And once the companies figure out the way to balance the extra material density with the boat hulls, it could become a great commercial boat 3D model for different customers who wish to sail in a 3D printed object.

Read also: Is It Safe to Leave a 3D Printer on Overnight?

8. 3D Printing Boat (Autonomous)

Institutes and laboratories collaborate to create an exclusive 3D printed boat model that would be fully autonomous. Such vessels could change the future of the maritime sector.

Once the self-driving technologies are added to the 3D printed hulls, it may be possible to build floating boats and make as many fleets as needed.

Such autonomous vessels can help to perform many valuable duties, such as good delivery, waste collection, transportation, etc.

9. 3D Printed Boat Toy

Enthusiasts who just got their first 3D printer or wish to make a 3D printed boat toy for their kids can find many great models online. Gambody marketplace, for example, offers Patrol Boat 31 Mk 2 3D Printing Model STL files you can download and print.

Such US “Brown Water” Navy patrol boats were common during the Vietnam War from 1966 to 1971. You can make this piece to add to your collection or let your little ones play with this 3D printed boat toy!

If you are a fan of medieval 3D printed boat designs, you can recreate the God of War diorama using your 3D printer and “Old Kratos and Atreus” STL files . The half of an old-style boat you can assemble features a dragon stern and waves.

If you don’t feel ready to 3D print boat designs using complex highly-detailed STL files , you can always begin with making a benchy 3D printed boat. This famous testing object is available to all hobbyists for free.

10. 3D Printed Yacht

Companies do their best to introduce 3D printed yacht projects to customers all over the world. Some firms in New Zealand, Italia, and other countries work hard to produce boat parts and accessories via additive manufacturing.

The world would most likely soon see many 3D printed yacht models thanks to innovative firms that take full advantage of additive manufacturing today. We have already seen some 3D printing fishing boats and small sailboat AC9F to take part in America’s Cup.

What will come next?

If your 3D printer is not big enough to recreate a life-size 3D printed boat, you can always make a toy or test the simple benchy model. Make sure to join Gambody 3D Printing Community on Facebook to share photos of your new 3D prints. Hobbyists worldwide cannot wait to adore your next projects!

- Share Article:

Essential DnD Props: 3D Printed Dungeons and Dragons World Ideas

Newest Voxelab Aquila D1 3D Printer Unboxing & Review

May 3D Printed Figurines Pick of the Month

- --> NL --> EN --> Login/Signup -->