Refastening a Wooden Hull - Season 4, Episode 1 Now Available!

How to Build a Wooden Mast

A tapered, oval new york 32 spar from the original plans.

ISLA, New York 32 No.10 (of a total of 20), was thoroughly rebuilt last year by Buzzards Bay Yacht Services of Mattapoisett, Massachusetts. The job included a new mast, whose construction is detailed on the following pages.

W hen my company was hired to restore New York 32 No. 10, ISLA, in 2008, the boat had been out of service for over 25 years. The 20-boat New York 32 fleet was designed by Sparkman & Stephens in 1935 and built over the winter of 1935–36 by Henry B. Nevins of City Island, New York. When we found her, ISLA was a virtual time capsule, with an intact original interior and a complete set of original hardware. But the hull and deck were tired, to say the least, and the spars were beyond repair. So, included in the work list were a new mast and boom.

The New York 32 carries a hollow, oval mast measuring 63′ 5″. The owners were committed to maintaining ISLA’s originality, so we acquired the original spar drawings from the S&S plan collection at Mystic Seaport. These included ample detail: spreaders, tangs, boom, and masthead, along with the overall mast plan. The following steps describe how we turned those drawings into a new mast for ISLA.

Ordering and Preparing Lumber ISLA’s mast is built of Sitka spruce, which has long been prized by sparmakers for its long, clear lengths, light weight, and impressive strength for that weight. From the plans we developed a lumber list for the mast, boom, and spreaders. While it is still possible to acquire excellent-quality Sitka spruce, it takes some searching and a keen eye for defects. We required at least 12/4 stock to fashion the forward and after staves.

For spars, it’s imperative that the wood be dry (below 15 percent moisture content) and free of defects. The grain must be vertical. Our first attempt to procure lumber for this mast resulted in us receiving a batch of 12/4 Sitka spruce that was case-hardened. It was dry to both the touch and to the moisture meter, but once milled and its center exposed, its moisture content went off the scale. When we tried to rip it on the tablesaw, it pinched the saw’s blade and stopped the saw. We replaced that batch of wood with properly dried material, and learned a lesson in the process.

We ran the rough-sawn boards we had purchased through the thickness planer to take “fur” off of each one, allowing for a better inspection of the surface of the wood. When doing so, we kept in mind the minimum thickness of the staves, so we wouldn’t carelessly plane off too much. With this done, we examined each board, measuring its usable portion, marking visible defects, and labeling each piece for its intended location in the mast. A board with tight grain is slightly denser and thus heavier than one with wider ring spacing; we strived to locate these heavier pieces toward the bottom of the spar. If another board had slight grain runout, we’d consider using it in the mast’s heel where it is under less stress and is backed by solid blocking. It’s also important to keep in mind the locations of the scarfs when selecting the lengths of stock that will compose each stave, for the scarfs must be staggered.

Utilizing the Drawing

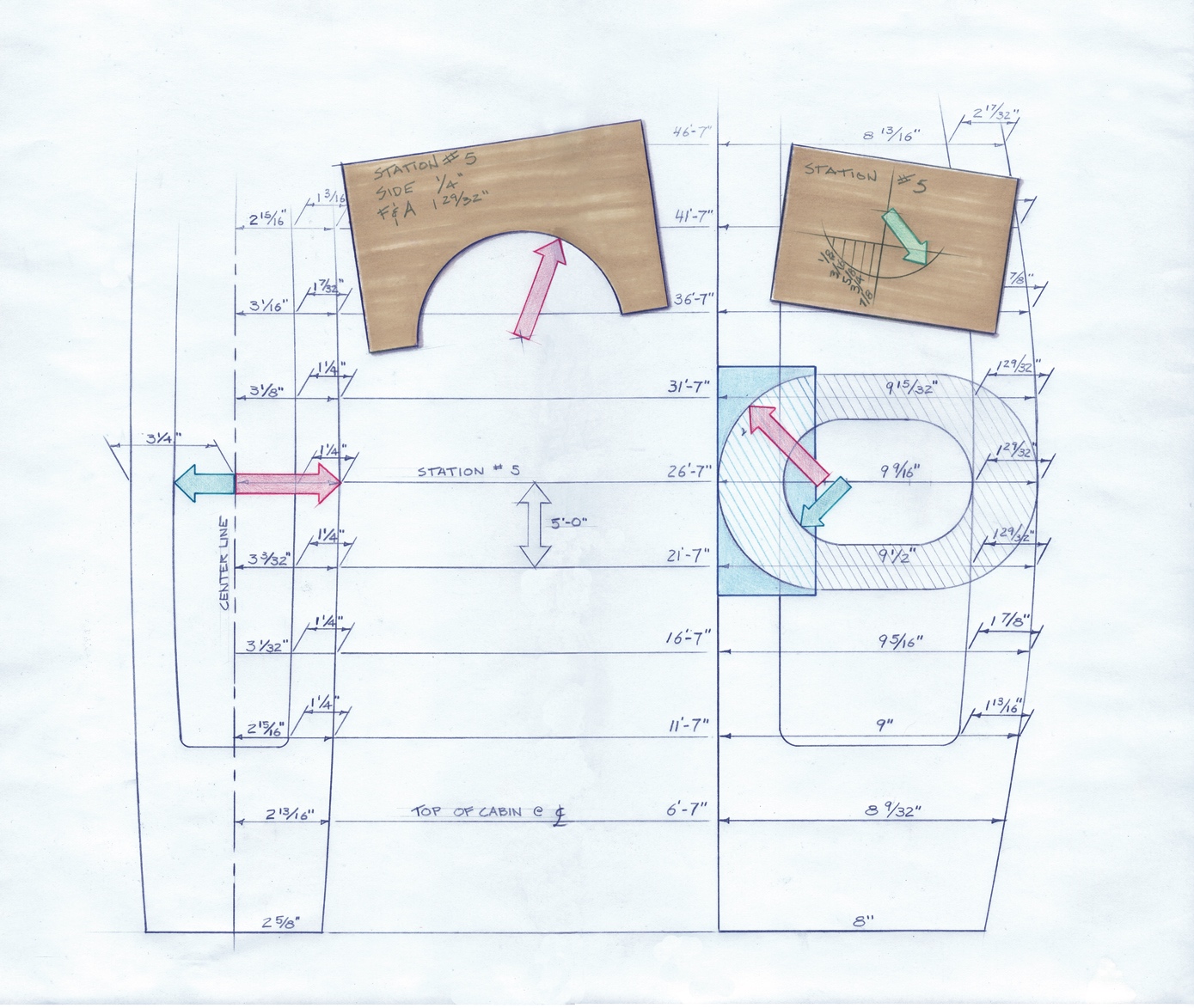

The drawing shown here is an illustration of the original Sparkman & Stephens mast plan for the New York 32, whose vertical scale was compressed in order to fit the mast’s dimensions onto a single sheet of paper. From the drawing we created a table of offsets for the mast. To do this we drew a series of stations, 5′ apart, perpendicular to the mast’s centerline. We did this for both the side and forward views of the mast.

The drawing shown here is an illustration of the original Sparkman & Stephens mast plan for the New York 32

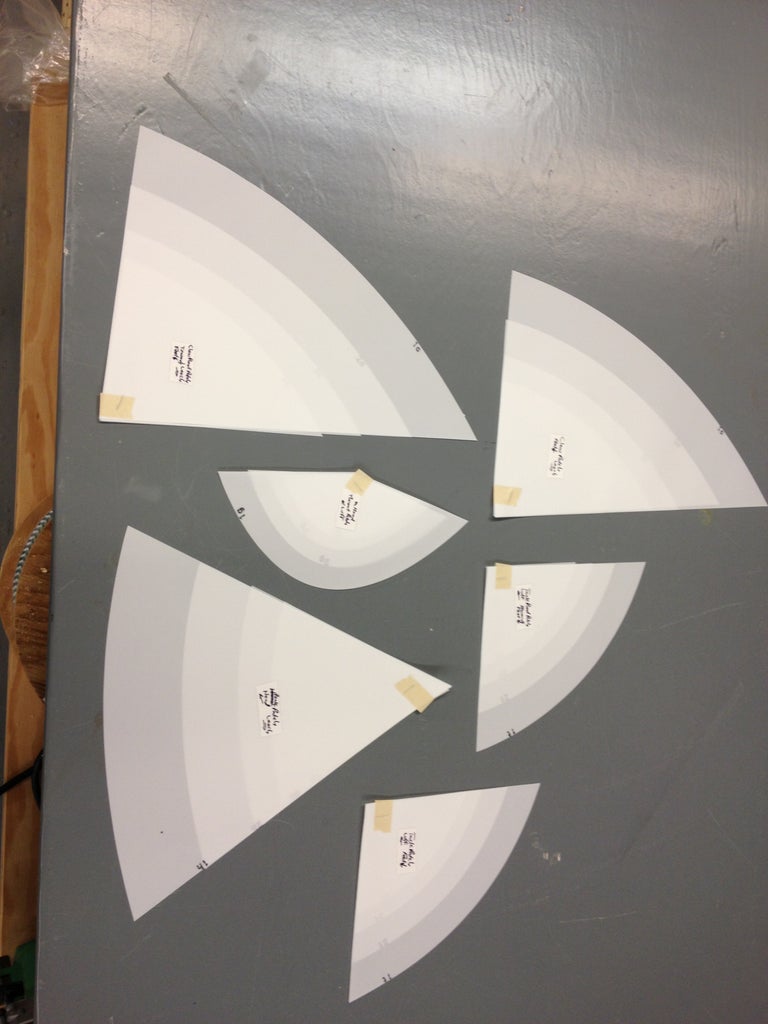

For the forward and after staves, we recorded the overall thickness of the stave (that is, its thickness before hollowing) and its half width. For the side staves, we recorded the thickness and width at each station. We converted the mast plan drawing from 32nds of an inch to decimal units, which I find best when working to close tolerances using digital calipers. We then made up 10″ × 10″ lauan templates on which to draw the sectional shape of the mast at each station. Since the forward and after profiles are arcs of a circle, we transferred these shapes from the drawing to the lauan with the aid of a compass. After each shape was transferred we cut out these lauan templates with a bandsaw. On each template, we also recorded the sidewall thickness, forward and after wall thicknesses, and distance from the heel of the mast. Building this New York 32 mast as was done originally requires hollowing out the thick forward and after staves in order to lighten their weight. So, once again using the mast plan, we made templates for the mast’s inside shape at each section.

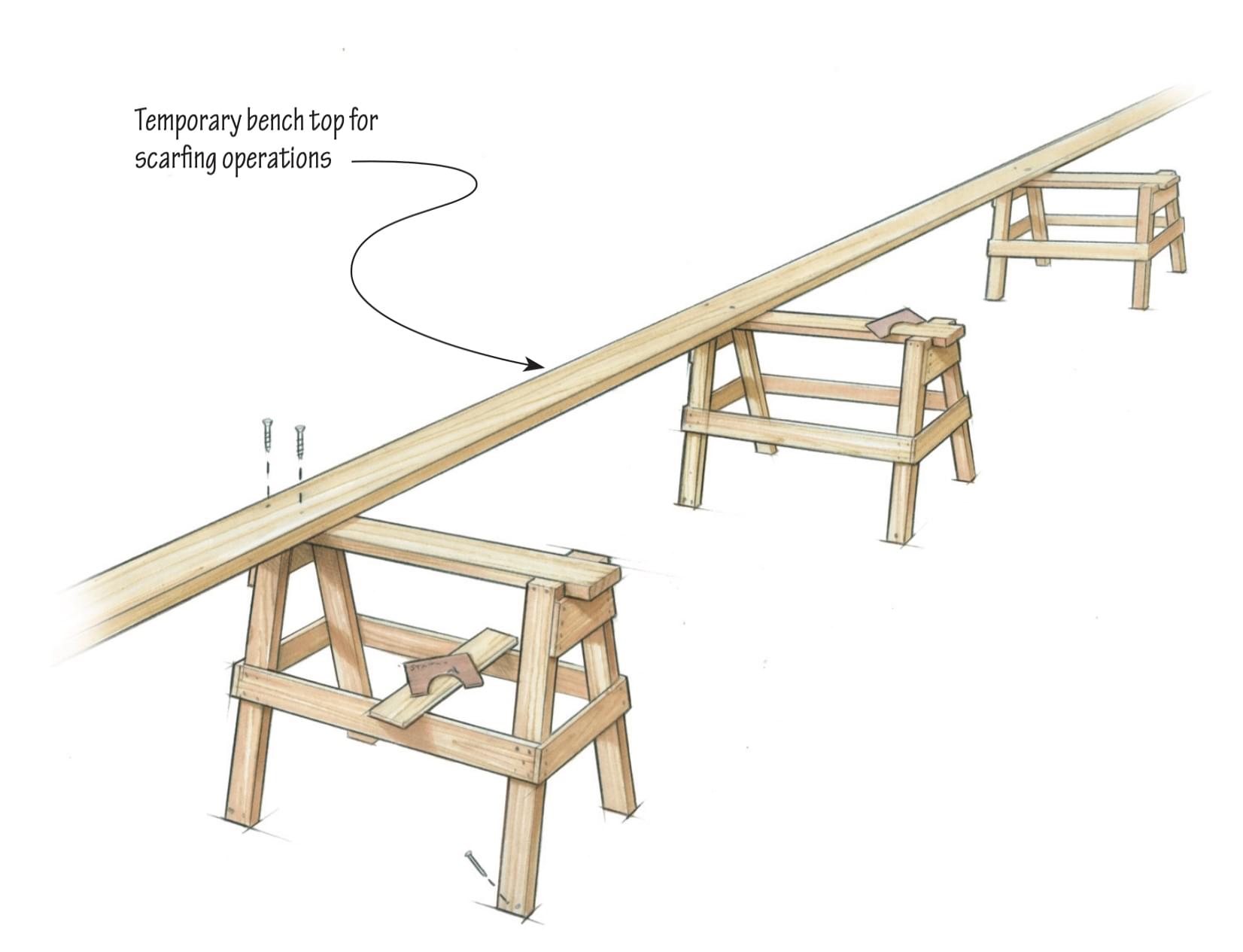

The Spar Bench

The first step in building the mast is to construct a spar bench. We wanted a sturdy bench that was straight and set at a good working height. Typically, a spar bench comprises a series of sturdy sawhorses spaced 5′ apart and fastened securely to the shop floor. Identical wooden sawhorses work well for this; once they were secured to the floor, a mason’s string was run to assure that the tops were all in the same plane; the tops were then shimmed as needed to achieve this. The 2 × 10 plank seen here being screwed to the sawhorses is to support the staves during the scarfing operation, and will later be removed.

Gluing Up Full-Length Staves

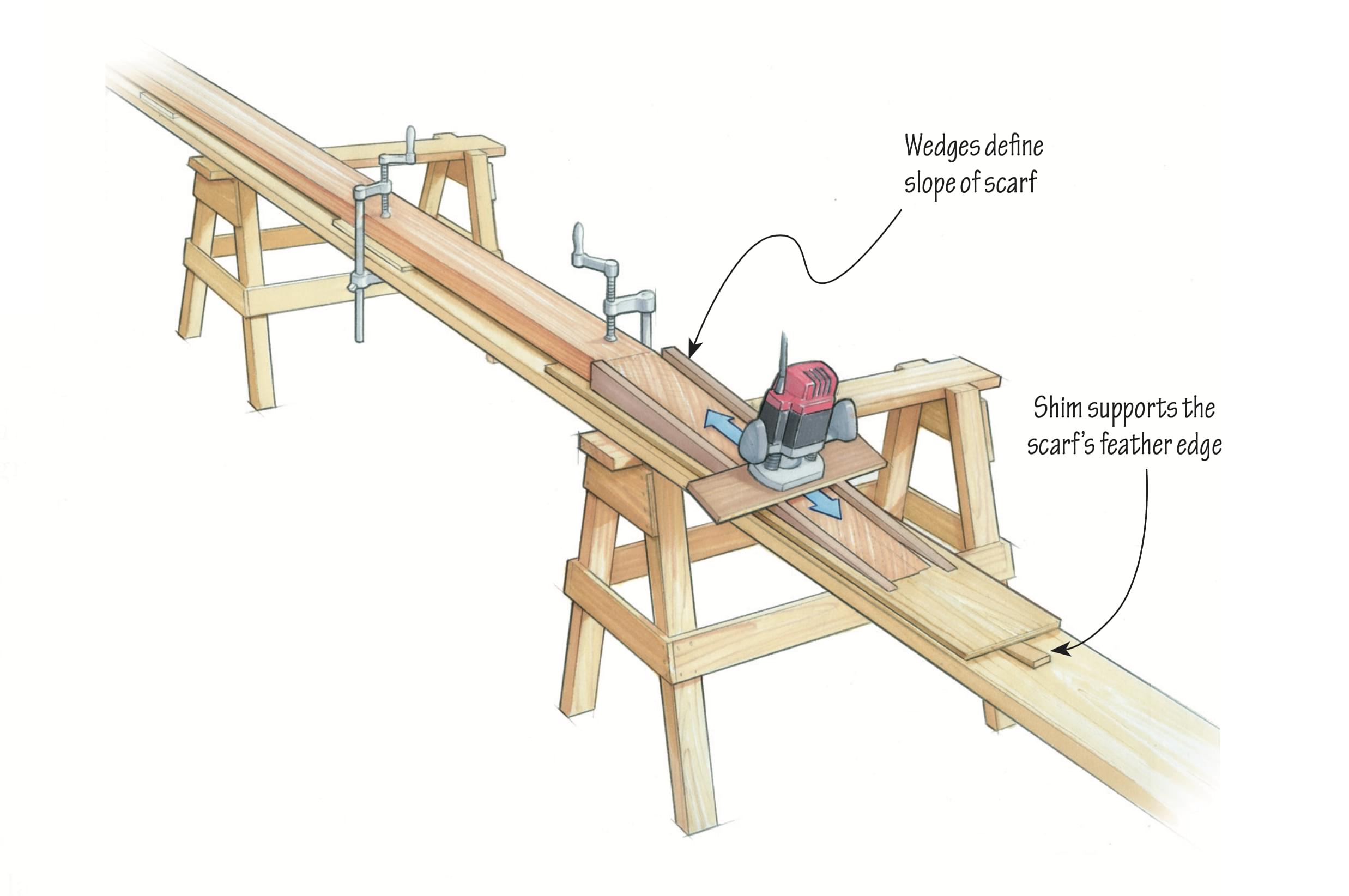

On our nice, solid bench, we laid out the wood for each of the mast’s four staves end-to-end and developed a final scarf plan. We planed the stock to the maximum designed thickness for the forward and after staves (2.875″) and for the side staves (1.25″). Then we scarfed the stock together to create the full-length staves. Careful layout and labeling were required for this step. We examined the stock and put the most visually pleasing sides facing out, and we spread out the scarf locations to avoid clustering them. Scarfs were cut to a slope of 12 to 1, with their lines drawn onto the edges of each piece. They were rough-cut on the bandsaw, and then finished with a jig and a router. With the scarfs cut, we assembled the pieces dry and ran a string down each of their centerlines to confirm that each of the four full-length staves, once glued, would be straight.

When we were certain that the staves would be straight and true, we screwed blocks to the spar bench to chock them in place. The individual pieces could then be removed from the bench, turned over for gluing, and placed back in their precise positions. The final step in preparing the scarf for epoxy glue was to rough up the surface of the glue joint. Eighty-grit sandpaper backed by a long block works well for this, as does the technique we used: a Japanese pull saw drawn across the grain so its teeth combed the surface. (This process is for epoxy gluing only; resorcinol and other glues rely on smooth mating surfaces.)

Once the surface was roughed up, we vacuumed both faces of the joint and then wiped them with a clean rag and denatured alcohol until the rags came up clean. We then wet out both gluing surfaces with straight epoxy and allowed that to stand for several minutes while it penetrated the wood. Dry spots were wetted a second time. We then applied epoxy thickened with colloidal silica to one face of the joint. Using large bar clamps and modest pressure, we clamped the joints, making sure we had a nice, even glue squeeze-out.

Tapering the Staves

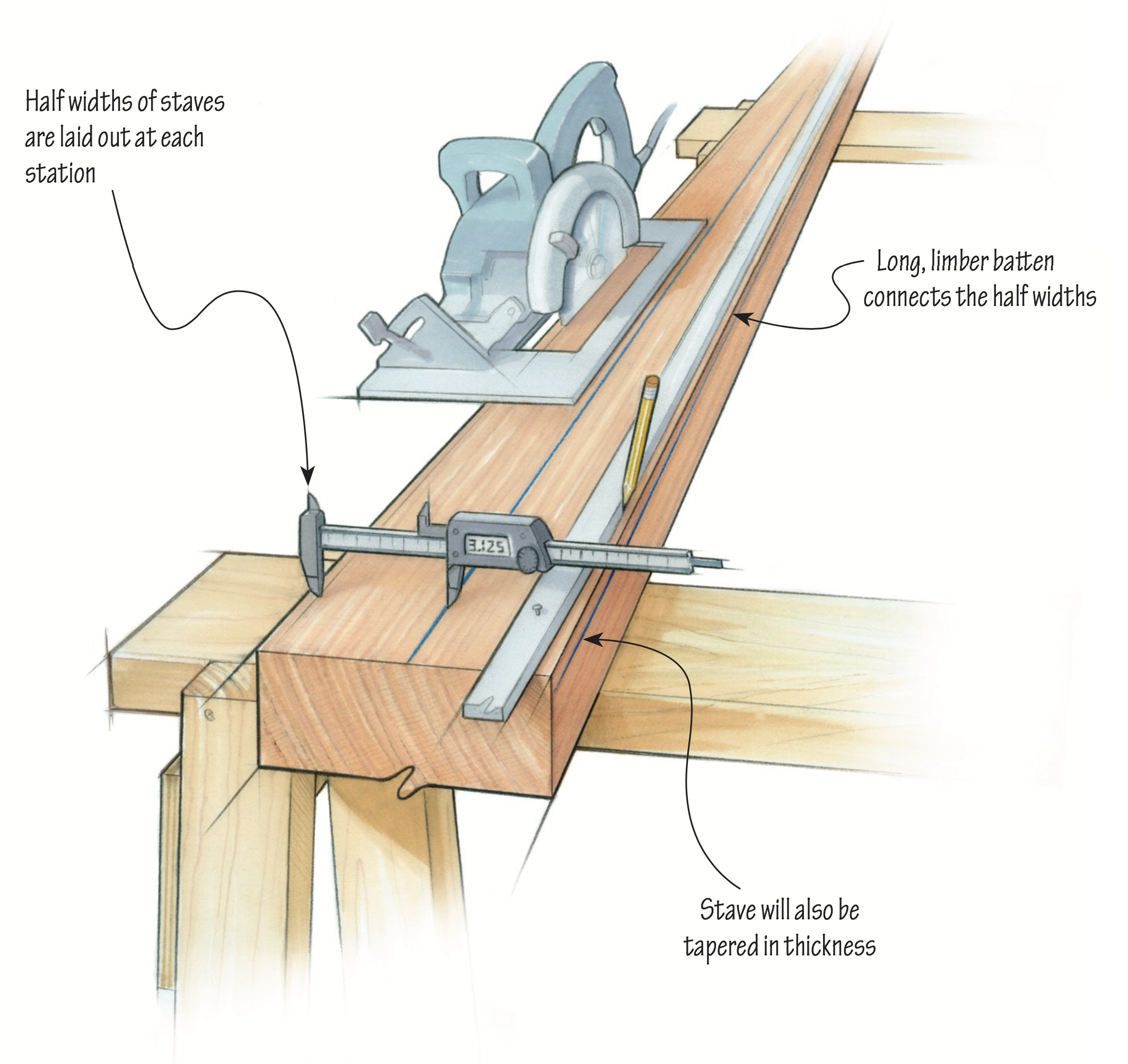

Once the staves were glued full-length, we selected the aft stave, blocked it straight on the spar bench, and snapped a centerline. Then, using the information from the lauan templates and the offset table, the points representing the stave’s profile were laid out and connected with a long, limber batten. One of the side staves was marked similarly.

We rough-cut the profiles with a worm-drive circular saw being careful to leave the lines intact. We then cut closer with a power plane, and then shaved precisely to the lines with an appropriate hand plane, making sure that the edges stayed perfectly square. With one stave of each profile now complete, we used each as a template for its mirroring stave, making the final cuts with a router and bearing bit to complete the second pair of staves.

To minimize weight aloft, the wall thickness diminishes as we progress up the mast. Once again we turned to the lauan templates on which we’d recorded the wall thickness at each station. Using digital calipers, we recorded on both edges of each stave the wall thickness at each station and connected the dots with our long batten.

This line, yet to be cut, is shown in the drawing. The stock was removed from the outside faces of the staves, the bulk of it with a power plane. The final cleanup was completed with a bench plane.

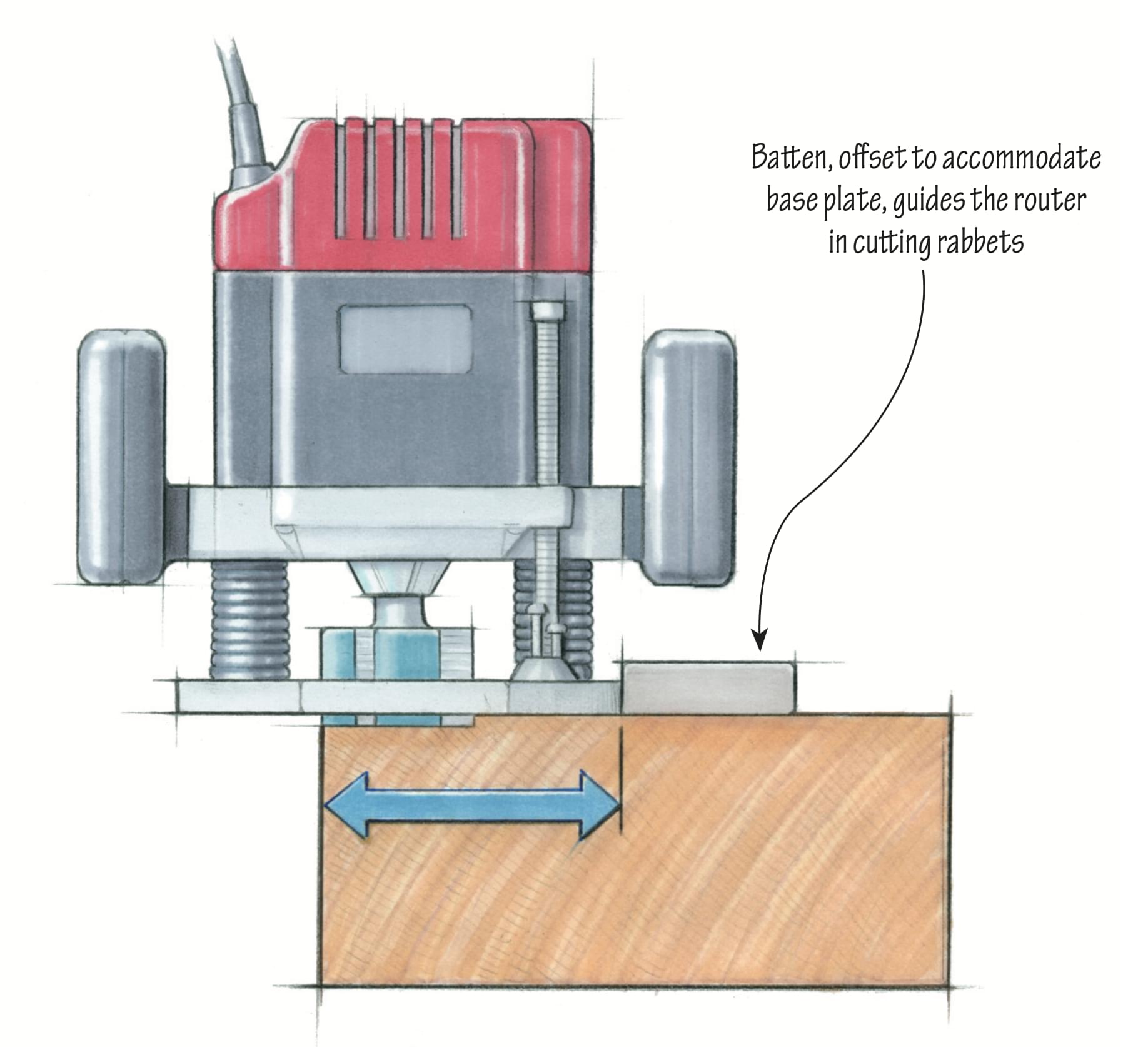

Rabbeting the Forward and After Staves

Hollowing the Forward and After Stave

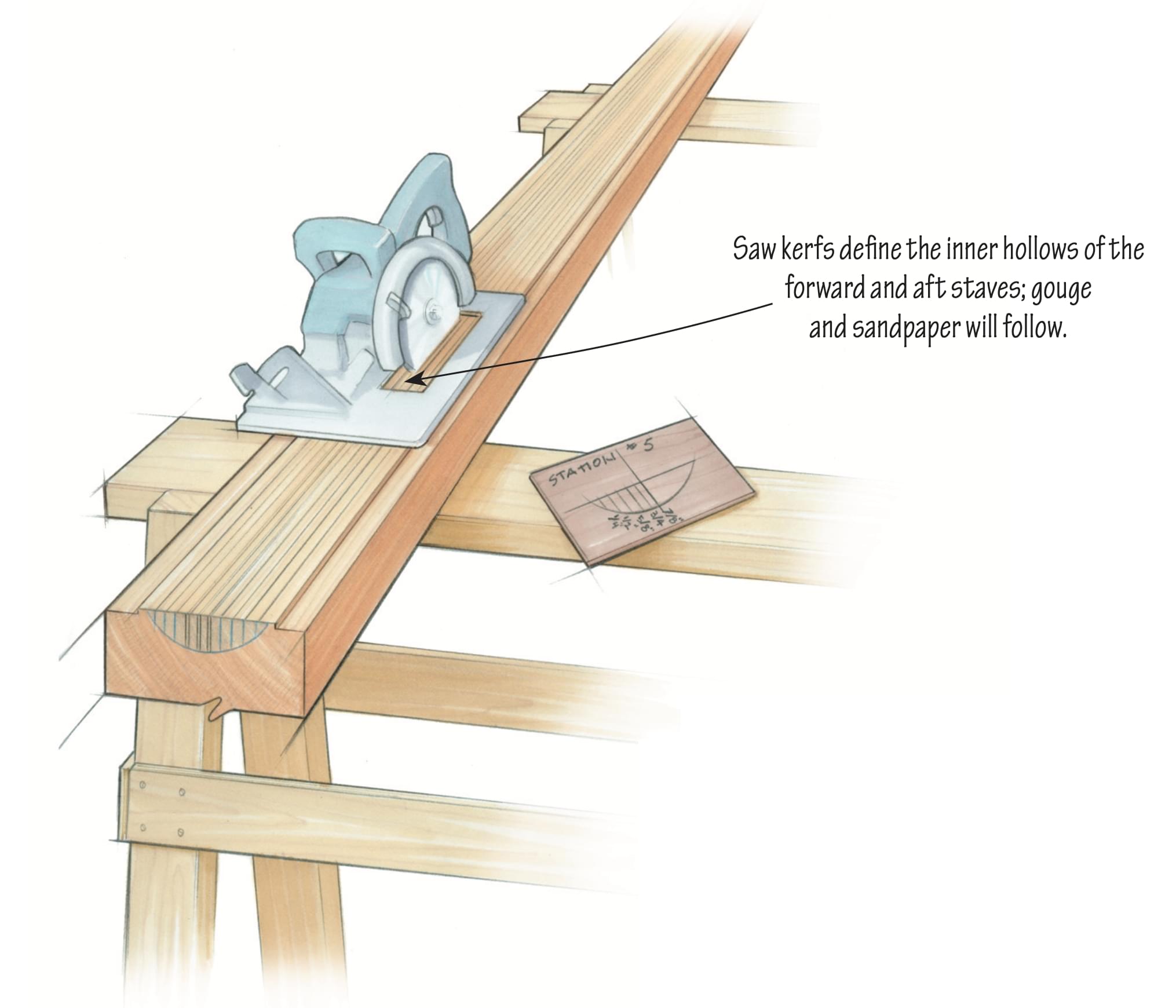

The final step before gluing the staves together was to hollow out the forward and after staves. On the lauan templates we referred to the inside profile shapes we had recorded from the mast drawing. Dividing the inside profile into 1⁄4″ sections, we measured and recorded the depth at each section. We did this at each station. The inside face of the stave was thus lined off in 1⁄4″ increments.

Then, using a circular saw set at the depth indicated by the lauan template, we cut kerfs in the inside face of the stave. With each pass of the saw, we reduced the depth of the cut as we moved toward the masthead and farther from the center of the stave. With the kerfs completed, we used a gouge to scoop out the waste. We arrived at the final shape by using a backing-out plane followed by 80-grit sandpaper on a round sanding block.

With the staves cut to their profiles and tapered in thickness, and the forward and after staves rabbeted and hollowed, we double checked that the spar bench was still straight. The next step was to lay the after stave on the bench, sail-track side down, and hold it straight with blocks screwed to the bench so the spar could not move. We then did a final dry-fit of the three remaining staves to make sure all joints were tight.

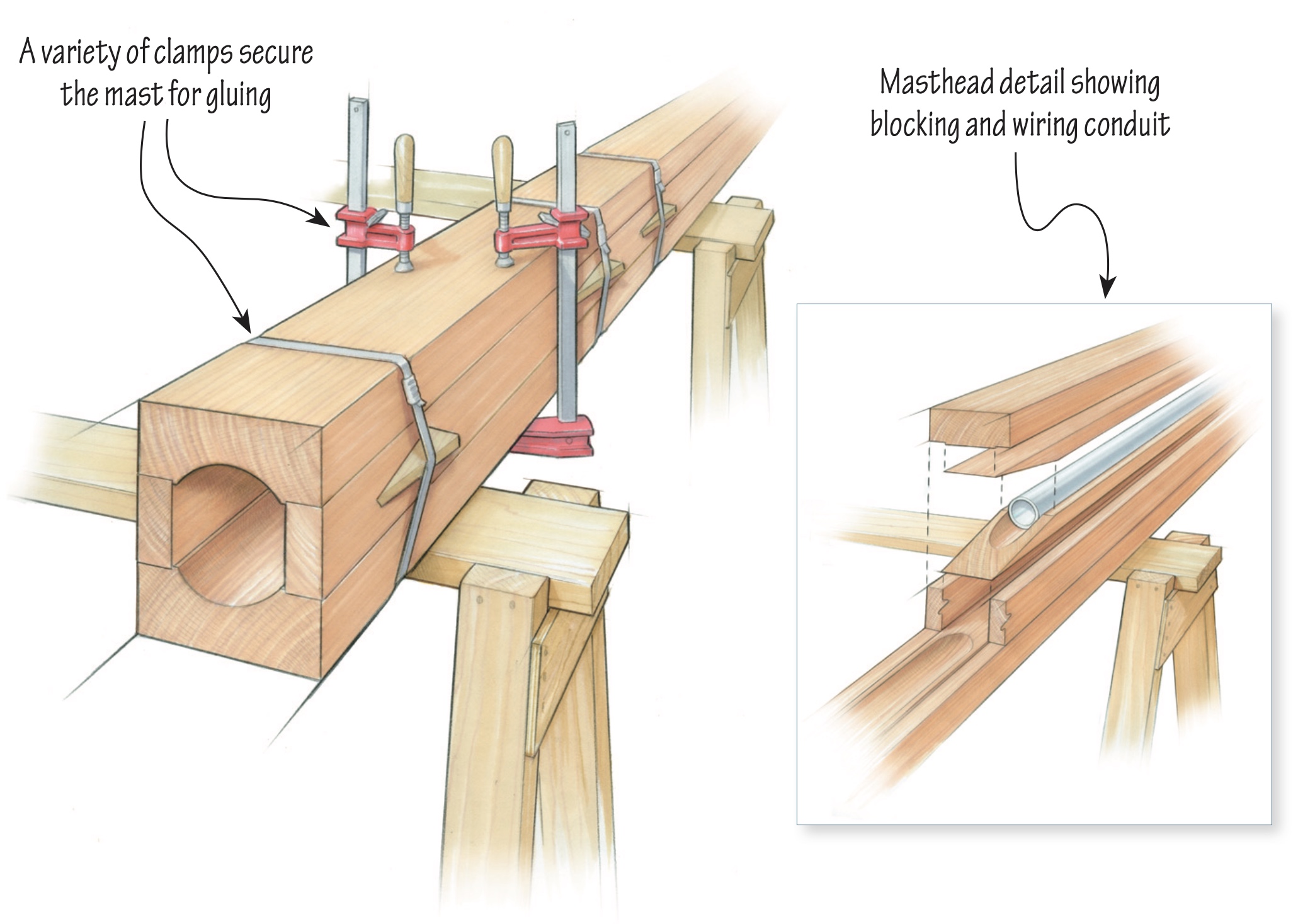

When satisfied with the bench and the joints, we began mixing glue. A large spar such as this takes about four people to glue up; any fewer, and panic would certainly ensue. The glue-up seems to work best as a two-step process. The first step was to glue the side staves to the after stave, using the forward stave as a dry-fitted guide to ensure that the side staves remained parallel. We clamped the spar in 1′ increments, checking that it remained square along its entire length. Using the two-step process allows ample time to fit and install the solid blocking at the head and heel of the mast. The drawing calls for blocking in the bottom 11′ of the spar and in the top 2′ 6″.

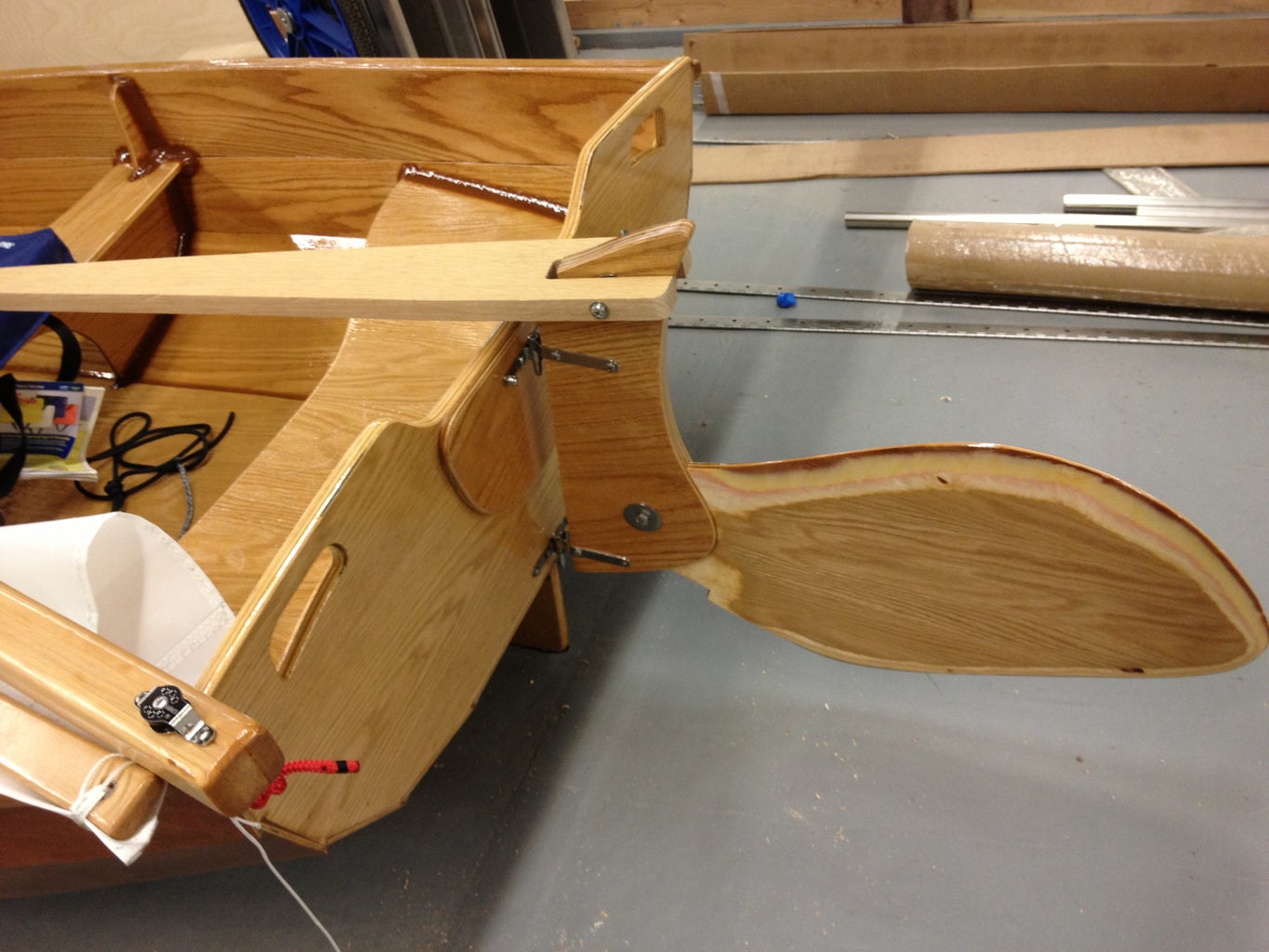

The blocking is solid until about the final foot, where it tapers to a feather edge on either side of the spar, forming a swallow-tail shape to avoid a hard spot. This heel blocking has a drain hole, in case of water intrusion. There is no blocking at the spreaders; instead, the spreaders have an external bracket and blocking system that transfers the load evenly to the spar.

We coated all interior surfaces with epoxy. At this stage, we also ran all of the wires inside the mast, securing them with large cable clamps. (Conduit fastened securely along the interior of the spar—and through the blocking—works well for this, too.) When everything was satisfactory inside the mast, the forward stave was glued to the side staves to cap the assembly. Several varieties of clamps can be used when gluing up a spar: spar clamps, bar clamps, C-clamps, or a banding tool. We used a combination of clamps and a banding tool supplemented with wedges to further tension the plastic band.

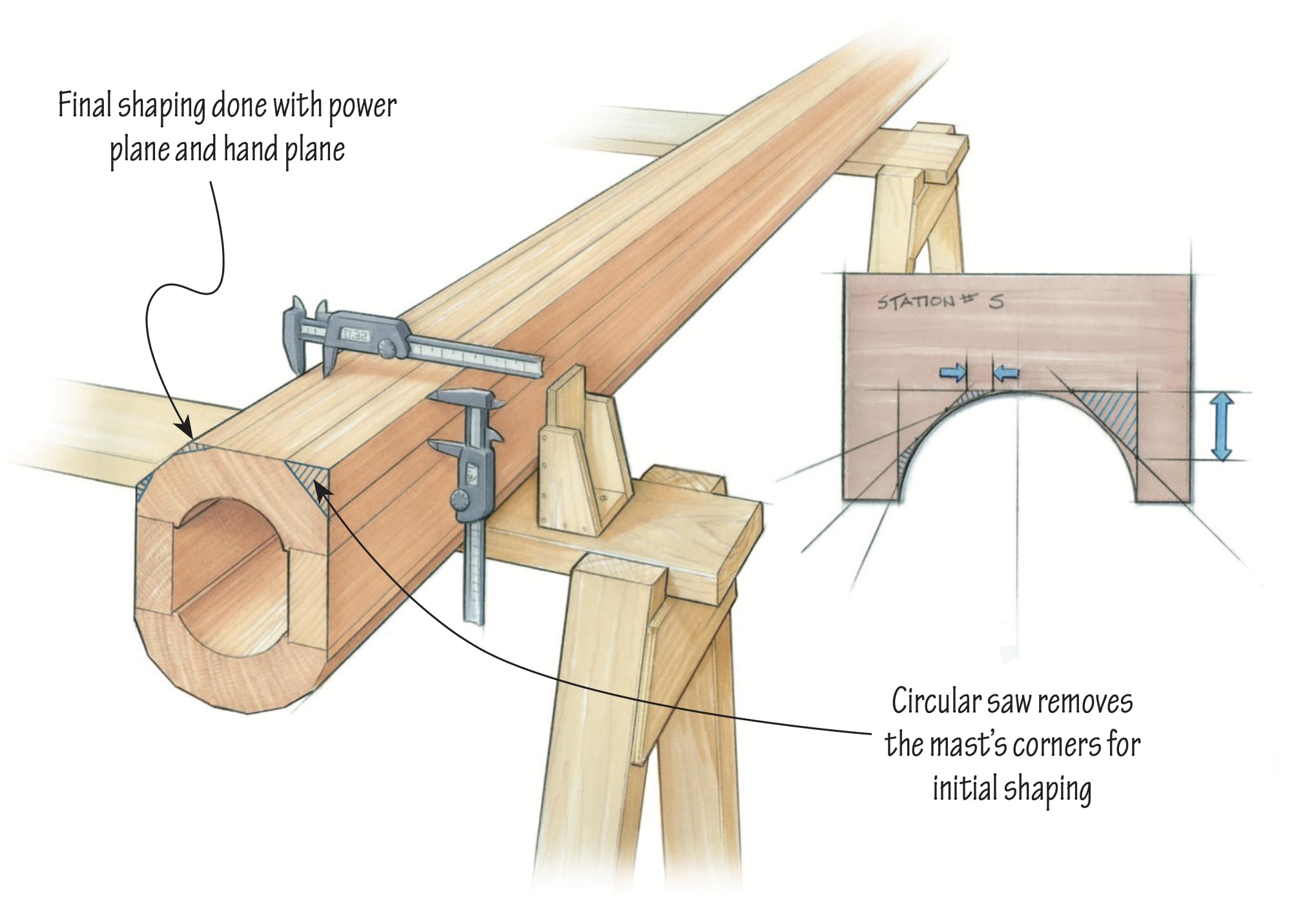

With the glue cured and the clamps off, it was time to begin the shaping process. The first step was to plane off the excess glue. With that done, we again turned to our handy lauan templates and began the process of eight-siding the spar. Using the exterior cross-section drawn on each template, we found where a 45-degree line would be tangent to the mast’s outside surface at each station. We transferred these points to the spar, and with the long batten connected them with fair lines.

We then set our circular saw to 45 degrees and made a cut, just leaving the line. Repeating this on all four sides of the mast, and then fairing up the saw cuts with a power plane followed by a hand plane, yielded an eight-sided spar. We then lined the spar off again to 16 sides, but this time we omitted the circular saw and removed the waste with only a power plane. When we had the spar 16-sided, we finished the rounding and fairing with hand planes and a custom-built concave fairing board. Once again our lauan templates came into play, as we used them to confirm the correct shape at each station. Two other details that had to be considered at this stage were the shape of the heel of the spar, and the masthead detail.

With the mast now shaped and sanded, we broke out the varnish and applied 10 coats before installing the track and hardware. We were fortunate to have all of the original tangs and other fittings for this spar, because fabricating them would have required quite a bit more work. With the spar varnished the hardware was installed, carefully bedded in soft compound. We were very careful in fastening into the Sitka spruce, as it is quite soft. We chose machine screws rather than wood screws for mounting the winches and the boom gooseneck track—after testing these fastenings on offcuts to find the best pilot-hole diameters.

This article was originally published in WoodenBoat No. 214, May/June 2010.

Related Articles

Marine plywood – a consumers guide, applying gold leaf to lettering, sheathing a plywood deck, building a classically inspired ship’s wheel, related videos, making a bird’s mouth hollow spar , the abcs of wooden spar construction, making a stem, reading boat plans, related book chapters, fitting bulkheads, laying down, subscribe for full access.

Flipbooks are available to paid subscribers only. Subscribe now or log in for access.

- For Sale/Wanted

- Readers Tips

- Your Yarns.

- Restoration

- Miscellaneous

- DIY Boat Yards

- Boat Building

- Cabin Cruisers

- Free Boat Plans

- Begin Boating

- Boating Terms

- Ropes and Rigs

- Just for Fun

- Celestial Navigation

- Passage Planning

- VHF Marine Radio

- Sailing Rigs

Wooden Mast and Spar Building

A mast or spar made from wood not only looks and feels good but it also takes advantage of the naturally ability that trees have developed over the centuries for creating a tall, strong, flexible pole.

Those tall straight pine and fir trees are able to grow to such heights and survive in wind storms because their natural elasticity absorbs the shock loads caused by gusting winds.

Structural Considerations

Solid/grown spars, rounding the square.

- Built Spars

- Your comments and suggestions

There are several reasons why soft woods are the chosen type of timber used in the making of masts and spars.

The first and most obvious is that so any soft wood trees grow exceedingly tall and straight.

And because they have grown so tall and straight they have developed the ‘elasticity’ to withstand all that the elements can throw at them.

Soft woods are also more likely to be lighter in weight.

Sitka Spruce (Silver, Tideland or Menzies Spruce) has long been the top choice for mast builders.

However many other spars have been built using whatever light, straight-grained wood was available, such as those shown below.

- Douglas fir (British Columbian, Oregon, Idaho, Red, pine also known as Red or Yellow fir)

- Scots pine (European redwood, Northern pine, Red pine, Redwood, Scots fir, Norway fir, Swedish fir, Finish fir)

- Port Orford cedar (Oregon cedar, White cedar, Ginger pine, Lawson’s cypress)

When choosing a timber look for one that is as light and straight grained as possible with, hopefully few knots.

However, a few small ones knots can be acceptable.

The timber should ideally be seasoned, especially if you are building a hollow spar.

I have heard of solid masts being made from green poles.

But green timber is more likely to develop shakes and will be less able to absorb any preservative, oil, varnish or whatever you use as a finish.

A mast/spar needs both strength and stiffness and be able to resist fatigue.

Sometimes these characteristics can be conflicting.

Strength or resistance to breaking in wood involves its elasticity which allows the wood to bend to absorb stresses.

Whereas stiffness is the resistance to bending.

All spars need to be able to absorb the shock of a gust which the wood absorbs by bending but too much bend will spoil the sail shape so a happy compromise is needed.

And stresses will differ depending on the types of rig and whether the mast keel stepped, deck stepped or in a tabernacle.

Another consideration is weight aloft.

Keeping weight within reasonable bounds is just one of the reasons for using soft woods.

It is also one reason for building a hollow mast.

However, most spars taper towards the top, as the diameter becomes smaller so the weight becomes less.

For the average cruising yacht the weight differences between a solid and a hollow spar are hardly significant.

The other advantage of the hollow, built spar is that it can be made from easily available timber sizes, and with a minimum of waste.

The simplest, easiest and least wasteful spars are produced from ‘grown’ timbers.

I theory it should be possible to acquire a trunk which has the length and taper needed for your spar.

In practice you will have to do some shaping, tapering and rounding.

While traditionally masts and spars were spherical, they don’t have to be.

However, in my opinion a spherical mast will produce the least turbulence to the air passing over the rig.

It is possible to make a spherical spar from one piece of square cross-section timber.

However, it will be much easier to source timers of smaller cross-section and then build the spar up from them.

And the advantage is that the grain can then be arranged in a radial fashion.

Building a spar from separate parts does require very careful attention to the gluing surfaces, they must be closely mating and the actual gluing must be precise.

If you are confident in your carpentry and gluing skills, short lengths can be scarffed to produce the required length.

Scarf joints are best at least ten times the thickness of the piece and when the various pieces are assembled the joints should be staggered.

And remember to never ever cut a piece of wood to its exact length until you absolutely have to.

First determine the required diameter of your spar and then where you want your it to taper and by how much.

This will depend on the design of you rig.

You may want the spar to have no taper for some of its length/height, to just above the partners, then have a slight taper, perhaps as far as the spreaders, then a bit more of a taper up to the truck.

Always best to start with the wood a little wider, thicker, and longer than the finished dimensions.

Plane one surface flat and level with your longest plane, preferably a jointer.

Then mark the center line on this planed face.

Use a string stretched between tacks in the middle of each end, use this to make several center marks on the timber.

Then join the marks using a long, straight batten.

Repeat on the opposite face.

Now use the centreline as the datum from which to mark the width of your mast at intervals along its length.

Then back to the batten to connect these marks.

You can now cut the outline of your mast to this drawn profile but cut it oversized as you still need to plane the timer square.

Now plane these two sawn, tapered faces flat and square to the original planed surface.

Repeat the steps for marking the center line and profile on these two new faces.

Cut this outline and plane these sides flat and square to their adjacent sides.

You now have a spar tapered to your requirement but it is still square in cross-section.

Now you need to start rounding the square.

So now you’ve got a nicely tapered, planed but square, four sided spar.

Next job is to plane off the four corners to give you an eight sided spar.

Then plane off those eight corners to give you a sixteen sided spar, which can then easily be rounded using sandpaper.

But before you start taking off the corners you need to mark the depth of the bevels.

The simple way is to draw a circle on the face of the timber with a compass.

The center of the circle will be on the centreline and the edge of the circle right on the edge of the face.

Then draw a line from the center of the circle, at 45 degree to the centreline and mark where it crosses the circle.

This mark is the edge of the bevel.

Do this for every transition point and as many points in between as possible, the more the merrier and do it foe both sides of the circle.

These marks can then be joined using your batten.

One you have planed the spar down to eight sides you can use the same method to mark it up for reducing it to sixteen sides.

But now the line from the center of the circle to the circumference needs to be 67 ½ degrees.

Now unless you are building a massive spar getting from 16 sides to 32 sides using the above measuring technique is going to become fiddly.

At this stage it is quicker to use your eye and your judgment to plane off the remaining corners.

Then the final rounding can be done by sanding.

Start with 60 or 80 grit paper for the initial shaping, then work the grits for finishing.

Use long strips of sandpaper wrapped around the spar and pull it backwards and forwards in a long, spiralling motion.

Occasionally sand along the length of the mast to help fair out any uneven spots.

Here is an easy way to mark out a tapered octagon using only one setting of your compass.

Building a spar is obviously much more difficult than simply shaping a solid pole.

However, if a pole of the required dimensions is not available building the spar might be the only option.

Built spars can be either solid or hollow.

But if you are building one it is relatively simple to make it hollow and thus save weight aloft and create a central channel for masthead wiring.

Building a simple cylindrical spar as those shown above from ‘square’ timbers does require wasting quite a lot of that expensive wood when 'rounding the square'.

One can build an almost waste free hollow spar which would suit a conventional bermudan rig.

However, a ‘square’ section with rounded corners such as this would be unsuitable for any rig which uses mast hoops or parrel beads or a lug rig where the spar turns against the mast.

The next problem when creating a hollow spar is that unlike the solid mast the taper cannot be created afterwards.

Any taper to the finished spar needs to be cut from the staves before they are assembled.

There have been several configurations used to increase the gluing areas across the width of built staves.

And several configurations which attempt to reduce wastage and at the same time produce large gluing surfaces.

Unfortunately while they will produce superb, strong spars they call for increasingly complex carpentry.

The ‘Birdsmouth’ technique developed by Nobles of Bristol UK is perhaps one of the most successful of these techniques.

However, it is a technique which really requires access to woodworking machinery, such as profiling and planing machines.

Setting up your standing rigging can be greatly simplified by using ‘Spectra’.

‘Spectra’ is virtually stretch free and can be tied off without much weakening.

It offers a real alternative to expensive swaged fittings, can be easily maintained and it is corrosion-free.

Previous posts

See What Others Have Posted

Recent Articles

Wooden Boat Events 2024

Apr 14, 24 05:15 AM

You might like these

Plywood and Veneer Guide for Marine use.

A guide to plywood for boat building and why you should use the best marine grade you can afford.

DIY Woodboat Building Questions

Woodboat building questions a Forum for wooden boat building, plans, lumber, caulking compounds and other boat building problems.

Boat Books for Wooden Boat Builders

Boat Books a series of boat books based on some of the 1960's, classic, Free Boat Plans that were published in magazines such as "Popular Mechanics", "Popular Science" and the "Boat Builder Handbook".

Build a Boat, tips for the DIY Wooden Boat Builder.

How to Build a Boat, Wooden Boat Building methods for the DIY, backyard, self-builders explained, carvel, lapstrake and plywood

Clench Nails, Fastening for Small Wooden Boats.

How to use Clench Nails, these provide a fast reliable method for fastening small wooden boats.

Wood Screws for Boat Building and Repair.

Wood Screws are the most widely used and versatile fasteners used on wooden boats. Which type to use and how to use them

Timber, Lumber for Boat Building.

A brief description of the most common Timber used for building Wooden Boats how to choose wood for your project boat

Timber Properties

A brief guide to timber properties and wood, characteristics such as strength, stiffness and elasticity for choosing lumber for wooden boat building and restoration.

Rivets and Copper Rove Wood Boat Fastenings.

How to use Copper Rivets and Roves construction guide to fasteners on your wooden boat.

Ring Nails for Marine Fastening.

Ring Nails sometimes call Gripfast or ring shank, silicon bronze boat nails are renowned for their holding power. but how to get them out?

14’ 1956 Chris Craft, side rail how should it be attached?

Apr 12, 24 03:38 AM

How to laminate plywood on the hull

Apr 10, 24 03:46 AM

The Dipping Lug Sail

The dipping lug sail, is perhaps the most efficient and cheapest, type of sailing rig especially for small sailboats however it isn't as handy as the standing lugger or the balanced lugsail.

UV Strip for Furling Sails

UV Strip, notes on repairing, fitting and replacing a sacrificial UV protection strip on furling sails using acrylic or UV protected Dacron.

Sailing Rigs, a Guide to Sail Shapes.

The basic shape of the Sailing Rigs most commonly found on wooden sailing boats of every size.

About sail cloth and the different materials for DIY sail making and the average leisure sailor.

Sail Balance

Notes on Sail Balance, designing a sailing rig, how set the relationship between the center of effort and the center of lateral resistance.

Lug Rigs for large and small sailboats.

Sailors have been using Lug Rigs for centuries because of their unique sailing abilities.

Junk Rig the ideal cruising sail.

How to rig a western version of the Chinese Junk Rig the basic lines and controls.

Junk Rig, How I Made My Own.

Junk Rig Sails How I built and rigged Mignonne with a Juk Sail

Junk Rig Conversion

Structural considerations for a Junk rig conversion of a wooden boat from bermudan rig to junk sail, where and how to site the mast.

Chinese Junk, the perfect cruising rig.

Chinese junk sail, why I rigged Mignonne with a Jukn Sail

Ropes and Rigs for Boating.

Boating ropes and rigs, knots, sailing, line handling and line care, what all boaters need to know.

Whipping Boat Ropes

Whipping marine ropes to prevent the ends fraying, how to use whipping twine to prevent rigging and yacht ropes from untwisting.

Splicing Three Strand Rope.

Splicing, tips and techniques, three strand eyes and rope ends, make your own dock lines why pay for something you can easily do yourself.

Rope types, what types, construction and materials to use on your boat when to use three strand and braided marine lines.

Knots for Sailors.

A brief description of and how to tie some of the most useful boating knots. Including some that every boater should know.

Handy Billy a traditional rope and sheave rig.

A Handy Billy made with two blocks and tackle can be used to give mechanical advantage wherever needed.

Blocks and Tackle lines and sheaves.

How Blocks and Tackle work to give mechanical advantage and how best to rig them.

Privacy Policy

Advertising Policy

Cookie Policy

I am perfectly aware that the majority of Wooden Boat aficionados are sensible folk. However, I need to point out that I am an amateur wooden boat enthusiast simply writing in order to try to help other amateur wooden boat enthusiasts. And while I take every care to ensure that the information in DIY Wood Boat.com is correct, anyone acting on the information on this website does so at their own risk.

May / June Issue No. 298 Preview Now

A “New” Method for Hollow Wooden Mast Construction

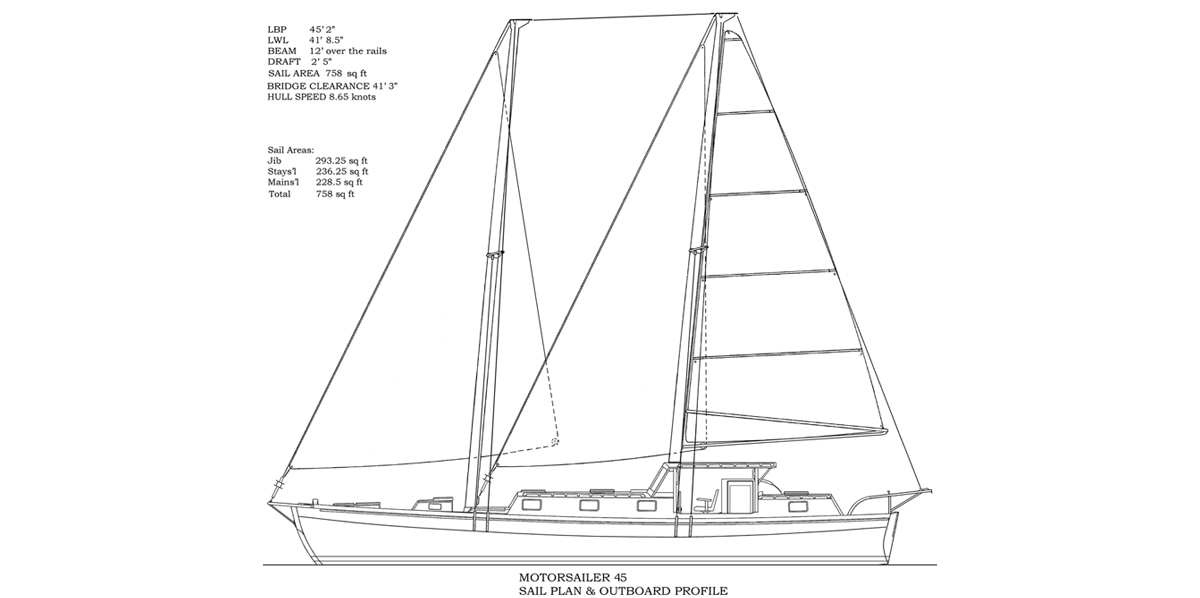

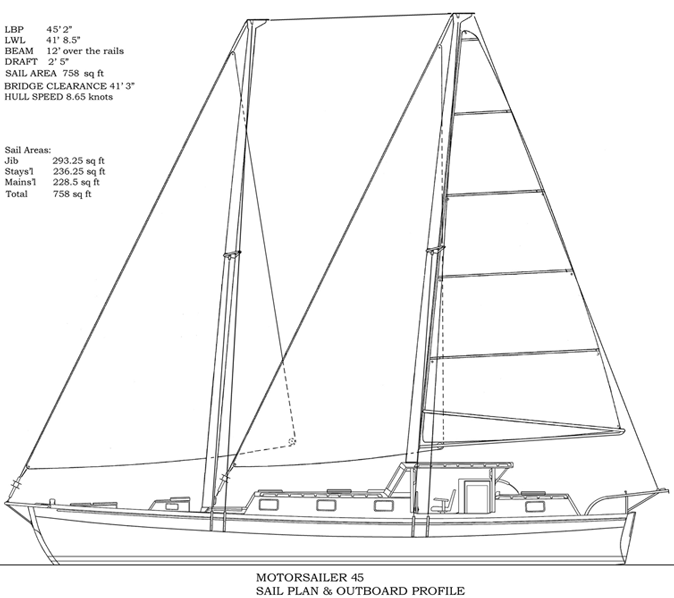

By reuel parker.

I have developed a “new” mast construction method for use on light- to moderate-displacement sailboats having a Marconi rig, and for motorsailers. I put “new” in quotes because I am sure it has been thought of before now.

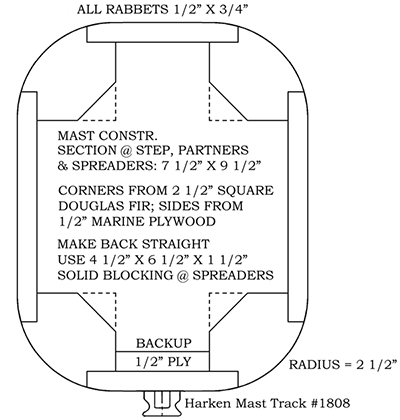

Mast Section from step to spreaders, 9 1/2″ x 7 1/2″ outside dimensions.

The four corners of the new construction sequence are all made identical in section, from Douglas fir or Sitka spruce 3″ x 3″ lumber. The corner pieces are rounded to a 2 1/2″ diameter radius, the inner corner is cut to a 45-degree bevel (to lighten the mast), and 1/2″ x 3/4″ rabbets are cut onto two corners to receive 1/2″ marine plywood front, back and sides. The corners are epoxy scarfed (8:1) full-height. They are identical in every location, greatly simplifying construction, as all corners are cut using a table saw set to the same settings. All mast taper is made on the plywood sides, back and front.

Construction uses epoxy glue and monel or stainless steel fasteners (staples, nails or screws) 6″ on center. With proper clamping, fasteners may be eliminated altogether.

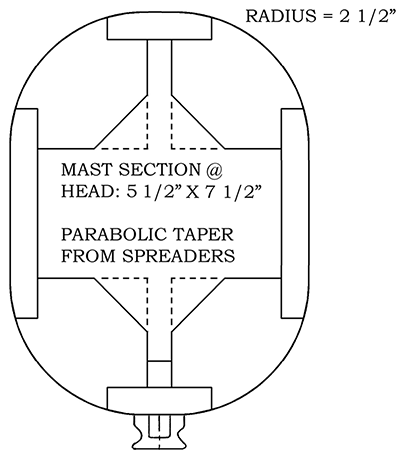

The mast section is uniform from step to spreaders (as shown above). Above the spreaders, mast section tapers parabolically to 5 1/2″ x 7 1/2″. If so desired, for further weight-savings aloft, the inside corners may be cut deeper, removing more material. Doing so will weaken the mast only very slightly.

Mast Section at Head is 5 1/2″ x 7 1/2″—taper is parabolic above spreaders.

All fore & aft mast taper is on the front only—the back of the mast is perfectly straight for its entire height unless built-in “pre-curve” is desired. [The purpose of pre-curve is to automatically flatten the sail chord for windward work as the sail is sheeted in.] A 1/2″ plywood backup block is installed inside the mast back to receive fasteners for the #1808 Harken track shown.

Plywood panels from step to spreaders are ripped on the table saw to uniform dimensions. Panels above the spreaders are ripped for parabolic taper (back edge straight for the sides). Front and back panels above the spreaders are ripped along both edges for taper. Plywood panels are scarfed 8::1. If desired, for greater durability, the mast may be wrapped in 4 oz Xynole-polyester fabric saturated with epoxy, with the seam located under the mast track (this will add weight). The inside of the mast is epoxy sealed. Wires (including lightning ground) are pulled in PVC pipe attached to a side panel prior to lay-up.

Note that in my drawings, the edges of the plywood are affected by the radii of the mast corners. When finishing shaping, the outer laminate will be abraded along the edges. Masts finished in this fashion will definitely require fabric/epoxy covering. You can avoid this by making the radius 2″ instead of 2 ½″, at the expense of a more “square” looking spar section.

For the nut-cases (I have been one) who insist on having varnished spars—make the corners (use the 2″ radius) and plywood from the same species wood; epoxy seal and apply 12 coats of varnish that has a good UV filter—I recommend using Douglas fir for the species. I generally prefer using epoxy primers covered with linear polyurethane topcoats—very durable—and almost no maintenance.

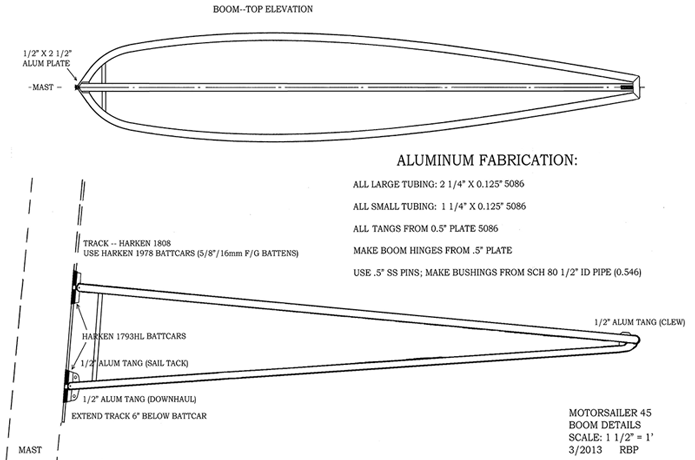

The Harken #1808 track shown uses “Battcars” designed to receive the forward ends of solid fiberglass full-length battens. The only sail cars necessary are one for each batten, and reef points are located immediately below each of the lowest three battens. This simplifies sail construction and cost, and simplifies reefing, especially when used in concert with my Basket Boom, which contains the reefed portion of the sail. Said boom (my wishbone-style Basket Boom), also uses Battcars located at the base of the track (see Boom Detail drawing below).

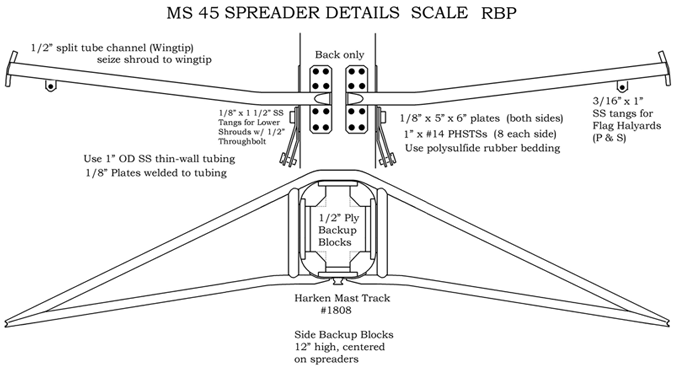

Spreader details.

Spreaders are made from polished 1″ stainless steel thin-wall tubing (or 3/4″ aluminum pipe) welded to 1/8″ stainless steel side and back plates. The plates are attached to the mast with 1″ x #14 flat head self-tapping screws, and are bedded with polysulfide rubber. Spreader lift angle should bisect the angle the upper shrouds make at the wingtips.

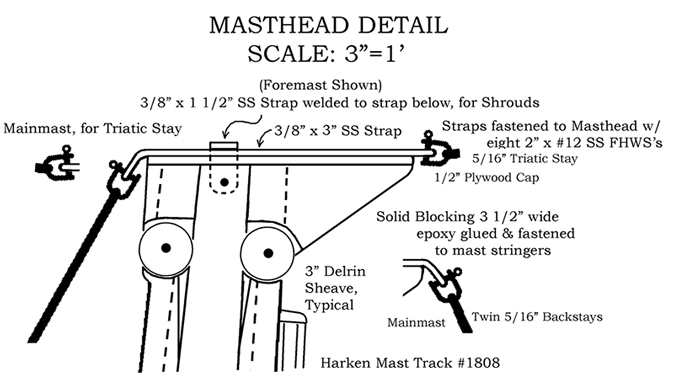

Detail of a masthead—the SS top plate is configured fore & aft for application (shown is the foremast for a schooner with equal height masts).

The masthead is made by adding solid wood sections fore & aft with a 1/2″ plywood cap to support two stainless steel straps, drilled and bent at their ends to receive shackles for stays and shrouds. Delrin sheaves (3″ Schaefer) are used for internal halyards as shown above. Sheave pins are 7/16″ SS. Dimensions shown are for masts on a 45’ motorsailer using 5/16″ shrouds, triatic stay and twin backstays, and 3/8″ forestay and main stay.

The mast construction, as drawn, is much stronger than necessary for the specific application intended (Motorsailer 45), and the solid corners could be made from 2x4s (as described below), in lieu of the 3x3s shown. This would save materials costs, and to a lesser extent, labor. I would stress, however, that air-dried wood is much preferable to kiln-dried wood for durability and rot-resistance. If using kiln-dried wood, I would be very thorough in epoxy sealing the mast interior, and I would cover the finished mast with Xynole-polyester fabric and epoxy. As always, great care should be taken with bedding compounds (these days I mostly use Bostik #920, above and below the waterline).

Basket Boom details.

I developed a new type of boom several years ago to utilize the Harken track. The upper portion is a “wishbone” boom, which clears both sides of the sail. The lower portion eliminates the need for a vang. When the sail is dropped, it falls inside the “basket”, which may have lacing on each side (not shown) to contain the sail and battens. A sail cover may be placed inside the basket boom with a top covering panel secured by Velcro. The boom could alternately be fabricated from polished stainless steel, using 1-1/2″ thin-wall tubing.

The basket boom uses two Harken Battcars at each attachment point (upper & lower), and should incorporate a downhaul to increase luff tension. In adapting this boom to other vessels, note that the wishbone must be designed to contact the after shroud (when reaching or running) before it touches the mast to prevent damaging the track and fasteners.

The new mast construction is intended for the Motorsailer 45 shown above, but may be employed on any light- to moderate-displacement vessel in this size range using the Marconi rig and single (or double) spreaders.

The new masts may be tabernacled, deck-stepped (over compression posts), or keel stepped. The overall weight of these masts will be as light or lighter than that for aluminum masts of equivalent strength .

For lighter loads or for even lighter-weight masts, corners may be made from 2x4s (on the flat at 45 degrees); and sides, front and back may be made from 3/8″ 5-ply marine plywood (such as Shelman or Joubert). Smaller masts and spars can use the same construction, with scantlings down-sized appropriately. Fabric/epoxy covering will prolong mast life, but is not particularly necessary structurally. All fasteners penetrating the finished mast should be either sleeved (bolts for shroud attachment) or carefully bedded using flexible, UV-resistant compound.

I know carbon-fiber masts are all the rage now, but I still firmly believe that well-designed and –made wood/epoxy masts are the overall best in terms of light-weight, strength, durability and low cost. A mast made using the above method will cost a fraction of an equivalent mast in carbon fiber or aluminum, and it will be more durable. As I keep telling people, aluminum is good for beer cans!

4/2/2014 St. Lucie Village, FL

ACCESS TO EXPERIENCE

Subscribe today.

Publishing dynamic editorial content on boat design construction, and repair for more than 40 years.

1 YEAR SUBSCRIPTION (6 ISSUES)

Print $39.95, digital $28.00, print+digital $42.95, from online exclusives, extended content.

Restoring Rambler

WoodenBoat Live with Reuben Smith

Antarktische Wildnis: Südgeorgien

Restoring KATIE MACK

From the community, boat launchings.

SHADOW of Gig Harbor, Wa USA. Maiden voyage April 14th, 2024.

1915 Stephens Brothers lake union

DEATH IN FAMILY. MUST SELL !

1942 copy of a Herreshoff Buzzards Bay Boat

Built on Deer Isle in 1942 , it has an 800 pound steel keel, 4 foot draft.

1956 39' Concordia Masthead Yawl $10,500

This vessel received a complete refit in 2007-2008 including re-powering, new decks, new standing

WOODEN BOW TIES

How to build a wooden sailboat: a beginner's guide.

Are you interested in building your own sailboat? If so, building a wooden sailboat can be a rewarding and fulfilling experience. Not only will you have a unique vessel to call your own, but you’ll also learn valuable woodworking skills along the way.

To get started, you’ll need to gather the necessary materials and tools. This may include oak plywood, epoxy resin and hardener, thickener, brad nails, masking tape, a pull-saw, and a table saw. Once you have everything you need, you can begin the process of building your sailboat. From creating a jig and frame assembly to making the mast, there are many steps involved in building a wooden sailboat. But with patience and attention to detail, you can create a beautiful and functional vessel that will bring you joy for years to come.

Understanding the Basics of a Wooden Sailboat

If you are interested in building a wooden sailboat, it’s important to understand the basics of how a sailboat is constructed. In this section, we’ll cover the parts of a wooden sailboat and the different types of wooden sailboats.

Parts of a Wooden Sailboat

A wooden sailboat is made up of several parts, each with its own unique function. Here are some of the most important parts:

- Hull : The hull is the main body of the boat. It is the part of the boat that sits in the water and provides buoyancy.

- Keel : The keel is a long, narrow fin that extends down from the bottom of the hull. It helps to keep the boat from capsizing by providing stability.

- Rudder : The rudder is a flat piece of wood or metal that is attached to the back of the boat. It helps to steer the boat.

- Mast : The mast is a tall, vertical pole that supports the sails.

- Sails : The sails are large pieces of fabric that are attached to the mast and other parts of the boat. They catch the wind and propel the boat forward.

- Boom : The boom is a horizontal pole that is attached to the bottom of the mast. It helps to control the shape of the sail.

Types of Wooden Sailboats

There are many different types of wooden sailboats, each with its own unique characteristics. Here are some of the most common types:

- Dinghy : A dinghy is a small sailboat that is typically used for recreational sailing or racing.

- Sloop : A sloop is a sailboat with a single mast and a fore-and-aft rig.

- Ketch : A ketch is a sailboat with two masts, with the main mast taller than the mizzen mast.

- Yawl : A yawl is a sailboat with two masts, with the mizzen mast located aft of the rudder post.

When choosing a type of wooden sailboat to build, it’s important to consider your needs and experience level. A dinghy is a good choice for beginners, while a ketch or yawl may be more suitable for experienced sailors.

By understanding the basics of a wooden sailboat and the different types available, you can make an informed decision about which type of boat to build.

Choosing the Right Materials

When building a wooden sailboat, choosing the right materials is crucial to ensure the boat’s durability and performance. In this section, we will discuss the two most important materials you’ll need to choose: wood and sails/rigging materials.

Selecting the Right Wood

Choosing the right type of wood for your sailboat is critical. You want a wood that is strong, lightweight, and resistant to rot and decay. Some of the most popular types of wood used in sailboat building include:

- Cedar: Lightweight and easy to work with, cedar is an excellent choice for planking and decking.

- Mahogany: Strong and durable, mahogany is often used for building frames and keels.

- Oak: A dense and hard wood, oak is commonly used for building frames and planking.

When selecting your wood, make sure it is free of knots, cracks, and other defects that could weaken the boat’s structure. You should also consider the wood’s grain pattern, as this can affect the boat’s strength and appearance.

Choosing Sails and Rigging Materials

The type of sails and rigging materials you choose will depend on the type of sailboat you’re building and your sailing needs. Some of the most common materials used in sail and rigging construction include:

- Dacron: A strong and durable synthetic material, dacron is commonly used for sailcloth.

- Nylon: Lightweight and flexible, nylon is often used for spinnaker sails.

- Stainless Steel: Strong and corrosion-resistant, stainless steel is commonly used for rigging hardware.

When selecting your sails and rigging materials, consider the conditions you’ll be sailing in and the type of sailing you’ll be doing. For example, if you’ll be racing, you may want to choose lightweight sails and rigging materials that will help you achieve maximum speed. On the other hand, if you’ll be cruising, you may want to choose more durable materials that can withstand rougher conditions.

By choosing the right materials for your wooden sailboat, you can ensure that your boat is strong, durable, and performs well on the water.

Designing Your Sailboat

Before you start building your wooden sailboat, you need to design it. This will involve creating a blueprint and determining the size and shape of your boat.

Creating a Blueprint

Creating a blueprint is an essential step in designing your sailboat. It will help you visualize your boat and ensure that you have all the necessary components in place. You can create a blueprint using software such as AutoCAD or SketchUp, or you can draw it by hand.

When creating your blueprint, consider the following:

- The length, width, and height of your boat

- The position of the mast and sails

- The location of the rudder and keel

- The number of cabins and their layout

- The placement of any storage compartments or equipment

Determining the Size and Shape

The size and shape of your sailboat will depend on several factors, including your budget, the type of sailing you plan to do, and the number of people who will be on board.

Consider the following when determining the size and shape of your sailboat:

- The type of sailing you plan to do (coastal cruising, racing, etc.)

- The number of people who will be on board

- The amount of storage space you will need

- The amount of deck space you will need

- Your budget

Once you have determined the size and shape of your sailboat, you can start gathering materials and building your boat.

Building the Hull

When building a wooden sailboat, the hull is the most important part of the boat. It is the main structure that holds everything together and keeps the boat afloat. Building the hull requires cutting and assembling the wooden frame.

Cutting the Wood

To begin building the hull, you will need to cut the wood into the appropriate sizes and shapes. The wood should be cut according to the plans or blueprints that you have created. You can use a saw or a jigsaw to make the cuts.

It is important to use high-quality wood that is free of knots or other defects. The wood should be strong enough to withstand the pressure and weight of the water. Common types of wood used for building a wooden sailboat include cedar, oak, and mahogany.

Assembling the Frame

Once you have cut the wood, you can begin assembling the frame of the hull. The frame is made up of vertical pieces of wood called frames, which hold the shape of the boat. The frames are attached to the keel, which is the main structure that runs down the center of the boat.

To assemble the frame, you will need to use a sawhorse or other support to hold the lumber in place. You can then use screws or bolts to attach the frames to the keel. It is important to ensure that the frames are level and straight.

After the frames are attached to the keel, you can add the planks to the hull. The planks are attached to the frames and keel using screws or nails. It is important to ensure that the planks are properly aligned and spaced.

Once the planks are attached, you can sand and finish the hull to give it a smooth and polished look. This will also help to protect the wood from the elements.

Building the hull of a wooden sailboat requires patience and attention to detail. With the right tools and materials, you can create a strong and beautiful hull that will last for years to come.

Installing the Deck and Cabin

Installing the deck and cabin of your wooden sailboat is a crucial step in the construction process. It not only adds to the aesthetics of your boat but also provides structural support. Here are some tips to help you through the process.

Deck Installation

The deck of your wooden sailboat should be installed after the hull has been completed and before the cabin is built. It is important to ensure that the deck is watertight to prevent any leaks. Here are the steps to follow when installing the deck:

- Cut the deck to fit the hull and sand the edges to ensure a tight fit.

- Apply a layer of epoxy to the hull and deck joint to seal it.

- Secure the deck to the hull using screws or bolts.

- Apply a layer of fiberglass cloth and epoxy to the deck to make it watertight.

- Sand the surface of the deck to prepare it for painting or varnishing.

Cabin Installation

The cabin of your wooden sailboat provides shelter and storage space. It is important to ensure that it is properly installed to prevent any leaks. Here are the steps to follow when installing the cabin:

- Build the cabin on a flat surface using marine-grade plywood.

- Cut the cabin to fit the deck and hull and sand the edges to ensure a tight fit.

- Apply a layer of epoxy to the cabin and deck joint to seal it.

- Secure the cabin to the deck using screws or bolts.

- Apply a layer of fiberglass cloth and epoxy to the cabin to make it watertight.

- Install any windows, hatches, or doors in the cabin.

- Sand the surface of the cabin to prepare it for painting or varnishing.

By following these steps, you can ensure that your wooden sailboat’s deck and cabin are properly installed and watertight. This will not only make your boat look great but also ensure that you have a safe and enjoyable sailing experience.

Setting Up the Mast and Sails

Now that you have built your wooden sailboat, it is time to set up the mast and sails. This process may seem daunting, but with a little patience and attention to detail, you can have your boat ready to sail in no time.

Step 1: Install the Mast

The first step is to install the mast. Depending on the design of your boat, the mast may be a single piece or assembled from multiple sections. Make sure the mast is secured properly and is straight. Use a level to ensure the mast is vertical in both directions.

Step 2: Prepare the Sails

Next, prepare the sails. Make sure the sails are clean and free of any debris or damage. Attach the sail to the mast using the halyard, which is a rope used to raise and lower the sail. Make sure the sail is hoisted all the way to the top of the mast.

Step 3: Attach the Boom

Attach the boom to the mast and secure it with a boom vang, which is a rope used to control the angle of the boom. The boom is the horizontal spar that holds the bottom edge of the sail.

Step 4: Set the Sail

Once the boom is attached, set the sail. Adjust the angle of the boom and the sail to catch the wind and start moving. You can use the main sheet to control the angle of the sail and the boat’s speed.

Step 5: Trim the Sail

Finally, trim the sail to optimize its performance. This involves adjusting the sail’s shape and position to maximize its power and minimize drag. Use the sail controls, such as the cunningham and outhaul, to adjust the sail’s shape. Use the main sheet to control the sail’s position relative to the wind.

Congratulations! You have successfully set up the mast and sails of your wooden sailboat. Now it’s time to hit the water and enjoy the thrill of sailing.

Applying Finishing Touches

When it comes to building a wooden sailboat, applying the finishing touches is a crucial step that can make all the difference in the final product. Here are some tips and tricks to help you get the perfect finish.

Sanding and Finishing

Before you can apply any finish, you need to make sure the surface is smooth and free of imperfections. This means sanding the wood with progressively finer grits of sandpaper until you achieve the desired smoothness. Once you’ve finished sanding, you can apply a wood conditioner to help the wood absorb the finish more evenly.

When it comes to choosing a finish, you have several options. Some popular choices include varnish, paint, and oil. Varnish is a popular choice for wooden boats because it provides a durable, glossy finish that can withstand the harsh marine environment. Paint is another option, but it requires more maintenance than varnish and may not provide as much protection against the elements. Oil is a good choice if you want a more natural look, but it may not provide as much protection as varnish or paint.

Painting and Varnishing

If you decide to go with paint or varnish, there are a few things to keep in mind. First, make sure you apply the finish in a well-ventilated area to avoid inhaling fumes. Second, make sure you apply thin, even coats and allow each coat to dry completely before applying the next. This will help prevent drips and ensure a smooth finish.

When it comes to varnishing, it’s important to use a high-quality brush and work quickly to avoid brush marks. You may also want to consider using a foam brush for hard-to-reach areas. Once you’ve applied the final coat of varnish, you can buff the surface with a soft cloth to achieve a high-gloss finish.

Painting requires a different approach. You’ll need to choose the right type of paint for your boat and make sure you apply it evenly. If you’re painting a large area, you may want to consider using a paint sprayer to achieve a smooth, even finish. Once the paint has dried, you can apply a clear coat to protect the paint and give it a glossy finish.

In conclusion, applying the finishing touches to your wooden sailboat is an important step that requires careful attention to detail. By following these tips and using the right tools and materials, you can achieve a beautiful, long-lasting finish that will protect your boat and make it stand out on the water.

Safety Measures

When building a wooden sailboat, safety should always be your top priority. Here are some safety measures you should take to ensure a safe and successful build.

Installing Safety Equipment

Before you start building, make sure you have all the necessary safety equipment installed in your workshop. This includes fire extinguishers, smoke detectors, and first aid kits. You should also have a clear and unobstructed path to the exit in case of an emergency.

When working with power tools, always wear eye and ear protection, as well as a dust mask to protect your lungs. If you are using chemicals, make sure you are working in a well-ventilated area and wear gloves and a respirator if necessary.

Conducting a Safety Check

Before you start working on your sailboat, conduct a safety check to make sure everything is in order. Check that all tools and equipment are in good working order and that there are no loose or damaged parts. Make sure your work area is clean and free of clutter, and that all cords and cables are properly secured.

When working with wood, be aware of any knots or cracks in the wood that could weaken the structure of your sailboat. Use only high-quality marine-grade wood and be sure to follow the plans carefully to ensure a strong and safe boat.

By following these safety measures, you can ensure that your wooden sailboat build is a safe and enjoyable experience.

Maintaining Your Wooden Sailboat

Congratulations on building your own wooden sailboat! Now that you have a beautiful vessel, it’s important to keep it well-maintained to ensure its longevity and safety on the water.

Regular Maintenance

Regular maintenance is essential to keep your wooden sailboat in top condition. Here are some tips to keep in mind:

- Clean your boat regularly with a mild soap and water to prevent dirt and grime buildup.

- Check for any signs of damage, such as cracks, rot, or loose fittings, and address them promptly.

- Apply a fresh coat of varnish or paint every few years to protect the wood from the elements.

- Keep your boat covered when not in use to protect it from the sun and rain.

Seasonal Maintenance

In addition to regular maintenance, there are also some seasonal tasks that you should perform to keep your wooden sailboat in top condition:

- At the beginning of the season, inspect the hull for any damage or wear and make any necessary repairs.

- Check the rigging and sails to make sure they are in good condition and make any necessary repairs or replacements.

- Before storing your boat for the winter, make sure to properly winterize it to protect it from the cold and moisture.

Additional Tips

Here are some additional tips to keep in mind when maintaining your wooden sailboat:

- Use high-quality marine-grade products when cleaning and maintaining your boat.

- Avoid using harsh chemicals or abrasive materials that can damage the wood.

- Regularly check the bilge for any water buildup and pump it out as needed.

- Keep your boat well-ventilated to prevent moisture buildup and mold growth.

By following these tips, you can keep your wooden sailboat in top condition and enjoy many years of safe and fun sailing.

Leave a Reply Cancel reply

You must be logged in to post a comment.

- Navigating the High Seas: A Comprehensive Guide to Sailboat Masts

Sailboat masts are the unsung heroes of the sailing world, silently supporting the sails and ensuring a smooth journey across the open waters. Whether you're a seasoned sailor or a novice, understanding the intricacies of sailboat masts is essential for a safe and enjoyable voyage. In this comprehensive guide, we will delve into the world of sailboat masts, discussing their types, maintenance, and everything in between.

Types of Sailboat Masts

Sailboat masts come in various configurations, each with its advantages and drawbacks. The two primary types are keel-stepped and deck-stepped masts.

Keel-Stepped Masts

Keel-stepped masts are the most common type, extending through the deck and resting on the boat's keel. They provide excellent stability and are suitable for larger sailboats. However, they require careful maintenance to prevent water intrusion into the boat's cabin.

Deck-Stepped Masts

Deck-stepped masts rest on the deck of the boat, making them easier to install and remove. They are commonly found on smaller sailboats and are more forgiving in terms of maintenance. However, they may offer slightly less stability than keel-stepped masts.

Components of a Sailboat Mast

To understand mast maintenance better, it's essential to know the various components of a sailboat mast. The key parts include the masthead, spreaders, shrouds, and halyard sheaves.

The masthead is the topmost section of the mast, where the halyards are attached to raise and lower the sails. It also often houses instruments such as wind indicators and lights.

Spreaders and Shrouds

Spreaders are horizontal supports attached to the mast to help maintain the proper angle of the shrouds (cables or rods that provide lateral support to the mast). Properly adjusted spreaders and shrouds are crucial for mast stability and sail performance.

Mast Materials: Choosing the Right One

Sailboat masts are typically constructed from three primary materials: aluminum, wood, and carbon fiber. Each material has its unique characteristics and is suited to different sailing preferences.

Aluminum Masts

Aluminum masts are lightweight, durable, and relatively easy to maintain. They are commonly used in modern sailboats due to their cost-effectiveness and longevity.

Wooden Masts

Wooden masts, while classic and beautiful, require more maintenance than other materials. They are best suited for traditional or vintage sailboats, where aesthetics outweigh convenience.

Carbon Fiber Masts

Carbon fiber masts are the pinnacle of mast technology. They are incredibly lightweight and strong, enhancing a sailboat's performance. However, they come at a premium price.

Mast Maintenance

Proper mast maintenance is essential for safety and longevity. Regular cleaning, inspection, and addressing minor issues promptly can prevent costly repairs down the line.

Cleaning and Inspection

Regularly clean your mast to remove salt, dirt, and grime. Inspect it for signs of corrosion, wear, or damage, paying close attention to the masthead, spreaders, and shrouds.

Common Repairs and Their Costs

Common mast repairs include fixing corroded areas, replacing damaged spreaders, or repairing shrouds. The cost of repairs can vary widely, depending on the extent of the damage and the materials used.

Extending the Lifespan of Your Mast

Taking steps to prevent damage is essential. Avoid over-tightening halyards, protect your mast from UV radiation, and keep an eye on corrosion-prone areas.

Read our top notch articles on topics such as sailing , sailing tips and destinations in our Magazine .

Stepping and Unstepping a Mast

Stepping and unstepping a mast is a crucial skill for any sailboat owner. This process involves removing or installing the mast on your boat. Here's a step-by-step guide for safe mast handling.

Step-by-Step Guide for Safe Mast Handling

- Gather the necessary tools and equipment.

- Disconnect all electrical and rigging connections.

- Use a crane or mast-stepping system to safely lower or raise the mast.

- Secure the mast in its proper place.

- Reconnect all electrical and rigging connections.

When and Why to Unstep a Mast

You may need to unstep your mast for various reasons, such as transporting your sailboat or performing extensive maintenance. It's crucial to follow the manufacturer's recommendations and ensure a safe unstepping process.

Sailboat Mast Boot: Protecting Your Mast

A mast boot is a simple yet effective way to protect your mast from water intrusion and damage caused by the elements. Here's what you need to know.

The Purpose of a Mast Boot

A mast boot is a flexible material that wraps around the mast at the deck level. It prevents water from entering the cabin through the mast opening, keeping your boat dry and comfortable.

Installing and Maintaining a Mast Boot

Installing a mast boot is a straightforward DIY task. Regularly inspect and replace it if you notice any signs of wear or damage.

Replacing a Sailboat Mast

Despite your best efforts in maintenance, there may come a time when you need to replace your sailboat mast. Here's what you should consider.

Signs That Your Mast Needs Replacement

Common signs include severe corrosion, structural damage, or fatigue cracks. If your mast is beyond repair, it's essential to invest in a replacement promptly.

The Cost of Mast Replacement

The cost of mast replacement can vary significantly depending on the type of mast, materials, and additional rigging needed. It's advisable to obtain multiple quotes from reputable marine professionals.

Yacht Masts: Sailing in Style

For those looking to take their sailing experience to the next level, upgrading to a yacht mast can be a game-changer.

Differences Between Sailboat and Yacht Masts

Yacht masts are typically taller and offer enhanced sail performance. They are often equipped with advanced rigging systems and technology for a more luxurious sailing experience.

Upgrading to a Yacht Mast

Consult with a marine professional to determine if upgrading to a yacht mast is feasible for your sailboat. It can be a significant investment but can transform your sailing adventures.

Sailboat Mast Steps: Climbing to the Top

Mast steps are handy additions to your mast, allowing easier access to perform maintenance or enjoy panoramic views. Here's how to use them safely.

Using Mast Steps Safely

Always use proper safety equipment when climbing mast steps. Make sure they are securely attached to the mast and regularly inspect them for wear or damage.

The Advantages of Mast Steps

Mast steps provide convenience and accessibility, making sailboat maintenance tasks more manageable. They also offer an elevated vantage point for breathtaking views while at anchor.

Mast Maintenance Tips for Beginners

If you're new to sailboat ownership, these mast maintenance tips will help you get started on the right foot.

Essential Care for First-Time Sailboat Owners

- Establish a regular maintenance schedule.

- Seek advice from experienced sailors.

- Invest in quality cleaning and maintenance products.

Preventing Common Mistakes

Avoid common pitfalls, such as neglecting inspections or using harsh cleaning agents that can damage your mast's finish.

Sailing with a Mast in Top Condition

A well-maintained mast contributes to a safer and more enjoyable sailing experience. It enhances your boat's performance and ensures you can rely on it in various weather conditions.

How a Well-Maintained Mast Improves Performance

A properly maintained mast helps maintain sail shape, reducing drag and improving speed. It also ensures that your rigging remains strong and secure.

Safety Considerations

Never compromise on safety. Regularly inspect your mast, rigging, and all associated components to prevent accidents while at sea.

Sailboat masts are the backbone of any sailing adventure, and understanding their intricacies is crucial for a successful voyage. From choosing the right mast material to proper maintenance and upgrading options, this guide has covered it all. By following these guidelines, you can sail the high seas with confidence, knowing that your mast is in top condition.

So what are you waiting for ? Take a look at our range of charter boats and head to some of our favourite sailing destinations .

The Ultimate Guide: How to Make a Sailboat – A Step-by-Step Tutorial

Alex Morgan

Making a sailboat can be an exciting and rewarding project for those who love the thrill of the open water. Whether you’re an experienced sailor or a beginner, building your own sailboat allows you to customize the design and create a vessel that suits your needs. This guide will take you through the step-by-step process of making a sailboat, from gathering materials and tools to launching and testing the final product.

Introduction to Making a Sailboat

Building a sailboat is a complex and intricate endeavor that requires careful planning, attention to detail, and a love for craftsmanship. In this article, we will explore the various steps involved in making a sailboat, including gathering materials and tools, designing and planning the sailboat, constructing the hull, building and rigging the sail, adding finishing touches, and finally, launching and testing the sailboat.

Gathering Materials and Tools

Before diving into the construction process, it is essential to gather all the necessary materials and tools. We will discuss the essential materials required for building a sailboat, such as wood, fiberglass, epoxy resin, and fasteners. we will explore the various tools needed, including saws, drills, clamps, and measuring instruments. Having the right materials and tools is crucial for a successful sailboat-building project.

Designing and Planning the Sailboat

When it comes to designing a sailboat, there are several factors to consider. We will delve into these considerations, including the type of sailboat, its intended use, and the desired performance characteristics. We will discuss how to create a blueprint or design plan that outlines the specific dimensions, layout, and structural details of the sailboat.

Constructing the Hull

The hull is the foundation of any sailboat, providing buoyancy and stability on the water. We will explore the process of building the framework of the hull, including shaping and assembling the different components. we will discuss the techniques used for planking the hull, such as carvel planking or cold-molded construction.

Building and Rigging the Sail

The sail is a vital component of a sailboat, harnessing the power of the wind to propel the vessel forward. We will discuss the materials required for constructing the sail, including fabric, battens, and hardware. we will cover the steps involved in assembling and attaching the sail to the sailboat, ensuring proper rigging for optimal performance.

Finishing Touches and Final Steps

To add the finishing touch to your sailboat, there are several details to consider. We will explore how to add decorative elements and functional accessories to enhance the overall appearance and functionality of the vessel. we will discuss the steps involved in painting and varnishing the sailboat, protecting it from the elements and giving it a polished finish.

Launching and Testing the Sailboat

After months of hard work and dedication, it’s time to launch your sailboat and test its performance on the water. We will guide you through the necessary preparations before the first launch, including ensuring the boat is properly balanced and rigged. we will discuss the safety precautions to follow when testing the sailboat, ensuring a smooth and enjoyable sailing experience.

By following this comprehensive guide, you will gain the knowledge and confidence to embark on your sailboat-building journey. So, let’s set sail on this exciting adventure of creating your very own sailboat.

Key takeaway:

- Making a sailboat maximizes creativity: Building your own sailboat allows you to express your creativity and create a unique vessel tailored to your preferences.

- Gathering essential materials is crucial: To build a sailboat, you need materials such as wood, epoxy, fiberglass, and marine plywood, which are vital for constructing a sturdy and seaworthy vessel.

- Proper planning ensures a successful build: Designing and planning a sailboat involves considering factors like stability, weight distribution, and sail area to ensure the boat performs well in various conditions.

Gathering materials and tools is crucial when it comes to making a sailboat. Follow these steps:

1. Begin by researching the type and size of sailboat you wish to build. Gather information on the required materials and tools.

2. Create a comprehensive list of all the necessary materials including marine-grade plywood, fiberglass, epoxy resin, screws, and hardware.

3. Make a separate list of all the tools that you will need such as a circular saw, jigsaw, drill, sander, clamps, and measuring tape.

4. Take the time to find reliable suppliers for the materials. Compare prices and quality to find the best options available.

5. Once you have identified the suppliers , go ahead and place orders for all the materials you need. Make sure to order sufficient quantities.

6. If you don’t already have the required tools in your workshop, consider purchasing or borrowing them from someone reliable.

7. It is important to set up a dedicated workspace that provides enough room for you to work comfortably and store both materials and tools.

8. Ensure that your workspace is clean and well-organized. Pay special attention to proper lighting and ventilation.

9. As soon as you receive the materials , inspect them thoroughly for any signs of damage or defects. If you find any issues, contact the supplier immediately.

By following these steps, you will be able to successfully gather all the necessary materials and tools to begin building your sailboat.

What are the Essential Materials for Building a Sailboat?

What are the essential materials for building a sailboat? The necessary materials for constructing a sailboat include high-quality marine-grade plywood for the hull and deck. To reinforce the structure, fiberglass cloth and epoxy resin are employed. As for the assembly, stainless steel hardware is utilized, along with various types of sailcloth for the sails. The rigging is composed of stainless steel mast, boom, and rigging wires . To protect the wooden surfaces, marine-grade paint and varnish are applied. Joint sealing is achieved by utilizing adhesive, sealant, and caulking . Finishing touches are made with bungs, plugs, and filler materials . By using these materials in conjunction with the appropriate tools, one can build a sailboat that is robust and dependable for countless enjoyable hours on the water.

What Tools are Needed for Building a Sailboat?

To successfully build a sailboat, you will require a number of essential tools. Below is a comprehensive list of the necessary tools needed for the construction process:

1. Measuring tools: To accurately measure and mark the boat’s dimensions, you will need a tape measure , ruler , and protractor .

2. Saws: In order to cut materials, both a hand saw and a power saw, such as a jigsaw or circular saw , are indispensable.

3. Drill: A drill with various sizes of drill bits is crucial for creating holes in the boat’s structure and attaching components.

4. Screwdriver: To tighten screws and fasten hardware, you will need both flathead and Phillips head screwdrivers.

5. Clamps: Clamps are necessary to hold components together while they are being glued or screwed.

6. Sanding tools: To achieve smooth surfaces and eliminate imperfections, you will require sandpaper and sanding blocks .

7. Chisels: Chisels are essential for shaping and carving wood for intricate details or joints.

8. Planer: A planer is necessary to level surfaces and reduce the thickness of wooden components.

9. Painting tools: Brushes and rollers are indispensable for the application of paint or varnish, which serves to protect and enhance the sailboat’s appearance.

10. Safety equipment: Make sure to have safety goggles , gloves , and a dust mask to ensure your protection while working.

By utilizing these tools effectively, you will be able to successfully and safely complete your sailboat building project.

When designing and planning the sailboat, it is important to follow these steps:

1. Research different sailboat designs and hull types to gather information and ideas.

2. Determine the size and dimensions of your sailboat based on your needs and the resources available to you.

3. Create a detailed blueprint or design that includes important aspects such as hull shape, rigging, and deck layout.

4. Select materials for the construction of your sailboat based on factors like durability, weight, and cost.

5. Ensure the inclusion of safety features and necessary equipment, such as navigation instruments and life jackets.

6. Calculate the sail area and carefully choose the appropriate sails for optimal performance.

7. Evaluate the stability and balance of the sailboat to ensure safe sailing.

8. It is always helpful to consult experts for advice and guidance throughout the designing and planning process.

To guarantee success, it is crucial to consider your needs, seek expert opinions, and give utmost importance to thorough research, attention to detail, and careful planning.

What Factors to Consider when Designing a Sailboat?

When designing a sailboat, there are several factors to consider for a successful and efficient vessel. These factors include the intended use, hull design, sail plan, structural integrity, and ergonomics and comfort.

Firstly , the intended use of the sailboat must be determined. This involves deciding whether the sailboat will be used for racing, cruising, or both. The intended use will determine the size, shape, and necessary features for optimal performance.

Next , the hull design plays a crucial role in sailing performance. Factors such as stability, speed, and maneuverability should be considered when choosing a design.

The sail plan is another important aspect to take into account. The type and configuration of the sails will depend on the boat size, intended use, and sailing conditions. Factors like ease of handling, sail material, and the number and size of sails should be considered.

Structural integrity is essential for safety and longevity. It is important to consider the materials and construction techniques that can withstand water and wind forces.

Lastly , the sailboat should be designed with ergonomics and comfort in mind. This involves considering factors such as seating arrangements, control access, and storage space.

To ensure the best sailboat design, it is advisable to consult naval architects or experienced sailors for expert advice and guidance. Their knowledge and expertise will help in creating a well-designed and functional vessel.

When designing a sailboat, it is important to consider these factors to ensure a successful and efficient vessel that meets the specific needs of the owner.

How to Create a Blueprint or Design Plan?

When creating a sailboat blueprint or design plan, follow these steps on how to create a blueprint or design plan:

- Research sailboat designs based on sailing conditions and intended use.

- Measure and calculate sailboat dimensions, including length, width, and height.

- Create a detailed sketch, indicating parts like the hull, mast, keel, and rigging.

- Specify durable, lightweight, and cost-effective materials for each part.

- Develop a comprehensive list of materials and resources required, including quantities and specifications.

- Add precise measurements and dimensions to ensure accuracy and alignment.

- Annotate the blueprint with construction notes and instructions, including specific techniques.

To create an effective blueprint or design plan, consult experienced boat designers or naval architects for structural integrity and functionality. Utilize software or online tools for enhanced precision and efficiency. Careful planning and considering all aspects of the sailboat’s design will lead to a successful construction process.

To successfully construct a sailboat hull, it is important to follow these steps:

1. Begin by designing the hull, taking into consideration factors such as size, shape, and the materials that will be used.

2. Gather all the necessary materials for the construction process, including fiberglass, wood, or aluminum, depending on your preference.

3. Prepare the mold if fiberglass is the chosen material. Create a mold that matches the desired shape and apply a release agent to ensure easy removal.

4. Once the mold is prepared, start applying layers of fiberglass sheets and resin smoothly, making sure to avoid any air bubbles.

5. After the fiberglass has cured, carefully remove the hull from the mold and use sandpaper to smooth out any rough edges or imperfections.

6. To strengthen the hull, consider adding reinforcements such as bulkheads or ribs to provide structural support.

7. Install any necessary fittings according to the design, including cleats, ports, and drains.

8. For added protection and to enhance the appearance, apply a suitable coating or paint to the hull.

9. Prior to completing the construction process, it is important to thoroughly inspect the hull for any defects or leaks. Test the sailboat in water to ensure its proper performance.

To ensure a successful sailboat hull construction, it is crucial to plan properly, paying attention to detail, and following safety standards. If needed, consult professional boat builders or utilize resources that offer specific guidance tailored to your project. Happy sailboat construction!

How to Build the Framework of the Hull?